Documente Academic

Documente Profesional

Documente Cultură

Failure of TRLY and TREG Card in MARK VI-OCT09pdf PDF

Încărcat de

sanjeevchhabraDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Failure of TRLY and TREG Card in MARK VI-OCT09pdf PDF

Încărcat de

sanjeevchhabraDrepturi de autor:

Formate disponibile

16

OCTOBER 2009 FEED BACK NO. 2

TS TIDINGS

Project: Silk Road Sugars private limited, Kakinada, Frame 6B GT, 1 x 35 MW. Problem: Failure of the TRLY and TREG cards in Mark-6 Panel. Details of the failure: Silk Road Sugars is supplied with a Frame 6B Gas turbine and Mark-6 is used for its control and protection. The Project scope for BHEL PSSR was to commission the machine with Gas firing. Due to non availability of gas, customer has planned for liquid fuel firing first and the contract for the conversion from Gas to Liquid fuel was given to BGGTS (BHEL GE Gas Turbine Services Pvt Ltd). The machine was put on ratchet and cranked on 24/10/2009. All the protection checks for the turbine were completed and GT was made ready for firing operation. The preparatory works for starting the Gas Turbine was going on and the necessary modules were switched on and the auxiliaries were started one by one. At this time it was found that fumes were coming out of the TRLY board at 2C3 location and immediately panel power supply was switched off and isolated. On further investigations, it was found that those fumes were due to the burning of Metal Oxide Varistor (MOVs) provided across the output contacts of the relays meant for suppression of the surges as shown in the figure circled. The relay termination point at which the varistor blown out was a dry contact providing the master control for the Warren AOP hooked up by BGGTS and the control supply fuse of the warren AOP MCC was found in blown condition after this incident

TECHNICAL SERVICES / PSSR

17

OCTOBER 2009

TS TIDINGS

The power supplies for the individual Terminal boards were kept isolated in the Power Distribution Module (PDM) and power was switched on to the panel in that condition. The terminal board connectors were connected one by one checking for the input DC supply for any disturbances. While connecting to the TREG Module the input power supply swung to negative side and the positive voltage reading was +3V and the negative side voltage was -125 V. Under healthy conditions these should be +62.5V and -62.5 V respectively. The power supply was common to two TREG boards and they were isolated. During physical checking of the board it was observed that one varistor was blown in this card also which was connected to the negative leg of the DC in which trip interlock circuit was connected as shown in the figure circled. All the remaining terminal board cards were checked thoroughly and found no damage has occurred. With the above two damaged cards kept off, the panel was charged and found to be working normally. Analysis for the failure: The terminal point in the TRLY Board, which was used by BGGTS to connect the MCC command for warren AOP was Output No.1. On inspection it was found that the Fuses FU1 and FU7 was in position leading a path for the negative DC Supply to come till the end of the Varistor. To the other end of the Varistor lies the 230V AC signal from the MCC and the Varistor was put to stress by applying AC signal at one end and negative DC at the other end which eventually broken down the Varistor. In that course it created a short circuit which mixed AC and DC supplies and the negative leg of the DC supply was mixed to the AC supply which resulted in the failure of one more Varistor connected in the negative leg of the DC supply as shown in the TREG Board drawing. Further damage was averted due to the blowing of control supply fuse in the Warren AOP MCC module

TECHNICAL SERVICES / PSSR

18

OCTOBER 2009

TS TIDINGS

Precautions to be taken for avoiding such failures Relay Nos 1 to 6 need not be assigned for MCC Commands as far as possible, instead relay nos 7 to 11 can be assigned for this purpose which can be used for dry contacts only where as the former can be used as wet contacts with the jumper JP1 and the Fuses in position. The warren AOP command signal was reassigned to dry contact type channel. Some more MCC contacts (like Vent fans and fire alarm signals) were also found to be assigned in relay number 1 to 6 and these were removed and reassigned at different spare locations to prevent such failures. If in any case if the first 6 relays had to be used, the corresponding fuses have to be removed and kept. In this case it is FU1 and FU7. The fuses and Jumpers has to be inserted only in the case where the output is assigned for wet contact applications like solenoids, MOVs etc.

TECHNICAL SERVICES / PSSR

19

OCTOBER 2009

TS TIDINGS

TECHNICAL SERVICES / PSSR

20

OCTOBER 2009

TS TIDINGS

TECHNICAL SERVICES / PSSR

S-ar putea să vă placă și

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDe la EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsEvaluare: 3 din 5 stele3/5 (2)

- Mark2 Kiigroundf Fault Ctif Tre Ficat TionDocument3 paginiMark2 Kiigroundf Fault Ctif Tre Ficat TionMohamed Bin IerousÎncă nu există evaluări

- LV Switchgear FinalDocument13 paginiLV Switchgear Finalvikivarma147100% (1)

- Faults CompediumDocument109 paginiFaults CompediumDevas ShuklaÎncă nu există evaluări

- اخطاء نضام التحكم التوربينيDocument9 paginiاخطاء نضام التحكم التوربينيMohamed Bin IerousÎncă nu există evaluări

- Site Comp End 02Document66 paginiSite Comp End 02Parameswararao BillaÎncă nu există evaluări

- VFDDocument95 paginiVFDvurumuu100% (1)

- Zimbabwe Electricity Supply Authority: Internal CorrespondenceDocument3 paginiZimbabwe Electricity Supply Authority: Internal CorrespondenceArchiford NdhlovuÎncă nu există evaluări

- CEIG - Electrical Inspector - Defective ReportDocument7 paginiCEIG - Electrical Inspector - Defective Reportjigyesh100% (1)

- TT418A DTCs P2135 & P2101 Theory & Diagnostics 1 11 2011Document3 paginiTT418A DTCs P2135 & P2101 Theory & Diagnostics 1 11 2011Investor Protection100% (2)

- Nikkai 800W Inverter Repair ReportDocument4 paginiNikkai 800W Inverter Repair ReportRichard SmithÎncă nu există evaluări

- Presention DetailsDocument7 paginiPresention DetailspvenkyÎncă nu există evaluări

- TM 11-5805-239-35 - Power - Supply - PP-1209 - 1966 PDFDocument27 paginiTM 11-5805-239-35 - Power - Supply - PP-1209 - 1966 PDFWurzel1946Încă nu există evaluări

- Wavetek SMG4032 Power Supply NotesDocument6 paginiWavetek SMG4032 Power Supply Notesampinto1Încă nu există evaluări

- ML 042960393Document10 paginiML 042960393TXEMAÎncă nu există evaluări

- AMX 4+ Error - ListDocument18 paginiAMX 4+ Error - Listmasroork_293% (15)

- CEI ComplianceDocument8 paginiCEI ComplianceAnonymous vcadX45TD7Încă nu există evaluări

- Master CH 15Document9 paginiMaster CH 15GAGANÎncă nu există evaluări

- B U L L E T I N: Application EngineeringDocument3 paginiB U L L E T I N: Application EngineeringMaria DazaÎncă nu există evaluări

- SPARK STAR-33 Station FaultDocument4 paginiSPARK STAR-33 Station FaultAnmar SabriÎncă nu există evaluări

- Emergency Stop - Test: TroubleshootingDocument14 paginiEmergency Stop - Test: TroubleshootingFLAVIO MARTINSÎncă nu există evaluări

- Balance T&C Punch List: An-Namas South 132/33 KV S/SDocument4 paginiBalance T&C Punch List: An-Namas South 132/33 KV S/SMohamed Ibrahim AbdoÎncă nu există evaluări

- NSX BL24Document31 paginiNSX BL24Alfredo Smith MurrayÎncă nu există evaluări

- Technical Service Bulletin 17B0001N01 PDFDocument2 paginiTechnical Service Bulletin 17B0001N01 PDFelekossÎncă nu există evaluări

- Electrocution RefineryDocument3 paginiElectrocution Refinerysonn the greatÎncă nu există evaluări

- General Information: Checks & RepairsDocument24 paginiGeneral Information: Checks & RepairsChristian BedoyaÎncă nu există evaluări

- Testing Surge ArrestersDocument6 paginiTesting Surge Arrestersgosalhs9395Încă nu există evaluări

- Technical Audit Report 500 KV Grid Station NTDC ShikarpurDocument10 paginiTechnical Audit Report 500 KV Grid Station NTDC ShikarpurEngr Fahimuddin QureshiÎncă nu există evaluări

- 11KV VCBDocument3 pagini11KV VCBeagles1109Încă nu există evaluări

- ELECTDocument10 paginiELECTThirunavukkarasuThiruÎncă nu există evaluări

- Wiring Harness (Open Circuit) - TestDocument2 paginiWiring Harness (Open Circuit) - TestIrfan Dhee DoodzÎncă nu există evaluări

- Visit To S1 Site (Begaluru) From 16.12.2019 To 22.12.2019 For ENDURANCE Test On RADARDocument2 paginiVisit To S1 Site (Begaluru) From 16.12.2019 To 22.12.2019 For ENDURANCE Test On RADARSreekanth NakkaÎncă nu există evaluări

- Dea Control Panel 202 E31Document7 paginiDea Control Panel 202 E31api-309684703Încă nu există evaluări

- Defects Captured During RRTDocument37 paginiDefects Captured During RRTdreamboy87Încă nu există evaluări

- ABB Transformers MV Medium Voltage Transformers GuideDocument81 paginiABB Transformers MV Medium Voltage Transformers GuideOmar FethiÎncă nu există evaluări

- Codigo de ErroresDocument18 paginiCodigo de ErroresReneÎncă nu există evaluări

- Swyd FailuresDocument35 paginiSwyd FailuresBheem NaveenÎncă nu există evaluări

- Introduction To C&IDocument31 paginiIntroduction To C&IKishore KumarÎncă nu există evaluări

- Ikc2-Service Tips PDFDocument18 paginiIkc2-Service Tips PDFzoltan esteban Hrotko gonzalez100% (1)

- Report On GTG-2 Rotor Earth Fault PipavavDocument4 paginiReport On GTG-2 Rotor Earth Fault PipavavhiiarindamÎncă nu există evaluări

- AC Loco Refresher-SCR-1Document126 paginiAC Loco Refresher-SCR-1SATYANARAYANA BODDULAÎncă nu există evaluări

- Deothang SubstationDocument5 paginiDeothang SubstationNima TsheringÎncă nu există evaluări

- Failure 01042016 PDFDocument5 paginiFailure 01042016 PDFpawan kumar raiÎncă nu există evaluări

- Kotson ManualDocument11 paginiKotson Manualsarat sahooÎncă nu există evaluări

- Technical Report MykonosDocument18 paginiTechnical Report MykonosMuhammed MekkiÎncă nu există evaluări

- b5 Ign Serv AhaDocument41 paginib5 Ign Serv AhacoronacoralineÎncă nu există evaluări

- Instruction Manual of Capacitor Voltage TransformersDocument22 paginiInstruction Manual of Capacitor Voltage Transformerst.o.i.n.gÎncă nu există evaluări

- Beko 14.2 PDFDocument33 paginiBeko 14.2 PDFMos CraciunÎncă nu există evaluări

- Notification of Safety Precautions: GeneraDocument17 paginiNotification of Safety Precautions: GeneraBalakrishnan Krishnan0% (1)

- Induction Motor ProtectionDocument42 paginiInduction Motor Protectionjayonline_4u91% (11)

- Case Study of DCS Failure and Black OutDocument18 paginiCase Study of DCS Failure and Black Outmd abÎncă nu există evaluări

- CT2 Motor Controller Installation - ComNavDocument11 paginiCT2 Motor Controller Installation - ComNavDare DoreÎncă nu există evaluări

- (DOL) Motor Starter: Instructions For Direct-On-LineDocument3 pagini(DOL) Motor Starter: Instructions For Direct-On-LineVenkata Suresh MandavaÎncă nu există evaluări

- Punch List Gr.272 - SA-VRI Section As On 30.11.22 L&TDocument2 paginiPunch List Gr.272 - SA-VRI Section As On 30.11.22 L&TSajidÎncă nu există evaluări

- Aiwa 327Document32 paginiAiwa 327marialyÎncă nu există evaluări

- Ec - Engine Control System PDFDocument75 paginiEc - Engine Control System PDFMoaed Kanbar88% (8)

- KDL 32R305C PDFDocument57 paginiKDL 32R305C PDFKimberly SolanoÎncă nu există evaluări

- Emergency Operation in Santaldih Thermal Power StationDocument23 paginiEmergency Operation in Santaldih Thermal Power Stationranit_das100% (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDe la EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesÎncă nu există evaluări

- D1300009 Sheet 1Document1 paginăD1300009 Sheet 1sanjeevchhabraÎncă nu există evaluări

- Aux Steam SystemDocument14 paginiAux Steam Systemsanjeevchhabra100% (1)

- Damage To Bottom Ash Handling SysDocument6 paginiDamage To Bottom Ash Handling SyssanjeevchhabraÎncă nu există evaluări

- Coal FeederDocument8 paginiCoal FeedersanjeevchhabraÎncă nu există evaluări

- High Axial Shift in Turbine, 210 MW Unit, 02-03 PDFDocument1 paginăHigh Axial Shift in Turbine, 210 MW Unit, 02-03 PDFsanjeevchhabra100% (1)

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDocument4 paginiGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraÎncă nu există evaluări

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDocument4 paginiGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraÎncă nu există evaluări

- Develop Project Charter CaseDocument25 paginiDevelop Project Charter Casesanjeevchhabra100% (1)

- Sample Construction Methodology For Civil WorksDocument6 paginiSample Construction Methodology For Civil WorksRotsen Kho YuteÎncă nu există evaluări

- Frequent Tripping of VFD On BUSHOG - JUN10 PDFDocument2 paginiFrequent Tripping of VFD On BUSHOG - JUN10 PDFsanjeevchhabraÎncă nu există evaluări

- 02 ACSR ZEBRA ConductorDocument37 pagini02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- Substation SpecDocument143 paginiSubstation Specsanjeevchhabra100% (2)

- Guaranteed Technical Parameters:: Inhibited Insulating OilDocument2 paginiGuaranteed Technical Parameters:: Inhibited Insulating Oilsanjeevchhabra100% (1)

- ProceduresDocument104 paginiProceduressanjeevchhabraÎncă nu există evaluări

- Self Priming Centrifugal Pump: Models 03H1-GL, 03H1-GR, 03H3-GL and 03H3-GRDocument4 paginiSelf Priming Centrifugal Pump: Models 03H1-GL, 03H1-GR, 03H3-GL and 03H3-GRdougÎncă nu există evaluări

- Pinhole Camera InformationDocument4 paginiPinhole Camera InformationD'ferti AnggraeniÎncă nu există evaluări

- 2c - Types of Stone, Brick and Block MasonryDocument20 pagini2c - Types of Stone, Brick and Block MasonryZeeshan ShoukatÎncă nu există evaluări

- Computer Viruses: What Is A Virus?Document4 paginiComputer Viruses: What Is A Virus?Ako GwapoÎncă nu există evaluări

- 5th Lecture - PhotojournDocument35 pagini5th Lecture - PhotojournMis Dee50% (2)

- Leadership and Management 2003Document46 paginiLeadership and Management 2003Ciella Dela Cruz100% (1)

- Sony DCR Sr47Document101 paginiSony DCR Sr47Mitesh ChauhanÎncă nu există evaluări

- 752 BMW Individual High End Audio SystemDocument2 pagini752 BMW Individual High End Audio SystemsteÎncă nu există evaluări

- Platinum Collection v-22 Osprey ManualDocument24 paginiPlatinum Collection v-22 Osprey ManualP0wer3D100% (2)

- Background of UNITAR International UniversityDocument3 paginiBackground of UNITAR International UniversityAin NadiaÎncă nu există evaluări

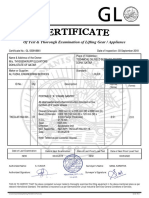

- Of Test & Thorough Examination of Lifting Gear / Appliance: - QatarDocument12 paginiOf Test & Thorough Examination of Lifting Gear / Appliance: - QatarChaimaÎncă nu există evaluări

- VM 6083 - 60B1 Data SheetDocument3 paginiVM 6083 - 60B1 Data SheetMinh HoàngÎncă nu există evaluări

- Sub Station ReportDocument43 paginiSub Station ReportSithartha SouryaÎncă nu există evaluări

- Workshop Manual Automatic Transmission 30 40leDocument2 paginiWorkshop Manual Automatic Transmission 30 40leDony TedyantoÎncă nu există evaluări

- Bridge Design Checklist Rev01Document7 paginiBridge Design Checklist Rev01ingjcmv67% (3)

- IEPE Connector - 2021Document2 paginiIEPE Connector - 2021Nguyen Ngoc TuanÎncă nu există evaluări

- Recorder Modifications - Alec Loretto 3Document4 paginiRecorder Modifications - Alec Loretto 3Clown e GregorianoÎncă nu există evaluări

- DIN EN 179 I 1125 PDFDocument3 paginiDIN EN 179 I 1125 PDFDushan RomicÎncă nu există evaluări

- Mechanical Engineering Manufacturing.149Document1 paginăMechanical Engineering Manufacturing.149Anonymous QvIxEazXGdÎncă nu există evaluări

- DM No. 312, S. 2021Document3 paginiDM No. 312, S. 2021sherileneÎncă nu există evaluări

- Global Trends 2030 Preview: Interactive Le MenuDocument5 paginiGlobal Trends 2030 Preview: Interactive Le MenuOffice of the Director of National Intelligence100% (1)

- Case Study ppt11Document25 paginiCase Study ppt11WHATS APP STATUSÎncă nu există evaluări

- Gunite Slack Adjuster: Service ManualDocument16 paginiGunite Slack Adjuster: Service ManualMarlon MontenegroÎncă nu există evaluări

- PAT Drilling Rig List (PAT)Document24 paginiPAT Drilling Rig List (PAT)Francisco Salvador MondlaneÎncă nu există evaluări

- Steam Generator ManualDocument25 paginiSteam Generator Manualcolleen berganciaÎncă nu există evaluări

- أثر جودة الخدمة المصرفية الإلكترونية في تقوية العلاقة بين المصرف والزبائن - رمزي طلال حسن الردايدة PDFDocument146 paginiأثر جودة الخدمة المصرفية الإلكترونية في تقوية العلاقة بين المصرف والزبائن - رمزي طلال حسن الردايدة PDFNezo Qawasmeh100% (1)

- M8JZ47Document5 paginiM8JZ47Leo GuillermoÎncă nu există evaluări

- Mohana Krishnan KsDocument2 paginiMohana Krishnan KsKanna MonishÎncă nu există evaluări

- VC02 Brass Ball Valve Full Port Full BoreDocument2 paginiVC02 Brass Ball Valve Full Port Full Boremahadeva1Încă nu există evaluări

- 3M Work Gloves BrochureDocument4 pagini3M Work Gloves BrochureherminÎncă nu există evaluări