Documente Academic

Documente Profesional

Documente Cultură

Steam Room Construction & Generator Sizing Guide

Încărcat de

asdthuDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Steam Room Construction & Generator Sizing Guide

Încărcat de

asdthuDrepturi de autor:

Formate disponibile

STEAM ROOM CONSTRUCTION & GENERATOR SIZING GUIDE

INTRODUCTION

The following information is presented as an aid to those installing a steam generator or constructing a steam room. Due to complex construction variables, climate variances and changes in the manufacturing specifications, this information represents suggestions only. It is recommended that you consult your architect, material manufacturer and/or specification engineer regarding your particular installation. Please see "Disclaimer" at the end of this guide. OBJECTIVE: When planning a steam room project the objectives of comfort and relaxation should be kept in mind. A room properly designed and constructed should maintain a temperature range of 115 to 120 Fahrenheit, heat to this temperature in 15 to 20 minutes and have a comfortable and relaxing seating arrangement. If space permits, seating which allows the bather to recline or even to lay down greatly enhances the steam bath experience.

STEAM ROOM DESIGN CONSIDERATIONS:

1. A steam room, unlike a sauna, is a moist environment. Avoid using construction materials which are subject to corrosion or decay. 2. All inside surfaces of the steam room must be completely sealed and covered with a waterproof finish such as tile. Sheet-rock surfaces are not recommended. However, fiberglass re-enforced cement Sheet-rock such as Dura Rock or Wonder Board may be used if properly sealed against moisture with a commercial waterproof paint. All joints or cracks including shower head, handle escutcheon and steam head escutcheon should be sealed with silicone. Acrylic enclosures recommended for steam by the manufacturer also make excellent steam rooms. 3. Ceiling and seats inside the steam enclosure should be sloped to allow condensation to run off the interior surfaces and prevent dripping on the bather. A ceiling slope of 2" per foot should be adequate. In some installations, sloping the ceiling from the center may be required to minimize the ceiling height. 4. A floor drain should be provided for cleaning and allowing water drainage. A nonskid floor surface should be used for safety. 5. Ceiling height should be limited to 8'. Heights in excess of 8' may result in hot or adequate temperatures near the ceiling but uncomfortably cool floor temperatures. 6. An area for mounting the steam generator must be selected to provide the following: a. Allow access for servicing and provide sufficient space to remove elements should they ever need replacing. b. Protect steam generator from freezing, moisture and areas which might exceed140 F. (Do not mount the generator in the steam room or in an outdoor location) c. The all copper line from the steam generator to the steam room should not exceed 25 feet, should always slope toward the steam generator or steam head, should not form traps or valleys allowing condensation to accumulate and should be insulated to prevent heat loss and prevent burns from accidental contact. d. The steam head should be located in accordance with the generator installation instructions and minimize potential user contact. e. When installing the generator, plumbing unions should be used to allow removal of generator should service be required. 7. When selecting a construction material for lining the inside of your steam room, make sure to contact the material manufacturer to determine that the material is warranted for the hot, moist conditions of a steam room. 8. The steam room must be totally enclosed. 9. Ceiling vents in the steam room are not recommended. If used, they must form a vapor-tight seal and positive closing. Ducts must be waterproof. 10. Skylights and exterior windows are not recommended. If used, they must be double pane. Caution must be used to insure that the height and size of a window or skylight in a steam room does not prevent the room from maintaining comfortable temperatures in a reasonable length of time. SELECTING THE PROPER STEAM GENERATOR: In order to achieve the objective of comfort and relaxation, the selection of the proper steam generator model and size are as critical as design of the steam room itself.

MODEL SELECTION CONSIDERATIONS:

1. Water Quality. The more impurities or minerals in the water the more flushing or filtration is required to reduce build up in the tank. An automatic flush and water filtration system should be considered where the water quality is poor to reduce manual flush maintenance requirements. 2. Thermostatic Control. The thermostatic controller gives the option to regulate the temperature of the room hotter or cooler to comfort. In installations where the steam generator is used frequently and for greater length of time the cost of a thermostatic control may be justified to provide a more even temperature in the steam room. 3. Digital Display. The preferences of the bather may be for simple on/off simplicity or for more advanced feed back, set temperature, temperature in the steam room and remaining steam bath duration.

POWER (KW) SELECTION CONSIDERATIONS:

1. Cubic footage of steam room and surface area. 2. Steam room surface material mass, R factor and thermal conductivity. 3. Ceiling height relative to height of seating. 6. To avoid rewiring and provide the capability to "size-up if it turns out a generator of insufficient size is installed, it is strongly recommended that the next larger or even second larger wire size be installed for the generator you select.

DISCLAIMER

4. Are steam room walls exterior walls subject to large temperature fluctuations? 5. Actual line voltage and phase available (one phase or three phase, 240 volt or 208 volt, the lower the voltage the lower the steam output). This information represents recommendations only. Due to conditions of your installation, these suggestions may not be applicable. We can not warrant and should not be relied upon for information given concerning steam room materials or construction techniques.

4211-38

07-27-09

INSTALLATION OVERVIEW & SUGGESTED SIZING PROCEDURE:

INSTALLATION OVERVIEW AND SUGGESTED SIZING PROCEDURE

1. Calculate the cubic footage of the enclosure. Length x Width x Height (in feet) = Cubic feet. Ignore deductions for benches or other intrusions as they represent surface area to heat. 2. Add the following adjustments to the cubic footage calculated in #1 above to account for your specific design features. A. Acrylic or Cultured Marble. B. Ceramic tile. C. For each glass or glass block wall or exterior wall (if freezing is possible). D. Natural Stones (Marble, Granite, Slate). LxWxH= __________

+ 0% + 20% + 10% +100% Total (1+2A+2B+2C+2D)

__________ __________ __________ __________ __________

*AVAILABLE

kW 4 5 6 7 8.5 10 12 14

MAX. CUBIC FOOTAGE (Single Phase) 240V 208V 75 100 160 220 300 400 500 600 50 60 85 110 190 250 375 435

* Larger kW models can be used to heat

smaller rooms.

4211-38

07-27-09

S-ar putea să vă placă și

- Guide To Build Steam RoomDocument2 paginiGuide To Build Steam RoomsidÎncă nu există evaluări

- Stulz Data C Climatiseur Entre CoolingDocument26 paginiStulz Data C Climatiseur Entre CoolingSoLiTaRiO33Încă nu există evaluări

- ENGI 273 Lec 5Document48 paginiENGI 273 Lec 5Haidy T. SakrÎncă nu există evaluări

- Solar Cooling: Kushal Panchal & Suraj Parihar 130813111006 & 120810111005 4 Sem EC Venus InternationalcollegeoftechnologyDocument26 paginiSolar Cooling: Kushal Panchal & Suraj Parihar 130813111006 & 120810111005 4 Sem EC Venus InternationalcollegeoftechnologyRavi Pratap SinghÎncă nu există evaluări

- Aircraft Flying Project (PRINT OUT)Document24 paginiAircraft Flying Project (PRINT OUT)Priyanka KumariÎncă nu există evaluări

- HVAC Chapters 1 5Document57 paginiHVAC Chapters 1 5Mcilwaine Dela CruzÎncă nu există evaluări

- Geothermal HVAC: Shifting Performance Risk From Buyer To SellerDocument5 paginiGeothermal HVAC: Shifting Performance Risk From Buyer To SellerKagitha TirumalaÎncă nu există evaluări

- Hvac Condensate Calculator: Difference in Specific Humidity gr/ft3Document4 paginiHvac Condensate Calculator: Difference in Specific Humidity gr/ft3Pradeep SukumaranÎncă nu există evaluări

- HPT Optimizing Outside Air With HPTDocument11 paginiHPT Optimizing Outside Air With HPTNGUYEN QUANGÎncă nu există evaluări

- 8 Managing Data Center Heat IssuesDocument42 pagini8 Managing Data Center Heat IssuesfabiokruseÎncă nu există evaluări

- Stair Pressurisation Zone Smoke Control SystemsDocument24 paginiStair Pressurisation Zone Smoke Control SystemsAshokÎncă nu există evaluări

- 3 Psychrometrics March 2014 SlidesDocument78 pagini3 Psychrometrics March 2014 Slidespaai1989_679523114Încă nu există evaluări

- Boiler Pumps Fans Sizing CalculationsDocument4 paginiBoiler Pumps Fans Sizing CalculationsFarrahxviiiÎncă nu există evaluări

- Psych Rome TricsDocument46 paginiPsych Rome TricsDenitta D'RoseÎncă nu există evaluări

- Tear Cooling Tower Energy Operating Cost SoftwareDocument9 paginiTear Cooling Tower Energy Operating Cost Softwareforevertay2000Încă nu există evaluări

- Energy Efficient Educational Buildings-5 PDFDocument27 paginiEnergy Efficient Educational Buildings-5 PDFMohammad Art123Încă nu există evaluări

- PRICE - Air Distribution GuideDocument5 paginiPRICE - Air Distribution Guidenvenkat.narayan100% (1)

- Machinery Room Ventilation Analysis ToolDocument48 paginiMachinery Room Ventilation Analysis ToolDon Quijote de la ManchaÎncă nu există evaluări

- High Performance BuildingDocument21 paginiHigh Performance BuildingPallab MukherjeeÎncă nu există evaluări

- Sizing Industrial DehumidifiersDocument7 paginiSizing Industrial DehumidifiersTanveer AzizÎncă nu există evaluări

- Cooling TowerDocument12 paginiCooling TowerLillianLinÎncă nu există evaluări

- Cooling Tower CalculationeditedDocument3 paginiCooling Tower CalculationeditedMark LouieÎncă nu există evaluări

- Combining DOAS and VRF, Part 2 of 2Document9 paginiCombining DOAS and VRF, Part 2 of 2miniongskyÎncă nu există evaluări

- Cooling Load1111 PDFDocument43 paginiCooling Load1111 PDFJason PaquibulanÎncă nu există evaluări

- Building Bulletin 101Document60 paginiBuilding Bulletin 101Michael LomaxÎncă nu există evaluări

- Exhaust Air Heat - Recovery SystemsDocument4 paginiExhaust Air Heat - Recovery SystemsBiya ZainÎncă nu există evaluări

- District Cooling Guide Second Edition - Unlocked-2Document2 paginiDistrict Cooling Guide Second Edition - Unlocked-2Ahmed LabibÎncă nu există evaluări

- RAC 32 Important QuestionDocument10 paginiRAC 32 Important QuestionBalvinderÎncă nu există evaluări

- Humidification Calculation ImtiyazDocument2 paginiHumidification Calculation Imtiyazimtiyaz94Încă nu există evaluări

- Cibse Heat Loss & Heat Gain (Apachecalc) Calculation MethodsDocument9 paginiCibse Heat Loss & Heat Gain (Apachecalc) Calculation Methodsวรศิษฐ์ อ๋องÎncă nu există evaluări

- Industrial Dehumidification Part 1Document20 paginiIndustrial Dehumidification Part 1Quora EarningÎncă nu există evaluări

- Design Points For Negative PressureDocument23 paginiDesign Points For Negative PressureShohei Namjoon LetoÎncă nu există evaluări

- Dr. Fixit Newcoat 105 1 PDFDocument3 paginiDr. Fixit Newcoat 105 1 PDFmohdrashidÎncă nu există evaluări

- Chiller Ahu and Fcu SystemsDocument67 paginiChiller Ahu and Fcu Systemsrawand adnanÎncă nu există evaluări

- Dedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity ControlDocument39 paginiDedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity Controlhtanh100% (1)

- Control Valves For Ahu Chilled WaterDocument4 paginiControl Valves For Ahu Chilled WaterHussein Akil100% (1)

- Floating Floor Calculation (1) .Chillers AreaDocument1 paginăFloating Floor Calculation (1) .Chillers Areajomy_pj81060% (1)

- Technical Training - Air DistributionDocument163 paginiTechnical Training - Air Distributionrasheedillikkal100% (1)

- Water Cooled Chiller Plant (All-Variable) : Design Envelope Application GuideDocument10 paginiWater Cooled Chiller Plant (All-Variable) : Design Envelope Application GuideKaushikÎncă nu există evaluări

- HVAC Thermal Load EstimatingDocument28 paginiHVAC Thermal Load EstimatingIntisar Ali SajjadÎncă nu există evaluări

- LEED Application GuideDocument40 paginiLEED Application GuidejonathandacumosÎncă nu există evaluări

- Saiver AHUDocument12 paginiSaiver AHUNorsyafiqah Rozi100% (1)

- Sound Attenuator Selection Path Report: Source Sound Power Level Total Air Flow (M3/sec)Document1 paginăSound Attenuator Selection Path Report: Source Sound Power Level Total Air Flow (M3/sec)mefaisal75Încă nu există evaluări

- Cooling Load EstimationDocument37 paginiCooling Load EstimationHazem MohamedÎncă nu există evaluări

- HVAC - Overview of Space Heating Systems PDFDocument68 paginiHVAC - Overview of Space Heating Systems PDFFredie UnabiaÎncă nu există evaluări

- 5.16. Psychrometrics - Example 1. Summer CycleDocument7 pagini5.16. Psychrometrics - Example 1. Summer CycletehtehtehÎncă nu există evaluări

- AHU Friction Loss CalculationsDocument4 paginiAHU Friction Loss CalculationsAdnan AttishÎncă nu există evaluări

- The Armstrong Humidification HandbookDocument40 paginiThe Armstrong Humidification HandbookCraig RochesterÎncă nu există evaluări

- Using VAV Systems To Limit Humidity at Part LoadDocument5 paginiUsing VAV Systems To Limit Humidity at Part LoadTonyChuangÎncă nu există evaluări

- ASHRAE - HVAC-HospitalBook - Room Design PDFDocument4 paginiASHRAE - HVAC-HospitalBook - Room Design PDFalialavi2Încă nu există evaluări

- Heatload Calculation 2Document44 paginiHeatload Calculation 2Mustansir Pancha50% (2)

- AC V For Fast Food RestaurantsDocument4 paginiAC V For Fast Food Restaurantselijah namomoÎncă nu există evaluări

- Saving Energy in Lab Exhaust SystemsDocument11 paginiSaving Energy in Lab Exhaust Systemspal_stephenÎncă nu există evaluări

- Ch3 - PPT - HEAT AND MOISTURE TRANSFER IN PDFDocument50 paginiCh3 - PPT - HEAT AND MOISTURE TRANSFER IN PDFBLa ProductionÎncă nu există evaluări

- Application of Hydronic Radiant & Beam SystemsDocument86 paginiApplication of Hydronic Radiant & Beam SystemsDhirendra Singh Rathore100% (1)

- BESF DOAS Presentation Final 2019 12Document42 paginiBESF DOAS Presentation Final 2019 12Malek AqlanÎncă nu există evaluări

- Steam Technical InfoDocument2 paginiSteam Technical InfoAnonymous 7z6OzoÎncă nu există evaluări

- Typical Schematic For Single Hot Water Heat PumpDocument12 paginiTypical Schematic For Single Hot Water Heat PumpVin Bds100% (1)

- JOHN WOOD Water HeaterDocument6 paginiJOHN WOOD Water HeaterkapokÎncă nu există evaluări

- Instruction Manual: Fully Automatic Thermic Fluid HeaterDocument15 paginiInstruction Manual: Fully Automatic Thermic Fluid HeaterSubrato SahaÎncă nu există evaluări

- ADMAPN065ENDocument8 paginiADMAPN065ENasdthuÎncă nu există evaluări

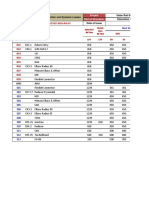

- Specification May Change According To Project RequirementDocument1 paginăSpecification May Change According To Project RequirementasdthuÎncă nu există evaluări

- The Institution of Engineers, Sri Lanka (Iesl)Document4 paginiThe Institution of Engineers, Sri Lanka (Iesl)asdthuÎncă nu există evaluări

- Facilities Standards Service (003C2B) : Contact ListDocument2 paginiFacilities Standards Service (003C2B) : Contact ListasdthuÎncă nu există evaluări

- Hot and Cold Water Supplies: Plumbing Engineering Services Design GuideDocument1 paginăHot and Cold Water Supplies: Plumbing Engineering Services Design GuideasdthuÎncă nu există evaluări

- Maharagama SchedulesDocument31 paginiMaharagama SchedulesasdthuÎncă nu există evaluări

- What's The Difference Between DOL Start, Star-Delta, Soft Starter and A Variable Speed Drive?Document1 paginăWhat's The Difference Between DOL Start, Star-Delta, Soft Starter and A Variable Speed Drive?asdthuÎncă nu există evaluări

- HVAC AuditoriumDocument2 paginiHVAC AuditoriumasdthuÎncă nu există evaluări

- Engineering: LEED Energy and Atmosphere, Credit 1 - Measuring Efficiency To Maximize PointsDocument6 paginiEngineering: LEED Energy and Atmosphere, Credit 1 - Measuring Efficiency To Maximize PointsasdthuÎncă nu există evaluări

- City of Colombo Developmenty PlanDocument107 paginiCity of Colombo Developmenty PlanJeganath KabilÎncă nu există evaluări

- Jirla Ksudúh: Ë (ÑPŠ Œñp PV™ ( ŠV Ënƒ Š (..Document28 paginiJirla Ksudúh: Ë (ÑPŠ Œñp PV™ ( ŠV Ënƒ Š (..asdthuÎncă nu există evaluări

- Cummins C350D5 Diesel Generator Data SheetDocument3 paginiCummins C350D5 Diesel Generator Data SheetasdthuÎncă nu există evaluări

- Standard Genset Features Generator Set Performance Generator Set OptionsDocument2 paginiStandard Genset Features Generator Set Performance Generator Set OptionsasdthuÎncă nu există evaluări

- Flowmatic Filter CartridgesDocument14 paginiFlowmatic Filter CartridgesasdthuÎncă nu există evaluări

- 1 s2.0 S2405882316300485 Main PDFDocument14 pagini1 s2.0 S2405882316300485 Main PDFasdthuÎncă nu există evaluări

- VRVX BroucherDocument45 paginiVRVX BroucherasdthuÎncă nu există evaluări

- Fire Sprinkler Guide IBC 2015Document43 paginiFire Sprinkler Guide IBC 2015asdthu100% (5)

- Electrical Installation-Sample Design LightingDocument9 paginiElectrical Installation-Sample Design Lightingasdthu100% (1)

- Daikin Split Type Air Conditioners PDFDocument20 paginiDaikin Split Type Air Conditioners PDFasdthuÎncă nu există evaluări

- AHU Elements Heat RecoveryDocument38 paginiAHU Elements Heat RecoveryasdthuÎncă nu există evaluări

- Mta 6 Mta 8Document5 paginiMta 6 Mta 8Janaka Wijeyesinghe65% (23)

- BBQ & Fire PitsDocument16 paginiBBQ & Fire PitsasdthuÎncă nu există evaluări

- 460 Pipe Sizing ASHRAEDocument6 pagini460 Pipe Sizing ASHRAEasdthuÎncă nu există evaluări

- Grade 7 Math Lesson 22: Addition and Subtraction of Polynomials Learning GuideDocument4 paginiGrade 7 Math Lesson 22: Addition and Subtraction of Polynomials Learning GuideKez MaxÎncă nu există evaluări

- Kimberly Jimenez Resume 10Document2 paginiKimberly Jimenez Resume 10kimberlymjÎncă nu există evaluări

- Tom Rockmore - Hegel's Circular EpistemologyDocument213 paginiTom Rockmore - Hegel's Circular Epistemologyluiz100% (1)

- Month Puzzle Two VariableDocument6 paginiMonth Puzzle Two VariableNayan KaithwasÎncă nu există evaluări

- Directorate of Technical Education, Maharashtra StateDocument47 paginiDirectorate of Technical Education, Maharashtra StatePandurang GunjalÎncă nu există evaluări

- Auditing BasicsDocument197 paginiAuditing BasicsMajanja AsheryÎncă nu există evaluări

- PICUDocument107 paginiPICUsarikaÎncă nu există evaluări

- Recruitment Process Outsourcing PDFDocument4 paginiRecruitment Process Outsourcing PDFDevesh NamdeoÎncă nu există evaluări

- Algorithm Design: Figure 1. Architecture Diagram For Greykite Library's Main Forecasting Algorithm, SilverkiteDocument3 paginiAlgorithm Design: Figure 1. Architecture Diagram For Greykite Library's Main Forecasting Algorithm, Silverkitesiper34606Încă nu există evaluări

- Gita Ananda SDocument10 paginiGita Ananda Srosaanggita76Încă nu există evaluări

- CN Blue Love Rigt Lyrics (Romanized)Document3 paginiCN Blue Love Rigt Lyrics (Romanized)Dhika Halet NinridarÎncă nu există evaluări

- Ip TunnelingDocument15 paginiIp TunnelingBon Tran HongÎncă nu există evaluări

- Learning Activity No.2Document1 paginăLearning Activity No.2Miki AntonÎncă nu există evaluări

- Practical Research 2Document16 paginiPractical Research 2Benedict Coloma BandongÎncă nu există evaluări

- Operations Management Stevenson 11th Edition Test BankDocument10 paginiOperations Management Stevenson 11th Edition Test BankAries Gonzales Caragan50% (2)

- How To Spend An Hour A Day in Prayer - Matthew 26:40-41Document1 paginăHow To Spend An Hour A Day in Prayer - Matthew 26:40-41Steve GainesÎncă nu există evaluări

- Lecture Planner - Chemistry - MANZIL For JEE 2024Document1 paginăLecture Planner - Chemistry - MANZIL For JEE 2024Rishi NairÎncă nu există evaluări

- Bhagavatam English Chapter 10bDocument22 paginiBhagavatam English Chapter 10bsrimatsimhasaneshwarÎncă nu există evaluări

- Livro Spectrochemical AnalysisDocument9 paginiLivro Spectrochemical AnalysisRicardo PossebonÎncă nu există evaluări

- Christine Remembered That Today Is The Birthday of Her BossDocument1 paginăChristine Remembered That Today Is The Birthday of Her BossA.Încă nu există evaluări

- Adolescents and Career DevelopmentDocument10 paginiAdolescents and Career DevelopmentMasrijah MasirÎncă nu există evaluări

- Atlantis Implant Compatibility Chart 79214-US-1107Document2 paginiAtlantis Implant Compatibility Chart 79214-US-1107Jean-Christophe PopeÎncă nu există evaluări

- 8 TH Linear Equations DBDocument1 pagină8 TH Linear Equations DBParth GoyalÎncă nu există evaluări

- MODULE 1 - Contemporary WorldDocument4 paginiMODULE 1 - Contemporary WorldaapÎncă nu există evaluări

- 56257375851Document3 pagini56257375851Anneliese FernandesÎncă nu există evaluări

- Serie10 User Man ProgDocument1.042 paginiSerie10 User Man Progfahmi derbel100% (1)

- Smart English 2 PDFDocument44 paginiSmart English 2 PDFmishhuana90% (21)

- Math Cad 15Document3 paginiMath Cad 15Kim ChanthanÎncă nu există evaluări

- Task 3: New - HTMLDocument12 paginiTask 3: New - HTMLGONELA SAI LOKESH (RA2011028010100)Încă nu există evaluări

- Final ExamDocument2 paginiFinal ExamblacmsÎncă nu există evaluări