Documente Academic

Documente Profesional

Documente Cultură

Acce Le Rom Meters

Încărcat de

Anurag Singh PatelDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Acce Le Rom Meters

Încărcat de

Anurag Singh PatelDrepturi de autor:

Formate disponibile

Accelerometer

An accelerometer is a transduction device that converts mechanical energy into an electrical signal (the output). The output is expressed in terms of millivolts per g, or in the case of a charge mode accelerometer the output is expressed in terms of pC per g.

Common Types of Accelerometers:

Capacitive-Metal beam or micromachined feature produces capacitance; change in capacitance related to acceleration Piezoelectric-Piezoelectric crystal mounted to mass voltage output converted to acceleration Piezoresistive-Beam or micromachined feature whose resistance changes with acceleration Hall Effect-Motion converted to electrical signal by sensing of changing magnetic fields Magnetoresistive-Material resistivity changes in presence of magnetic field Heat Transfer-Location of heated mass tracked during acceleration by sensing temperature

Typical Accelerometer Applications:

-Tilt / Roll Vibration / Rough-road detection Can be used to isolate vibration of mechanical system from outside sources Vehicle skid detection Often used with systems that deploy smart braking to regain control of vehicle Impact detection To determine the severity of impact, or to log when an impact has occurred Input / feedback for active suspension control systems Keeps vehicle level

Technology selection:

The first step in the selection process is to determine the type of measurement to be made. There are three widely used technologies used for acceleration measurements. Piezoelectric (PE) accelerometers are the most widely used accelerometers for test and measurement applications. These devices offer a very wide measurement frequency range (a few Hz to 30 kHz) and are available in a wide range of sensitivities, weights, sizes and shapes. These accelerometers should be considered for both shock and vibration measurements. PE accelerometers are available with a charge or voltage (IEPE) output.

Piezoresistive (PR) accelerometers generally have low sensitivity making them desirable for shock measurements. They are also used extensively in transportation crash tests. Because of the low sensitivity, they are being used less for vibration measurements. PR accelerometers generally have a wide bandwidth and the frequency response goes down to zero Hz (often called DC responding) or steady state, so they can measure long duration transients. Variable capacitance (VC) is among the newer accelerometer technologies. Like PR accelerometers, they are DC responding. VC accelerometers have high sensitivities, a narrow bandwidth and outstanding temperature stability. These devices are highly desirable for measuring low frequency vibration, motion and steady state acceleration.

The frequency response is an important parameter when considering any accelerometer. This parameter is usually specified within 5% of the reference frequency (usually 100 Hz). Many devices will have the specifications extended to 1 dB and in some cases 3 dB. Vibration: Piezoelectric accelerometers are the first choice for most vibration measurements since they have a wide frequency response, good sensitivity and resolution and are easy to install. There are two subdivisions of piezoelectric accelerometers which include the basic charge-mode accelerometer and the voltage mode Internal Electronic Piezoelectric (IEPE) types. a) IEPE piezoelectric: In recent years, the IEPE type has become the most commonly used accelerometer type. Basically, an IEPE accelerometer is a device with the charge amplifier built-into the accelerometer. They require no external charge amplifiers and use ordinary low cost cable. The accelerometer does require a constant current power source and many data acquisition systems have built-in power sources. If the user knows the vibration range and the operating temperature is in the range of -55C (-67F) to 125C (257F) then an IEPE device should be considered. Note that high temperature versions are available in some models that have a maximum operating temperature of 175C (350F). b) Charge mode piezoelectric: Charge mode piezoelectric accelerometer advantages include high temperature operation and an extremely wide amplitude range. A typical charge mode accelerometer will have an operating temperature range of -55C to 288C (-67 to 550F). Special purpose accelerometers are available for extreme environments as low as -269C (-452F) to as high as 760C (1400F). Special radiation hardened charge mode accelerometers are available for use in a nuclear environment.Unlike the IEPE accelerometer, the charge type accelerometer requires the use of special low noise cable. The low noise cable is expensive compared to the standard commercial coaxial cable. A charge amplifier, or an in-line charge converter is also required. Variable capacitance: In instances where vibration measurements at very low frequencies are required, a variable capacitance (VC) accelerometer is a choice to consider. VC accelerometers have a frequency response from 0 Hz to 1 kHz, depending on the sensitivity required. When making very low frequency measurements, a VC accelerometer with a frequency range from 0 Hz to 15 Hz will provide a high sensitivity of 1 Volt/g. VC accelerometers are useful on electro hydraulic shakers, flutter measurements and many transportation applications.

Shock: Two technologies are available for shock measurements and a variety of accelerometers are available depending on the levels and final data required. It is important to know the expected shock level, since this will determine the type of accelerometer to be used. Here is a rough guide to assist the reader in choosing the proper accelerometer. Low level < 500 g Crash < 2000 g Far field 500 g to 1000 g sensor located 2 meters from the point of impact Near field > 5000 g with the sensor located < 1 meter fr om the point of impact For low-level shock measurements, a general purpose accelerometer will generally do the job. The accelerometer will need a linear range of at least 500 g and a shock survivability rating of 500 g. An IEPE type is usually preferred since they are less susceptible to producing erroneous results from cable motion. The user should use an amplifier with a low-pass filter to attenuate the accelerometer resonance. Automotive crash testing is a rather specialized area of shock testing. Piezoresistive accelerometers are usually used. For far field shock measurements, a special shear mode accelerometer with a built-in electronic filter is often adequate. These are usually lightweight IEPE types with solder connections. The electronic filter electronically attenuates the resonance frequency of the accelerometer to prevent overloading of the data acquisition equipment. Near field measurements are usually very high levels often in excess of 20 000 g. Here the choice of accelerometers is dependent upon the type of test being conducted. Specialized accelerometers of either piezoelectric (charge mode and IEPE) or piezoresistive may be appropriate. Typically, an IEPE with characteristics similar to the far-field accelerometer is appropriate, but with the addition of an internal mechanical filter. The mechanical filter will ensure the survivability of the accelerometer and will generally eliminate zeroshift. In general terms, the zeroshift phenomenon appears with the time history not returning to the zero acceleration level following the shock event. This shifting results in distortion of data when performing integration. If a piezoresistive accelerometer is selected, zeroshift is rare. As is the case with vibration, the frequency response is an important parameter for shock. In general, a shock accelerometer should have a wide frequency response range (10 kHz is typical), depending on what is being tested. Motion, constant acceleration and low frequency vibration: This category is where variable capacitance (VC) accelerometers should be considered. This technology allows for the measurement of low level, low frequency vibration with a high output level. They also provide a high degree of stability over a broad temperature range.When a VC accelerometer is placed in a position where the sensitive axis is parallel to the earths gravity, an output equal to 1 g will be produced. This phenomenon is often referred to as DC responding. Because of this characteristic, VC accelerometers are very useful for measuring centrifugal force or for the measurement of acceleration and deceleration of devices such as elevators.In the realm of vibration testing, VC accelerometers are used in applications where low frequency events are to be studied and preservation of phase data is important.VC accelerometers have found their niche in the area of aircraft flutter testing. They are also valuable tools for measuring vehicular ride quality. The low frequency characteristics make VC accelerometers ideal for ride quality measurements in automobiles, trucks and railroad equipment. These are low frequency devices and a wideband frequency response is not a characteristic of VC devices.

S-ar putea să vă placă și

- Catia V5R19: CATIA - Automotive Body in White Templates 2 (ABT)Document4 paginiCatia V5R19: CATIA - Automotive Body in White Templates 2 (ABT)Anurag Singh PatelÎncă nu există evaluări

- Floating Solar TeasureDocument1 paginăFloating Solar TeasureAnurag Singh PatelÎncă nu există evaluări

- Structural Optimization Automotive Chassis Heavy VehicleDocument16 paginiStructural Optimization Automotive Chassis Heavy VehicleAnurag Singh PatelÎncă nu există evaluări

- Product Catalogue 2016 PDFDocument87 paginiProduct Catalogue 2016 PDFAnurag Singh PatelÎncă nu există evaluări

- Mahila Sangeet Special MenuDocument2 paginiMahila Sangeet Special MenuAnurag Singh PatelÎncă nu există evaluări

- Aditya HridayamDocument0 paginiAditya Hridayamumesh_khanna_3Încă nu există evaluări

- Achieving Optimum Performance Using Transmission 4Document16 paginiAchieving Optimum Performance Using Transmission 4Anurag Singh PatelÎncă nu există evaluări

- Achieving Optimum Performance Using Transmission 7Document15 paginiAchieving Optimum Performance Using Transmission 7Anurag Singh PatelÎncă nu există evaluări

- CV BKJ Aug 13Document2 paginiCV BKJ Aug 13Anurag Singh PatelÎncă nu există evaluări

- Achieving Optimum Performance Using Transmission 6Document16 paginiAchieving Optimum Performance Using Transmission 6Anurag Singh PatelÎncă nu există evaluări

- Condenser MicrophoneDocument1 paginăCondenser MicrophoneAnurag Singh PatelÎncă nu există evaluări

- Automobile CarDocument6 paginiAutomobile CarAnurag Singh PatelÎncă nu există evaluări

- Achieving Optimum Performance Using Transmission 2Document17 paginiAchieving Optimum Performance Using Transmission 2Anurag Singh PatelÎncă nu există evaluări

- Achieving Optimum Performance Using Transmission 5Document16 paginiAchieving Optimum Performance Using Transmission 5Anurag Singh PatelÎncă nu există evaluări

- Achieving Optimum Performance Using Continuously Variable TransmissionDocument20 paginiAchieving Optimum Performance Using Continuously Variable TransmissionAnurag Singh PatelÎncă nu există evaluări

- Achieving Optimum Performance Using Transmission 1Document18 paginiAchieving Optimum Performance Using Transmission 1Anurag Singh PatelÎncă nu există evaluări

- Achieving Optimum Performance Using Transmission 2Document17 paginiAchieving Optimum Performance Using Transmission 2Anurag Singh PatelÎncă nu există evaluări

- Ece R94Document77 paginiEce R94Anurag Singh PatelÎncă nu există evaluări

- Achieving Optimum Performance Using Continuously Variable TransmissionDocument20 paginiAchieving Optimum Performance Using Continuously Variable TransmissionAnurag Singh PatelÎncă nu există evaluări

- GoDocument8 paginiGoAnurag Singh PatelÎncă nu există evaluări

- 07 VariableDocument32 pagini07 VariableAnurag Singh PatelÎncă nu există evaluări

- High Performance CVT ComponentsDocument7 paginiHigh Performance CVT Componentsakhilaggarwal100Încă nu există evaluări

- Achieving Optimum Performance Using Continuously Variable TransmissionDocument20 paginiAchieving Optimum Performance Using Continuously Variable TransmissionAnurag Singh PatelÎncă nu există evaluări

- Ece R66Document61 paginiEce R66Anurag Singh PatelÎncă nu există evaluări

- Ece R94Document77 paginiEce R94Anurag Singh PatelÎncă nu există evaluări

- Ece R66Document61 paginiEce R66Anurag Singh PatelÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Random Songs + Ukelele ChordsDocument9 paginiRandom Songs + Ukelele ChordsLourd Bonilla Tandayag100% (1)

- Song of Sorrow MSU VERZIJA - Drum SetDocument4 paginiSong of Sorrow MSU VERZIJA - Drum SetMakMurtićÎncă nu există evaluări

- New York Bus MapDocument1 paginăNew York Bus MapSzabÎncă nu există evaluări

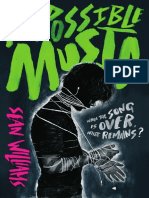

- Impossible Music by Sean Williams ExtractDocument16 paginiImpossible Music by Sean Williams ExtractAllen & UnwinÎncă nu există evaluări

- F-16b Pacer AircraftDocument91 paginiF-16b Pacer Aircraftbmccune7187Încă nu există evaluări

- Yann Tiersen - Comptine D'un Autre Été PDFDocument2 paginiYann Tiersen - Comptine D'un Autre Été PDFkinÎncă nu există evaluări

- Happy Brass QuintetDocument11 paginiHappy Brass QuintetadripetÎncă nu există evaluări

- SRKDocument1 paginăSRKhardikÎncă nu există evaluări

- J.A.Keene - The Influence of Jazz Harmony and Jazz Style On Selected Bass Trombone Solo LiteratureDocument75 paginiJ.A.Keene - The Influence of Jazz Harmony and Jazz Style On Selected Bass Trombone Solo LiteratureAndrea PiergentiliÎncă nu există evaluări

- TNPM IbmDocument6 paginiTNPM IbmAadil KashanÎncă nu există evaluări

- OneForFive Baseball Scorecard v15 8Document1 paginăOneForFive Baseball Scorecard v15 8JasonÎncă nu există evaluări

- Khatib Dissertation FinalDocument193 paginiKhatib Dissertation FinalMonalisa MohantyÎncă nu există evaluări

- XXXXXXXXXXXXXXXXDocument4 paginiXXXXXXXXXXXXXXXXANGEL ALFONSO NAVARRO LA ROSAÎncă nu există evaluări

- Arriflex 416: Quiet, Bright and LightDocument24 paginiArriflex 416: Quiet, Bright and Lightggtd4553t6gbÎncă nu există evaluări

- Service Manual: ZS-SN10Document50 paginiService Manual: ZS-SN10boroda2410Încă nu există evaluări

- W5 20190214 Group1 MatlabreportDocument18 paginiW5 20190214 Group1 MatlabreportVõ Hoàng ChươngÎncă nu există evaluări

- IPC HDBW4431E ASE 28 - EngDocument3 paginiIPC HDBW4431E ASE 28 - EngAle isÎncă nu există evaluări

- Noise Generation in Dynamic Wireless Power TransferDocument4 paginiNoise Generation in Dynamic Wireless Power TransferChristian DavidÎncă nu există evaluări

- We Don't Talk About Bruno: Lin-Manuel MirandaDocument2 paginiWe Don't Talk About Bruno: Lin-Manuel MirandaTravis Mc Dowall100% (1)

- 5Y18 Hitachi CDH29GFS12-Service ManualDocument45 pagini5Y18 Hitachi CDH29GFS12-Service ManualVicente MalvicaÎncă nu există evaluări

- Impressionism Sheet Easy UpdatedDocument3 paginiImpressionism Sheet Easy Updatedmarkrwinn7287Încă nu există evaluări

- The Rocky Horror Picture Show - ScriptDocument44 paginiThe Rocky Horror Picture Show - ScriptFranky Waffles100% (1)

- Manuale HP LP2475w PDFDocument55 paginiManuale HP LP2475w PDFElia ScagnolariÎncă nu există evaluări

- Top 200 Dance Hits of The 80'sDocument4 paginiTop 200 Dance Hits of The 80'sHoracio MarmotoÎncă nu există evaluări

- La Festa Del Poble - Pasodoble MoriscoDocument18 paginiLa Festa Del Poble - Pasodoble MoriscoMateo Gutiérrez GarcíaÎncă nu există evaluări

- Ohmega Resistors For PWBs Recent Development in Lead Free A PDFDocument15 paginiOhmega Resistors For PWBs Recent Development in Lead Free A PDFEliel PoggiÎncă nu există evaluări

- Don't Think Twice, It's All RightDocument1 paginăDon't Think Twice, It's All RightFabio Valentino100% (1)

- FTTH Materials Comparison Rev1Document1 paginăFTTH Materials Comparison Rev1Victor EstomoÎncă nu există evaluări

- SJP Virtually Schedule Defo Final 2020Document1 paginăSJP Virtually Schedule Defo Final 2020The Journal of MusicÎncă nu există evaluări

- Smart CareDocument47 paginiSmart CareEudes Salvador PintadoÎncă nu există evaluări