Documente Academic

Documente Profesional

Documente Cultură

List of Spreadsheets

Încărcat de

uetian729Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

List of Spreadsheets

Încărcat de

uetian729Drepturi de autor:

Formate disponibile

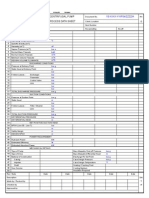

No.

Name

Description

Main input Data

Main Output Data No of fans, Air cooler Dimension, bare area, no of rows, Fan Diameter, fan power hysys model input data (vessel diameter and total volume, liquid volume, metal density)

AIRCOOLER

Air cooler preliminary sizing

cooling duty, process in/out temperature, inlet air temperature

BLOW DOWN FACILITATOR

preparing input data for hysys depressuring tool to match model specifications with actual system

vessel/pipe dimensions, liquid level, wall thickness for actual system

BUFFER VESSEL

buffer vessel sizing

consumption flow rate, initial and final pressure, holding time

buffer vessel dimensions

BURN PIT

horizontal flare sizing

flow rate, heat of combustion, Mach No.

Tip diameter, dimension of burn pit area

COMPRESSIBLE FLOW

calculation of established flow between high and low pressure gas volumes

upstream & downstream pressure, pipe length & diameter, fitting quantity, gas MW and specific heat ratio flow rate, suction temperature, suction & discharge pressure, Polytrophic efficiency condensate flow and density, reboiler orientation and dimension, tube bundle pressure drop, dimension of connecting line control valve suction and discharge hydraulic specification including pipe dimension, fittings, location (pump discharge, others)

flow regime (critical/subcritical), established gas flow rate

COMPRESSOR

compressor calculation

discharge temperature, motor power

CONDENSATE POT

sizing of steam condensate pot for vertical and horizontal reboilers control valve hydraulic calculation for liquid and gas service

condensate pot diameter and height, liquid levels

CONTROL VALVE HYDRAULIC

suction and discharge pressure at minimum, normal and maximum flow

CONTROL VALVE SIZING

control valve sizing for gas, liquid fluid flow rate and physical properties, control and steam as well as two phase valve pressure drop flow fluid flow rate and physical properties, control relief rate calculation due to valve pressure drop at relieving condition, control valve wide opening (liquid Rated Cv relief and gas break through) Cv selection for all ball, gate, needle, butterfly and regulator control valve

Control Valve CV

10

CONTROL VALVE WO

relief rate

11

CV SELECTOR

type of valve, CV at three opening%

valve size, valve CV at 100% opening (Rated CV), valve characteristics

12

DEPRESSURING

depressuring flow rate calculation system volume, initial pressure, depressuring and valve sizing requirements differential pressure, initial & final liquid level, vessel diameter, drain line length & diameter, fluid properties type of driver, fuel & electrical cost, material cost, labor cost, hydraulic parameter (flow, pressure, physical properties)

peak flow rate, valve CV

13

DRAINING TIME

calculation of required time for draining an specified volume pump discharge , compressor suction and discharge line sizing based on economic factors equivalent length calculation (more than 60 fittings are available)

drain flow rate by time, total draining time

14

ECOPIPE

pump suction line, compressor suction line, compressor discharge line

15

EQUIVALENT LENGTH

pipe size, pipe length, no of fittings

total K value, equivalent length

16

EVAPORATION POND

sizing of evaporation pond

inlet water flow, precipitation rate, evaporation rate, TSS and TDS

depth, length and width of pond

17

EXPANSION VESSEL

sizing of expansion vessel for heating media cycle

system volume, minimum and maximum density flow rate, differential pressure, suction temperature, motor RPM, Motor to fan pulley ratio

vessel diameter and length, level setting

18

FAN

Fan sizing and Rating

Motor power

www.chemwork.org

Page 1 of 5

No.

Name

Description

Main input Data

Main Output Data

19 FILTER SEPARATOR

vertical and horizontal filter separator sizing relief rate calculation in fire case for wetted/unwetted case, vertical/horizontal, different head caps Flare Knock Out Drum Calculation of flare purge requirement during different conditions with or without purge reduction seal flare stack sizing based on component toxicity limit

gas and liquid flow, gas and liquid density, cartridge size, hold up time

size of filter separator, no of cartridge

20

FIRE

vessel dimension, liquid level, TL elevation, liquid latent heat (W), vessel configuration

Exposed area to fire, relief rate

21

FLARE KOD

flow specification, hold up requirements, No of inlet nozzle, liquid droplet Purge gas composition and condition, Flare system size, H2S concentration, Flared gas heat of combustion toxic component flow rate and properties, wind velocity and ambient condition, maximum concentration at grade combustible component flow rate and properties, wind velocity and ambient condition gas flow and properties, wind velocity, maximum allowable Mach No. and heat intensity at grade

vessel size, nozzle size

22

FALRE PURGE

Flare purge requirement for flash back protection, temperature purge, (H2S) sweep purge, start up and assist gas flare stack height, maximum toxic concentration at grade

23

FLARE STACK 1

24

FLARE STACK 2

flare stack sizing based on flammability limit

flare stack height

25

FLARE STACK 3

flare stack sizing based on radiation limit

tip diameter and riser height, heat intensity radiation map

26

FLOW REGIME DETERMINATOR

two phase flow regime for vertical vapor and liquid flow rates and densities, line and horizontal line as per shell internal diameter DEP

mixed density and velocity, gas and liquid Froude number, flow regime appropriate flow meter, available size, limitation, accuracy, design consideration, Cost, advantage, disadvantage density, combustion properties, thermodynamic properties, heat and mass transfer properties total heat gain/loss, fluid outlet temperature, insulation thickness

27

FLOWMETER SELECTION

flow meter type selection

measuring fluid characteristics

28

GASPRO

gas properties calculation based on GPSA Data book

gas composition, temperature, pressure

29 HEAT INSULATION 1

insulation thickness calculation for pipe with flowing fluid inside

flow rate and inlet temperature, pipe dimension and thermal specification, insulation specifications, ambient temp.

30 HEAT INSULATION 2

initial temperature, pipe dimension and total heat gain/loss, fluid temperature insulation thickness calculation thermal specification, insulation specifications, profile, insulation thickness for pipe with stagnant fluid inside ambient temperature profile data interpolation for simple and complicated tables/figures

31

INTERPOL

table or figure data

table or figure data at requested point

32

LEVEL INSTRUMENT

level instrument type selection

fluid characteristics

appropriate level measurement technology

33

LINE DP 1

line pressure drop calculation for incompressible fluid

flow and physical properties, pipe dimension and no of fitting (more than 50 type of fittings available)

actual pressure drop of pipe for gas and liquid services

34

LINE DP 2

line pressure drop calculation for compressible fluid line sizing for gas (assume incompressible, compressible) and liquid services line sizing for vertical and horizontal two phase flow lines

flow and physical properties, pipe dimension

pressure drop of pipe

35

LINE SIZING

flow rate, density , viscosity

DP/100m or 100ft, velocity

36

LINE SIZING TWO PHASE

liquid and vapor flow and properties

Flow Regime, DP/100m or 100ft, velocity

www.chemwork.org

Page 2 of 5

No.

Name

Description

Main input Data

Main Output Data

37

MATERIAL

design pressure, blowdown (temp vs. pressure material selection for Depressuring process based on curve), vessel diameter, Material Yield Stress, corrosion allowance ASME UCS-66 calculation of nitrogen gas required for vacuum, pressurized and continuous purging orifice sizing for liquid and gas service system volume, initial & final pressure, initial oxygen concentration

MDMT, Material of construction

38

NITROGEN PURGING

no of cycles, total nitrogen consumption

39

ORIFICE

fluid flow and properties, pressure at inlet and outlet of RO, bore area

bore area (known flow & DP), Flow rate (known bore area & DP)

40

ORIFICE TWO PHASE

orifice sizing for two phase flow

liquid and vapor flow and properties, pressure at inlet and outlet of RO, bore area

bore area (known flow & DP), Flow rate (known bore area & DP)

41

PACKED TOWER

preliminary sizing of packed column

vapor and liquid flow and specifications, packing type, size and packing factor

column diameter and packed section height

42

PARTICLE FILTER

particle filter sizing for gas and liquid service

gas or liquid flow, size of cartridge, filter inlet nozzle size light and heavy liquid flow, density and viscosity, light and heavy droplet, plate pack specification relief rate, set and back pressure, fluid specification

filter diameter and length, no of cartridge

43

PLATE PACK

sizing of plate pack for 3 phase separator PSV sizing for liquid, vapor, steam and two phase flow (API old approach) PSV sizing for supercritical fluid in fire and none fire case

required length for separation (plate pack length) calculated orifice area, selected orifice area, orifice designation, no of PSVs, inlet and outlet size

44

PSV

45

PSV SUPERCRITICAL

vessel dimension, extensive physical properties data

PSV orifice area size

46

PSV TWO PHASE 1

calculated orifice area, selected orifice PSV orifice sizing for two phase vapor and liquid flow and specifications, PSV area, orifice designation, no of PSVs, set pressure and backpressure, relieving temp flow as per method inlet and outlet size calculated orifice area, selected orifice PSV orifice sizing for two phase vapor and liquid flow and specifications, PSV area, orifice designation, no of PSVs, flow as per API 520 - APP. D set pressure and backpressure, relieving temp inlet and outlet size PSV orifice sizing for two phase flow (analytical solution to HEM model) determination of pump design parameters psv flow rate, set pressure, relieving temperature

47

PSV TWO PHASE 2

48

PSV TWO PHASE 3

mass flux, psv size

49

PUMP CALCULATION

pump design and hydraulic parameter

pump minimum flow, pump efficiency, NPSHR, Acceleration loss

50

PUMP HYDRAULIC

pump hydraulic calculation

pumping flow, fluid properties, suction and discharge hydraulic data,

pump differential pressure, NPSHA, shut off pressure, brake horse power

51

REACTOR DP

calculation of reactor pressure drop during depressuring salt balance for single stage, two stage and single stage plus upstream separator configurations sizing the cooler required for sampling

depressuring rate, bed length and diameter, catalyst specifications oil and wash water salt content, oil flow rate, mixing efficiency, outlet oil spec (TBP, water%) Process fluid flow and specifications, cooling fluid specifications, coil material and thermal spec.

reactor pressure drop

52

SALT BALANCE

Fresh wash water consumption, internal circulation and overall circulation rate

53

SAMPLE COOLER

coolant flow rate, coil dimensions

54

SCHOEPENTOETER

sizing of Schoepentoeter for vertical and horizontal vessels

vessel diameter, inlet nozzle size

Schoepentoeter dimensions

www.chemwork.org

Page 3 of 5

No.

Name

Description settle out calculation of compressor loop and any other cases Sound power level calculation in flare network piping (applicable to pipe larger than 12")

Main input Data reactor, vessel, air cooler, pipe, compressor and heater dimension, fluid pressure, temperature and physical properties

Main Output Data

55

SETTLE OUT

settle out pressure

56

SOUND POWER

gas flow rate, pipe pressure drop, fluid temp

sound power level (dB), design consideration

57

SRK

SRK equation of state solution gas composition, temperature, vessel volume for a mixture with more than 450 and mass of gas component Condensate pressure upstream and downstream of valve, condensate flow

SRK coefficients, gas pressure

58

STEAM CONDENSATE LINE

steam condensate line sizing

flashed condensate weight fraction, steam-condensate mix density, and mixture pressure drop & velocity strainer pressure drop at 100% clean and 50% clogged conditions

59

STRAINER DP

pressure drop calculation for basket strainer

pipe size, flow rate, and physical properties, mesh diameter and length, mesh size

60

SURGE

surge analysis for liquid pipelines

liquid flow and density, pipeline length and wall thickness, liquid bulk modulus

pipeline period, surge pressure

61

TANK

determining tank size for different types of tank Preliminary heat loss calculation and steam coil sizing for storage tanks detailed heat loss calculation for tanks normal and emergency venting requirements for storage tanks as per API-2000 normal venting requirements for storage tanks as per ISO 28300 final pressure of trapped liquid and relief rate due to liquid thermal expansion are per API521 vertical and horizontal three phase separator sizing with different internal configuration including submerged weir, heat exchanger tube rupture relief rate for single and two phase flow vertical and horizontal two phase separator with or without wire mesh based on GPSA Horizontal two phase separator sizing based on DEP

working volume, tank type, roof type, nozzle size, pump out rate tank dimension, required & initial fluid temp, min ambient temp. tank dimension, plate and insulation thickness of shell/bottom/roof, plate and insulation thermal conductivity, liquid/air/soil temperature

tank diameter & height, nominal capacity, liquid levels tank heat loss, steam consumption, coil area, no of circle of coil

62

TANK COIL

63

TANK HEAT LOSS

heat loss from shell/roof/bottom

64

TANK VENTING 1

tank dimension, filling and emptying rate, inbreathing and out breathing flow, fire liquid normal boiling point, liquid height, liquid relief rate latent heat tank dimension, filling and emptying rate, storage temp., vapor pressure, latitude, insulation specification Initial pressure and temperature, final temperature, liquid cubical expansion coefficient and isothermal compressibility, line diameter and elasticity, heat transfer rate, inlet fluid flow and properties, hold up time, type of separation (gravity or mesh pad), internal configuration HP side operating pressure, LP side design pressure, tube diameter and length, fluid physical properties inlet fluid flow and properties, hold up time, type of separation (gravity or mesh pad)

65

TANK VENTING 2

inbreathing and out breathing flow

66

THERMAL EXPANSION

final pressure, relief rate

67

THREE PHASE SEPARATOR

vessel diameter and length, interface alarm and switch as well as other alarm and switch level in vessel

68

TUBE RUPTURE

tube rupture relief rate

69

TWO PHASE SEPARATOR 1

vessel diameter and length, alarm and switch level in vessel

70

TWO PHASE SEPARATOR 2

vapor and liquid flow & physical properties, internal type, liquid level setting

vessel dimension, liquid hold up between levels

71

VANE PACK SEPARATOR

inline and two stage vertical vane separator sizing determination of whether the vessel is categorized as wetted or unwetted

vapor and liquid flow & physical properties

Vane box dimensions, vessel dimensions

72

WETTED / UNWETTED

vessel dimension, liquid hold up inside the vessel, operating temp and pressure, PSV set pressure

vessel category

www.chemwork.org

Page 4 of 5

No.

Name

Description calculation of established flow between high and low pressure liquid volumes calculation of steam trap for steam main and steam traced process line/equipment Free and forced convection heat transfer coefficient inside and outside of pipe/equipment

Main input Data

Main Output Data

73

INCOMPRESSIBLE FLOW

upstream & downstream pressure, pipe length & diameter, fitting quantity main steam/process diameter, temperature, ambient temp, insulation efficiency, tracer length, tracing steam pressure (latent heat), steam load safety factor system dimension and orientation, Fluid temperature and physical properties (density, viscosity, conductivity, heat capacity), fluid velocity

established liquid flow rate

74

STEAM TRAP

overall heat transfer coefficient, total heat loss, steam trap flow rate

75

HEAT TRANSFER COEFFICIENT

Heat transfer coefficient for gas and liquid

www.chemwork.org

Page 5 of 5

S-ar putea să vă placă și

- A Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesDocument1 paginăA Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesyogacruiseÎncă nu există evaluări

- Pump CalculationDocument3 paginiPump CalculationSaeid Rahimi Mofrad100% (1)

- Demister DatasheetDocument1 paginăDemister Datasheetdeion29Încă nu există evaluări

- Equivalent Length CalculationDocument1 paginăEquivalent Length CalculationSaeid Rahimi MofradÎncă nu există evaluări

- Inlet Separator Design APIDocument8 paginiInlet Separator Design APIIlham Dwiyanto Emzar100% (1)

- C06 006 Process Calculation (02V 6010) RevEDocument6 paginiC06 006 Process Calculation (02V 6010) RevEAlphaEcc EngineeringTeamÎncă nu există evaluări

- J3X & JF3X PDFDocument2 paginiJ3X & JF3X PDFMukiara LuffyÎncă nu există evaluări

- Knock Out Drum: Wiring DiagramsDocument8 paginiKnock Out Drum: Wiring DiagramsAlinaIordacheÎncă nu există evaluări

- FL1627Document2 paginiFL1627Isaac Montero BarreraÎncă nu există evaluări

- CS SS - Pipe Weight CalculationDocument1 paginăCS SS - Pipe Weight CalculationTashrif Yusuf0% (1)

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 paginiDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoÎncă nu există evaluări

- Cadworx Customising Backing SheetDocument27 paginiCadworx Customising Backing Sheetalan172081100% (1)

- Knock Out DrumDocument2 paginiKnock Out Drummujeebtalib100% (1)

- Vertical Separator SizingDocument8 paginiVertical Separator SizingAnonymous yLPPdPwÎncă nu există evaluări

- Section 10 - Air Cooled Heat ExchangersDocument70 paginiSection 10 - Air Cooled Heat ExchangersCHANADASÎncă nu există evaluări

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pagini7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPÎncă nu există evaluări

- Pneumatic Conveying Spreadsheet-ContentDocument27 paginiPneumatic Conveying Spreadsheet-Contentaladdin4dÎncă nu există evaluări

- Process Heat Transfer Hof MasterDocument140 paginiProcess Heat Transfer Hof MastervijayÎncă nu există evaluări

- Prism Letter of ExclusivityDocument1 paginăPrism Letter of ExclusivityMohammad Mahdi MozaffarÎncă nu există evaluări

- Plumbing Data SheetDocument2 paginiPlumbing Data SheetzhobeysÎncă nu există evaluări

- CT Deep Boiler Emissions CalculatorDocument8 paginiCT Deep Boiler Emissions Calculatorsissam.adilÎncă nu există evaluări

- WG's Process Engineers' Codes & StandardsDocument7 paginiWG's Process Engineers' Codes & StandardsAinur RohmanÎncă nu există evaluări

- Branch Reinforcement - ASME 31.1Document8 paginiBranch Reinforcement - ASME 31.1zakir84md3639Încă nu există evaluări

- Htri Datasheet & Application Note - Datasheet ArchiveDocument4 paginiHtri Datasheet & Application Note - Datasheet ArchiveShantanuÎncă nu există evaluări

- Data Sheet-Ball ValveDocument2 paginiData Sheet-Ball ValveJatin Vadhera VCSP100% (1)

- Heat Ex Changers EstimationDocument46 paginiHeat Ex Changers Estimationshankarbt83Încă nu există evaluări

- PSV Sizing (Steam)Document2 paginiPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Seprasol Plus: Liquid/Gas CoalescersDocument4 paginiSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiÎncă nu există evaluări

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 paginăCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaÎncă nu există evaluări

- Process DesignDocument7 paginiProcess DesignEK63Încă nu există evaluări

- Fluid Flow Basics OF Throttling ValvesDocument43 paginiFluid Flow Basics OF Throttling ValvesSandro AraújoÎncă nu există evaluări

- Shell and Tube Heat Exchanger Design: Fluid AllocationDocument6 paginiShell and Tube Heat Exchanger Design: Fluid AllocationLungeloÎncă nu există evaluări

- Steam HXDocument1 paginăSteam HXrajachemÎncă nu există evaluări

- TENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Document25 paginiTENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Anonymous bHh1L1Încă nu există evaluări

- Gas Vessel PecoDocument16 paginiGas Vessel PecopsycopaulÎncă nu există evaluări

- Pressure Gauge DatasheetDocument2 paginiPressure Gauge DatasheetazlanÎncă nu există evaluări

- Equipment DatasheetDocument3 paginiEquipment DatasheetmdgouseahmedÎncă nu există evaluări

- LWN FlangesDocument8 paginiLWN Flangesfranckx1960Încă nu există evaluări

- Part 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsDocument1 paginăPart 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsRafael ReyesÎncă nu există evaluări

- Criteria To Determine Adequacy of Existing Pump - Industrial Professionals - CheresourcesDocument3 paginiCriteria To Determine Adequacy of Existing Pump - Industrial Professionals - CheresourcesDhamotharan ChinnaduraiÎncă nu există evaluări

- 2.0 Annexure-III Detailed Technical Specifications of RO Water MakerDocument10 pagini2.0 Annexure-III Detailed Technical Specifications of RO Water MakerjrladduÎncă nu există evaluări

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 paginăSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarÎncă nu există evaluări

- Pipeline Pressure Drop Per 100 M - BAK - 14062011Document3 paginiPipeline Pressure Drop Per 100 M - BAK - 14062011Bharat A. KaduÎncă nu există evaluări

- Globe Valve1 DatasheetDocument1 paginăGlobe Valve1 DatasheetobumuyaemesiÎncă nu există evaluări

- CDA Data CollectionDocument2 paginiCDA Data Collectiondford8583Încă nu există evaluări

- PT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsDocument7 paginiPT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsAnshuman ChoudhuryÎncă nu există evaluări

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Document8 paginiAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraÎncă nu există evaluări

- M17Document28 paginiM17Adrian GuzmanÎncă nu există evaluări

- Oil Cooler - Pre Design Data SheetDocument3 paginiOil Cooler - Pre Design Data SheetSakthi VelÎncă nu există evaluări

- Summer Internship Project Report MAY - JUNE 2018: "Energy Balance of Distillation Column"Document14 paginiSummer Internship Project Report MAY - JUNE 2018: "Energy Balance of Distillation Column"krishan palÎncă nu există evaluări

- Orifice Plate BrochureDocument39 paginiOrifice Plate Brochureronzies100% (1)

- VEFV3100Document19 paginiVEFV3100adolfocienfuegosÎncă nu există evaluări

- Weight of Piping MaterialDocument9 paginiWeight of Piping Materialviny22Încă nu există evaluări

- Training On Equipment Sizng of Process EquipmentDocument15 paginiTraining On Equipment Sizng of Process EquipmentAgam Duma Kalista WibowoÎncă nu există evaluări

- HvacDocument4 paginiHvacشريف بكرىÎncă nu există evaluări

- Pump Sizing CalculationDocument12 paginiPump Sizing CalculationLee Min Hyuk100% (3)

- Pipe Flow CalculatorsDocument7 paginiPipe Flow CalculatorsdasubhaiÎncă nu există evaluări

- J O Turbosonic ResumenDocument10 paginiJ O Turbosonic Resumenjosedalceggio1955Încă nu există evaluări

- Process Equipment Design-05Document42 paginiProcess Equipment Design-05PARAG DAHARWAL 20CH10020Încă nu există evaluări

- Shell & Tube Heat ExchangersDocument16 paginiShell & Tube Heat ExchangersShawala AzharÎncă nu există evaluări

- Process HydraulicsDocument22 paginiProcess Hydraulicsuetian729Încă nu există evaluări

- Chegg SolutionsDocument9 paginiChegg SolutionsRambabu R100% (1)

- Guidelines For Preparing ProposalDocument1 paginăGuidelines For Preparing Proposalsaeid59Încă nu există evaluări

- 7 Types of Regression Techniques You Should Know PDFDocument31 pagini7 Types of Regression Techniques You Should Know PDFuetian729Încă nu există evaluări

- Inherent Safety Through Intensive Structured Processing: The Impulse ProjectDocument5 paginiInherent Safety Through Intensive Structured Processing: The Impulse Projectuetian729Încă nu există evaluări

- Pipe Flow Calculations PDFDocument12 paginiPipe Flow Calculations PDFharrypop418Încă nu există evaluări

- Water Is EnergyDocument4 paginiWater Is Energyuetian729Încă nu există evaluări

- Safer Design Concepts Applied To LaboratoriesDocument4 paginiSafer Design Concepts Applied To Laboratoriesuetian729Încă nu există evaluări

- Requirements For ApplicantsDocument1 paginăRequirements For Applicantsuetian729Încă nu există evaluări

- Student Express: Zone 1 2 3 4 5 6 7 8 9 10Document1 paginăStudent Express: Zone 1 2 3 4 5 6 7 8 9 10ahumairÎncă nu există evaluări

- Safer Design Concepts Applied To LaboratoriesDocument4 paginiSafer Design Concepts Applied To Laboratoriesuetian729Încă nu există evaluări

- Information For New International StudentsDocument8 paginiInformation For New International Studentsuetian729Încă nu există evaluări

- UntitledDocument18 paginiUntitledapi-272166056Încă nu există evaluări

- 2013 PG ApplicationListDocument1 pagină2013 PG ApplicationListuetian729Încă nu există evaluări

- Energy Volume 11 Issue 11-12 1986 (Doi 10.1016 - 0360-5442 (86) 90047-2) Ahmad Mumtaz Arshad M. Khan - Prospects For Coal Gasification in PakistanDocument9 paginiEnergy Volume 11 Issue 11-12 1986 (Doi 10.1016 - 0360-5442 (86) 90047-2) Ahmad Mumtaz Arshad M. Khan - Prospects For Coal Gasification in Pakistanuetian729Încă nu există evaluări

- Ammonia 2013 Program WebDocument2 paginiAmmonia 2013 Program Webuetian729Încă nu există evaluări

- Prentac CCPSD Brochure Rev 0Document2 paginiPrentac CCPSD Brochure Rev 0uetian729Încă nu există evaluări

- Jump Start Aspen Custom Modeler V8 PDFDocument26 paginiJump Start Aspen Custom Modeler V8 PDFAlessandro TrigilioÎncă nu există evaluări

- StatementofPurposeApril2011-2 000Document20 paginiStatementofPurposeApril2011-2 000chvenkatwÎncă nu există evaluări

- Prentac Pgdpe Brochure Rev 0Document2 paginiPrentac Pgdpe Brochure Rev 0uetian729Încă nu există evaluări

- Ustani Aur Taxi Driver by Inayat Ullah Urdu BookDocument135 paginiUstani Aur Taxi Driver by Inayat Ullah Urdu Bookuetian72940% (5)

- Sciencedirect Home PageDocument8 paginiSciencedirect Home Pageuetian729Încă nu există evaluări

- CFSE Exam Sample QuestionsDocument6 paginiCFSE Exam Sample Questionsrlimaye91% (11)

- Sciencedirect Home PageDocument8 paginiSciencedirect Home Pageuetian729Încă nu există evaluări

- Experimental Investigation of Attrition Resistance of Zeolite Catalysts in Two Particle GSS FluidizaDocument7 paginiExperimental Investigation of Attrition Resistance of Zeolite Catalysts in Two Particle GSS Fluidizauetian729Încă nu există evaluări

- Chinese Journal of CatalysisDocument8 paginiChinese Journal of Catalysisuetian729Încă nu există evaluări

- PAS Proceedings 49 No. 3 September 2012Document75 paginiPAS Proceedings 49 No. 3 September 2012uetian729Încă nu există evaluări

- Fire Heat Flux To Unwetted Vessels For Depressuring CalculationsDocument4 paginiFire Heat Flux To Unwetted Vessels For Depressuring Calculationsuetian729Încă nu există evaluări

- An Adsorption Kinetic Model For Sulfur Dioxide Adsorption by Activated CarbonDocument8 paginiAn Adsorption Kinetic Model For Sulfur Dioxide Adsorption by Activated Carbonuetian729Încă nu există evaluări

- KATP Modelling - HYSYS For AmmoniaDocument1 paginăKATP Modelling - HYSYS For Ammoniauetian729Încă nu există evaluări

- Conceptual Design and Development of Shredding Machine For Agricultural WasteDocument7 paginiConceptual Design and Development of Shredding Machine For Agricultural WasteVJ CarbonellÎncă nu există evaluări

- Bad Effects of Festivals On The EnvironmentDocument10 paginiBad Effects of Festivals On The EnvironmentSahil Bohra85% (52)

- Steen Kamp 2021Document16 paginiSteen Kamp 2021LARANSA SOLUNA GOGO SIMATUPANGÎncă nu există evaluări

- Msds M-Toluoyl ChlorideDocument4 paginiMsds M-Toluoyl ChloridecrisÎncă nu există evaluări

- Lord You Know All Things, You Can Do All Things and You Love Me Very MuchDocument4 paginiLord You Know All Things, You Can Do All Things and You Love Me Very Muchal bentulanÎncă nu există evaluări

- Intelligent: - 60 AMP - 80 AMPDocument8 paginiIntelligent: - 60 AMP - 80 AMPHayson NuñezÎncă nu există evaluări

- 4Dx - Series B Capital Raising IMDocument42 pagini4Dx - Series B Capital Raising IMsamÎncă nu există evaluări

- Bagmati River Rejuvenation.1.0Document27 paginiBagmati River Rejuvenation.1.0navonil.senÎncă nu există evaluări

- High Voltage - WikipediaDocument7 paginiHigh Voltage - WikipediaMasudRanaÎncă nu există evaluări

- Registration of Hindu Marriage: A Project On Family Law-IDocument22 paginiRegistration of Hindu Marriage: A Project On Family Law-Iamit dipankarÎncă nu există evaluări

- ComFlor 80 Load Span Tables PDFDocument4 paginiComFlor 80 Load Span Tables PDFAkhil VNÎncă nu există evaluări

- Serbia Malta & Bermuda Medical Instructions PDFDocument3 paginiSerbia Malta & Bermuda Medical Instructions PDFGISI KeyBOarD0% (1)

- Urie BronfenbrennerDocument27 paginiUrie Bronfenbrennerapi-300862520100% (1)

- Heating Ventilation Air Conditioning Hvac ManualDocument4 paginiHeating Ventilation Air Conditioning Hvac ManualShabaz KhanÎncă nu există evaluări

- Plumber PDFDocument68 paginiPlumber PDFshehanÎncă nu există evaluări

- Startup Time Reduction For Combined Cycle Power PlantsDocument8 paginiStartup Time Reduction For Combined Cycle Power PlantsEnrique TamayoÎncă nu există evaluări

- 2457-Article Text-14907-2-10-20120724Document6 pagini2457-Article Text-14907-2-10-20120724desi meleniaÎncă nu există evaluări

- Phillips LoFloDocument29 paginiPhillips LoFlokawaiiriceÎncă nu există evaluări

- Physical Fitness TestDocument1 paginăPhysical Fitness TestGiessen Fran RamosÎncă nu există evaluări

- 13 ECCMinorAmendReqDocument2 pagini13 ECCMinorAmendReqal bentulanÎncă nu există evaluări

- Group 4 - Cadbury - Final ProjectDocument11 paginiGroup 4 - Cadbury - Final ProjectPravalika ReddyÎncă nu există evaluări

- 2.2 WaterDocument32 pagini2.2 WaterHelena GlanvilleÎncă nu există evaluări

- User's Manual Eco Friendly Park BenchDocument35 paginiUser's Manual Eco Friendly Park BenchAmirulHanif AlyahyaÎncă nu există evaluări

- Corporate Security Policy TemplateDocument4 paginiCorporate Security Policy TemplateCoronaÎncă nu există evaluări

- NG Uk RTR 0220 r15 PDFDocument9 paginiNG Uk RTR 0220 r15 PDFDuong Thai BinhÎncă nu există evaluări

- Dowry SystemDocument10 paginiDowry SystemBhoomejaa SKÎncă nu există evaluări

- Goat AnatomyDocument8 paginiGoat AnatomyLochi GmÎncă nu există evaluări

- Corp Given To HemaDocument132 paginiCorp Given To HemaPaceÎncă nu există evaluări

- A - S-2W & B - S-2W Series: 2W, Fixed Input, Isolated & Unregulated Dual/Single Output DC-DC ConverterDocument5 paginiA - S-2W & B - S-2W Series: 2W, Fixed Input, Isolated & Unregulated Dual/Single Output DC-DC ConverteranonbeatÎncă nu există evaluări

- Helicobacter Pylori InfectionDocument18 paginiHelicobacter Pylori InfectionPMÎncă nu există evaluări