Documente Academic

Documente Profesional

Documente Cultură

20120507091321

Încărcat de

Muhammad SaquibDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

20120507091321

Încărcat de

Muhammad SaquibDrepturi de autor:

Formate disponibile

PROJ No:_________ CALC No:_________

Self Chk:________ Date:________

Chkd:________ Apprvd:________ Date:_______ Date:_______

INTRODUCTION TO RELIEF VALVE SIZING PROGRAM

Program Name Revision Author Rev. Date Purpose

Relief valve sizing 0 MJA 15-Apr-03

This program is designed to assist with sizing of relief valves for vapour and liquid relief using the guidelines of API 520, Part-I, 7th Ed itio n , Jan u ary 2000. For two phase relief, the sizing method has not been included in this revision. Until this method has been included in the next version, the individual orifice areas calculated separately for liquid and vapour components would be added together to obtain the total orifice area

Instructions for use

1. Copy the protected programme from the 'Approved Software' directory into relevant project directory. 2. Go to the desired worksheet (PSV Vapour relief, PSV Liquid relief by clicking on the relevant button at the bottom of this spreadsheet program. Fill in designated input (sheet is self- explanatory) and press print buttons as required. PSV fo r vap o u r relief 2a. Input the following process data for sizing of PSV for vapour relief in worksheet "PSV Vapour Relief". - Select the relieving scenario and design code of the vessel protected by the PSV from drop-down list boxes. - Input Mass Flowrate, Molecular W eight, Relief temperature, Compressibility, Cp/Cv, Set pressure and Back pressure. - Input back pressure correction factor 'Kb' if available. This input is optional. The program defaults to a value of 1. - Input % accumulation if it is different from the value selected by program. This input is optional. For vessels designed to ASME section VIII, Div. 1 and 'Fire relief' scenario, the program defaults to 21% accumulation. For all other cases, the program defaults to 10% accumulation. 3a. The program calculates the orifice area for the PSV, selects the next higher standard orifice size and gives preliminary size of the selected PSV. The program also calculates the relieving capacity of the selected relief valve. PSV fo r liq u id relief 2b. Input the following process data for sizing of PSV for liquid relief in worksheet "PSV Liquid Relief". - Input the relieving scenario and design code of the vessel protected by the PSV. - Input Mass Flowrate, Density and Viscosity at flowing conditions, Set pressure and Back pressure. - Input % accumulation if it is different from the value selected by program. This input is optional. The program defaults to 10% accumulation for all liquid relief cases. 3b. The program calculates back pressure correction factor, viscosity correction factor, orifice area for the PSV, selects the next higher standard orifice size and gives preliminary size of the selected PSV. The program also calculates the relieving capacity of the selected relief valve. PSV fo r tw o p h ase (vap o u r+liq u id ) relief 2c. The sizing method for two phase relief from PSV is being finalised in API 520. Till the new method is available calculate individually the orifice area for the vapour and liquid components using worksheets 'PSV Vapour Relief' and PSV Liquid Relief' respectively and obtain the total orifice area. Select the PSV size manually.

Limitations

1. No choice of RV type is given. For backpressure higher than 10% of the maximum relieving pressure (set pressure+accumulation), the program automatically selects balanced bellow relief valve and uses sizing equation for critical flow in gas service (see also 'Limitation note 2'). For backpressure <10% conventional valves are assumed. 2. Per API 520, critical flow equations are used for all balanced bellows in gas service. To adjust for subcritical flow, manufacterer's back-pressure correction factor (Kb) should be obtained and used in the optional 'user input' cell provided. 3. The program selects from the full orifice sizes defined in API 526 (1997) (ie. D,E,F,G,H,J,K,L,M,P,Q,R,T). 4. For orifice area exceeding the T size orifice, the program gives a message that 'Multiple RV's' are required. User to select the number and size of PSVs. 5. For use of multiple RVs, the user is required to split the flow at the data input stage. Refer to API 520 for set point considerations of multiple RVs. 6. RVs for steam system relief has not been considered.

FEEDBACK: All feedback should be sent to the Owner (Assigned Custodian) - see Revision Status sht.

STD CALCULATION NO: PEL-BMS-CAL-P-0300

PROJ No:_________ CALC No:_________

Self Chk:________ Date:________

Chkd:________ Apprvd:________ Date:_______ Date:_______

Date: Spreadsheet name: Revision: Std Calculation number Date: Assigned owner

15-Apr-03 Relief valve rev0 0 PEL-BMS-CAL-P-0300 15-Apr-03 MJ Allen

Revision History

Revision 0 J and M standard orifice sizes added to look up tables. Validated for use. Date 15/04/03 Prepared MJA Checked RL Approved LJF

STD CALCULATION NO: PEL-BMS-CAL-P-0300

PROJ No:_________ CALC No:_________

Self Chk:________ Date:________

Chkd:________ Apprvd:________ Date:_______ Date:_______

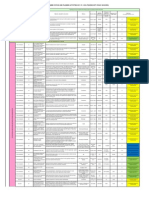

RELIEF VALVE SIZING CALCULATIONS VAPOUR OR GAS RELIEF

Client: Job No: Project: Tag No: Location PROCESS DATA Vapour or Gas relief Relieving Scenario Vessel Design Code Mass Flow Gas Molecular W eight Relief Temperature Compressibility Cp/Cv RV Set pressure Back Pressure Back Pressure Correction Factor Kb Accumulation kg/h kg/kmol C

Software validation PEL-BMS-CAL-P-0303 Vapour service 20-PSV-011 Test Separator

bar(g) bar(g)

(Default value = 1)

6444,7 20,20 119,00 1,00 1,40 3,50 0,10 1,00 10 70,53

User Input for Kb (Optional).

User Input for accumulation (Optional). (default 21% for ASME, 10% for BS 5500).

% psia psia

Note, do not exceed defaults.

CALCULATIONS / RESULTS Acc. absolute press. Critical backpressure Critical flow / Subcritical flow Type of RV Effective coefficient of Discharge K d Calculated Orifice Area Selected Orifice Selected Orifice Area Relieving Capacity of Selected RV Preliminary RV Size (Inlet x Outlet) Orifice Designation

inch 2 inch 2 kg/h

37,26 Critical Flow Balanced Bellow 0,975 Default Value as per API-520. 3,345 M 3,600 6935 4"X6" M

STD CALCULATION NO: PEL-BMS-CAL-P-0300

PROJ No:_________ CALC No:_________

Self Chk:________ Date:________

Chkd:________ Apprvd:________ Date:_______ Date:_______

RELIEF VALVE SIZING CALCULATIONS LIQUID RELIEF

Client: Job No: Project: Tag No: Location PROCESS DATA Liquid relief Relieving Scenario Vessel Design Code Mass Flow kg/h Density at flowing conditions kg/m Absolute Viscosity at FC cP RV Set pressure Ps bar(g) Back Pressure Pb bar(g) Accumulation % CALCULATIONS / RESULTS Upstream Relieving Pressure psig % of guage backpressure (Pb/Ps)x100 Back Pressure Correction Factor Kw Based on API 520 Fig.35 Based on API 520 Fig.36 Viscosity Correction Factor Kv Effective coefficient of Discharge K d (API-520 default=0.65) Type of RV inch2 Calculated Orifice Area Selected Orifice inch2 Selected Orifice Area Relieving Capacity of Selected RV kg/h

Software validation PEL-BMS-CAL-P-0304 Liquid service 20-PSV-011 TEST SEPARATOR (V-2005)

Blocked outlet 515,00 1130,00 3,49 1812,50 4,60 10,00 28909,38 0,25 1,00 0,96 0,65 Conventional 0,001 D 0,110 107076

User Input for accumulation (Optional)

User Input for accumulation (Optional)

Preliminary RV Size (Inlet x Outlet) Orifice Designation

1"x 2" D

STD CALCULATION NO: PEL-BMS-CAL-P-0300

PROJ No:_________ CALC No:_________

Self Chk:________ Date:________

Chkd:________ Apprvd:________ Date:_______ Date:_______

RELIEF VALVE SIZING CALCULATIONS VAPOUR + LIQUID

SIZING METHOD FOR TWO PHASE RELIEF IS BEING FINALISED IN API 520 PART-I

PLEASE CALCULATE INDIVIDUALLY THE THE ORIFICE AREA FOR FLASHED VAPOUR AND UNFLASHED LIQUID AND ADD THE INDIVIDUAL AREAS TO OBTAIN THE TOTAL ORIFICE AREA TILL THE NEW METHOD IS AVAILABLE.

THIS WORKSHEET TO BE DEVELOPED ONCE API 520 IS REVISED TO GIVE NEW METHOD

STD CALCULATION NO: PEL-BMS-CAL-P-0300

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- CP S HW CH 9 DetailedDocument6 paginiCP S HW CH 9 Detailedkirandas_mullasseryÎncă nu există evaluări

- HazMat Math The Rest of The StoryDocument4 paginiHazMat Math The Rest of The Storykirandas_mullasseryÎncă nu există evaluări

- Eplc Meeting Minutes TemplateDocument4 paginiEplc Meeting Minutes TemplateAbdelRhman ElfkyÎncă nu există evaluări

- 8KL FERMENTER DESIGN CALCULATIONSDocument3 pagini8KL FERMENTER DESIGN CALCULATIONSkirandas_mullasseryÎncă nu există evaluări

- Performance of One Unit Shell Side Tube SideDocument1 paginăPerformance of One Unit Shell Side Tube Sidekirandas_mullasseryÎncă nu există evaluări

- Hermes-2012-Thermodynamic Design of Condensers and Evaporators-2100Document9 paginiHermes-2012-Thermodynamic Design of Condensers and Evaporators-2100kirandas_mullasseryÎncă nu există evaluări

- 2010 Rockwell Collins Shuttle Badminton LeagueDocument2 pagini2010 Rockwell Collins Shuttle Badminton Leaguekirandas_mullasseryÎncă nu există evaluări

- HazMat Math The Rest of The StoryDocument4 paginiHazMat Math The Rest of The Storykirandas_mullasseryÎncă nu există evaluări

- Heat Exchangersdasd DasdfsdfaffsdDocument15 paginiHeat Exchangersdasd Dasdfsdfaffsdkirandas_mullasseryÎncă nu există evaluări

- Design of AgitatorDocument23 paginiDesign of Agitatorkirandas_mullassery100% (3)

- Ballbal DirectDocument13 paginiBallbal DirectDavid RojasÎncă nu există evaluări

- Demister PadDocument4 paginiDemister PadPatel Mehulkumar0% (1)

- Heat TransferDocument1 paginăHeat TransferhuangjlÎncă nu există evaluări

- Limpet Coil CalculationDocument1 paginăLimpet Coil Calculationkirandas_mullassery100% (1)

- Ccs 125m FundingDocument3 paginiCcs 125m Fundingkirandas_mullasseryÎncă nu există evaluări

- Guide To Inspecting The WorkplaceDocument29 paginiGuide To Inspecting The Workplacekirandas_mullasseryÎncă nu există evaluări

- 2010 Rockwell Collins Shuttle Badminton LeagueDocument2 pagini2010 Rockwell Collins Shuttle Badminton Leaguekirandas_mullasseryÎncă nu există evaluări

- Design of AgitatorDocument23 paginiDesign of Agitatorkirandas_mullassery100% (3)

- ACS ProcessDocument24 paginiACS Processkirandas_mullasseryÎncă nu există evaluări

- DRC - SP - DRC 11-35 Ps Guide Important For Safety Items - EngDocument30 paginiDRC - SP - DRC 11-35 Ps Guide Important For Safety Items - Engkirandas_mullasseryÎncă nu există evaluări

- Productflyer - 978 0 7923 1202 4Document1 paginăProductflyer - 978 0 7923 1202 4kirandas_mullasseryÎncă nu există evaluări

- Ccs 125m FundingDocument3 paginiCcs 125m Fundingkirandas_mullasseryÎncă nu există evaluări

- Design NewDocument9 paginiDesign Newkirandas_mullasseryÎncă nu există evaluări

- ACS ProcessDocument24 paginiACS Processkirandas_mullasseryÎncă nu există evaluări

- Guide To Inspecting The WorkplaceDocument29 paginiGuide To Inspecting The Workplacekirandas_mullasseryÎncă nu există evaluări

- Material Safety Data Sheet: Product Name: Mobil Stern Tube LubricantDocument9 paginiMaterial Safety Data Sheet: Product Name: Mobil Stern Tube Lubricantkirandas_mullasseryÎncă nu există evaluări

- 2010 Rockwell Collins Shuttle Badminton LeagueDocument2 pagini2010 Rockwell Collins Shuttle Badminton Leaguekirandas_mullasseryÎncă nu există evaluări

- Design of AgitatorDocument23 paginiDesign of Agitatorkirandas_mullassery100% (3)

- Binary Distillation McCabe ThieleDocument2 paginiBinary Distillation McCabe Thielelsastré_11Încă nu există evaluări

- Chapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument85 paginiChapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallNadirah RahmanÎncă nu există evaluări