Documente Academic

Documente Profesional

Documente Cultură

Carpets - Feasibiltiy Study For Wash and Cut Facility PDF

Încărcat de

aghorbanzadehTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Carpets - Feasibiltiy Study For Wash and Cut Facility PDF

Încărcat de

aghorbanzadehDrepturi de autor:

Formate disponibile

V.

Feasibility Study for Carpet Subsector Plan: Operationalising Cut and Wash Facilities

The comprehensive feasibility study of the MRRD selected business opportunity Operationalising Cut and Wash Facilities for the carpet subsector shall be presented in this section, covering both the economic viability and technical feasibility. The Econo mic Viability analysis includes market analysis, competitive analysis, business justification, marketing plan, alternative financing options, realistic cost flow statement, cost benefit analysis, breakpoint point, and contribution of potential entrepreneurs. The Technical Feasibility analysis includes: demand and supply analysis, availability of required resources, availability of technical know-how, and alternative supply sources. There is a special focus on Balkh.

5.1

Business Description

A washing and cutting facility with links to smaller units with quality control, which can put a label on the carpet, arrange transportation and contact with sales outlets in market (limited). Traders or carpet weavers / carpet production units / associations pay for cutting and washing services. The Company bulk buys inputs reducing costs. Customers would include weaver associations and traders who will then be able to sell directly to international markets. Company receives commission for sales of carpets. Services 1. General cutting and washing services for production units and associations in Mazar. Paid directly for their services. 2. Cutting and washing for member traders / associations with additional marketing services in selling on commission base or acting as wholesalers, initially to Kabul and Pakistan. 3. Training of cutting and washing workers and assisting with establishing small cut and wash franchises (extension workers / training centre) including facilitating access to credit for cut and wash units. 4. Labeling for cut / finished carpets general and customized. Large existing facility connected to existing smaller sites.

Organisational model End products Estimated employment

Finished Carpets for direct marketing / export. 33+ 35 extra people employed

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

49

5.2

Economic Viability

The Market / Overview

Industry Analysis

General carpet industry Afghanistans world famous carpet trade is steeped in history and tradition, reflecting Afghanistans diverse culture and heritage. Characterized by cottage home based production (mostly by women), Afghanistan is one of the last places in the world where carpets are produced following ancient traditions25 . Afghanistan produces several types of handmade carpet including felted wool carpets (namads), flat non-pile fabric woven carpets (kilims) and pile and knotted carpets made from wool, silk and cotton. 26 The carpet industry represents a strong subsector in Afghanistan and is heavily active in the North part of the country (Balkh, Jowzjan, Maimana and Kunduz provinces), where there is 70 per cent of production and 50-70 per cent of national trading. Approximately a quarter of villages in Balkh weave carpets. 27 It is estimated that there are over 10,000 weavers in this province with total production levels of ~150,000 m2 / annum. Carpets are mainly made in Daulatabad, Aqcha, Dehdadi, Balkh and Chahar-Bolak districts. Current export is quoted at $140 M / annum (OTF 2006). Afghanistan Export Promotion Agency (EPAA) estimates that 2 million carpets are exported per year. With an average carpet size of 3.2 m2 , this equates to 6.4 million m2 carpet / year. However, the real figure may be closer to 6.6 million m2 carpet / year. Afghanistan Carpet Exporters Guild (CEG) estimates that there are over one million Afghans working in the production of carpets (with further millions involved in support industries such as wool production, cutting / washing and design)28 . The industry still relies largely on a traditional system for carpet / wool production and marketing. This means that carpets are produced at home, and the traders facilitate marketing. Mazar in Balkh is a key location for carpet trading, networks and services. Over 65 per cent of carpets made in Afghanistan (and probably 90 per cent in Balkh) are channeled through this city. Traders predominantly facilitate the finishing of the carpets (over 90 per cent) through Pakistan, and export directly from Pakistan onto Western markets. There is substantial scope to broaden the carpet (and wool) industry in Balkh creating a carpet business cluster zone through the development of support enterprises such as wool production (second grade wool), cutting and finishing services, design support and direct marketing services. There is also scope for broadening product development.

25 26 27 28

CNFA 2005 McCord 2007. See Appendix 5. McCord 2007

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

50

Cutting and washing carpet support industry Cutting and washing is often an independent support industry to the carpet production industry (perhaps 20 per cent of traders carry this out in-house). The cutting and washing of carpets is as integral to [the] overall production process as is weaving29 . This process helps remove excess dye, washes out loose fibres and brings out the sheen and lustre of the carpet. The current capacity within Afghanistan to do this is limited (both in terms of quantity and quality). Facilities are mainly based in Kabul (maximum 1-15 facilities), Mazar (maximum 10 facilities) and Herat (maximum 5-10 facilities). Of these, perhaps only 25 per cent are able to offer services of competitive quality. It is indicated that 80-90 per cent of carpets currently produced are exported to Pakistan for cutting and finishing (and are then subsequently branded Made in Pakistan), although OTF (2006) quotes as high as 95 per cent. This means that current capacity only meets a maximum of 10 per cent of demand. Pakistan has a number of excellent quality cutting and finishing facilities in Peshawar. Financial incentives to invest in cutting and finishing in Afghanistan have been low due to the high costs of land etc. Pakistan also benefits from a number of advantages in this business: ease of access to chemicals (made in Pakistan), access to expertise and skilled labour, a warm climate (year round warm weather means that carpets can be dried outside) and efficient / secure export. Afghan capacity to carry out good quality of cutting and washing exists but requires scaling up with appropriate assistance. 30 The following SWOT analysis provides a comprehensive overview of strengths, weaknesses, opportunities and threats in the carpet subsector (with a focus on Balkh).

29 30

McCord 2007 OTF 2006

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

51

SWOT-analysis CARPET SUBSECTOR/BALKH PROVINCE

STRENGTHS OPPORTUNITIES

Perception/appreciation in the world market for (uniqueness of) traditional handmade Afghan carpet Long historical tradition of weaving by hand at home in villages/unique product Large number of skilled weavers in Balkh (~10,000), high level of production (>150,000m2 / annum with approximately 12,500 m2 produced per month) Quantity and quality of traditional designs and patterns Availability of raw material (wool, but it is unprocessed) Availability of antique carpets Availability of the natural dyes Favorable conditions in Mazar (electricity, water?)

WEAKNESSES

Export directly, instead of via Pakistan Adding value by cut and wash (but environmental unfriendly); as long as quality is guaranteed Learn new styles and adopt to market demand Target specific niches in world market Zero tax tariff with a number of countries Creating a (socially-conscious) branding Wool-processing (spinning, dyeing, washing) US market recovering and pushing world demands World market for carpets is growing at 2-3 yearly Access to vertical looms for larger carpets (US market) Small expat-community in the domestic market Product-differentiation Developing a marketing entity representing Balkh producers Plant for washing chemicals

THREATS

Cutting and washing facilities in the north / Balkh are not sufficient (only meet ~10% demand) Quality of available cut and wash facilities is low or varying Constraints in access to chemicals, have to be imported from Pakistan, and they are expensive Limited market linkages for exports Limited to zero domestic demand for traditional handmade Afghan carpets Access to raw materials: quality white wool and natural dyes, for limited supporting services in wool subsector Use of child labour to make costs low Not able to adapt to market demands (new color and styles) Poor working conditions for weavers Little quality control with home-based weavers Transportation from Mazar is expensive Lack of marketing capabilities with traders Low technical expertise level on processing wool, dyeing, cutting and cleaning of carpets High-level carpet market (handspun, hand woven) is limited

Government of Pakistan subsidizing carpet industry (transportation) Strong Pakistani market linkages Development of a strong Pakistani brand, by carpets made by Afghan weavers) The competition of cheaper machine made carpets from other countries (Iran, The competition of modern style carpets from other countries (India, Kashmir) Western attitude towards child labour Appreciation for product is subject to fashion influences (interior decoration) Growing tendency among customers to buy lower quality carpets and change more often (instead of focusing on durability) Irregularities of hand-spun, hand woven carpets are unappealing to some markets

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

52

Market Analysis

General carpet industry The major Afghan hubs for carpet trading include Kabul, Herat, and Mazar (primary). It is said that more than 90 per cent of carpets are exported out of Pakistan and onwards (EU, USA). Value chain analysis has shown that Afghanistan can capture 3-5 times more value by trading closer to the end customer and processing / exporting out of Afghanistan. 31 Exports include finished and unfinished carpets. The US and Germany are the largest global carpet buyers (with the US just marginally ahead).32 There is strong demand for (some) Afghan carpets (the market is more stable for high quality, traditional Afghan carpets) in regional markets as well as in the US and Europe (Germany). The hand-knotted carpet market remains highly competitive although competition from good quality machine-made carpets is pushing prices down and decreasing their value.33 Two new characteristics in the global market include34 : the desire for a one stop shop for all types of carpets (machine made and hand spun, different designs) rather than dealing with smaller product specific traders. Another new and worrying development for the Afghan handspun carpet is the decreasing differentiation between (mid range) handspun and machine woven carpets. Style and colour seem to be the most dominant factors in the purchase of carpets, and are changing rapidly35 . The table below describes attributes most desired by the two largest markets, US and Germany. Attributes sought after by major markets

Attribute Colour Design German market Earthy tones Bright colours very popular Contemporary designs as well as simple florals Tribal designs (some) Intricate design not favoured Chobis in natural dyes Bright colours / earth tones in contemporary design may be popular US Earthy tones No bright colours Tribal designs in contemporary as well as simple florals Intricate design not favoured Khazakhs and Chobis in natural dye would do well Gabbehs may also be popular

Type

Source: derived from OTF 2006

Cutting and washing carpet support industry Cutting and washing facilities are mainly based in Kabul, Mazar and Heart in Afghanistan. Clients are Afghan based companies including high-end, medium-end and low-end carpet dealers. At present the capacity to offer good quality cutting and finishing is low although in each location it does exist. In Mazar, there is one renowned cutting and finishing service near the Silo run by Naim company.

31 32 33 34 35

CNFA 2005 OTF 2006 OTF 2006 OTF 2006 OTF 206

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

53

This facility offers excellent quality services although at higher prices than its local competitors. Demand for this service is high however. The carpet finishing service (cutting and washing36 ) in Pakistan (Peshawar) is quoted at $4.89 / m2 (not including costs of transport however) compared to Afghanistan at $4-7 / m2.

Co mpetitor Analysis

General carpet industry International competitors include Pakistan (export $246 M), Iran (export $391 M), Nepal (export $100M), China (export $121M), and India (export $148 M). 37 Trends in the market indicate that contemporary designs are becoming more popular. India and Nepal are responding quickly to these changes and are strong competitors in the handspun market. The carpets produced in China are increasingly made with machine-spun wool and high wages are diminishing the hand knotted carpet industry. Afghan exports in 2004 were worth $140M, up 10 per cent on the previous year. 38 More recently though, the marketing of high value Afghan carpets has been challenged with the sudden mass production of cheap, machine made carpets from China. Going forward, Afghanistans predominant competitive advantage lies with branding their carpets handspun / made in Afghanistan (with local Afghani / Ghazni wool) to capture their higher value, although ultimately with modernization - a range of products may make the industry more sustainable. The Afghan chob rang type is the most sought-after on the international markets. The wholesale price per m2 of Afghan carpets is between $74-131. In India, Indian knotted high quality carpets are given at $102 / m2, and medium quality Chobi is $97 / m2 (OTF 2006). Afghanistans prices are competitive with those from India and Nepal, but will be challenged by low prices of the machine made carpets in the region ($40 /m2) if they do not pursue branding. Afghanistan carpet price structures Knot density 35x40 40x40 50x50 Best ($) 90 107 131 Good ($) 85 98 115 Poor ($) 74 79 82

Source: derived from ADB Landell Mill Limited March 2007

Cutting and washing support industry Competitors in the cutting and washing industry include both Afghan and international companies. Within Afghanistan, there are a few good quality cutting and finishing units as discussed, although in general the capacity remains thin. The quality of services is not externally verified or graded, so it is difficult to differentiate between the providers except by reputation. In Mazar, there are a total of 10 facilities but only one facility (run by the Naim company near the Mazar Silo) remains fully competitive (cost and quality). The table below contrasts the prices of the Silo cutting and finishing

36 37

ADB Landell Mill Limited March 2007 OTF 2006 38 OTF 2006

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

54

against two other units. As a result of inconsistent quality, nine of the facilities are struggling to survive, whilst the Silo facility is inundated in contracts. In Kabul, the prices are similar (and quality likewise). Kabuls cutting and washing facilities are generally further from the Northern production areas, and do not currently pose a threat to cutting and finishing in Mazar. International competition is mostly based in Peshawar, Pakistan. The quality of the services is high and the costs are low (see earlier / $4.89 / m2 ). However, carpets from Afghanistan must be transported to Pakistan ($2 / m2). 39 Yet, if carpets are still exported from Pakistan, incentives exist for the finishing of carpets to be carried out there too. Research indicates that increasing numbers of carpets are now being exported from Kabul. Typical costs of cutting and finishing in Mazar Facility Dusting / m2 Washing / m2 Cutting / m2 Total cutting and finishing / m2 $6 / m2 ~$3-5 / m2 $3 / m2

Large C/F Silo Small C/F Haji Surajudi Small C/F Ali Khan

(Not given) $0.2 / m2 $0.2 / m2

(Not given) $2 / m2 $2 / m2

(Not given) Not currently using $0.6 / m2

C usto mers/markets Kabul/direct export

General carpet industry Over 90-95 cent of Afghan produced carpets are exported. Only 5 per cent of locally carpets are purchased in Afghanistan (predominantly by internationals), mostly in Mazar and Kabul (with a small fraction in Herat). Carpets are predominantly exported through Pakistan (80-90 per cent) part motivated by cutting and washing services - and onto customers in the US and Europe (often through Germany). A small percentage is exported from Kabul directly (10-20 per cent). In terms of the value chain, traders tend to have contracts with weavers through local trading agents. Traders issue the inputs, and the weavers provide the weaving service. Traders usually have contact with a Pakistani agent that is linked to the end buyer in US / Europe and the agent facilitates direct export from Peshawar. Cutting and washing support industry For cutting and finishing facilities in Kabul, Mazar and Herat in Afghanistan, customers are Afghan only. For the smaller facilities, business is piecemeal with local carpet owners or small traders negotiating individual contracts per job. These facilities do not take on larger consignments due to their limited capacity; they also have poorer reputations (and their quality is not competitive with cutting and finishing in Pakistan) and thus find it difficult to secure larger and regular contracts. For the larger facilities (e.g. the Naim company near the Silo in Mazar), large / medium and small traders negotiate the cost of bulk cutting and washing contracts. The quality is high and competitive with Pakistan on both end quality and cost (if transport costs are included). As stated, services in

39

OTF 2006

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

55

Afghanistan could theoretically be increased nine fold, since only 10 per cent of local market demand is currently met.

Demand and supply analysis

General carpet industry Afghanistan has seen a rise of 10 per cent in direct export (2003-2004). Afghanistan is the fourth largest global exporter of carpets (direct export). Yet while Pakistan appears to be the second largest exporter, over 70 per cent of these Pakistani carpets are in fact Afghan. Afghan carpets are currently cut and finished in Pakistan, and exported as Pakistan carpets. Market demand is thus significant for Afghan carpets although a lack of appropriate branding (as handspun, made in Afghanistan etc) has recently been forcing Afghan carpets to compete with Chinese / Indian machine made carpets. Global exporters of carpets and growth 2003-04

Source: derived from USAID 2004, cited in OTF 2006.

As stated earlier, EPAA (2007) estimates that 2 million carpets are exported per year. With an average carpet size of 3.2 m2 , this equates to 6.4 million m2 carpet / year. However, the real figure may be closer to 6.6 million m2 carpet / year. Carpet production zones are based around the north of Afghanistan. Balkh province is estimated to produce over 150,000 m2 of carpets a year or >12,000 m2 a month. Carpets are mainly made in Daulatabad, Aqcha, Dehdadi, Balkh and Chahar-Bolak districts (see Appendix 2 for district breakdown). Cutting and washing support industry Demand for Afghan cutting and finishing services has increased dramatically in recent years (since 2001). In the past, these services existed and the same companies also facilitated direct export (e.g. to Frankfurt). Currently the services on the ground in Afghanistan only meet 6-10 per cent of demand (demand includes cutting and finishing of Balkh carpets as well as other Northern provinces). At present, it is estimated that Balkh cutting and finishing facilities complete 4,000-6,000 m2 / month against a potential demand of over 60,000 m2 (derived from research data in Mazar). There is obvious demand for quality cutting and finishing services in Mazar if they are competitive with Pakistani (Peshawar) services on both price, and quality.

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

56

As stated previously, cutting and finishing facilities are mostly based in Kabul, Mazar and Herat. Services vary in quality. In Mazar, there is only one good quality service provider available. The other units (nine) are only barely operational. See earlier for details.

Business justification in Balkh

At present, there are limited facilities for cutting and washing in Mazar despite increasing market demand (only 10 per cent of market demand is met). One large facility (run by the Naim company near the Mazar Silo) has a thriving business and has more contracts than they can manage whilst several smaller units - almost non-operational - face high costs of inputs and provide inconsistent quality services with few trader links. Recently, the government issued subsidized land for expanding cutting and finishing businesses but this has no water / electricity or proper drainage, and thus businessmen have been hesitant to invest. This situation has led to the following: Currently, only approximately 10 per cent of carpets traded in Mazar are cut and finished in Balkh, Weaver / production units and associations sell unfinished products to Kabul or Pakistani traders losing the opportunity to sell higher value products directly, or use local marketing channels, Small local cutting and finishing facilities in and around Mazar suffer from limited trader contracts, a lack of quality inputs (chemicals see below) and poor / inconsistent cutting and finishing standards (putting off prospective traders), (Increasingly expensive) chemicals for finishing / washing the carpets are being imported from both Turkmenistan and Pakistan due to a lack of local supplies (and these degrade in transit - increasing the costs (since more of the chemical must then be used to compensate). [ A new dealer based in Mazar will resolve this problem]

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

57

Financial Pla n 40

Capital requirement 35,000 US$ 35,000 US$ 35,000 US$ 105,000 US$

Owners Equity: MRRD grant: Bank Loan: Total:

Capital Investments

Capital Investments Land Building Drainage (2) Equipment Blow dryer (2) Washing material (2) Cutting machine Stabilizer (2) Transportation Generator

US $ 0 0 30,000 10,000 6,000 4,000 8,000 0 0 58,000

C Financing options (and contribution of potential entrepreneurs) See A. Loan will be paid back within 18 months, at an interest rate of 13% with a grace period of four months.

D N/A

40

Landed costs

In the final Business Plans, some of this data may be tweaked.

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

58

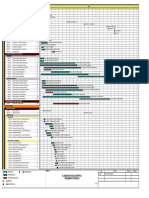

Operations Forecast

The production capacity will double with the two new sites. Current production is 100m2 a day. The below table will state the production capacity with the expansion. Operation Forecast Summer Day 200 Winter Day Month 100 3,050

Capacity Finished carpet m2

Month 6,100

T TLHYR 36,600

T TL/HYR 18,300

T TL/YR 54,900

During the winter months, capacity will be at 50%, due to the weather conditions.

Income Statement US$ Sales revenue Costs of goods sold Chemicals TO TAL Gross Profit Expenses Rent Utilities (water, electricity, fuel) Salaries Other labor costs Transportation Costs Other administration costs Loan Deprecation TO TAL Net Income before Tax Less: Income Tax Net Income US$ 296,460

59,292 59,292 237,168 36,000 7,896 114,468 24,000 7,488 6,000 26,600 6,000 228,452 8,716 1,743 6,973

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

59

Cash Flow and Break-Even Analysis

Cash flow Overview year 1 35,000 35,000 35,000 296,460 401,460 year 2 119,716 0 0 296,460 416,176 year 3 142,328 0

Opening balance Grant Loan Collection from sales Total receipts Payments Purchase of land Building Purchase vehicle Rent Chemicals Transportation Labor costs Other labor costs Administrative costs Loan payments Utilities Total payments Balance

296,460 438,788

0 0 0 36,000 59,292 7,488 114,468 24,000 6,000 26,600 7,896 281,744 119,716

0 0 0 36,000 59,292 7,488 114,468 24,000 6,000 26,600 0 273,848 142,328

0 0 0 36,000 59,292 7,488 114,468 24,000 26,600 0 0 267,848 170,940

Break Even Analysis To tal Production m2 54,900 54,900 54,900 Variable Costs m2 (US$) Sales Price m2 (US$) Fixed Costs (US$)

Direct labor costs Chemicals Total Direct Costs

US$ 95,040 59,292 154,332

BEP (m2)

2.81

6.00

133,412

41,691

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

60

G Cost benefit analysis *CBA) Please refer to all of the above for preliminary cost / benefits. A full CBA will be included in the Draft Final Report / Business Plan.

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

61

Marketing Plan

Targeting Strategy

The company will continue working with existing customers, over time sorting out the better customers and creating a customer relationship that is based on mutual trust. The company is by nature independent, which means that is able to work with any trader, carpet production factory, carpet producers association and/or carpet weavers directly. Herewith it differs from other cutting and washing facilities, which are usually owned by a trader. The company will consistently put efforts into business development, in order to attract new customers, over time ceasing to work with bad customers, that cannot or will not issue payments according to the given time schedules.

Service Strategy

The company will firstly aim at good quality services, delivered timely and according to estimated time schedules. The company will do cutting and washing according to the customers specifications. Over time, the company will diversify to three different products of cutting and washing, different quality and price levels.

Pricing Strategy

The company will maintain its current pricing policy, over time aiming to develop different products at different price levels. The company will strive to check the prices of competition in Mazar-e Sharif and Kabul, Pakistan in order to maintain a level of competitiveness. Current sales price is 6 USD per m2.

Advertising

The company will use direct sales contact with potential new clients as a sales promotion tool. The company will use other sales tools, like discounts on larger orders, and/or special price offerings offseason.

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

62

Sales Forecast

Sales Forecast m2 Total Production Year 54,900 Price (US$) 6 T TL SALES 10% Bad (US$) Customers 32,9400 32,940 T TL Yearly Sales Revenue (US$) 296,460

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

63

5.3

Technical Feasibility

(Demand and supply analysis was presented under the previous section.)

Manag eme nt

Management Managing Director/Business Owner: Naim Maimanaghi End responsible for Overall Management, Finance, Marketing & Sales, and Human Resources. Manager: Mr. Shams Responsible for Finance, Administration, and Human Resources Financial Administration The company will do the financial administration in the main factory. Accounting software (QuickBook, etc.) will be bought for the financial administration. The company will receive technical assistance with the implementation of a professional computerized financial administration and the use of accounting software from MRRD. At the main factory Internet-connection will be present and at least one PC for the administration. Administrative and financial controls - Bookkeeping system - Accounting system - Accounts receivable and account payable management system

B (i)

Availability of required reso urces (technical, infrastructure and equipment) Infrastructure

Existing core infrastructure is present on the ground at the Naim company cutting and finishing facility with access to water and electricity. The business will link up this existing functional facility with several other smaller facilities in Mazar. (ii) Equipment / materials

Equipment exists on the site. Additional equipment will need to be purchased including blow dryer (custom made locally), cutting machine (available locally), washing material (available locally) and stabilizer (available locally). (See financial plan)

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

64

(iii)

Technical / Business Assistance

The business does not depend on this assistance to be operational. The company will receive additional management, finance, marketing and technical training / support (the training support / plan is described under Appendix 4). Management support: The Company will receive management support from a Kabul based consultant during the first year of operations which will be paid for by MRRD. The monthly meetings will be focused at Coaching, mentoring, troubleshooting, support service contract management, HR management, monitoring and evaluation. (Total cost = $21,600) Financial support: The Company will receive Accounting / Quickbook training and assistance from a Kabul based Consultant in the establishment of a Financial Management System. (Total cost = $3,800) Marketing and Business training: The Company will receive a three-day marketing and BDS training from a Kabul-based BDS provider which will be paid for by MRRD. Modules including marketing, business development, supply chain management and export. (Total cost = $1,800). Technical support: The Company will receive assistance for establishing guidelines for quality of cutting and washing, environmental friendly cleaning and working conditions, as well as training workers on general technical skills and quality control. (Total cost = $1,500) (iv) Raw Materials

Carpets: Local carpets are available for servicing in Mazar and the Company has links with traders. As stated earlier, there are at least 12,000 m2 of carpets produced monthly from Balkh alone, which require cutting and finishing (other Northern provinces also channel their carpets through Mazar totaling at least three times the Balkh production). Chemicals: The main raw material required for carrying out the cutting and finishing service itself are the chemicals that are used for washing (sodium peroxide). A new dealer based in Mazar will enable the company to source the chemicals directly without facing high costs in transport and degradation of the chemical in transit. The chemical costs approximately x / litre. Alternatively, chemicals are already imported from Pakistan and with increased volumes a better price can be negotiated.

Subsector Analysis and Business Plan Development / North & NE /Economic Viability & Technical Feasibility Dec 07

65

S-ar putea să vă placă și

- Grant's Interest Rate Observer Summer Issue (Free)Document24 paginiGrant's Interest Rate Observer Summer Issue (Free)hblodget100% (1)

- JoshuaDocument88 paginiJoshuaaghorbanzadeh67% (3)

- Community Property - Checklist (1) Basic Presumptions (You MUST Put This at The Top of EVERY Community Property Essay)Document3 paginiCommunity Property - Checklist (1) Basic Presumptions (You MUST Put This at The Top of EVERY Community Property Essay)Kat-Jean FisherÎncă nu există evaluări

- The Labor Market in Saudi ArabiaDocument28 paginiThe Labor Market in Saudi ArabiaAbdulaziz AlzahraniÎncă nu există evaluări

- Project Planning and SchedulingDocument14 paginiProject Planning and Schedulingdnahas1Încă nu există evaluări

- Wealth Prophecy - SummaryDocument4 paginiWealth Prophecy - Summarybob james100% (3)

- Import Shipping ManualDocument82 paginiImport Shipping ManualaghorbanzadehÎncă nu există evaluări

- Negotiation Style Self Assessment A VersionDocument9 paginiNegotiation Style Self Assessment A VersionKarsten0% (1)

- Project Control Stages A Complete Guide - 2019 EditionDe la EverandProject Control Stages A Complete Guide - 2019 EditionÎncă nu există evaluări

- Project Management Using Excel - Gantt Chart TemplateDocument3 paginiProject Management Using Excel - Gantt Chart TemplatezapclinkÎncă nu există evaluări

- Project Management CourseworkDocument17 paginiProject Management CourseworkEqui AgbasiÎncă nu există evaluări

- Primavera Earned Value Management: Quick Install GuideDocument4 paginiPrimavera Earned Value Management: Quick Install GuideVivekÎncă nu există evaluări

- Value Of Work Done A Complete Guide - 2020 EditionDe la EverandValue Of Work Done A Complete Guide - 2020 EditionÎncă nu există evaluări

- Project Background BhopalDocument13 paginiProject Background Bhopalbnkarthik00dbÎncă nu există evaluări

- Diagnostic Test: Fundamental of Accounting Business & Management 1Document3 paginiDiagnostic Test: Fundamental of Accounting Business & Management 1Dindin Oromedlav Lorica75% (4)

- W2 - Project Life Cycle Models & Project SelectionDocument58 paginiW2 - Project Life Cycle Models & Project SelectionThảo My TrươngÎncă nu există evaluări

- Article-How To Make Reliable Project Schedule and Cost EstimatesDocument12 paginiArticle-How To Make Reliable Project Schedule and Cost EstimateslihavimÎncă nu există evaluări

- Kingshuk Sarkar CV - PlannerDocument3 paginiKingshuk Sarkar CV - PlannerKingshuk SarkarÎncă nu există evaluări

- Tollgate-Based Project Management TemplateDocument9 paginiTollgate-Based Project Management TemplateKulanthaivelu RamasamyÎncă nu există evaluări

- Riskanalysissimplified PDFDocument12 paginiRiskanalysissimplified PDFmirakulÎncă nu există evaluări

- Eu One Page SummaryDocument4 paginiEu One Page Summarytiwari_anunay1689Încă nu există evaluări

- Estimate Categories Improve Budget FormulationDocument4 paginiEstimate Categories Improve Budget FormulationCPittmanÎncă nu există evaluări

- Project ManagementDocument37 paginiProject ManagementAlfakri WaleedÎncă nu există evaluări

- 2 Engineering Full Technical Report GG FinalDocument4 pagini2 Engineering Full Technical Report GG FinalAdesoji LawalÎncă nu există evaluări

- Productividad Economica.Document8 paginiProductividad Economica.Andres Felipe Arguelles PinedaÎncă nu există evaluări

- Hazard Heat Map Training: Lufkin IndustriesDocument33 paginiHazard Heat Map Training: Lufkin IndustriesjoshuaÎncă nu există evaluări

- Template - Financial PlanDocument10 paginiTemplate - Financial PlanGryswolfÎncă nu există evaluări

- Minggu Ke 10 - Keadah-Keadah Pengurusan ProjekDocument43 paginiMinggu Ke 10 - Keadah-Keadah Pengurusan ProjekNur'Aina Farhana NorzelanÎncă nu există evaluări

- Developing A Housing Microfinance Product - The First Microfinance Banks Experience in AfghanistanDocument32 paginiDeveloping A Housing Microfinance Product - The First Microfinance Banks Experience in AfghanistanBhagyanath MenonÎncă nu există evaluări

- Afghan Slaughterhouse Pre-Feasibility Study ADB-RBSP November 2008Document53 paginiAfghan Slaughterhouse Pre-Feasibility Study ADB-RBSP November 2008balajicrackÎncă nu există evaluări

- Website Marketing Budget ProjectDocument8 paginiWebsite Marketing Budget Projecteng_waleed2008Încă nu există evaluări

- Risk - RegisterDocument2 paginiRisk - RegisterJoe OliveraÎncă nu există evaluări

- Class 1 Risk Management For ConstructionDocument68 paginiClass 1 Risk Management For ConstructionasmjewelÎncă nu există evaluări

- Al Mussafah A Al Mussafah Ahalia Hospital Al Mussafah Ahalia HospitalDocument4 paginiAl Mussafah A Al Mussafah Ahalia Hospital Al Mussafah Ahalia HospitalChâu TúÎncă nu există evaluări

- Ax2012 Si WBSDocument36 paginiAx2012 Si WBSAli FakihÎncă nu există evaluări

- 2014 CTB3365DWx Water - Consumption PDFDocument11 pagini2014 CTB3365DWx Water - Consumption PDFzmiyurÎncă nu există evaluări

- International Business: AssignmentDocument7 paginiInternational Business: AssignmentariaÎncă nu există evaluări

- Mod3 Feasibility Study GuidelinesDocument37 paginiMod3 Feasibility Study GuidelinesJacob BataquegÎncă nu există evaluări

- Kyakulumbye, Et Al Project Management Ebook 2018Document270 paginiKyakulumbye, Et Al Project Management Ebook 2018MbavhaleloÎncă nu există evaluări

- CDC UP Project Scheduling Practices GuideDocument0 paginiCDC UP Project Scheduling Practices Guidejunlab0807Încă nu există evaluări

- What To Do When Preparing A Project ScheduleDocument2 paginiWhat To Do When Preparing A Project ScheduleCristian Steven SilvaÎncă nu există evaluări

- Project Proposal TemplateDocument5 paginiProject Proposal TemplateKoushik RaoÎncă nu există evaluări

- WRENCH Working Steps-Consolidated PDFDocument47 paginiWRENCH Working Steps-Consolidated PDFAnonymous IwqK1NlÎncă nu există evaluări

- Project Title:: Voice Activated Personal Assistant DeviceDocument7 paginiProject Title:: Voice Activated Personal Assistant Devicecfur1Încă nu există evaluări

- Developing The Project PlanDocument8 paginiDeveloping The Project PlanStephanie BucogÎncă nu există evaluări

- Textbook SpringDocument242 paginiTextbook SpringAditya D RÎncă nu există evaluări

- FMCTI EPRV BrochureDocument2 paginiFMCTI EPRV BrochureKaren AndradeÎncă nu există evaluări

- Excel 2010 Pivot Tables Tutorial PDFDocument2 paginiExcel 2010 Pivot Tables Tutorial PDFChelseaÎncă nu există evaluări

- SCL Delay Protocol Gets Rider 1 UpdateDocument3 paginiSCL Delay Protocol Gets Rider 1 UpdateJailanee ImakÎncă nu există evaluări

- PMO SWOT Analysis: Strengths WeaknessesDocument1 paginăPMO SWOT Analysis: Strengths WeaknessesmaxangelicdemonÎncă nu există evaluări

- CH 10Document7 paginiCH 10Witness Wii MujoroÎncă nu există evaluări

- Project Cost-Time-Risk Diagram for Planning and Risk ManagementDocument8 paginiProject Cost-Time-Risk Diagram for Planning and Risk ManagementGuillermo BandaÎncă nu există evaluări

- Implementation of Pmo and Epm MicrosoftDocument72 paginiImplementation of Pmo and Epm MicrosoftSALAH HELLARAÎncă nu există evaluări

- Unit 1 Basics of Project Management: StructureDocument20 paginiUnit 1 Basics of Project Management: StructurebevinjÎncă nu există evaluări

- Introduction To Amrutlal & Hansraj CoDocument41 paginiIntroduction To Amrutlal & Hansraj CoKrunal VyasÎncă nu există evaluări

- Factors Affecting Construction Labour Productivity in Trinidad and TobagoDocument9 paginiFactors Affecting Construction Labour Productivity in Trinidad and TobagoNonkosi DlaminiÎncă nu există evaluări

- Critical Path: (PMPG 5000 RNA, Semester 1, Winter 2022)Document7 paginiCritical Path: (PMPG 5000 RNA, Semester 1, Winter 2022)priyanshuÎncă nu există evaluări

- Primavera P6 Lookahead Filters in 40 StepsDocument8 paginiPrimavera P6 Lookahead Filters in 40 StepshichemokokÎncă nu există evaluări

- A1 - Critical Review of The Causes of Cost Overrun in Construction Industries in Developing CountriesDocument10 paginiA1 - Critical Review of The Causes of Cost Overrun in Construction Industries in Developing CountriesTong Yi NieÎncă nu există evaluări

- Part A Memorandum of ProcedureDocument24 paginiPart A Memorandum of ProcedureSyed Umair HashmiÎncă nu există evaluări

- UN Procurement ManualDocument378 paginiUN Procurement Manuallengyianchua206Încă nu există evaluări

- ENGT 3510 Project Management Class DeliverablesDocument58 paginiENGT 3510 Project Management Class DeliverablesMontellia GantÎncă nu există evaluări

- Why EVM Doesnt WorkDocument10 paginiWhy EVM Doesnt Workaqeel_al_triniÎncă nu există evaluări

- Business Strategies Complete Self-Assessment GuideDe la EverandBusiness Strategies Complete Self-Assessment GuideÎncă nu există evaluări

- Critical Path Method A Complete Guide - 2020 EditionDe la EverandCritical Path Method A Complete Guide - 2020 EditionÎncă nu există evaluări

- Shorecrest High School - Stakeholder Survey - May 2010Document4 paginiShorecrest High School - Stakeholder Survey - May 2010aghorbanzadehÎncă nu există evaluări

- Joshua Wilton House: Restaurant & InnDocument1 paginăJoshua Wilton House: Restaurant & InnaghorbanzadehÎncă nu există evaluări

- Irish BlessingsDocument1 paginăIrish BlessingsaghorbanzadehÎncă nu există evaluări

- Order Form 333Document7 paginiOrder Form 333aghorbanzadehÎncă nu există evaluări

- 07 Cutting Table and Driver StationDocument9 pagini07 Cutting Table and Driver StationaghorbanzadehÎncă nu există evaluări

- Practical Exercise 1.3.2.3: ObjectivesDocument5 paginiPractical Exercise 1.3.2.3: ObjectivesaghorbanzadehÎncă nu există evaluări

- 1 - Lista Ta Pagamenti - MIN20 (27!07!10)Document2 pagini1 - Lista Ta Pagamenti - MIN20 (27!07!10)aghorbanzadehÎncă nu există evaluări

- EXPO HIRE Electrical Order FormDocument1 paginăEXPO HIRE Electrical Order FormaghorbanzadehÎncă nu există evaluări

- Store Clocks Inventory ListDocument1 paginăStore Clocks Inventory ListaghorbanzadehÎncă nu există evaluări

- 5 Radius Notching Cutter Head For Nail CuttingDocument1 pagină5 Radius Notching Cutter Head For Nail CuttingaghorbanzadehÎncă nu există evaluări

- Promo ACDelco Batteries08Document1 paginăPromo ACDelco Batteries08aghorbanzadehÎncă nu există evaluări

- Catalogue Price List - Mar 2013Document4 paginiCatalogue Price List - Mar 2013aghorbanzadehÎncă nu există evaluări

- Chapter 1 Order Form Invoice and PaymentDocument3 paginiChapter 1 Order Form Invoice and PaymentaghorbanzadehÎncă nu există evaluări

- Nail CutterDocument6 paginiNail CutteraghorbanzadehÎncă nu există evaluări

- Order Queensland publicationsDocument1 paginăOrder Queensland publicationsaghorbanzadehÎncă nu există evaluări

- QFC Mini CatalogueDocument8 paginiQFC Mini CatalogueaghorbanzadehÎncă nu există evaluări

- Catalogue Price List - Mar 2013Document4 paginiCatalogue Price List - Mar 2013aghorbanzadehÎncă nu există evaluări

- Cut Hidden Siding Nails EasilyDocument1 paginăCut Hidden Siding Nails EasilyaghorbanzadehÎncă nu există evaluări

- 5 Radius Notching Cutter Head For Nail CuttingDocument1 pagină5 Radius Notching Cutter Head For Nail CuttingaghorbanzadehÎncă nu există evaluări

- Nail Clippers: Input/Output Functional ModelDocument4 paginiNail Clippers: Input/Output Functional ModelaghorbanzadehÎncă nu există evaluări

- Adl PTC-2Document1 paginăAdl PTC-2aghorbanzadehÎncă nu există evaluări

- Clep Military Transcript Order FormDocument1 paginăClep Military Transcript Order FormaghorbanzadehÎncă nu există evaluări

- Vha 10 0426 FillDocument2 paginiVha 10 0426 FillaghorbanzadehÎncă nu există evaluări

- CVS MAIL SERVICE ORDER FORMDocument2 paginiCVS MAIL SERVICE ORDER FORMaghorbanzadehÎncă nu există evaluări

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document2 pagini400 Bad Request 400 Bad Request Nginx/1.2.9aghorbanzadehÎncă nu există evaluări

- Va40 1330Document4 paginiVa40 1330aghorbanzadehÎncă nu există evaluări

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document2 pagini400 Bad Request 400 Bad Request Nginx/1.2.9aghorbanzadehÎncă nu există evaluări

- Russell Indexes ConstructionDocument48 paginiRussell Indexes ConstructionMichael RitterÎncă nu există evaluări

- Ar KCL 2018-19Document120 paginiAr KCL 2018-19Harshana NadeeshanÎncă nu există evaluări

- Uber PresentationDocument15 paginiUber PresentationmirzaÎncă nu există evaluări

- SS 18 QuestDocument12 paginiSS 18 QuestjusÎncă nu există evaluări

- OracleDocument40 paginiOraclejaggaraju8Încă nu există evaluări

- Accounting For Income Taxes SlidesDocument51 paginiAccounting For Income Taxes SlidesparmitchoudhuryÎncă nu există evaluări

- Chap 020Document18 paginiChap 020stella0616Încă nu există evaluări

- Second Phase: Toyota Analysis Project IFE MatrixDocument7 paginiSecond Phase: Toyota Analysis Project IFE MatrixAnonymous 1hE9917mpzÎncă nu există evaluări

- ABS Market MakersDocument4 paginiABS Market Makerschuff6675Încă nu există evaluări

- Alam Maritim AR17 PDFDocument215 paginiAlam Maritim AR17 PDFAzwanÎncă nu există evaluări

- Pob Form 3Document6 paginiPob Form 3yuvita prasadÎncă nu există evaluări

- FIN515 Week 2 Homework AssignmentDocument6 paginiFIN515 Week 2 Homework AssignmentNatasha DeclanÎncă nu există evaluări

- Adani Power Ltd. - Balance Sheet - Consolidated: INR CroresDocument46 paginiAdani Power Ltd. - Balance Sheet - Consolidated: INR CroresIshan ShahÎncă nu există evaluări

- Partnerships Formation - RevisedDocument10 paginiPartnerships Formation - RevisedBerhanu ShancoÎncă nu există evaluări

- DB 45 PDFDocument120 paginiDB 45 PDFzaheeruddin_mohdÎncă nu există evaluări

- An Analysis of Grameen Bank and ASADocument45 paginiAn Analysis of Grameen Bank and ASAAye Nyein ThuÎncă nu există evaluări

- Chap 02 Aem 421Document41 paginiChap 02 Aem 421trollingandstalkingÎncă nu există evaluări

- Ar2018 PDFDocument102 paginiAr2018 PDFNurul JannahÎncă nu există evaluări

- Achievements CimbDocument6 paginiAchievements CimbShirlie ChongÎncă nu există evaluări

- Dividend Policy of Everest Bank Limited: A Thesis Proposal byDocument9 paginiDividend Policy of Everest Bank Limited: A Thesis Proposal byRam khadkaÎncă nu există evaluări

- Consolidated Policy Schedule PDFDocument6 paginiConsolidated Policy Schedule PDFmanoharÎncă nu există evaluări

- Chapter 17 - Earnings Per Share and Retained Earnings PDFDocument59 paginiChapter 17 - Earnings Per Share and Retained Earnings PDFDaniela MacaveiuÎncă nu există evaluări

- About Company: World, Processing Sophisticated UHP (Ultra High Power)Document24 paginiAbout Company: World, Processing Sophisticated UHP (Ultra High Power)RJ Rishabh TyagiÎncă nu există evaluări

- 8963 80Document16 pagini8963 80OSDocs2012Încă nu există evaluări

- Report IFA For Norway On Interest DeductionDocument19 paginiReport IFA For Norway On Interest DeductionAnna ScaoaÎncă nu există evaluări