Documente Academic

Documente Profesional

Documente Cultură

Guide Nox Anglais PDF

Încărcat de

yinglvTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Guide Nox Anglais PDF

Încărcat de

yinglvDrepturi de autor:

Formate disponibile

The French Cement Industry Guide to NOx Emissions Reduction Measures

1. NOx Emissions 2. Regulation 3. Objectives 4. Reference Data 5. Primary Measures 6. Secondary Measures 7. Costs Balance 8. Conclusions Appendix 1: evolution of the regulation Synthetic Projects Sheets

p. 2 p. 2 p. 3 p. 4 p. 6 p. 10 p. 11 p. 14 p. 16 p. 18

A Convention between ADEME

(French Agency for Environment and Energy Management)

& the CEMENT INDUSTRY under the aegis of MEDD

(Ecology and Sustainable Development Ministry)

16 decembre 2002

-2-

AC.245R 16 decembre 2002

The French Cement Industry Guide to NOx Emissions Reduction Measures

Five companies form the French cement industry, running 33 cement plants with a total production of 20 millions tonnes of cement in 2001 and 5230 employees. Cement consumption in France has been decreasing since the middle of the 70s: there were 25 millions tonnes produced in 1990.

1. NOx Emissions In 1990, the French cement industry NOx emissions (NO et NO 2) were of 40 770 tonnes, and of 29 760 tonnes in 2000. NOx formation in cement plants is 95 % nitrogen monoxide ; NO2 formation occurs at low temperatures in contact with the air in the atmosphere. Total French NOx emissions in 2000 were of 1 905 000 tonnes. Cement plants account for 1,56 % of national emissions, while total industrial NOx emissions account for about 11 %. The cement industry is a significant industrial contributor with a manufacturing process which requires a flame around 2000 C in order to bring about the necessary chemical combinations. Current French cement industry NOx emissions average out at about 1,8 kg/t of manufactured clinker.

2. Regulation Nitrogen oxides are the subject of sustained attention at the European level (see appendix 1). The European Directive of 4 December 2000 transposed in the 20 September 2002 decree on Waste incineration and co-incineration, has set limit values of 800 mg/Nm3 for existing cement plants and of 500 mg/Nm3 for future cement plants. Emission values for wet-process kilns, or those burning waste below 3 t/h can go as far as 1200 mg/Nm3 until 1st January 2008. From 1999 to 2010, France will also have to reduce its NOx emissions by about 47 %, within the framework of the National Emission Ceilings Directive and of the Geneva Convention.

-3-

The European directive on Integrated pollution prevention and control (IPPC) has also presented the Best Available Technology (BAT) concept, developed in view of cement plants application.

3. Objectives The relative inexperience of France in this domain has led the cement industry to set up a tests program in 1999, through the impetus of both National Planning & Environment Ministry and ADEME, in order to dispel the last remaining uncertainties ( i n d u s t r i a l f e a s i b i l i t y , p e r f o r ma n c e s , c o s t s , ) o v e r an u mb e r o f p r a c t i c a l d i f f i c u l t i e si n the application of the BAT Working Group conclusions, or concerning certain performance levels, possible cross-effects or the application of certain technologies on the cement process. This program comprises fifteen different projects, with 1,77 M Euros financed by ADEME on a 6,34 M Euros planning budget, through a convention signed jointly with ATILH and the cement companies. The present document presents the industrial feedback on those technological o p t i o n sr e f e r e n c e di nt h ec e me n ti n d u s t r y sB R E F (Best available technology REFerence document) and is to be circulated as widely as possible amongst all those concerned: the cement industry, inspection authorities & personnel in c h a r g eo f c l a s s i f i e df a c i l i t i e s , e t c . .

The test projects can be divided into two main groups: primary measures, which aim to reduce NOx formation in the cement kilns or during the process (staged combustion), secondary measures, which aim to destroy the ensuing pollutants at the facilities output, by chemical means (SCR, selective catalytic reduction or SNCR, selective non-catalytic reduction).

An SO2 emission reduction test was also performed in a cement plant. Outside this convention, contacts with other countries, Germany and Switzerland in particular, have shown that treatments belonging to the primary option were the more widespread, whereas secondary option equipment are usually set in place only to allow supplementary emission reductions as and when required by kiln operations. Germany has 25 % of its kilns set up with secondary treatment equipment, this when regulatory compliance requires NOx content to remain below 800 mg/Nm3. Of course, these elements tend to favour primary option measures, even if, at first g l a n c e ,t h e s e me a s u r e sd o n ts e e mt ob ea b l et od e l i v e rl e v e l sa sl o wa st h o s e reached by the secondary option measures. This options guide provides the technological elements necessary to help operators reduce their NOx emissions (expressed as NO2 equivalents) below 800 mg/Nm3 before the end of December 20051 for existing facilities, and also gives out prospects for attaining even lower values in compliance with the IPPC and National Emission Ceilings Directives looming on the 2007 2010 horizon, which also concern SO2.

Value expressed as a daily average value, at 10% O2, dry gas, 273K, 101,3 kPa

-4-

4. Reference Data The NOx measurements were realised on-line on all installations. The measures were integrated and their means calculated so as to obtain a daily average2.

4.1. Histogram of Daily Averages of on-line measures in 1999, 2000 and 2001: NOx Emissions - (1999, 2000, 2001 and 2002) for all companies Histogram of the Daily Averages of On-line Measurements

Number of values for 1999 = 7953, for 2000 = 8116, for 2001 = 8990, for 2002 = 9855

2504

3000

2284

2659 2189

2500

1620 Number of d.a. 1518 1572

2175

1682

1665

1589

2000

1016

1650

1999

1464

2000 2001

958

1500

879 616

1310

2002

875 756 812 692 522 481 151 127

1000 500 0

259

165

231

347

0-200

200-400

400-600

600-800

800-1000

1000-1200 1200-1500

(Dry gas at 11 % O2)

>1500

mg/Nm3

This histogram centers around 666 mg/Nm3 in 2001 with 1,9 % of the results greater than 1 500 mg/Nm3 in 1999, 1,6 % in 2000 and 0,7 % in 2001, and with marked progress on the higher values.

4.2. Precision Assessment Uncertainty of instant NOx measurement3 is estimated at a maximum of 18 % by INERIS (French national institute of industrial environment and risks, under supervision of ad hoc Ministry). European directive concerning Hazardous waste incineration and co-incineration admits subtracting from each measured value the confidence interval of 95 %. This confidence interval must not, however, go beyond 20 % of those limit emission values set down for nitrogen oxides in the directive. Applying the statistical technique of variograms on the daily averages of each kiln in 2000, the cement industry has computed the experimental uncertainty for the year, taking analytic and sampling uncertainties into account: on average, uncertainty comes out at 23 %, with variation from 13 % to 37 % depending on the kilns and their operating conditions. It must be pointed out that variograms computations are particularly sensitive to data instability, which could account in part for the differences in precision.

This level of precision implies that the test results for which incidence of NOx emissions can be considered as belonging to the same order of magnitude than that of the 95 % confidence interval on the measure itself should be assessed with some caution.

2 3

the NOx reporting methodology is described in the ATILH document of 24/05/02 or confidence interval at 95 %

62

84

-5-

That is particularly the case for some primary measurements, so that we must remain quite careful in assessing the resulting data, not on a qualitative level, but on their potential for emission reduction.

4.3. Results Analysis Nonetheless several elements are interesting: in 1999, which can be used as a reference year before the reduction and monitoring tests, we note that most of the 616 measures in the 0-200 class corresponded to data-collecting system or kiln operating system breakdowns. Both have all but disappeared in 2000. In 2001, there are fewer measures in the over-800 mg/Nm3 classes than in 2000, which were already fewer than in 1999. Again, almost all measures in the under-800 mg/Nm3 classes are more numerous in 2001 than in 2000 or 1999. This indicates that, following emission monitoring set-up, the greater awareness of personnel and probable instructions modifications have resulted in a small but definite progress. Results average has thus come down from 743 mg/Nm3 in 1999 to 738 mg/Nm3 in 2000 and again 666 mg/Nm3 in 2001.

4.3.1.Effect of Process Type Another important thing to keep in mind is that these histograms are made out of elementary measures collected from all the cement kilns by ATILH. They follow an almost normal law which shows no differenciation between manufacturing processes or NOx formation #location, so that no process can be singled out as provoking more NOx concentration than another. This can be deduced from the fact that we know that we have here one wet-process cement plant, which process has demonstrably been proven as generating markedly more NOx than the others in the United States. NOx reduction potential does vary with the type of process however, and processes which allow staged combustion give the best results with primary measures.

4.3.2. Effect of Raw Materials On the other hand, there are important factors in NOx differences with equivalent processes (which cannot be detailed here for competitive reasons) such as the combination of raw material burnability and clinker saturation level 4. These are directly related to the quarry which feeds the plant and to the type of cement manufactured ; this is quite obvious in the case of white cement with no iron and thus little flux with which to reduce the clinkering process temperature. Those factors cannot be directly controlled even though they explain a big part of the differences observed in reference measures and test results. The Swiss sector-specific agreement on NOx reduction, for instance, takes the raw material and production process variabilities of each site into account. It will probably be rewarding to take another look at those mineralizers which heighten raw material burnability and which are also mentioned in the BAT document when assessing NOx reduction technological and economical costs while complying with the ma r k e t s q u a l i t y l e v e l s .

coefficient which defines the ratio of calcium oxide mass present in the feed to that which can effectively chemically combine with the other three oxides during burning process

-6-

4.3.3. Effect of Cement Types The French cement market is very distinctive in Europe, as its shares in highly reactive cements (52.5, 52.5R) are very high. This requires producing clinker with a higher level of saturation, which is harder to burn. So even though this factor is important in the process, it seems rather difficult to alter.

4.3.4. Effect of Fuels The influence of fuel characteristics on NOx emissions was not directly studied in this program.

5. Primary Control Measures Primary measures are control measures which focus on emission reduction by acting on the combustion process: optimising firing conditions compatible with raw material characteristics and clinker quality demands, curbing excess oxygen, reducing flame temperature, creating a reducing zone. 5.1. Kiln Operation Control The least expensive system is to include NOx measurements in the kiln operations control instrumentation (sheet n 3: Altkirch, sheet n 5: Le Teil, sheet n 15: Grave de Peille). Sensor positioning is important. It may seem preferable to measure NOx in the exhaust gas box as reaction time is thus shortened, but NOx can still be generated or reduced by fuels coming in up-stream - when considering the direction of meal flow - from the sensors. These two locations can be complementary depending on the type of process. Setting up the sensor at the exhaust gas allows any NOx increase due to slight overburning to be efficiently eliminated. A better control of the NOx rate can lead to a slight reduction in excess oxygen and thus to another reduction in NOx emission rates. The test reported for sheet n 5 show a NOx reduction from 1200 mg/Nm3 to 850 mg/Nm3 merely through instrumentation control. Operating parameters allowing this were maintained for only a day as a clogging ring was starting to form in the kiln. This plant was using a stable synthetic raw meal and liquid fuels only, favourable factors for kiln operational stability. Preliminary tests realised for sheet n 15 (La Grave de Peille) decreased NOx rates from an average of 1150 mg/Nm3 with 1400-1600 mg/Nm3 peaks to an average 900 mg/Nm3 with 1200-1300 mg/Nm3 peaks. This result was obtained through kiln operating control maintaining the oxygen level at 3-4 % in kiln feed end instead of the previous 6 %. Tests for sheet n 15 show very favourable results when extending oxygen control to the expert system, with peaks over 900 mg/Nm3 disappearing. This control results in an average decrease of 100 mg/Nm3.

-7-

O nt h eo t h e r h a n d , t e s t sd o n ef o r s h e e t n 3h a v e n t b e e na b l et os h o w me a s u r a b l e differences in NOx emission levels depending on whether expert system is on or off. We think this is due to the length of time since this expert system was set up, which has lead, over the years, to an harmonisation of human and expert system control strategies. NOx is not the only parameter to take into account in process control. Chemical analysis on a plant where the quarry feed is not very regular allows to anticipate firing requirements. Continuous chemical analysis of the quarry should limit over-firing periods, according to a supplier. Tests done in another plants yielded no significant results. The debate of expert system vs. human operators remains open, as the performance of the former is strongly dependent on the levels of parameter complexity, and on their possible anticipation through human-operated controls or their possible rapid correction through expert systems. Half the cement kilns in France run without. A common conclusion is held by all though: taking NOx parameter into account under ordinary kiln operating conditions allows significant emission reduction and an almost total suppression of overburning emission peaks. 5.2. Low-NOx Burners These burners (sheet n 2: La Grave de Peille) give various results depending on their set-up. If the initial burner runs on a low percentage of primary air, a low NOx burner will have a marginal effect. This was the case for the La Grave de Peille plant, where the test was not done as the suppliers could not guarantee a gain in comparison with the existing burner. Setting up this kind of burner in other kilns however, lead to real gains, up to 300 mg/Nm3 NOx when compared to a previous burner from an older generation with 15 % primary air. Primary air percentage is a key point in NOx control. In very specific cases, primary air can be altogether eliminated when the fuel is in gaseous form. But this type of fuel is usually not economically sound for a cement plant. In fact, fuels used in cement plants are those difficult to use in other thermal facilities, particularly solid fuels with difficult ignition. The French cement industry is willing to start research and development projects concerning pulverised product transportation and kiln injection. Today, techniques used for solid fuel or meat and bone meal (MBM) injection remain simple and require a high percentage of primary air, which leads to NOx increase. Concerted works on those subject should lead to cold air injection reduction, and to a better control of the flame d i s t a n c ed a c c r o c h a g ewhile avoiding scorching the burner nozzle, as happened in certain tests

5.3. Flue Gas Recirculation This technique (sheet n 1: Gargenville) realises partial or complete primary air substitution in the burner, lowering the oxygen level of the fuel in the hottest zones, and theoretically reducing NOx formation, aiming for reduction levels identical to the low NOx burner technique. Tests did lead to important reduction rates of 20 % to 30 % but without reaching the objectives, and starting from rather high initial levels. Furthermore, performances turned out to be rather uneven.

-8-

This is a difficult technique to implement, as flue gas must have very little oxygen, no dust particles and be at an acceptable temperature for the Roots blower. Flue gas recirculation also lengthens the kiln flame and increases CO generation. Flue gas are also incompatible with MBM injections, as they tend to gel, provoking unacceptable injection irregularities. This process was unsuccessfully tried in Germany, were it brought about serious operating breakdowns. But on the other hand, it is being applied with great success in Italy, on a long granules kiln with an operating history of great regularity. A thorough gas treatment to provide very low dust contents, and a constant temperature are prerequisites for using this technique, obviously efficient when it works ! Pyrolysis of waste fuels may turn out to be an interesting path to explore, despite a certain complexity in the initial process. NOx reduction potential and the cost per ton of thus avoided NOx still remain to be determined however.

5.4. Injecting Pure Water or Water with Additives ( s h e e t n 6 : G a r g e n v i l l e , s h e e t n 7 : G r a v ed eP e i l l e , s h e e t n 8 : V a l d A z e r g u e s ) 5.4.1 Pure Water Injection Pure water injection also decreases the NOx average by reducing the temperature in the high temperature zone of the flame ; this mostly eliminates the peaks by simple flow control. The injection can be done at different locations and in different forms: PILLARD ZV2 burners assist liquid fuel injection with water vaporisation, with good results. Water can be injected in the flame centre with great efficiency: such was the case in sheet n 6, where 500 to 2000 l/h were injected, resulting in an average reduction of 100 mg/Nm3 of NOx with initial emissions at 1000mg/Nm3, but more markedly, a decrease in the standard deviation of measurements from 286 to 126 mg/Nm 3, which quantifies the reduction of emission peaks. 5.4.2 Injection of Water with Additives In sheet n 8, injection in the centre of the burner reduced stack emissions from 1650 to 1200 mg/Nm3, initial NOx emissions being relatively high. It was also possible in this particular case to try lateral injection on the flame with a separate injector, with greatly similar results (1250 mg/Nm3). Injection tests were also done directly in the secondary air duct, for instance sprayed on the clinker chute, but results were less convincing (1400 mg/Nm3). Water with carbonate additives gives out interesting results: the tests done for sheet n 6 show similar results in NOx reduction for an injection of water with additives at 16 l/tonne of clinker and for pure water injection at 20 l/tonne of clinker. Beyond the direct effect of water, we can suppose that a staged combustion effect favourable to NOx reduction operates here. A slighter loss in production (1,6% for 10 l/tonne of clinker) can be observed, when compared with pure water injection.

-9-

This result is confirmed by tests in sheet n 7, which indicate that 500 l/h of pure water has had no influence, whereas 500 l/h of water + 200 l/h of hydrocarbons lead to a decrease of 200 to 300 mg/Nm3 in the 900 mg/Nm3 zone.

5.5. Staged Combustion Staged combustion is a promising NOx reduction technique and is already operating in a few plants, in California amongst other. The key points of the process are the use of fuel to create a reducing zone, that of excess air at kiln feed end and the temperature in the sintering zone. The specific MINOX test at Port la Nouvelle (sheet n 9) was inconclusive because of operational instability in the process. It was possible to obtain a NOx reduction of about 200 mg/Nm3 with initial emissions at 1000 mg/Nm3 zone during the test but during too short a period due to process instability. Other similar systems based on the same principles have also given promising results. Precalciner kilns allow independent settings of the oxidation/reducing levels in the cement kiln and in the precalciner kiln. Injection of part of the fuel in the exhaust gas box can then decrease NOx emissions. Similarly, adding fuel to the grate of LEPOL kilns can lead to a significant NOx reduction, but implies keeping an eye on the evolution of the other air pollutant emissions. Cyclone preheater kilns without precalciner also allow slight reductive runs when injecting fuel in the exhaust gas box, though to a lesser degree. Permanent monitoring of SO2 and VOC levels becomes necessary as they tend to increase because of the local reducing zone. A long kiln with mid-kiln staged combustion has been operating in the Los Angeles area in the United States for several years now. Even though the data is confidential, results show that the principle is interesting and worth going further into for this type of process. Staged combustion is the object of collaborative studies in Germany, followed with interest by the French cement industry, as this technique presents a NOx reduction potentiality probably very near that of SNCR.

- 10 -

6. Secondary Control Measures Secondary measures are those that reduce already formed NOx into N2 and H2O through chemical reactions. The two techniques already in use in several industrial sectors - SNCR and SCR - reduce NOx by the action of urea or ammonia. Several prerequisites concerning temperature, residence time, gas mixture and NH3/NO molar ratio must be fulfilled if these selective reactions are to be successful. Very briefly put, reducing temperature ranges for SNCR are in the 850-1050C range, with a molar ration of more than 1, even 2 in certain cases, and in the 250-400C range for SCR with a molar ratio around 1 on a catalysts. 6.1. Selective Non-Catalytic Reduction System (SNCR). There is a clear NOx reduction when injecting urea or ammonia with the stoichiometric ratio. This is a very efficient NOx emission reducing system (sheet n 10: Saint Pierre la Cour, sheet n 11: Hming, sheet n 12: Lumbres, sheet n 13: Cruas). Except in the case of an injection with a rotating connection on a long wet kiln (sheet n 12), it becomes quite possible to respect the 800 mg/Nm3 limit value and even stay well under if necessary. The injection zone varies with the type of kiln process. Injection technique for rotary kilns seems quite applicable to long kilns, but presents serious reliability problems and can still be improved. . Cost issue aside, SNCR used continuously may also give out smells through NH3 slips at the stacks, or, mostly, in the fines recycled from the filters. This was also pointed out in Germany where a correlation between NH3 injection and a corresponding concentration in the fines was established. Optimising process implementation should solve these problems. Process costs would decrease if the product used came from waste. The use of recycled ammonia water from a Kodak plant is an example, other possibilities probably exist. ADEME could help the French cement industry find alternative product sources and take part in costs optimisation. Installing SNCR technology nevertheless costs about 500 000 to 1 M , w h i c he x p l a i n s the small number of sites where it is operating, even in countries where the process is deemed to work. 6.2. Selective Catalytic Reduction System (SCR) Tests done in laboratories (sheet n 4: IRMA) show that implementing this technique strongly depends on the temperature and the overall dust loading conditions. To operate, a catalytic process that can bear the high dust levels usual in the firing zone must be used (high dust system), or the exhaust gases reheated after dedusting (low dust system), which would mean additional energy costs and very important investments. A full scale test of catalysts in a "high dust" system was set up in Solnhofen (sheet n 4 bis: Solnhofen). ATILH toured this plant at the beginning of October 2002. According to the company, the installation has been operating without any major hitches for 9 000 hours, after a few operating parameters were adjusted (reheating of cleaning air, upstream circulation of gases for 20% of time).

- 11 -

This equipment reduces NOx emissions from 1200 to 800 mg/Nm3 at a stoichiometry of 0,6 and a temperature of 300C, a rather disappointing result that can just as well be obtained through primary measures. The installation seems oversize and air consumption is such that costs balance for SNCR is negative. Investments at Solnhofen cost 3,5 M , e s t i ma t e da t 2 , 5Mf o r ak i l nw i t ha1 5 0 0t o n n e so f c l i n k e r p e r day capacity, to which costs for setting-up and adapting the heat exchanger must be added. Estimated operating costs are 0,75 / t c l i n k e r f o r ar e d u c t i o no f 4 0 0 mg / N m3, with 0,5 to 1 / tc l i n k e ra d d e df o rr e p l a c i n gt h ec a t a l y s t s ,me a n sa t o t a l c o s to f 2100 / t o f r e d u c e dN O xa n d1 , 9 3 / t c l i n k e r . T h e r eb e i n gn op r e c i s ea n dv e r i f i a b l e data to control the results announced, those numbers remain theoretical. The cement i n d u s t r y sp o s i t i on is that it is somewhat premature to consider this technique as available. Catalytic systems evolving rather quickly, a technology watch on the subject will be set up at ATILH so as to be able to react rapidly in case the "low dust" process or a better characterization of the Solnhofen test emerge.

6.3. SO2 Reduction Combustion quality, and more particularly absence of CO in the installation is the first primary factor in limiting SO2 volatilization in the kiln. Secondary measure limitation of SO2 is efficient (from 600 to 300 mg/Nm3) with sodium bicarbonate (sheet n 14: Beffes), but this technique is valid only when alkaline content of raw meal is very low, as sodium bicarbonate injection adds 0,1 % alkalis to the clinker, which may turn out to be undesirable. Injection of pulverized lime or calcium can still be refined, but coating formation in kiln is a determining point. Other SO2 reduction techniques, such as using a wet scrubber (one operating installation in Sweden, one in Austria) or a dry scrubber (one operating installation in Switzerland) on exhaust gases can be set up, but information from the German cement industry indicates a process cost, that is, for instance, 20 times over that of absorbent additions to the raw meal in a dry process.

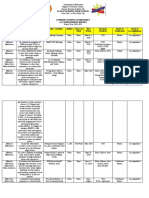

7. Costs Balance 7.1 Estimation of Tests Costs Balance The table below summarises: capital costs specific to each plant (or estimated) taking already existing equipment into account, total estimated costs (payback and operating costs) specific to each plant, per tonne of manufactured clinker and per tonne of reduced NOx, Estimated invested sums are affected with an uncertainty factor corresponding to calculations done at the preliminary stage of project. Measurement uncertainty must also be kept in mind, and the fact that operating an installation can lead to both good and bad surprises where maintenance costs and consequences for the installation are concerned.

- 12 -

25/10/2002 Sheet Plant Site 1 2 3 4 Gargenville Grave de Peille Altkirch IRMA Process [a] Testing DP Flue gas recirculation DP Low NOx burner [d] PrC Expert system Lab SCR [d] Capacity t clinker /day 1 340 3 100 1 200 3 600

Capital Costs [k] Euros

Total Cost p e r t o n n e p e r t o n n e of clinker of NOx 0,17 0,07 [b] 3,60 2 200 282

Initial NOx Effectiveness Level mg/Nm [c] 1.010 1.260 530 peaks cut off 80% in laboratory

3

mg/Nm [c]

300.000 455.000 [b] 8.200.000

-200

4 5 6

bis

Solnhofen Le Teil Gargenville

DP SCR [e] alum. Expert system DP Injection of water with additives DP Injection of water with additives

1 500 150 1 340

2.500.000 60.000 [b] 10.000

1,93 0,20 0,06

2.100 226 184

1.200 1.210 1.015

-400 [g] -250 - 100 peaks cut off -250 -300 -200 [f]

7 8 9

Grave de Peille

3 100 1 400 2 200

116.000 [n] 600.000 [h] 1.500.000 [m]

0,19 0,23 [h] 0,28 -

583 418 [h]

1.200 1.300 1.060

Val d'Azergues SDP Injection of aqueous waste Port la Nouvelle PrC Staged combustion [f] St Pierre la PrC SNCR Cour Hming Lumbres Cruas Grave de Peille SDP SNCR WP SNCR [f] DP SNCR DP Expert system

10 11 12 13 15

4 000 1 200 700 570 3 100

1.130.000 510.000 551.500 600.000 59.000

0,71 0,84 Not pertinent 1,76 0,01

478 820

1.200 880 900

-700 -300 [i] 20 - 70 % [ f] -400 [i] - 100 peaks cut off -300

622 67

1.210 950

14

Beffes

SDP SO2 reduction raw meal lime

1750

214.500 0,12 0,55 146 943

670

[a]:

DP: dry process SDP: semi-dry process WP: wet process alum.: calcium aluminate cement process PrC: precalciner

[b]: [c]: [d]: [e]: [ f]: [g]: [h]: [i]: [k]: [m]: [n]:

gross industrial costs including productive investments at 10 % O2 ,dry gas, or in % there where no industrial full-scale tests and costs are estimated not part of the ADEME convention: information provided by VDZ non viable reduction technique in the industrial operating conditions of the test at a stoichiometry of 0,6 data provided by Lafarge Ciments (cf. sheet for assessment context) the certified bodies have reported better periodic measurement results sums correspond to effective realisation or estimations, as the case may be estimated from 1000 to 1500 ka n dt h eh i g h e r v a l u eu s e df o r c o s t s c a l c u l a t i o n s payback period of 5 years instead of 10 years as for the other capital investments

- 13 -

7.2 Costs Instances (in Euro/tonne of NOx) from Other Industrial Sectors The economical aspect of any environmental technology is of major importance for its market prospects. To be accepted as Best Available Technique (BAT), a technique must be both efficient (important emission reduction) and performing (not too costly and no undesirable sideeffects). Costs is probably where the greatest stakes are involved. Several uncertainties remain, on the level of investments required (up-scaling from prototype to industrial installation, gross capital assessment, adapting existing equipment) as well as on the operating costs. Nonetheless, the following estimations can be of help when planning middle or long term policies. As quite a lot of cost figures were given at the NOXCONF 2001 congress, it seems reasonable to think they were of sufficient quality to be accepted as indicative figures. Cost in Euro/tonne of NOx HNO3 SCR (CRI) Burning plants/ waste incineration plants or gas turbines. SCR (CRI) LCI 800 MWth + SCR Refineries reducing their emissions to 200 mg/m3 (French examples) SCR cement (Austrian evaluation) Waste (1 French example/SCR) Waste (Dutch reference) Glass SCR (from 2-1 to 0,5 g/m3) Glass SCR (from 1-0,7 to 0,5 g/m3) Flat glass (Euroglas example) SCR, gas combustion Japanese refinery reducing its emissions to 65 mg/m3 SCR: Selective Catalytic Reduction HNO3: nitric acid LCI: Large Combustion Installation Minimum 420 800 1500 1850 966 9000 3900 1000 3000 650 3800 Maximum 450 1500 2500 2350 1594 4400 3000 7000 1600 5640

7.3 Comparing Reduction Technique Costs-Cement Selling Price Ratios The cement industry wishes to draw attention to the reduction technique costs per tonne of cement to cement selling price ratio, which indicates the strong sensitivity of this industry to reduction costs. The average selling price of the cement tonne in 2001 was 86 . Reduction technique costs: (source: Solnhofen + tests + NOXCONF 2001) 1,9 to 3,6 / t c e me n t , S C Rt e c h n i q u e , ( 2 2 0 0 / t o f a v o i d e dN O x ) , 0,7 to 1,8 / t c e me n t , S N C Rt e c h n i q u e ,( 4 8 0t o8 2 0 / t o f a v o i d e dN O x ) ,

It would be interesting to compare this sensitivity to that of other industrial sectors concerned.

- 14 -

8. Conclusions This NOx reduction techniques test program, set up and carried out by the French cement industry following the impetus of both the Ecology and Sustainable Development Ministry and ADEME, provided an industrial feed-back on several of the t e c h n i q u e s p r e s e n t e di nt h ec e me n t i n d u s t r y s B R E Fd o c u me n t . B u t i t o b v i o u s l y c a n t provide answers for all of the field questions that may occur at plant level. The important efforts engaged by the various actors of the French cement industry have nonetheless resulted in a few interesting leads. Similarly to what may be observed in other industrial sectors, NOx emissions reduction actions must start with primary reduction measures, as they have a much lower economic impact on the plant (67 to 2825 / to f a v o i d e d N O x a n d 0,01 to 0,28 / t c l i n k e r , d u r i n go u r t e s t s ) . E mi s s i o n sc a nt h u sb er e d u c e d , a n dp e a k si n particular limited. This smoothing over will make later implementation of secondary measures that much easier (lower reactive agent consumption, possible less stringent requirements on the inherent performance of the secondary measure). These primary measures have also shown a further reduction potential. But their effects are not systematically cumulative and problems of both reproducibility and of breakdown in kiln operating conditions were noted. Still it is more than probable that primary measures wiIl enable the plants to respect the 800 mg/Nm3 limit in most cases. The French cement industry has noted that tests done during 2000 already have a definite impact on the average results for the industry: in 1999 and in 2000, emission averages collected by ATILH were respectively 743 and 738 mg/Nm3. In 2001 and 2002, because of the tests program extending to other plant sites, the industry average went down to respectively 666 mg/Nm3 and 667 mg/Nm3. This perceptible evolution should be taken into account when setting national emission thresholds. Aiming for an industry average below 500 mg/Nm3 for 2005 seems quite feasible. When further emissions reductions become necessary, to conform to national emission thresholds of 2010 for instance and come closer to the BAT performances described in the BREF document, SNCR is then the least economically punishing technique (478 to 820 / to fa v o i d e dN O xa nd 0,71 to 0,846 / tc l i n k e r )f o rmo s to r d i n a r y production capacities. Progress could be made on the dominating cost of the reactive agent by recycling ammonia water from the photographic industry for instance. Emission reduction of 40 to 70% were repeatedly observed during these tests, with high initial NOx values. Performance levels are closely linked to installation lay-out and to a careful implementation of the SNCR technique. SCR technique shows higher performance levels in other industries. But the cost of its implementation (2200 / to fa v o i d e dN O xa n d3 , 6 0 / tc l i n k e r , estimates for the low dust technique) undeniably slows down its dissemination. There are currently no project within the cement industry to set up full scale tests for this technique.

except Grave de Peille (test 7) with payback period of 5 years : 583 / t N O x , a n dV a l d ' A z e r g u e s( t e s t 8 ) w h e r ec o s t s calculations were not validated by ADEME : 418 / t N O x 6 except Cruas (test 13) with too small a capacity to be taken into overall account

- 15 -

An full-scale test of the "high dust" technique is currently under way at Solnhofen in Germany: it is early days yet to be able to judge its performances (2100 / t o f a v o i d e d NOx and 1,93 / t c l i n k e r ) i nv i e wo f t h et e c h n i c a l a n de c o n o mi c a l e l e me n t s p r o v i d e d . For SO2 emissions reduction, presented here only through a single test operation, actions on both combustion process and absorbent injection seem to lead to a definite emission reduction potential, even though results were relatively uneven.

- 16 -

Appendix 1

EVOLUTION OF NOX EMISSIONS REGULATION.

Nitrogen oxides (NO et NO2) are the object of particular attention from various public authorities at different levels. A the international level, what first comes to mind is the global perception of the issue as set in the Geneva Convention and in the NEC (National Emission Ceilings) Directive. Based on the modelisation of environmental impacts, of pollutant dispersion and transportation and of treatment costs optimisation, these two parallel approaches have resulted in setting global emission limits to the various countries working on the subject. F r a n c e s t a r g e t e mi s s i o n s a r ea s f o l l o w s : French 1999 emissions Limit in 2010 (Gteborg Protocol) Limit in 2010 (NEC Directive) Yearly NOx emissions (in Kt) 1534 860 810

Which means an overall industrial emission reduction of about 47 %. Emission reduction efforts will be distributed to each of the sources concerned. This global approach at the European Union level has a technological complement in its IPPC (Integrated Pollution Prevention and Control) Directive. This directive stipulates that emission limit values for the facilities concerned (cement plants included) will be based on the performances of the Best Available Techniques as of 1999 for new facilities and starting in 2007 for existing ones. Information exchanges were organised by the European Commission, to help member states implement this directive, and more precisely, help define the concept of Best Available Technique at an acceptable cost for the cement industry, in compliance with article 16.2 of the directive. The conclusions of these discussions were published in a document entitled BREF or BAT Reference Document, which should be referred to for all interpretations of the Best Available Technique (BAT) concept at an acceptable cost concerning cement industry nitrogen oxides emissions reduction. A short summary of these discussions can nonetheless be given here: Emission levels for an operating Best Available Technique will have a daily average between 200 and 500 mg/Nm3 at 10 % O2, dry gas, resulting from primary measure (flame temperature reduction, low-N O xb u r n e r s , ) , s t a g e dc o mb u s t i o no r t h eS N C R technique, or any combination of these techniques. Members of the working group have nonetheless posited that a range at 500-800 mg/Nm3 at 10 % O2, dry gas, would be more acceptable. The cement industry argues that the 200 mg/Nm3 value comes from the cement plant in Slite (Sweden), and should be considered as a very particular case and not applied generally.

- 17 -

Other members who hold selective catalytic reduction (SCR) to be a BAT with the associated emission level of 100-200 mg NOx/m3 (expressed as NO2 equivalents) have also contested the daily average BAT in the 200-500 mg/Nm3 range. This last position is based on feasibility studies, pilot tests and the fact that there are currently at least three suppliers in Europe proposing full-scale SCR units for the cement industry with performance levels said to be at 100-200 mg/m3. But the commissioning of the first full-scale SCR unit in the cement sector was not planned until the end of 1999 and in fact occurred much later. #This definition of BAT is completed by the following comments: - adaptability of individual facilities in respecting emission values in very site-specific: it seems rather improbable to count on having every kiln reach these levels on a given date. - setting up a SNCR unit requires an adequate range of temperature being available. the correct temperature range is easily had on preheater kilns, on preheater/precalciners kilns and probably on some Lepol kilns. There are currently no full-scale SNCR unit operating on a Lepol kiln, but tests made on pilot plants gave promising results. It could turn out to be very difficult though, maybe even impossible, to obtain the necessary temperature and residence time in long wet/dry process kilns. - there is a notable lack of SNCR experience in high reduction applications, and thus, an uncertainty concerning supplementary ammonia emissions that could come from the high injection rate of ammonia water. Ammonia slips could result in visible and sustained sulphate dust and ammonia chloride emissions, and unused ammonia could also prevent recycling dust in the cement. Lastly, the European Union set up limit emission values for the main pollutants in a classic sector-specific approach to waste elimination activities. Thus, ministerial decree of 20 September 2002 transposing European directive of 4 December 2000 pertaining to incineration and co-incineration facilities for hazardous waste has set, for those cement plants where it is applicable, a limit value of 800 mg/Nm3 for existing cement plants, and one of 500 mg/Nm3 for those new plants whose main activity has been authorised after official publication of the decree. Emission values for wet-process kilns, or those burning waste below 3 t/h can go as far as 1200 mg/Nm3 until 1st January 2008. Those few kilns who do not use waste remain regulated by the Decree of 3 May 1993, published in the Journal Officiel of 15 June 1993. Its main provisions concerning NOx are as follows: Kiln type Limit Emission Value in mg/Nm3, dry gas 1200

Dry process kilns with exhaust gas heat recovery for raw meal drying Semi-dry or semi-wet process kilns 1500 Wet and dry process kilns without exhaust gas heat recovery 1800 They will be applicable to existing cement plants as of 15 June 1998, but are immediately applicable to new plants.

- 18 -

ADEME Convention n 99-74-089 Company: CIMENTS CALCIA Plant site: Gargenville (78)

Summary Sheet: Project n 1

NOx Emissions Reduction Test and Evaluation of Flue Gas Recirculation

1. Objectives NOx emissions reduction in kiln from 1 000 to 800 mg/Nm3 at 10 % O2 ,dry gas, by recirculating oxygen-poor flue gas (8,5 %) over the main kiln burner NOx emissions reduction to less than 700 mg/Nm3 if coupling with water injections in the burner succeeds. 2. Plant and New Process Characteristics Dry process kiln with HUMBOLDT 4-stage preheater and a production of 1 340 t/d, GRECO low NOx multiple-circulation burner, 4,7 % primary air + 1,8 % conveying air, Fuels: pet coke, animal fat, edible oils, Exhaust gas by-pass installation on heat exchanger and stack outputs, recirculation to burner through dedusting cyclone, air-air exchanger, a Roots blower, cold air and flow control flaps, regulation and automation. 3. Results Best absolute result: 884 mg/Nm3 by recirculation through axial air with water injection, that is 12 % reduction, with reduction from 13 to 19 % for other periods in axial air, 14 % and 32 % reduction by radial air recirculation, with water injection, 24 % reduction by recirculation through the three air types with fresh air input and without water injection, The last tests do not confirm the first results. 4. Conclusions Objectives not met but promising results as reduced rates are important, Tests were disturbed by kiln operating problems, mostly because of blocked vertical flues with no relation to the tests, Tests were realised under almost complete recirculation and without water injection so as to measure process limitations and monitor the results over a long period, Costs were calculated after these rather unusual tests and as such, were based on hypotheses not necessarily reproducible on a long term basis, Cost per reduced NOx tonne: 282 / t , Cost per manufactured clinker tonne: 0,17 / t c l i n k e r

- 19 -

ADEME Convention n 99-74-165 Company: VICAT Plant site: GRAVE de PEILLE (06)

Summary Sheet: Project n 2

Low-NOx Burner

1. Objectives The initial objective of the test was to assess actual reduction gains after setting up a Low NOx b u r n e r a n dt oc h e c k o nt h ec o n f o r mi t y t ot h es u p p l i e r s c l a i ms . This was a very complex subject, given the heterogeneity of raw materials in use and the multitude of fuels burned on the plant site. But when setting up the initial program, it had nonetheless seemed interesting to try to assess the nitrogen oxide emissions reduction potential of the latest Low-NOx burner, set up on a kiln in replacement of an older burner, to test the effect of various control adjustments and, if relevant, to draw some useful rules and conclusions for future implementations. 2. Results Suppliers FLS and Pillard refuse to guarantee NOx reduction gains with Low-NOx burners. They claim that various other parameters such as fuel types, meal burnability, kiln operating mode, also play an important role.

3. Conclusions I nv i e wo f t h es u p p l i e r s l a c ko f c o n f i d e n c e , t h ev e r yh i g hc o s t sa n dt h ev e r yi mp o r t a n t changes that would be wrought on the firing hood, Vicat decided to postpone the investment, which did not seem to be the best technique for reducing NOx emissions at the Peille plant site. Other techniques give significant results. Potentially, a Low-NOx burner setting up and auxiliary equipment included would cost 450 k , o r 0 , 0 7 / t c l i n k e r .

- 20 -

ADEME Convention n 99-74-178

Summary Sheet: Project n 3

Company: HOLCIM Plant site: Altkirch (68) Dry process kiln with 4-stage cyclone preheater Evaluating Expert System Impact on NOx Emissions (with control variables not adjusted to NOx minimisation)

1. Test Programme Alternate continuous 7-days periods in conditions as identical as possible: Linkman ON ; Linkman OFF, Fuels, Kiln burner: 90% (pet coke, waste oils, solvents, treated sawdust) Precalcination: 10 % (tires, ground plastics), From 10/09/2001 to 27/11/2001, 11 weeks in total,

2. Results Stacks Emissions NOx CO SO2 O2 3 mg/Nm 1O % O2 % 523 1032 4,0 8,6 538 818 3,0 8,8

Linkman ON OFF

H2O % 19,3 19,1

CO2 % 13,8 13,5

Flow rate

Nm /h 109.600 111.700

T C 131 133

Classdistributionof half-hour NOxemissionaverages for kilnoperatingperiodswithandwithout expert system (valuesgiveninmg/N m3, 10%O 2, drygas) 20% 18% 16% 14% 12% 10% 8% 6% 4% 2% 0% 25 75 125 19% 19% 18% 16% 16% 12% 12% 7% 6% 16% 13% 9% 6% 6% 5% 3% 5% LinkmanO FF LinkmanO N

LINKM ANO FF nbr. values=808 AVERAG E=538 m in. value=225 max. value=915 Std. deviation=126

LINKM ANO N nbr. values=1198 AVERAG E=523 m in. value=164 max. value=926 Std. deviation=105 3% 3% 1% 0% 0% 175 225 1% 1%

1% 1% 1% 0% 0% 0% 775 825 875 925 975

275

325

375

425

475

525

575

625

675

725

3. Conclusions alternate Linkman ON/OFF7 campaigns showed similar NOx emission levels, yet histograms show a reduction of NOx emissions in the higher values, over 700 mg/Nm 3, in our opinion, the fact that the expert system has been in use for quite some time h e r eh a sl e a dt oa nh a r mo n i s a t i o no f t h ek i l ns t a f f so p e r a t i n gp r o c e d u r e s , w h i c h has in turn influenced the results, when compared to usual assessments.

7 )

The facility already had an expert system, which would today require an investment of about 210 k . The ABB company which supplies the expert system does not have a specific module for NOx reduction

- 21 -

ADEME Convention n99-74-179 Company: IRMA

Summary Sheet: Project n 4

Selective Catalytic Reduction of Nitrogen Oxides

1. Objectives Run laboratory-scale tests of selective catalytic reduction of nitrogen oxides using ammonia on gaseous compound with a composition close to that of cement plant effluents, but without the dust. 2. Programme Testing catalysts based on zeolithes exchanged by various cations: - Pentasil zeolithe copper 2,3 %, ammonium form, 127 g/l of active matter, - Pentasil zeolithe copper 2,3 %, platinum 0,2%, 161 g/l of active matter, - Pentasil zeolithe Si/Al: 13,5, iron: 2,5 %, ammonium form, 200 g/l of active matter, - Pentasil zeolithe Fe: 3,2 %, 134 g/l of active matter, - Pentasil zeolithe Si/Al: 13,5, platinum: 0,54 %, sodic form, 117 g/l of active matter, - commercial catalyst of the V2O5-TiO2 type 3. Results Copper and iron Pentasils have rather similar behaviour. Both catalysts are stable at 300C and deactivation below this temperature (275C) is quite clear: NOx transformation rate drops quickly due to ammonium sulphate formation that clogs porosity and restrains access to active sites. Adding platinum to copper Pentasil seems interesting, as it lowers reaction temperatures. There were 85 % of NOx conversion at 300C during 70 h, but with a NH3/NO ratio of 1,3. There is slightly more N2O, which seems unavoidable in the presence of platinum. A platinum zeolithe with a NO2-rich compound can manage to eschew N2O, but deactivation, though real enough, is rather slow. This catalyst would give interesting resuslt in cycle runs of a day or two, with two catalyst beds and and a periodic regeneration. 4. Conclusion Selective catalytic reduction tests give acceptable results at temperatures over 300C, without dust. But gases at these temperatures in the cement manufacturing process are loaded with dust (around 10-100 g/Nm3), being upstream of dedusting. Dedusted g a s e s a r ea t l o w e r t e mp e r a t u r e s w h i c hw o n t a l l o wc a t a l y t i c r e a c t i o n . Investments for an SCR unit with dedusted gas reheating is estimated at 8,2 Mf o r a 3600 t/d kiln. Operating costs would be 3,6 / t c l i n k e r , a n d2 2 0 0p e r t o n n eo f a v o i d e d NOx, with an increase in exhaust gas volume of 15 %. In other industrial sectors, NOx reduction rates can reach 80-90 % with favourable temperature and dust loading conditions. The Solnhofen plant site in Germany has done full-scale tests, which results are presented in sheet 4bis.

- 22 -

Solnhofen Project

Company: Solnhofer Portland-Zementwerke A.G. Plant site: Solnhofen (Germany)

Summary Sheet: 4 bis

Selective Catalytic Reduction of Nitrogen Oxides on an Industrial Scale

(information provided by the cement industry)

1. Objectives

Reduction of NOx emissions to less than 800 mg/Nm at 10 % O2, dry gas, by running dust loaded hot gases through a selective catalytic reduction system.

3

2. Plant and New Process Characteristics

Dry process, preheater kiln with production capacity of 1500 t/d The SCR system is set-up at the preheater lower end, connected to its output duct with possible by-pass. Exhaust gas flow through the catalysts from top-down under normal operating conditions and bottom-up 20 % of the time, to improve catalyst grate dust cleaning. Pression loss of the installation is of 5 to 9 mb. Catalyst lifetime expectation is 3 years. Ammonia injection for SCR is done at preheater output end, NOx emissions reduction tests with SNCR were also done at this plant site with a stoichiometry of 1,8.

3. Results

The NOx selective catalytic reduction system has now been working without major problems 3 for 9 000 hours. NOx emissions were reduced from 1200 to 800 mg/Nm with 0,6 stoichiometry at a temperature of 300C. According to the supplier, SCR technology could reduce emissions from other pollutants, but this has not been verified. To this day, no record of unusual equipment wear.

4. Conclusions

Information given during the 1 October 02 tour of Solnhofen was provided by the SCR system supplier (LURGI). As such, it is theoretical and does not necessarily pan out with elements previously given out by the cement plant, for reasons both of confidentiality and of lack of previous industrial application characterization. This somewhat strains the credibility of the information given to the visiting delegation. The system seems to be operating satisfactorily. The plant operator thinks that an SNCR system is enough, and that the main interest of SCR is to avoid ammonia (NH3) stack emissions. Capital investments in Solnhofen were of 3,5 M . C a p i t a l i n v e s t me n t sa r ee s t i ma t e da t 2 , 5M for a 1500 t clinker/day kiln, to which general set-up operations and necessary preheater adaptations must be added. This technique seems to work, but we have seen that primary measures in France decreased 3 emissions from 1200 to 800 mg/Nm . The motive put forward for choosing SCR seems difficult to believe: no NH3 stack emissions and foreseeable savings if NOx rates can be reduced. The VDZ (Verein Deutscher Zementwerke e.V.) has been following this test, and though no certified operational summary has been done up to now, records that the technique seems to work. 3 Operating costs are 0,75 / t c l i n k e r f o r ar e d u c t i o no f 4 0 0mg / N m 3 Maintenance costs are mostly catalysts replacement costs: 7 500 to 15 000 / m , which means an added 0,5 to 1 / t c l i n k e r Total costs hover from 1,93 to 2,43 / t c l i n k e r , o r a g a i n2 1 0 0t o2 6 4 0 / t o f r e d u c e dN O x .

st

These elements still being theoretical today, the technological and economical context of SCR implementation remains in need of further precision and validation.

- 23 -

ADEME Convention n 99-74-180 Company: LAFARGE ALUMINATES Plant site: Le Teil

Summary Sheet: Project n 5

Setting up an Expert System for Reducing NOx Emissions on a Calcium Aluminate Cement Production Line

1. Objectives A reduction of about 20% in the NOx stack emissions of the Le Teil plant production line, using expert system LUCIE. More ambitious yet, reduce the exhaust gas NOx concentration below the 800 mg/Nm3 threshold (with 10 % O2, dry gas), starting from an initial concentration of 1207 mg/Nm3, as measured by the AIF (certified third-body agency) before expert system set-up. 2. Programme 1) Measure NOx emissions during five days before expert system installation 2) Set up expert system 3) Measure NOx emissions during five days after expert system installation 4) Modify expert system targets 5) Measure NOx emissions during five days after expert system modification. We intended to add two more sensors on the process line: - an infra-red camera for the thermal characterization of the burning zone, which idea was abandoned after an unhappy experience on our West Thurrock plant site (too sensitive to dust emissions). - a continuous NO analyser on the stack, also abandoned, because the NO kiln output analyser which had us worried at the beginning of the program finally operated quite normally. 3. Modifications Outside the Program We changed the air gas cooler before the electrofilter to a combined air/water gas cooler, which increased production at an identical flow rate. 4. Results of AIF measurements Step 1) 878 mg/Nm3, at 13 % O2, dry gas, or 1207 mg/Nm3 at 10 % O2 dry gas Step 3) 893 mg/Nm3, at 9,8 % O2, dry gas, or 877 mg/Nm3, at 10 % O2 dry gas Step 5) June 02 measurements: 847 mg/Nm3 at 10 % O2, dry gas, (on one day only) NOx rate flow per tonne of manufactured clinker went from 2,22 kg/t to 1,79 kg/t with the expert system, then to a further 1,32 kg/t after optimisation. 5. Conclusions NOx concentration was reduced by 30 % using the expert system, more than was aimed for (20%), but couldn t b er e d u c e db e l o w8 0 0mg/Nm3. Capital investment for expert system modification 60 k . Costs per reduced tonne of NOx: 226 / t , Costs per tonne of manufactured clinker: 0,20 / t c l i n k e r .

- 24 -

Convention ADEME n 99-74-181 Company: CIMENTS CALCIA Plant site: Gargenville (78)

Summary Sheet: Project n 6

NOx Emissions Reduction Test and Evaluation of Water Injection with Additives

1. Objectives Kiln NOx emissions reduction from 1000 to 800 mg/Nm3, at 10 % O2, dry gas, by injecting pure water or water with added domestic fuel on the flame and in the secondary air duct. 2. Plant and New Process Characteristics Dry process kiln with HUMBOLDT 4-stage preheater and a production of 1340 t/d, GRECO low NOx multiple-circulation burner, 4,7 % primary air + 1,8 % conveying air, Fuels: pet coke, animal fat, edible oils, Injection of 500 to 2000 l/h pure water, then with added domestic fuel, in the flame centre with a injector rod using compressed air, Injection of pure water in kiln secondary air duct, NOx measured at the stack, controlled through water flow rate. 3. Results Cutting-off of higher values through flame injection: average about 100 mg/Nm 3 lower, and measurement standard-deviation decreased from 286 to 126 mg/Nm3, Best results: 947 mg/Nm3 with pure water, 930 mg/Nm3 with additives, Kiln operation breakdowns at the beginning of the tests, under control afterwards, Differences in water injection with and without additives not noticeable, No secondary air injection reduction observed, as tests were interrupted for the flue gas recirculation tests. 4. Conclusions On a Low-NOx burner with low primary air rate, injecting water in the flame clips the h i g h e s t v a l u e s b u t h a s n t a n y n o t i c e a b l ei mp a c t o nt h eo v e r a l l a v e r a g e , Water injection implies smoother kiln operations, banning too abrupt actions on fuel flow rate, Injection has no noticeable effect on kiln thermal rate and consumption. Capital investments: 10 000 Costs per reduced tonne of NOx: 184 / t Costs per tonne of manufactured clinker: 0,06 / t c l i n k e r

- 25 -

ADEME Convention n 99-74-182 Company: VICAT Plant site: Grave de Peille (06)

Summary Sheet: Project n 7

Injection of Water with Organic Additives

1. Objectives Define optimal injection conditions of water with additives to obtain the highest possible reduction of nitrogen oxide emissions. 2. Results Reference data: the following conclusions concerning standard cycle runs without organic water injections are based on the average quarter-hour readings and the daily averages (7400 values): up until the beginning of 2001, for reasons of greater burnability, kiln operators maintained excess air in kiln feed end at 6%. NOx emission rate expressed at 11% O2 had an average of 1150 mg/Nm3 with peaks at 1400-1600 mg/Nm3 (on 246 daily averages). Since the beginning of 2001 efforts were made to keep oxygen level at a maximum of 3 to 4%, which incidentally heightens the risk of CO formation. NOx emissions were reduced to 903 mg/Nm3 (on 162 daily averages). Peaks were limited to 1200-1300 mg/Nm3. Since November 2001, an expert system has again reduced the average rate and cut out the peaks over 1100 mg/Nm3. The tighter monitoring of oxygen level at kiln feed end is very probably behind this. The fuel type PITCH or PET COKE has had no noticeable influence on the emission rate during the tests. Water injection tests, with and without hydrocarbons were run several times during the 500 h kiln operation, in several campaigns. Flow rates of 500 l/h of water + 200 l/h of hydrocarbons were required before NOx decrease became noticeable, about 200 to 300 mg/Nm3 less in the 900 mg/Nm3 zone. Water without hydrocarbons at identical flow rates has no impact. 3. Conclusions On the whole, these tests turned out to be positive for the plant since emissions went from 1200 to 850 mg/Nm3, gaining from this action combined with oxygen rate reduction at kiln feed end, Capital investments for a continuous injection of water with hydrocarbons would be about 116 000 , w i t hp a y back in 5 years at 6%, Operating costs (compressed air and pumps): 60 kWh at 0,04 o r2 , 4 / h (16 800 / y e a r ) . Ma i n t e n a n c e : 1 00 0 0 / y e a r , Flame yield loss: 0,5 t/h evaporation = 9 / h( 6 3000 / y e a r ) , Total = 89 800 / y e a r +( 1 1 60 0 0 / 4 , 2 1 ) =1 1 7353 / y e a r , Costs per reduced tonne of NOx: 583 / t , Costs per tonne of manufactured clinker: 0,19 / t c l i n k e r ,

- 26 -

ADEME Convention n 99-74-183 Company: LAFARGE CIMENTS Plant site: Val d'Azergues (69)

Summary Sheet: Project n 8

Nitrogen Oxide Emissions Reduction. Test and Evaluation of Water Injection with Additives

The use of waste in cement plants for more than 10 years has showed a positive influence of aqueous waste on nitrogen oxide emissions. This phenomenon is sitespecific but in certain situations can reduce emission levels by almost 40 %. 1. Objectives There are two key parameters to this NOx emission minimisation when using aqueous waste: temperature, and the volatile contents of said waste. Several types of aqueous waste are tested, with various organic matter contents, injected at the main kiln burner, near the main kiln burner and at the Lepol kiln grate burner. Industrial runs without aqueous waste are also tested. ADEME aimed to reduce NOx emissions below 800 mg/Nm3, at 10 % O2, dry gas. 2. Tests Aqueous waste injection tests were done at the main kiln burner and at the Lepol kiln grate burner to determine their impact on NOx reduction. Several test configuration were run: Variation of aqueous waste flow rate Variation of aqueous waste organic matter contents Variation of injection locations 3. Results At grate burner: - 10 % NOx reduction by injection of G2000 - 10 % to 25 % NOx reduction by injection of G3000 At kiln burner: - 25 % NOx reduction by injection of G2000 - optimisation of configuration by central injection 4. Conclusions Short tests showed, for the G2000 burner flow rate of 20 l/t clinker: Positive 25 % NOx reduction (not found by certified third-body) No impact on clinker quality Negative 3 to 7% less in clinker production 35 th/t clinker increase in heat consumption A less even process run Costs, provided by Lafarge Ciments - Capital investments: 600 000 ( a q u e o u s w a s t ea c c e p t a n c e , s t o r a g ea n di n j e c t i o n ) - Costs per reduced tonne of NOx: 418 / t - Costs per tonne of manufactured clinker: 0,23 / t c l i n k e r

I nL a f a r g e s c o s t s c a l c u l a t i o no f N O x t e c h n i q u e , p r o d u c t t a x , i n v e s t me n t p a y b a c k a n di n s t a l l a t i o n maintenance were held to compensate one another. Water evaporation and production loss of 72400 / year were taken into account as well as clinker production of 315000 t/year and NOx reduction of 173 t/year. Several of these hypotheses, however, could not be verified very precisely.

- 27 -

Convention ADEME n 99-74-184 Company: LAFARGE CIMENTS Plant site: Port-la-Nouvelle (11)

Summary Sheet: Project n 9

NOx Emissions Reduction by Staged Combustion

The Port-la-Nouvelle plant was modernised in 1998, with, among other major innovations in the kiln line, the setting up of a CLE Technip precalciner operating on the staged combustion principle (MINOX process). According to Lafarge Ciments, Port-laN o u v e l l e s MINOX was designed to operate with 100 % sulfurated pet coke. 1. Objectives - Define possible technical hitches in implementing the MINOX process, - Validate process performances - Asses its economic impact, - Reduce NOx emissions below 500 mg/Nm3 (at 10 % O2) - Maintain CO emissions and combustion residues at their present levels, - Keep the kiln line running smoothly. 2. Tests Three sets of test were necessary before reaching a quasi industrial operating level during a week. It was impossible to produce clinker in satisfactory operating conditions during the first sets: reducing conditions set off very high SO2 volatilisation which in turn rapidly clogge dt h ek i l ne n d . T h es y s t e m sa e r a u l i c sw e r ea l s ov e r yd i f f i c u l t t o manage. Important modifications to the installation had to be made to improve its operations: adding a burner to the precalciner, modifying the tertiary air dampers, improving feed line in l e t Furthermore, during the last tests set, there occurred a period where the raw meal burned very easily and COMBSU (waste fuel) was injected at the burner. Kiln emissions were thus quite lower during all this period. 3. Conclusions Positive: - decrease of stacks NOx down to 800mg/Nm3, at times, (impact of the precalciner burner), - positive impact of waste fuels, - positive impact of the new precalciner burner. Negative: - process difficulties (ring formation, concretion), - up to 10 % loss in production - according to Lafarge Ciments, operating the MINOX with the contractual fuel did not lead to the expected performances. Set-up costs of MINOX process: from 1 to 1,5 M , i nt h ec a s ew h e r et h ep l a n t a l r e a d y has a precalciner, Costs per reduced tonne of NOx: non viability of reduction technique at industrial level of operation, Costs per tonne of manufactured clinker: 0,28 / t c l i n k e r ,

- 28 -

ADEME Convention n 99-74-185 Company: LAFARGE CIMENTS Plant site: Saint-Pierre-la-Cour (53)

Summary Sheet: Project n 10

SNCR on Dry Process Kiln with Precalciner

The Saint-Pierre-La-Cour plant of Lafarge Ciments agreed to test SNCR NOx reduction and reduce NOx emissions below 500 mg/Nm3, at 10 % O2, dry gas. 1. Objectives 1. Define possible technical hitches 2. Validate process performances 3. Asses its economic impact 4. Reduce NOx emissions below 500 mg/Nm3 at 10 % O2. without deteriorating equipment operations without increasing, and if possible, on the contrary, decreasing other emissions (residual NH3, ) 2 . Tests An alkali solution (25% NH3) was injected on both gas flows, that in the preheater kiln burner and that in the precalciner burner, to determine their respective reaction rates. D Several test configuration were run: Variation of ammonia flow rate with a NH3/NO molar ratio of 0 to 3 Optimisation in injector site distribution on the equipment Variation of injector type With a NH3/NO molar ratio of 1, NOx reduction were of: 80 % on the preheater kiln line, for downstream combustion NOx 70 % on the precalciner line, for upstream combustion NOx These results are in conformity with those found in professional literature. These tests lead to finding the optimal configuration for a 15-days continuous run, as defined in project specifications. 3. Conclusions Positive: NOx reduction from 1200 to 500 mg/Nm3, no particular smell to recycled dust. Measurements at the stacks done by monitoring body have shown emission levels as low as 430 mg/Nm3, Negative: 2 % loss in production, calculated energy consumption increase of 1 %, combustion deterioration (more concretions), Capital investment: 1 130 000 Costs per reduced tonne of NOx: 478 / t Costs per tonne of manufactured clinker: 0,71 / t c l i n k e r Comments: - Electrofilters: a slight increase in dust emission as the tests ran on. - NH3 increase during tests, to maximum 10mg/Nm3 what about slips in the longterm ?

- 29 -

ADEME Convention n 99-74-186

Summary Sheet: Project n 11

Company: HOLCIM Plant site: Hming (57) Semi-dry process with LEPOL grate kiln (1200 t/d) Test and Evaluation of Urea SNCR on a Semi-dry Process Kiln

1. Test Programme SNCR performance was judged on: 1. The NOx reduction rate (APAVE measurements), 2. The incidence on other emissions (NH3, CO, N2O, SO2, COV) (APAVE measurements), 3. The presence of smells in emissions or recycled dust (IAP International Sentic), Limited in time, these tests did not allow assessing the impact on: 1. Additional concretion formation and possible clinker production loss, 2. Health and safety (working in the filters, in particular), 3. Additional maintenance costs due to corrosion, 2. Calendar Objectives Show feasibility Optimisation of injection parameters urea SNCR evaluation Period length 1 day 4 days (3 to 6h injection per day) 2 campaigns of 4x24 continuous hours

Preliminary test Optimisation tests Long-term tests

3. Results and conclusions Aqueous urea solutions SNCR can be applied to a LEPOL kiln. Performances displayed in long-term tests are: NH2/NO2 NOx reduced rate Urea costs 1 kg/t clinker 1 1,5

1 2

Total costs payback included 2 / t c l i n k e r 0,60 0,84 / t r e d u c e dN O x 675 820

/ t c l i n k e r 0,43 0,65

37 % 43 %

3,6 5,4

0,12 / k gu r ea capital investments of 510.000 ( 1 0y e a r p a y b a c k p e r i o d , a t 6%) N2O, CO, SO2: undetectable impacts of SNCR on those emissions. NH3: slip < 10 mg/Nm3 at 10 % O2, dry gas, with a stoichiometry of 1, up to 13 mg/Nm3 at 10 % O2, dry gas, with a stoichiometry of 1,5. Smells: a slight smell is detected in kiln dust due to amine residue fixation. After mixing the dust with cement, the olfactory impact seems minor.

- 30 -

ADEME Convention n 99-74-187 Company: HOLCIM Plant site: Lumbres (62) wet process kiln

Summary Sheet: Project n 12

Test and Evaluation of Urea SNCR on a Wet Process Kiln 1. Tests programme The programme laid out in the convention was only partially realised as technical problems occurred which could not be solved within time frame of ATILH / ADEME convention Partial programme : Setting up an experimental injection line on a rotary kiln: 1. Set up 2 lines, one for air, the other for the water + urea mix, 2. Feed the 2 sets of 3 injectors in mid-kiln (1050C and 1100C), 3. Look for solutions to improve technique reliability. Short term SNCR tests 2. Calendar Objectives Show feasibility Development and realisation Optimisation of injection parameters Repair and modify injection circuits to make them more reliable Purchase injection gantry and NH3 Canal Arrive at permanent air and water injections SNCR test with sole injector still operational Period length 1 day 4 days (3 to 6h injection per day)

Preliminary Test Experimental line Optimisation tests Improvements

Circuit testing Urea injection

6 months 19 tests in 13 days

3. Results Results of these short term tests show a NOx reduction potential from 20 to 70 %, with ammonia slip problems whatever the reduction rate. These results were obtained without optimising the injection circuit (use of 5 injectors on the 6 available with a stoichiometric molar ratio of 1,5) and need confirmation. Nozzle orientation can probably also play a major role in technique performance and in NH3 slip control, which latter could turn out to be problematical if unchecked. 4. Conclusion Failure of continuous urea injection: for technical reasons, mainly, thermal resistance of kiln linings, injector build-ups, vibration resistance of double rotary connections and thermal stress of conveying pipes alongside the kiln. A complementary programme exceeding convention time limit is currently under way.

- 31 -

ADEME Convention n99-74-188 Company: CIMENTS CALCIA Plant site: Cruas (07)

Summary Sheet: Project n 13

NOx Emissions Reduction Test and Evaluation of SNCR on White Cement Production Unit.

1. Objectives NOx emissions reduction of kiln below 500 mg/Nm3, at 10 % O2, dry gas, without deterioration of facility operations. Short-term ammonia injection test, then long-term urea injection test. 2. Plant and New Process Characteristics 2 stage dry process kiln with 570 t/d capacity and clinker cooling system by water immersion, 450C primary air mono-circuit burner, Fuels: pet coke and high viscosity fuels, Urea solution at 43,5% or ammonia solution at 20,5% injected in the vertical heating duct through 2 or 4 injectors with air and water compression, Injection rate: 50 to 200 l/h urea, 73 to 219 l/h ammonia, Exhaust gas analysis through continuous MIR 9000 system (O2, NOx) and FTIR Gazmet analyser (NH3, N2O, NO, NO2), NOx emission control by reactive agent rate flow . 3. Results NOx reduction to 800 mg/Nm3 with 150 l/h urea, residual ammonia emission of 75 mg/Nm3, Reduction to 500 mg/Nm3 with 200 l/h urea, residual emission at 170 mg/Nm3, Similar results with ammonia: slightly less efficient NO reduction, and higher residual emissions of ammonia, but lower N2O et NO2 emissions, Tendency concretion formation in vertical heating duct, Kiln draft breakdown and exhaust gas cooling with water sprays leads to a slightly lower kiln flow rate. 4. Conclusions Reduction objectives reached using 150 200 l/h urea, but high residual emissions of ammonia, probably due to the small dimensions of unit which meant too short a residence time (200 ms) Optimisation of injection conditions could not reduce residual emissions. Capital investment: 600 000 Costs per reduced tonne of NOx: 622 / t Costs per tonne of manufactured clinker: 1,76 / t c l i n k e r

- 32 -

ADEME Convention n 99-74-189 Company: CIMENTS CALCIA Plant site: Beffes (18)

Summary Sheet: Project n 14

Emission Reduction of Sulphur Oxides Test and Evaluation of Raw Meal, Lime and Carbonate Injections

1. Objectives SO2 emission reduction of at least 50 %, that is below 400 mg/Nm3, at 10 % O2, dry gas, through raw meal, lime and sodium bicarbonate injections. 2. Plant and New Process Characteristics semi-dry process LEPOL kiln with precalcination and a capacity of 1750 t/d, fuels: pet coke, meat and bone meal, treated sawdust, injection equipment: 150 m3 silo with filter, extraction sieve, weighing hopper, Roots blower and rotary valves, pipes, and a reactive agent flow rate adjustable from 100 to 1000 kg/h injection locations: recirculation duct, decarbonation chamber, grate outlet duct. 3. Results SO2 residual emission: 321 mg/Nm3 that is 52 % with 480 kg/h raw meal in recirculation duct, 686 mg/Nm3 that is 27 % with 200 kg/h lime in recirculation duct, 325 mg/Nm3 that is 49 % with 200 kg/h sodium bicarbonate in recirculation duct, 794 mg/Nm3 that is 31 % with 200 kg/h lime at grate outlet, No reduction through raw meal or lime injection at precalciner level Results are better with low CO content in exhaust gas. 4. Conclusions Significant reductions with injection in recirculation duct, but initial objectives are met only under favourable conditions when CO contents in exhaust gas are low, Results not easily reproducible and not necessarily in proportion to injected reactive agent flow rate, Best results are with sodium bicarbonate but we note an increase of alcali contents in the clinker, detrimental to cement quality in general, and to Beffes cements in particular, as their alcali contents is already high. Tests to be continued, working on the combustion first, to reduce exhaust gas CO contents, and thus SO2. Capital investment: 214 500 Costs per reduced tonne of SO2: 943 / t w i t hl i me , 146 / t w i t hr a wme a l Costs per tonne of manufactured clinker: 0,55 / t c l i n k e r w i t hl i me , 0,12 / t c l i n k e r w i t hraw meal

- 33 -

ADEME Convention n 99-74-190 Company: VICAT Plant site: Grave de Peille (06)

Summary Sheet: Project n 15

Expert System

1. Objectives Development of a set of control variables complementary to existing expert system rules that will minimise NOx emissions while maintaining a high combustion. 2. First results with expert system operating without specific variables A significant improvement in NOx emissions is noted, through the disappearance of peaks/peaks over 900 mg/Nm3, which already represents a gain of about a hundred mg/Nm3. From 2000 to 2001, simply lowering the oxygen from 6 to 4% at kiln feed end reduced NOx emission around 200 mg/Nm3. 3. Results with expert system operating with specific variables

NOx at 11%O2 (without water injection) Jan to Nov 2001

837 mg/Nm3 average in nov 2001 with expert system 2001 average: 903 mg/Nm3 (162 daily averages) 2000 average: 1150 mg/Nm3 (246 daily averages)

50% 40% 30% 20% 10% 0%

2001

2000

with expert system

mg/Nm3

Specific NOx variables resulted in a sustainable 2 % oxygen rate, which is lower than what an operator can manage to obtain permanently on this kiln. This leads to a 100 mg/Nm3 gain. Other factors also apply, such as meal burnability as characterised by its chemical composition and fineness as well as by the regularity of its composition, which can lead to a 200 to 300 mg/Nm3 gain. 4. Conclusions - 1200 mg/Nm3 initially - 1100 mg/Nm3 when following feed end oxygen rate at 4 %. - 950 mg/Nm3 with classic expert system - 800 mg/Nm3 with specific variables Costs - Capital investment for expert NOx system module: 59 000 , - No day-to-day expenses, - Expected reduction: 120 t NOx per year, - Costs per avoided tonne of NOx: 67 / t N O x , - Costs per tonne of manufactured clinker: 0,01 / t c l i n k e r

0 90 0 10 00 11 00 12 00 13 00 14 00 15 00 16 00 17 00 18 00 19 00 20 00

0 60

10

20

30

40

50

70

80

S-ar putea să vă placă și

- Sewage Sludge Quality Standards Required by Polish Cement PlantsDocument3 paginiSewage Sludge Quality Standards Required by Polish Cement PlantsyinglvÎncă nu există evaluări

- Hexavalent Chromium in Portland CementDocument5 paginiHexavalent Chromium in Portland Cementyinglv100% (1)

- VANCOUVER Reference Style Guide: NotesDocument6 paginiVANCOUVER Reference Style Guide: NotesMuhammad MoazzamÎncă nu există evaluări

- Accurate Rapid Analysis of Alkali Contents in Portland CementDocument4 paginiAccurate Rapid Analysis of Alkali Contents in Portland CementyinglvÎncă nu există evaluări

- Long-Term Leaching of Toxic Trace Metals From Portland Cement ConcreteDocument7 paginiLong-Term Leaching of Toxic Trace Metals From Portland Cement ConcreteyinglvÎncă nu există evaluări

- Assessment of Pollution Potentialities of Some Portland Cement PDFDocument3 paginiAssessment of Pollution Potentialities of Some Portland Cement PDFyinglvÎncă nu există evaluări

- The Special Features of Cement Standards in China PDFDocument5 paginiThe Special Features of Cement Standards in China PDFyinglvÎncă nu există evaluări

- Formation of Ettringite From Monosubstituted Calcium Sulfoaluminate Hydrate and Gypsum PDFDocument6 paginiFormation of Ettringite From Monosubstituted Calcium Sulfoaluminate Hydrate and Gypsum PDFyinglvÎncă nu există evaluări

- Role of Phosphogypsum in The Hydration of Calcium Sulphoaluminate PDFDocument8 paginiRole of Phosphogypsum in The Hydration of Calcium Sulphoaluminate PDFyinglvÎncă nu există evaluări

- The Composition and Crystallography of An Anhydrous Calcium Aluminosulphate Occurring in Expanding Cement PDFDocument5 paginiThe Composition and Crystallography of An Anhydrous Calcium Aluminosulphate Occurring in Expanding Cement PDFyinglvÎncă nu există evaluări