Documente Academic

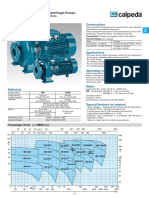

Documente Profesional

Documente Cultură

1 s2.0 S0141029611002173 Main

Încărcat de

Arjun Kisan ShendeDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 s2.0 S0141029611002173 Main

Încărcat de

Arjun Kisan ShendeDrepturi de autor:

Formate disponibile

Engineering Structures 33 (2011) 33173328

Contents lists available at SciVerse ScienceDirect

Engineering Structures

journal homepage: www.elsevier.com/locate/engstruct

Development of passive viscoelastic damper to attenuate excessive

floor vibrations

I. Saidi

a,

, E.F. Gad

a,b

, J.L. Wilson

a

, N. Haritos

b

a

Faculty of Engineering and Industrial Sciences, Swinburne University of Technology, Australia

b

Department of Civil and Environment Engineering, Melbourne University, Australia

a r t i c l e i n f o

Article history:

Received 27 July 2009

Received in revised form

3 May 2011

Accepted 12 May 2011

Available online 28 July 2011

Keywords:

Floor vibrations

Viscoelastic materials

Tuned mass dampers

a b s t r a c t

Recent changes in the construction of building floors have included the use of light material composite

systems and long span floor systems. Although these changes have many advantages, such floor systems

cansuffer fromexcessive vibrationdue to humanactivities. This problemis exacerbatedinoffice buildings

due to the reduction in inherent damping associated with modern fit outs. Excessive floor vibrations are

often realised after the completion of construction or following structural modifications and normally

arise due to inadequate knowledge of the damping values in the design process. Thus rectification

measures are normally required to reduce floor accelerations. This paper proposes a new innovative

passive viscoelastic damper to reduce floor vibrations. This damper canbe easily tunedto the fundamental

frequency of the floor and can be designed to achieve various damping values. The paper discusses the

analytical development of the damper withexperimental results presentedona prototype to demonstrate

its effectiveness.

Crown Copyright 2011 Published by Elsevier Ltd. All rights reserved.

1. Introduction

Building floors are subjected to dynamic loads from people

when they walk, run, dance or engage in aerobics activities. Such

excitation forces cannot be easily isolated from the structure and

they occur frequently [1]. Typical pacing rates for walking are

between 1.6 and 2.4 Hz (slow to fast walk) whilst for jogging

the rate is about 2.5 Hz and running occurs at rates up to about

3 Hz.

Although the excitation from pedestrians is dominated by the

pacing rate, it also includes higher harmonic components with

frequencies corresponding toaninteger multiple of the pacing rate.

Since annoying vibration amplitudes are caused by a coincidence

of the natural frequency of the floor (f

1

) with one of the harmonics

of the walking excitation, the problem may be avoided by keeping

these frequencies away fromeach other. For this reason, engineers

may aim to design floor systems to have a fundamental frequency

greater than three times the walking frequency (i.e. above about

6 Hz) [2]. This is a simple and effective approach for design but

it does not necessarily guarantee acceptable floor performance

since it does not take account of damping. Indeed composite

floors with very low damping (2%), can experience high levels

of vibration even if their fundamental natural frequency is above

7.5 Hz [3].

Corresponding author.

E-mail address: isaidi@swin.edu.au (I. Saidi).

The reaction of people who experience floor vibration depends

on the activity they are engaged in, as reflected in the commonly

used acceptance criteria as illustrated in Fig. 1. For example, offices

and residences are normally designed to have a maximum peak

acceleration of about 0.5% gravity (g) whereas pedestrian bridges

can be designed for acceleration levels 10 times greater (5% g) [4].

In addition to acceleration amplitude, peoples perception is also

affected by the characteristics of the vibration response including

frequency and duration [1]. Comfort studies for automobiles

and aircraft have found that humans are especially sensitive to

vibration in the frequency range of 48 Hz. This is explained by

the fact that many organs in the human body resonate at these

frequencies [5] whilst outside this frequency range, people accept

higher vibration acceleration levels [4] as shown in Fig. 1.

There are several design models for predicting the maximum

response of a floor due to walking excitation. One of the most

commonly used method is that documented in the American

Institute of Steel Construction Design Guide 11 (AISC DG11) [5,4].

This is the most popular method used by Australian designers.

This method is based on reducing the floor structure to a Single

Degree of Freedom(SDOF) system. The peak acceleration response

is calculated using Eq. (1) (the full derivation of this expression can

be found in [4]).

a

p

g

=

P

0

Exp(0.35f

1

)

1

W

(1)

where a

p

/g is estimated peak acceleration in units of gravity

acceleration (g), f

1

is the fundamental frequency of the floor

0141-0296/$ see front matter Crown Copyright 2011 Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.engstruct.2011.05.017

3318 I. Saidi et al. / Engineering Structures 33 (2011) 33173328

Fig. 1. Acceptance criteria for floor vibrations.

structure, P

0

is a constant force based on a persons weight and

taken as 0.29 kN,

1

is the damping ratio of the floor and W is

the effective weight of the floor which oscillates because of the

walking. The a

p

/g value has to satisfy the values in Fig. 1 for

satisfactory performance.

Other methods for calculating the floor peak response and as-

sessing the performance include the recently published European

Commission guide [68]. In this method, the total damping of the

floor is taken as the sumof contributions fromstructural damping,

furnishing and finishes. Similar to the AISC DG11, this method di-

rectly relates the peak response to the total damping which has to

be assumed during the design phase. However, damping in prac-

tical structures is seldom fully understood as it cannot be deter-

mined directly based on the structural properties, as is the case for

stiffness and mass. Damping is generally determined based on ex-

perimental and historical data. Therefore, in applying assessment

methods design engineers have to estimate the damping based on

available knowledge during the design phase. However, the de-

signers in many cases may not knowthe details of the fit out which

are specified by the client or architect. Consequently, overestima-

tion of damping or altering the fit out of the floor can lead to ex-

cessive vibrations.

2. Control of floor vibrations

There are a fewremedial options available to rectify a floor with

excessive levels of vibration, including increasing the stiffness and

hence the frequency or increasing the damping. The installation

of tuned mass dampers can be performed more cheaply than

structural stiffening, and often offer the only practical means of

vibration control in existing structures [9]. In new constructions

viscoelastic materials can be incorporated within the floor system

to increase its damping. Both embedded viscoelastic materials and

tuned mass dampers represent typical passive damping options

whilst more sophisticatedandexpensive solutions may include the

addition of active dampers.

2.1. Viscoelastic materials

Embedded viscoelastic materials (VEM) offer the advantage of

reducing vibrations over a broad range of frequencies compared

with TMDs. However, viscoelastic damping works optimally only

Fig. 2. Illustration for Resotec product in composite floor (after [11]).

for a specific mode of vibration. Nevertheless use of VEMs is a

cheap method of increasing the damping if incorporated during

construction [10].

An example of viscoelastic damping is the Resotec system

which is illustrated in Fig. 2. This product comprises a thin layer

of high-damping viscoelastic material with an overall thickness

of about 3 mm. Resotec is sandwiched between the top flange of

the floor steel beams and concrete slab for a proportion of the

beam near each end where the shear stresses are the greatest. It is

reported that the damping of a fitted out floor is typically doubled

by the incorporation of Resotec [11]. However, this product needs

to be incorporated within the floor during construction and is not

suitable as a rectification measure.

2.2. Tuned mass dampers (TMD)

The principle of a TMD was initially utilised when Den Hartog

in 1947 reintroduced the dynamic absorber invented by Frahm in

1909 [1214]. Generally, a TMD consists of a mass, spring, and

dashpot and is tuned to the natural frequency of the primary

system. When the primary system begins to oscillate it excites

the TMD into motion and hence the TMD absorbs energy from

the vibrating floor [15]. The TMD inertia forces produced by this

motion are anti-phase to the excitation force. The first use of a TMD

for floor vibration application was reported by Lenzen [16] who

used small TMDs with a total mass of about 2% of the floor mass.

The TMDs were made of steel hung by springs and dashpots from

the floor beams. Lenzen reported floors with annoying vibration

characteristics became satisfactory by tuning the TMDs to a natural

frequency of about 1.0 Hz less than that of the floor and using

a damping ratio of 7.5% [17]. An example of a more recent TMD

is a Pendulum Tuned Mass Damper (PTMD) shown in Fig. 3.

Experiments were undertakento test the performance of the PTMD

and it is reported that the damper reduced the floor vibrationin the

range of 50%70% [17].

Floor vibrations due to walking excitation typically produce

very small floor displacements which are generally less than

0.1 mm. A TMD would typically have a maximum displacement

around ten times larger than the floor (i.e. in the order of 1 mm).

In reality, it is difficult to produce a practical viscous damper

that provides a reasonable level of damping given this very

small displacement. Viscous dampers were used in some floor

applications such as in the Terrace on the Park building in New

York (1992). This problematic floor was cantilevered with a low

natural frequency of 2.3 Hz and responded to footfall vibrations

with 7% g acceleration and 3.3 mm maximum displacement. In

this application the damper used was large and extended fromthe

lower floor to the point of maximum response of the problematic

floor. Indeed such access is not always available for office floors.

Other applications for viscous TMDcanbe foundinstadia. However

such structures tend to have long span cantilevers with larger

displacements associated with crowd activities especially from

I. Saidi et al. / Engineering Structures 33 (2011) 33173328 3319

Fig. 3. Pendulum tuned mass damper for floor vibrations (after [17]).

concerts. Therefore viscous dampers can be effective in these cases

due to the large motion associated with vibrations and in turn

energy can be dissipated through their typical dashpot systems.

For floor retrofitting applications there are usually physical

limitations associated with access and presence of mechanical

services attached to the soffit of the slab and beams. Hence for a

floor damper to be practical, it needs to be sufficiently small to

be accommodated in the available ceiling space and it should also

allowfor easy adjustment of frequency for tuning. Given the above

mentioned limitations, an alternative novel viscoelastic damper

specifically for floor vibration is proposed in this paper.

3. Fundamentals of a tuned mass damper

In floor design, it is common to idealise the floor as a single

degree of freedom (SDOF) system. A floor can be represented with

an equivalent mass (m

1

), stiffness (k

1

) and damping (c

1

) by a

SDOF system as shown in Fig. 4. The maximum response occurs

when the frequency of the excitation force coincides with the

natural frequency of the system, hence the maximumacceleration

response is given by Eq. (2) [18]:

|

X

1

| =

F

0

2

1

m

1

. (2)

The addition of a TMD converts the floor into a two degrees of

freedomsystemas illustrated in Fig. 5. In such a systemthe damper

mass (m

2

) and its spring stiffness (k

2

) are tuned so that the TMD

has the same natural frequency as the primary (floor) system.

The addition of damping (c

2

) to the TMD reduces the overall

response of the combined system as shown in Fig. 6. One method

to assess the efficiency of the TMD is to compare the response of

the original SDOF system and the two degrees of freedom system.

The formulation of response of a generic two degrees of freedom

system is presented in Section 3.2.

TMDs are typically effective over a narrow frequency band and

must be tuned to a particular natural frequency. They are not

effective if the structure has several closely spaced frequencies and

they can potentially increase the vibration if they are off-tuned

[9]. A TMD splits the natural frequency of the primary system

into a lower (f

1

) and higher frequency (f

2

) as shown in Fig. 6. If

there is zero damping then resonance occurs at the two undamped

resonant frequencies of the combined system (f

1

& f

2

). The other

extreme case occurs when there is infinite damping, which has the

effect of locking the spring (k

2

). In this case the system becomes

one degree of freedomwithstiffness of (k

1

) anda mass of (m

1

+m

2

).

Using anintermediate value of damping suchas optimumdamping

(

opt

), it is possible to control the vibration of the primary system

Fig. 4. Schematic of an SDOF system.

Fig. 5. Schematic of a two DOF system.

Fig. 6. Example showing the effects of attaching a TMD to an SDOF system.

over a wider frequency range [19]. In the optimum damper the

values of the dampers natural frequency and damping ratio (

opt

)

are specified to obtain minimum and equal height peaks at f

1

&

f

2

[20].

3.1. Properties of an optimum damper

The first step in the design of a TMD is to determine the desired

mass ratio () as defined by Eq. (3):

=

m

2

m

1

. (3)

The larger the mass of the damper (m

2

) the larger the separation

between the two new frequencies (f

1

& f

2

in Fig. 6) which

are created by the damper. This would normally increase the

effectiveness of the damper over a broader range of frequencies

and also decreases the vibration level of the primary system.

3320 I. Saidi et al. / Engineering Structures 33 (2011) 33173328

However, there are normally some structural and physical

limitations on the size of the damper and its mass. For most

practical cases a mass ratio of 0.010.02 is recommended.

The optimumnatural frequency of the damper (f

2

) is defined by

Eq. (4):

f

2

=

f

1

1 +

(4)

where f

1

is the natural frequency of the primary system, which can

be obtained from Eq. (5):

f

1

=

1

2

_

k

1

m

1

. (5)

The optimum damping ratio of the damper

2

=

opt

(is where

response peaks at f

1

& f

2

are equal) can be found using Eq. (6) [13]:

2

=

_

3

8(1 + )

. (6)

3.2. Response of retrofitted system

To determine the response of the two DOF system, the equation

of motion as expressed in Eq. (7) needs to be solved. The values of

m

2

, k

2

and

2

of the damper are obtained from optimum damper

equations (3)(6).

_

m

1

0

0 m

2

_ _

x

1

x

2

_

+

_

c

1

+ c

2

c

2

c

2

c

2

_ _

x

1

x

2

_

+

_

k

1

+ k

2

k

2

k

2

k

2

_ _

x

1

x

2

_

=

_

F

1

(t)

0

_

(7)

where c

1

= 2

1

k

1

m

1

and c

2

= 2

2

k

2

m

2

.

Eq. (7) consists of two coupled second-order ordinary differen-

tial equations. There are several approaches to solve this equation,

and a convenient method of solving this system is to use vectors

and matrices. This method requires the damping matrix to satisfy

Eq. (8). Otherwise for the case of arbitrary damping one of two

options needs to be considered. The first is to assume the modal

damping based on experience and the second is to convert the

damping matrix to a proportional damping model using a propor-

tional method [21].

[C] =

1

[M] +

2

[K] (8)

where [C], [M] and K are damping, mass and stiffness matrices

respectively, and

1

&

2

are mass and stiffness multipliers

respectively.

The two splitting frequencies (f

1

& f

2

) in Fig. 6 can be calculated

using Eq. (9) (see Box I) [22].

The response acceleration of the primary system|

X

1

| can be found

by solving Eq. (7) using the Mechanical Impedance Method (x

1

=

X

1

e

it

, x

2

= X

2

e

it

and F

1

(t) = F

0

e

it

), resulting in the expression

presented by Eq. (10) (see Box II):

The system resonates at both splitting frequencies and the

maximumacceleration can be calculated using Eq. (10) (see Box II)

by substituting either = 2f

1

or = 2f

2

as obtained from

Eq. (9) (see Box I).

4. Equivalent viscoelastic damper

In Section 3 of the paper, the required properties of a typical

viscous TMD to dampen floor vibration are discussed. From

Section 3, the values of classical mass, spring stiffness and dashpot

Fig. 7. Typical sandwich beam.

are determined. In this section of the paper, the equivalent

properties are developed for a viscoelastic TMDrather than viscous

TMD. The proposed viscoelastic TMD is in the form of a cantilever

beam with a sandwiched rubber layer.

The use of viscoelastic materials in reducing the effect of

vibrations is common in mechanical engineering applications

especially in machine vibration. Recently it also became a solution

for floor vibrations as illustrated in Fig. 2. Indeed an effective

way to increase damping and reduce transient and steady state

vibration is to add a layer of viscoelastic material, such as rubber,

to an existing structure. The combined systemwould have a higher

damping level and thus reduces unwanted vibration [23].

The simplest form of a viscoelastic damper is a constrained

viscoelastic layer ina beam. This couldbe made of two constraining

metal plates bonded together with high damping rubber. In this

composite sandwich beam, the viscoelastic material experiences

considerable shear strain as it bends, dissipating energy and

attenuating vibration response [24]. The proposed damper in this

paper has the form of a sandwich beam.

There are many factors which affect the damping performances

of viscoelastic materials in sandwich beams including material

type, thickness, temperature and bonding. The viscoelastic damper

proposed in this paper is for internal use so variation in the

temperature is not significant. The resinusedfor bonding the layers

can be easily designed so that it does not allowa slip to occur at the

interfaces of the layers. Hence the two mainremaining factors to be

taken into account for the design of the damper are the viscoelastic

material type and thickness.

In order for the viscoelastic sandwich beam (as shown in

Fig. 7) to be used as a damper its natural frequency and damping

need to be estimated. There are two methods for obtaining a

solution, normally, an exact solution and an approximate method

as discussed below.

4.1. Exact solution

The equation of motion for sandwich beams has been consid-

ered by a number of researchers. Kerwin [25] analysed the three

layer system and derived an expression for flexural stiffness of

sandwich beams DiTaranto [26] derived a sixth order differential

equation governing the motion of sandwich beams. In contrast,

Eq. (11) was derivedby MeadandMarkus [27] for a sandwichbeam

with arbitrary boundary conditions subjected to forced vibration.

The solution of Eq. (11) is complex as it involves solving a sixth

order differential equation. This solution can be complicated fur-

ther by boundary conditions such as the addition of an end mass to

the tip of the cantilever. Classical exact solutions are discussed by

Mead and Markus [28,29].

W

vi

n

g

(1 + j) (1 + Y) W

iv

n

2

n

(1 + j

n

)

_

A

D

t

_

_

W

ii

n

g

W

n

(1 + j)

_

= 0 (11)

I. Saidi et al. / Engineering Structures 33 (2011) 33173328 3321

f

1,2

=

1

2

_

m

1

k

2

+ m

2

(k

1

+ k

2

)

_

[m

1

k

2

+ m

2

(k

1

+ k

2

)]

2

4k

1

k

2

m

1

m

2

2m

1

m

2

(9)

Box I.

|

X

1

| =

2

F

0

_

2

c

2

2

+ (k

2

2

m

2

)

2

2

_

c

2

k

1

+ c

1

k

2

2

(c

1

m

2

+ c

2

(m

1

+ m

2

))

_

2

+

_

k

1

k

2

(c

1

c

2

+ k

1

m

2

+ k

2

(m

1

+ m

2

))

2

+ m

1

m

2

4

_

2

(10)

where F

0

is the excitation force and is the excitation force circular frequency.

Box II.

where W, n, g

, , Y, , , , A and D

t

are mode shape function,

mode number, shear parameter, viscoelastic material loss factor,

geometric parameter, circular natural frequency, overall dissipa-

tion loss factor, density, cross-sectional area of the beamand flexu-

ral rigidity of the constraining layers respectively, while j =

1.

Eq. (11) is based on the following realistic assumptions related

to the behaviour of the damper:

(i) the viscoelastic core resists shear but not direct flexural stress;

(ii) shear strains in the constraining plates are negligible;

(iii) transverse direct strains in both core and constraining plates

are neglected; and

(iv) no slip occurs at the interfaces of the core and constraining

plates.

4.2. Approximate analytical method

In this alternative approximate analytical method developed by

Mead [30], the flexural rigidity EI

total

and the overall dissipation

loss factor of the composite system are estimated based on

the dissipation loss factor of the viscoelastic material , thickness

of viscoelastic layer, geometric parameters and Young moduli of

the top and bottom plates constraining the viscoelastic material.

This method can be applied to any composite beam configuration

such as simply supported or cantilever beams as illustrated in the

following subsections.

4.2.1. Flexural rigidity (EI

total

) of viscoelastic cantilever beam

The flexural rigidity EI

total

of the viscoelastic cantilever beamcan

be calculated using Eq. (12) together with Eqs. (13)(15) [30];

EI

total

=

_

1 +

g

Y(1 + g

(1 +

2

))

1 + 2g

+ g

2

(1 +

2

)

_

_

E

1

I

1

+ E

3

I

3

_

(12)

where is the dissipation loss factor of the rubber and Y is a

geometric parameter calculated using Eq. (13):

Y =

(E

1

A

1

)(E

3

A

3

)d

2

(E

1

A

1

+ E

3

A

3

)(E

1

I

1

+ E

3

I

3

)

(13)

E

1

and E

3

are the moduli of elasticity of the top and bottom

constraining plates, A

1

and A

3

are the cross-sectional area of the

top and bottom constraining plates, I

1

and I

3

are the moment of

inertia of top and bottom constraining plates about their neutral

respective axes and d is the distance between their respective

centroids.

The shear parameter g

is calculated using Eq. (14):

g

=

Gb

h

2

K

2

B

_

1

E

1

A

1

+

1

E

3

A

3

_

(14)

where G, b and h

2

are shear modulus, width and thickness of the

viscoelastic core respectively and K

B

is the wave number of the

beam.

When the core shear stiffness is very low, the constraining

layers dominate the flexural stiffness of the beamandthe sandwich

beam vibrates in the same mode as a EulerBernoulli beam [27].

The wave number for a cantilever sandwich beam without an

end mass can be calculated using Eq. (15) [23]:

K

B

= 1.875/L (15)

where L is the length of the viscoelastic cantilever beam.

4.2.2. Viscoelastic cantilever beam with an end mass

The mass of the damper for a given mass ratio must satisfy

Eq. (3). Therefore, an end mass would normally be required to

attain the mass ratio of the optimum damper.

The natural frequency of a viscoelastic cantilever beamdamper

can be estimated as:

f

2

= 2

_

k

2

m

2

(16)

where k

2

and m

2

are the effective stiffness and effective mass of

the cantilever beam respectively.

The stiffness k

2

can be calculated based on basic beamtheory as

shown in Eq. (17):

k

2

=

3EI

total

L

3

(17)

where EI

total

and L are the flexural rigidity obtained from Eq. (16)

and the length of the viscoelastic cantilever beamrespectively. The

effective mass of a uniform viscoelastic cantilever beam can be

calculated from Eq. (18):

m

2

=

33

140

AL + m

end

(18)

where and A are total mass density and total cross-sectional area

of the viscoelastic cantilever beamrespectively and m

end

is the end

mass. The addition of an end mass at the free tip of the cantilever

allows easy adjustment of the mass ratio and fundamental

frequency of the damper in order to achieve optimum design.

The addition of the end mass will change the wave number as a

result of corresponding change in the system natural frequency as

shown in Eq. (19) [30,31]:

K

2

B

= 2f

2

_

A

EI

total

(19)

where and A are mass density and overall cross-sectional area of

the sandwich beam, respectively.

Substitution of Eq. (19) into Eq. (14) yields:

g

e

=

Gb

2h

2

f

2

_

EI

total

A

_

1

E

1

A

1

+

1

E

3

A

3

_

(20)

where g

e

is the shear parameter for the viscoelastic cantilever beam

with end mass.

3322 I. Saidi et al. / Engineering Structures 33 (2011) 33173328

Finally, the overall dissipation loss factor of the viscoelastic

damper (viscoelastic cantilever sandwich beam) can be estimated

using Eq. (21). The dissipation loss factor is equal to two times the

critical damping ratio of the damper , and is directly proportional

to the material dissipation loss factor .

= 2 =

g

e

Y

1 + g

e

(2 + Y) + g

2

e

(1 + Y)(1 +

2

)

. (21)

4.3. Design of viscoelastic damper

Having developed a mathematical solution for determining the

dynamic properties of the viscoelastic damper, a simple procedure

for the design of an optimum damper can now be specified as

follows.

(i) Determine the basic dynamic properties of the primary

system (floor) to be retrofitted with a damper (i.e. f

1

,

1

and

k

1

for an equivalent SDOF system). The properties are to be

based on the as built conditions.

(ii) Determine a suitable mass ratio (Eq. (3)) for the damper

based on given physical limitations and the required

reduction in the response of the primary system. Amass ratio

of 1%2% is practical in most cases.

(iii) The optimum natural frequency of the TMD, f

2

, can be

calculated using Eq. (4).

(iv) The optimum damping ratio of the damper

2

can now be

calculated using Eq. (6).

(v) Trial dimensions for the damper can be proposed to suit

any physical limitations (i.e. h

1

, h

2

, h

3

, L and b illustrated

in Fig. 7). In addition, the material properties for the

constraining layers and viscoelastic material need to be

specified (E

1

& E

3

for the constraining layers and & G for

the viscoelastic material). For simplicity the top and bottom

layers can be of the same material (i.e. E

1

= E

3

).

(vi) Calculate the overall flexural rigidity (EI

total

) of the beam

without an end mass using Eqs. (12)(15).

(vii) Calculate the natural frequency of the damper with an end

mass using Eqs. (16)(18). The damper frequency is critical

in reducing the overall floor vibrations and the end mass can

be used to fine tune the damper frequency.

(viii) Calculate the overall dissipation loss factor and then the

estimated damping ratio

2

of the damper using Eqs. (12),

(20) and (21).

This procedure is required to be repeated by altering the

material and dimensions of the viscoelastic damper until the

optimum damper properties are achieved.

One of the main factors that affect the performance of a

viscoelastic damper is the material dissipation loss factor . This

material property needs to be established for the type of rubber to

be used which is discussed in the following section.

5. Determination of viscoelastic material properties

Many types of commercially available rubbers do not have ad-

equate technical specifications concerning their material proper-

ties and consequently it becomes necessary to undertake specific

tests on the acquired rubber to determine the shear modulus G and

loss factor . This can be achieved using one of two types of tests,

(i) by direct measurements using a Dynamic Mechanical Analyser

(DMA) [32,33] or (ii) by back calculation from experimental re-

sults performed on a prototype damper. These methods were both

utilised to find the properties of the rubber used in developing the

viscoelastic cantilever damper proposed in this paper.

Dynamic mechanical analysis is a testing technique that

measures the mechanical properties of materials as a function

of time, temperature and frequency. In DMA testing, a small

deformation is applied to a sample in a cyclic manner with

the measured response providing information on the stiffness

and damping properties for the material. For the rubber used in

developing the damper presented in this paper, three samples

measuring 35 10.8 5.2 mm were tested. The average loss

factor () was 0.12 and the average measured shear modulus (G)

was 690 kPa based on the assumption that E = 3G for elastomeric

materials [31].

The rubber dissipation loss factor can also be back calculated

from vibration tests if access to a Dynamic Mechanical Analyser is

not available. This method requires the construction of a prototype

sandwich beam damper with the designed rubber. This is then

tested to obtain the overall damping ratio of the damper (

2

) and

the total flexural rigidity (EI

total

) frombasic vibration testing. These

two measured properties along with the geometric parameters

and other material properties of the damper are substituted into

Eqs. (12)(21) to back calculate the and G values of the rubber.

The flexural rigidity EI

total

can be obtained from the measured

natural frequency using Eqs. (16)(18). The damping ratio

2

of

the viscoelastic beam can be estimated from the time domain of

the excited viscoelastic beam using the Logarithmic Decrement

Method (LDM). As a comparison, based on this back calculation

method the estimated average values of Gand of the rubber were

found to be 640 kPa and 0.10 respectively which were in very good

agreement with the values of 690 kPa and 0.12 obtained from the

DMA test.

It should be noted that the dissipationloss factor of the rubber

is the factor that determines the upper limit of overall dissipation

loss factor of the composite system. In other words, the value

(=2 ) of the composite system cannot exceed the value of the

rubber [33,31].

6. Validation of damper properties

The analytical model described in Section 4.2 for determining

the viscoelastic dynamic properties of the damper was then

validated by experimental testing as well as by comparison with

finite element (FE) results.

6.1. Experimental test

Two prototype viscoelastic cantilever dampers of length 500

and750mmwere constructedwithout anendmass andtwo others

with an end mass. For all four dampers, the constraining layers

were 1 mm thick steel plates and the rubber core was either 12 or

32 mm thick. Tables 1 and 2 show the details of the four dampers

along with their predicted fundamental frequency and damping

ratio. The rubber loss factor and shear modulus were obtained

using a Dynamic Mechanical Analyser (DMA) machine discussed

in Section 5. Each cantilever was fixed at one end to a rigid support

and subjected to pluck tests. A non-contact accelerometer was set

to measure the time domain response of the excited viscoelastic

cantilever beam. Using the recorded response time history, the

damping ratio was calculated using the log decay method while

the natural frequency was obtained from Fast Fourier Transform

(FFT) analysis.

One of the key influencing properties of the damper is its natural

frequency as this affects its performance as a TMD. As can be seen

from Tables 1 and 2, the approximate analytical model predicted

the natural frequency well with an average error of approximately

8%. The error is larger for the cases withendmass due to the greater

approximation for the wave number K

B

in Eq. (19). The average

error in damping ratio between the predicted and measured values

was in the vicinity of 12%.

I. Saidi et al. / Engineering Structures 33 (2011) 33173328 3323

Table 1

Dynamic properties of a damper without an end mass as obtained from analytical model, FE analysis and experimental testing.

Dimensions (mm) Analytical FE model Experiment

h

1

h

2

h

3

b L f

2

(Hz)

2

(%) f

2

(Hz)

2

(%) f

2

(Hz)

2

(%)

1 32 1 25 750 10.2 5.8 9.1 5.5 10.4 4.9

1 12 1 25 500 12.2 5.5 10.6 4.5 12.0 4.5

Table 2

Dynamic properties of a damper with an end mass as obtained from analytical model, FE analysis and experimental testing.

Dimensions (mm) Analytical FE model Experiment

h

1

h

2

h

3

b L f

2

(Hz)

2

(%) f

2

(Hz)

2

(%) f

2

(Hz)

2

(%)

1 32 1 25 750 4.8 5.1 5.1 5.1 5.7 5.3

1 12 1 25 500 4.1 4.8 4.1 4.9 4.6 5.3

6.2. Damper FE models

For the FE modelling, the commercially available software

package ANSYS was used. The constraining layers and rubber core

were modelled with solid elements. The constraining layers were

assumed to be linear elastic, while the rubber layer was assumed

to be hyperelastic. Modal analysis was performed using ANSYS

to obtain the vibration natural frequencies and corresponding

mode shapes. The damping was modelled for each material as a

stiffness multiplier. In addition to the modal analysis, harmonic

and transient dynamic analyses were performed so that the

performance of the damper could be investigated in both the time

and frequency domains.

The overall damping of the damper was obtained from the

FE analysis using the conventional methods of logarithmic decay

in the time domain and the half power bandwidth method in

the frequency domain. The damping values from the FE analyses

obtained from the two methods were in very good agreement.

Logarithmic decay values are presented in Tables 1 and 2 for both

the FE model and the experimental tests. The FE results for both

frequency and damping are in good agreement with analytical

and experimental results. This indicated that the approximate

analytical method for determining the damper properties can be

used with confidence. Furthermore, FE models can also be utilised

for determining damper properties with good accuracy.

7. Application of viscoelastic TMD

Prototypes of the proposed viscoelastic damper were con-

structed to demonstrate the application of the new damper and

illustrate its efficiency. Furthermore, sensitivity analyses were per-

formed to examine the performance of the damper if it were not to

have optimum properties.

Two case studies are presented below which cover both

experimental and analytical work.

7.1. Case study 1steel beam

This case study is for a 3 m long simply supported steel beam

having properties as shown in Table 3. This beam was initially

tested as a bare beam. The beam was then retrofitted with a

viscoelastic cantilever damper as shown in Fig. 8 with a mass ratio

of 1%. The aim of these tests was to examine the effectiveness of

the designed viscoelastic cantilever damper.

7.1.1. Bare steel beam test

The effective mass and natural frequency of the steel beam

were calculated using standard classical expressions for simply

Table 3

Simply supported steel beam properties for Case Study-1.

Length (mm) 3000

Width (mm) 100

Thickness (mm) 25

Natural Frequency f

1

(Hz) 6.3

Damping ratio

1

0.3%

supported beams. The total mass of the steel beam was approxi-

mately 59 kg, hence the effective mass of the beam is 29.5 kg (50%

of the total mass) and the stiffness of the beam can be calculated

using Eq. (22) [34]:

K =

6144EI

125L

3

. (22)

The natural frequency of the steel beam was obtained as 6.3 Hz

using Eq. (5).

In order to measure the natural frequency and the damping

ratio of the steel beam experimentally, the bare beam was

subjected to pluck tests to record the free vibration of the steel

beam. The natural frequency of the steel beam was then extracted

from the time history using the Fast Fourier Transform technique.

It was found that the natural frequency was in excellent agreement

with value obtained fromEq. (5). The damping ratio obtained from

the pluck tests using the log decay method was about 0.3%.

Harmonic excitation was imposed using a mechanical shaker

located at a distance of about one third of the span from one of

the ends to measure the maximumresponse of the steel beam. The

response of the steel beamdue tothis excitationinthe time domain

is shown in Fig. 9.

7.1.2. Retrofitted steel beam test

The optimum damper properties were obtained from Eqs. (3)

(6) and a viscoelastic damper was designed according to the

procedure outlined in Section 4.3. The damper was attached at

the mid-span of the simply supported beam using a rigid bracket.

The mass, stiffness, and damping properties of the cantilever were

tuned to satisfy the optimum design, with the properties listed in

Table 4 including

opt

= 6%. It should be noted that the bending

moment due to additionof the damper at the mid-spanof the beam

is negligible because it just produces an additional moment of

about 1% of the bending moment produced by the primary system.

The responses of the bare and retrofitted beam were predicted

fromEqs. (2) and (10) (see Box II for Eq. (10)) using a force of 1 Nas

shown in Fig. 10. The predicted reduction factor fromthe analytical

model was about 12.5.

The bare and retrofitted beams were experimentally tested

with a harmonic excitation using a mechanical shaker located

at a distance of about one third of the span from one of the

ends. Fig. 9 shows the acceleration responses of the bare and

3324 I. Saidi et al. / Engineering Structures 33 (2011) 33173328

Fig. 8. Viscoelastic damper attached to a vibrating beam.

0 10 20 30 40 50 60

0 10 20 30 40 50 60

-4

-2

0

2

4

6

-4

-2

0

2

4

6

Fig. 9. Case Study 1steel beam response with and without damper attached.

Table 4

Viscoelastic damper properties for Case Study 1.

Length (L) 500 mm

Width (b) 25 mm

Thickness of steel top constraining layer (h

1

) 1 mm

Thickness of rubber (h

2

) 12 mm

Thickness of steel bottom constraining layer (h

3

) 1 mm

Dissipation loss factor of rubber () 0.12

Rubber shear modulus 690 kPa

End mass (m

end

) 220 g

Natural frequency of damper (f

2

) 6.2 Hz

Damping ratio (

2

) of damper 5.4%

Fig. 10. Steel beamresponse in the frequency domain (Eqs. (2) and (10)) (see Box II

for Eq. (10)).

the retrofitted beams. It is clear that the response of the beam

is reduced by a factor of 10 which is in good agreement with

the predicted reduction factor of about 12.5. The overall damping

of the retrofitted system was estimated using the half power

bandwidth method using curve fitting [35] and was found to be

about 3%, which is a significant increase from the original 0.3%

damping.

7.1.3. Finite element model

The bare steel beam and retrofitted beam with the TMD were

both modelled in ANSYS using the method described in Section 6.2.

The properties of the damper were as built with rubber properties

being the same as described earlier with G = 690 kPa and =

0.12. In order to assess the effects of the damper, a harmonic

excitation was imposed on each beam and the peak response

compared.

The FE results for the cases with and without dampers showed

that the peak acceleration response would be reduced by a factor

of 12 due to the TMD. This reduction factor is in good agreement

with experimental results (reduction factor of 10). This further

demonstrates that an FE analysis can be used for predicting the

performance of the proposed damper which would be particularly

useful for complex floor systems.

7.1.4. Sensitivity analysis

Investigations of the performance of the viscoelastic damper

due to variation in damping ratio, mass ratio and location of the

damper along the steel beam were undertaken analytically and

experimentally.

In order to assess the effectiveness of the damper for when it

does not have the optimum damping value, the damper damping

ratio (

2

) was varied from approximately 1%9%. The optimum

damping value

opt

was calculated earlier to be 6%. Fig. 11 shows

the predicted reduction factor in the acceleration response of the

steel beamfor this range of

2

. It canbe seenthat the damper canbe

quite effective over the range of 4.5%7.5% for

2

. This corresponds

to a variation of approximately 25% from the optimum value.

However, it shouldbe notedthat if the damping ratio of the damper

is not at the optimum the response amplitude at the two split

frequencies (f

1

& f

2

) would not be equal as shown in Fig. 12.

The sensitivity to damper performance of the variation in the

dampers point of attachment along the length of the beam was

investigated as shown in Fig. 13(a). The study indicates that the

damper would remain effective in reducing the vibration if it is

located within the central one third of the length of the beam.

Another experimental sensitivity analysis was performed to in-

vestigate the effect of variation of the damper end mass and hence

damper frequency on the system response. The experimental re-

sults are summarised in Fig. 13(b) and clearly show that a varia-

tion in the end mass of up to 20% (10% of the damper frequency)

from the optimum value has little effect on the efficiency of the

viscoelastic damper due to the very low damping of the primary

system. The natural frequency of the damper due to the varia-

tion in the end mass was also calculated using Eqs. (16)(18). It

was foundthat a frequency within10%of the optimumfrequency

does not degrade the effectiveness of the damper.

I. Saidi et al. / Engineering Structures 33 (2011) 33173328 3325

Fig. 11. Calculated response reduction factor for retrofitted steel beamwith a TMD

having different damping ratio (Eq. (10), see Box II).

Fig. 12. Steel beam response with a TMD having different damping ratios when

subjected to harmonic excitation (Eq. (10), see Box II).

7.2. Case study 2reinforced concrete T beam

In order that the effectiveness of the new viscoelastic damper

could be fully assessed another prototype was developed for an

Fig. 14. RC T-beam cross-section.

experimental floor. The experimental floor used in this case study

is essentially a segment of a reinforcedconcrete floor systemwitha

reinforced concrete beam and composite slab. The cross section of

the experimental floor is shown in Fig. 14 and is referred to herein

as a T beam.

7.2.1. Bare reinforced concrete T beam

The T beamhas a span of 9.5 m, a total weight of 6000 kg and is

simply supported at the ends. The long span of the T beam and its

geometry, makes it relatively flexible and easily excited by foot fall

excitation. Hence the T beamwas a prime candidate for retrofitting

using the newly developed viscoelastic damper. Prior to the design

of the damper, the T beam floor was tested using various forms of

excitation including heel drop, walking and impulse loading using

a modal impact hammer. From the tests, the natural frequencies,

mode shapes and damping ratios were determined using modal

analysis. In addition, simpler assessment techniques which would

normally be used in the field such as log decay and half power

bandwidth were used to estimate the apparent overall damping.

Based onthe experimental results it was found that the T beamhad

a fundamental natural frequency of 4.2 Hz, and apparent damping

of 2.9%. The higher than expected damping is simply due to the

presence of cracks in the beam because of earlier load tests.

The reduction in the response of the T beamdue to the addition

of the damper was predicted to be around a factor of 2 using

Eqs. (2) and (10).

7.2.2. Viscoelastic damper design

For a simply supportedbeamwitha uniformly distributedmass,

the effective mass is half of the total mass. Hence, for the equivalent

SDOF system, the effective mass of the T beam can be taken as

3000 kg. For a tuned mass viscoelastic damper, with a mass ratio

Fig. 13. Results from sensitivity analysis for steel beam in Case Study 1: (a) Effect of location of damper along the beam. (b) Effect of change of mass of damper.

3326 I. Saidi et al. / Engineering Structures 33 (2011) 33173328

Fig. 15. Response of T beam due to the variation in damping ratio of the TMD

(Eq. (10)).

Fig. 16. Tuned mass viscoelastic cantilever damper attached to the experimental

T beam.

of 1%, the required mass is 30 kg. Using Eqs. (8)(11) (see Box I for

Eq. (9) and Box II for Eq. (10)) the optimum damper is required to

have a natural frequency of 4.2 Hz and damping ratio of 6%.

A commercial rubber with a dissipation loss factor of 0.15

was used to develop the viscoelastic damper. The geometry and

natural frequency of the damper were obtainedfromEqs. (13)(21)

and the resulting damper properties are listed in Table 5. It should

be noted that the dissipation loss factor of this rubber is not

sufficient to provide the optimum damping ratio of 6% for the

TMD with the given thickness, width and length of the rubber and

plates. A rubber with a higher dissipation loss factor would be

needed to increase the damping (such rubbers can be sourced from

specialist suppliers but are not readily available). However a less

than optimumdamper can still provide a major improvement [36].

The sensitivity of damper performance to the damping ratio was

investigated using Eq. (14) and Fig. 15 shows that the coupled

system is not very sensitive to the damping ratio of the damper

in the range 4.5%7.5% as discussed previously in Section 7.1.4.

The viscoelastic damper was attached to the T beam as shown

in Fig. 16 and tuned to the natural frequency of the optimum

damper. The effectiveness of the damper was thentestedaccording

to the response of the T beam due the heel drop and walking

excitations.

7.2.3. Performance of the damper due to heel drop excitation

Fig. 17 shows the response of the T beam in the frequency

domain due to heel drop excitation for both cases with and without

damper. The value of reduction in the acceleration is about 2.

Table 5

Viscoelastic damper properties for Case Study 2.

Length (L) 510 mm

Width (b) 100 mm

Thickness of top constraining layer (steel) 6 mm

Thickness of rubber (h

2

) 38 mm

Thickness of bottom constraining layer (steel) 6 mm

Dissipation loss factor of rubber () 0.15

Rubber shear modulus 637 kPa

End mass (m

end

) 29 kg

Natural frequency of damper 4.2 Hz

Damping ratio (

2

) of damper 4.5%

Fig. 17. T beam response due to heel drop excitation.

Fig. 18. Time domain decay due to heel drop excitation for cases of T beam with

and without damper.

Fig. 18 clearly shows the increase of damping in the time history

response of the T beam, the overall damping ratio of the T beam

with damper was found to be 6.1% using the logarithmic method.

The bare T beam and the T beam with the attached damper

were also modelled using ANSYS as discussed in Section 6. Based

on the ANSYS results the expected reduction factor acceleration

response was predicted to be 1.9 which is in good agreement with

the experimental reduction factor of 2.

7.2.4. Performance of the damper due to walking excitation

The effectiveness of the damper in reducing the T beam

response due to walking excitation was also investigated in this

experiment. It was found that the reduction factor was about 1.4

as shown in Fig. 19. This apparent reduction in the effectiveness

of the damper for walking excitation compared with heel drop is

due to the fact that the T beam did not reach the full steady state

resonant motion [4].

I. Saidi et al. / Engineering Structures 33 (2011) 33173328 3327

Fig. 19. T beam response due to walking excitation based on averaging of 24

records for each of the two cases.

Fig. 20. Sensitivity of the damper due to variation in its natural frequency by 10%

from the optimum value.

The averaged maximum acceleration of the T beam for 24 time

history samples due to walking excitation was about 3.6% g as

shown in Fig. 19. The maximumacceleration obtained fromEq. (1)

using Design Guide 11 assessment method [4] was about 3.8% g. It

is quite evident that the value of maximum acceleration obtained

from experiment is in good agreement with value obtained from

Eq. (1). Clearly, the damper will perform better if the T beam

were to be excited to full steady state resonance which condition

may not happen in floors for office use. However the damper is

still effective in producing a reasonable reduction in the T beam

response. An option to further reduce the T beam response would

be to specify a higher mass ratio for the damper.

7.2.5. Sensitivity of the damper performance to its natural frequency

and damping ratio of the T beam

In order to assess the sensitivity of the viscoelastic damper to

variation in its natural frequency, the end mass of the damper was

experimentally changed to alter its natural frequency by 10%

from its optimum frequency. The T beam with damper was sub-

jected to heel drop tests for each newfrequency. The experimental

results shown in Fig. 20 illustrate that the efficiency of the damper

was considerably reduced. This highlights the importance of tun-

ning the damper to its optimum natural frequency. It should be

noted that the efficiency of the damper due to the variation in the

frequency (10% change fromthe optimumfrequency) in this case

is quite different fromthat of the steel beam(Case Study 1) because

the damping ratio of the T beam is significantly higher.

In addition to the experimental results presented in Fig. 20, an

analytical analysis was also performed. In this sensitivity analysis

using Eqs. (2) and (10), two parameters were investigated. The

natural frequency of the damper was changed in the range of 10%

Fig. 21. Effect of T beam damping ratio on the performance of damper with

different damper natural frequency (Eqs. (2) and (10)).

from the optimum value and the damping ratio of the T beam was

also changed from 0.5% to 5%. The damping ratio of the damper

itself was kept constant at 6%. The results from this study are

presented in Fig. 21. It is clear fromFig. 21 that the effectiveness of

the damper is significantly degraded when the natural frequency

of the damper departed fromthe optimumvalue. The investigation

indicates that the damper has to be tuned in order to attain the

optimum performance. This is particularly important for floor

systems which have relatively high damping. For floor systems

with low damping (<1.5%) an off tune damper would still reduce

the floor response significantly as shown by Fig. 21.

8. Concluding remarks

This paper has presented a summary of the development of a

new viscoelastic tuned mass damper for floor applications. The

proposed damper is based on the concept of a sandwich beamwith

the energy dissipated by shearing of a constrained rubber layer.

Two viscoelastic dampers were developed according to a

procedure presented in this paper. The two prototypes were built

for use on a steel beam with a 3 m span and a reinforced concrete

T beam floor segment with a 9.5 m span. An analytical model

was used to predict the required optimum damper for the steel

beam and the RC T beam. The predicted values were in excellent

agreement with the test results in terms of the natural frequency

and damping ratio of the prototype damper.

With the addition of the viscoelastic damper to the steel beam,

the damping ratio was increased from 0.3% to about 3%. The

departure of the viscoelastic damper from its optimum position

did not appear to degrade its effectiveness. The response reduction

factor was found to be insensitive to the variations in position of

damper location within the middle third of the span. Systematic

variation in the end mass of the viscoelastic damper also appeared

to have no significant effect on the performance of the damper

because of the low damping ratio of the steel beam. A 20% change

in end mass (a 10% change from the optimum frequency) was

observed to have a minimal effect on the response reduction factor.

The T beam was tested under heel drop and walking excitation

with and without the viscoelastic damper. Without the damper,

the T beam had a measured damping ratio of 2.9%. The overall

response was halved with a corresponding increase in overall

damping to 6.1% with the addition of the viscoelastic damper. The

system was found to be more sensitive to the variation in the

damper frequency because of the highdamping ratioof the T beam.

The measured reduction in response due to the damper was found

to be in excellent agreement with that predicted by the analytical

as well as from the FE analysis.

3328 I. Saidi et al. / Engineering Structures 33 (2011) 33173328

The developed viscoelastic damper can be easily tuned to given

properties and optimised to fit in available spaces. The testing

and analyses conducted demonstrate clear advantages of such a

viscoelastic damper over conventional viscous dampers for floor

vibration applications where displacements are small. By using

several dampers in one location or in a distributed system a large

frequency range of effectiveness can be addressed.

References

[1] HanaganLM, Murray TM. Active control approachfor reducing floor vibrations.

J Struct Eng 1997;123(11):1497505.

[2] Bachmann H, Ammann WJ, Deischl F, Eisenmann J, Flogel I, Hirsch GH, et al.

Vibration problems in structures: practical guidelines. Berlin: Birkhauser

Verlag; 1995.

[3] Haritos N, Gad E, Wilson J. Evaluation the dynamic characteristics of

floor system using dynamic testing ACAM2005, Melbourne, Australia: 2005,

p. 22530.

[4] Murray TM, Allen DE, Ungar EE. Floor vibrations due to human activity.

Chicago, Ill: American Institute of Steel Construction; 1997.

[5] Alvis SR. An experimental and analytical investigation of floor vibrations.

Master thesis, Faculty of the Virginia Polytechnic Institute and State

University; 2001.

[6] European Commission, Human-induced vibration of steel structures Hivoss,

2010.

[7] Hechler O, Feldmann M, Heinemeyer C, Galanti F. Design guide for floor

vibrations Eurosteel, Austria, 35 September 2008. Graz University of

Technology: Institute for Steel Structures and Shell Structures, 2008.

[8] Willford M, Young P. Adesignguide for footfall induced vibrationof structures.

CCIP-016. The Concrete Centre. Camberley, UK; 2006.

[9] Webster AC, Vaicaitis R. Application of tuned mass dampers to control

vibrations of composite floor systems. Eng J AISC 1992;29(3):11624.

[10] Ljunggren F, gren A. Development of a new damper to reduce resonant

vibrations in lightweight steel joist floors. Appl Acoust 2002;63(11):126780.

[11] Willford M, Young P, Algaard WH. A constrained layer damping system for

composite floors. The Struct Eng 2006;84(4).

[12] Hartog JPD. Mechanical vibrations. Mcgraw-Hill; 1956.

[13] Rana R, Soong TT. Parametric study and simplified design of tuned mass

dampers. Eng Struct 1998;20(3):193204.

[14] Silva CWD. Seismic base isolationandvibrationcontrol. Taylor &Francis; 2005.

[15] Lee C-L, Chen Y-T, Chung L-L, Wang Y-P. Optimal design theories and

applications of tuned mass dampers. Eng Struct 2006;28(1):4353.

[16] Lenzen KH. Vibration of steel joist-concrete slab floors. AISC 1966;3(3):1336.

[17] Setareh M. Floor vibration control using semi-active tuned mass dampers.

Canad J Civil Eng 2002;29(1):7684.

[18] Thorby D. Structural dynamics and vibration in practice: An engineering

handbook. Amsterdam, London: Butterworth-Heinemann; 2008.

[19] Smith. Vibration of structures: applications in civil engineering design.

London, New York: Chapman and Hall; 1988.

[20] Puksand H. Optimum conditions for dynamic vibration absorbers for variable

speed systems with rotating or reciprocating unbalance. The International J

Mech Eng Edu 1975;3:14552.

[21] Angeles J, Ostrovskaya S. The proportional-damping matrix of arbitrarily

damped linear mechanical systems. J Appl Mech 2002;69(5):64956.

[22] Irvine M. Structural dynamics for the practising engineer. London: Allen &

Unwin Ltd.; 1986.

[23] Inman DJ. Engineering vibration. Prentice-Hall Inc.; 1996.

[24] Mace M. Damping of beam vibrations by means of a thin constrained

viscoelastic layer: evaluation of a new theory. J Sound Vibration 1994;172(5):

57791.

[25] Kerwin JEM. Damping of flexural waves by a constrained viscoelastic layer. J

Acoust Soc Amer 1959;31(7):95262.

[26] DiTaranto RD. Theory of vibratory bending for elastic and viscoelastic layered

finite length beams. J Appl Mech 1965;8816.

[27] Mead DJ, Markus S. Loss factor and resonant frequency of encastre damped

sandwich beam. J Sound Vibration 1970;12(1):99112.

[28] Mead DJ. The measurement of the loss factors of beams and plates with

constrained and unconstrained damping layers: a critical assessment. J Sound

Vibration 2007;300(35):74462.

[29] Mead DJ, Markus S. The forced vibration of a three-layer, damped sandwich

beam with arbitrary boundary conditions. J Sound Vibration 1969;10(2):

16375.

[30] Mead DJ. Vibration control (I). In: White RG, Walker JG, editors. Noise and

vibration. Ellis Horwood Limited; 1982.

[31] Nashif AD. Vibration damping. New York: John Wiley & Sons; 1985.

[32] DMA2980, 2002, Dynamic mechanical analyzer, Operators manual, TA

instruments-waters LLC.

[33] Menard KP. Dynamic mechanical analysis a practical introduction. Boca Raton,

Fla: CRC Press; 1999.

[34] Buchholdt HA. Structural dynamics for engineers. London: Telford; 1997.

[35] Haritos N. Implementationof a low-cost structural dynamics investigative sys-

tem ninth international conference on computational structures technology.

Stirlingshire, Scotland: Civil Comp Press; 2008.

[36] Saidi I, Gad EF, Wilson JL, Haritos N. Innovative passive viscoelastic damper to

suppress excessive floor vibrations AEES Conference 2008. Ballarat, Victoria,

Australia, 2123 November, Australian Earthquake Engineering Society;

2008.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- IS 875 - 1987 Part 4 Design Loads For BLDG & STR - Snow Load PDFDocument10 paginiIS 875 - 1987 Part 4 Design Loads For BLDG & STR - Snow Load PDFArjun Kisan ShendeÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- IS 875 Part 1-1987Document40 paginiIS 875 Part 1-1987bhapar44Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Septic Tank-Model PDFDocument1 paginăSeptic Tank-Model PDFArjun Kisan ShendeÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Finall Reportt 5 27-05-13 6Document79 paginiFinall Reportt 5 27-05-13 6Arjun Kisan Shende100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Retrofitting of Earthquake Affected BuildingsDocument131 paginiRetrofitting of Earthquake Affected BuildingsArjun Kisan ShendeÎncă nu există evaluări

- 1 s2.0 0141029695000345 MainDocument16 pagini1 s2.0 0141029695000345 MainArjun Kisan ShendeÎncă nu există evaluări

- On Pre Stressed ConcreteDocument6 paginiOn Pre Stressed ConcreteArjun Kisan Shende50% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Effect of Rice Husk Ash On Properties of High Strength ConcreteDocument8 paginiEffect of Rice Husk Ash On Properties of High Strength ConcreteArjun Kisan ShendeÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Power Train: - 170 - STMGXXX 4/97Document66 paginiPower Train: - 170 - STMGXXX 4/97Evan AT YoelÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Construction: Close Coupled Centrifugal PumpsDocument11 paginiConstruction: Close Coupled Centrifugal PumpsAhmed AbarchidÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Chapter 1 Introduction To Biochemistry and ThermodynamicsDocument4 paginiChapter 1 Introduction To Biochemistry and ThermodynamicsMamamiaÎncă nu există evaluări

- Coffee Brewing: Wetting, Hydrolysis & Extraction RevisitedDocument8 paginiCoffee Brewing: Wetting, Hydrolysis & Extraction Revisitedsheetalnirmal02Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Symbols of Oil Gas PipingDocument3 paginiSymbols of Oil Gas PipingDelvin Davis M0% (1)

- Practice Paper Chem 12, Unit-IiDocument2 paginiPractice Paper Chem 12, Unit-IiANUPAM S PRAKASHÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- 1603 03093Document51 pagini1603 03093pippoÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- ASME Cases of Boiler and Pressure Vessel CodeDocument3 paginiASME Cases of Boiler and Pressure Vessel CodeSanthosh ShrinivasÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- May 2022 Ce Board Exam Policarpio 3: Eview NnovationsDocument3 paginiMay 2022 Ce Board Exam Policarpio 3: Eview NnovationsKian InductivoÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- 7 Design of Singly Reinforced BeamsDocument16 pagini7 Design of Singly Reinforced Beamskiran sreekumarÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Theodolite HandbookDocument37 paginiTheodolite HandbooksuhasÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Analysis of G+20 RC Building in Different Zones Using Etabs: Narla Mohan, A.Mounika VardhanDocument14 paginiAnalysis of G+20 RC Building in Different Zones Using Etabs: Narla Mohan, A.Mounika VardhanRohan ChauguleÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- TurbochargerDocument8 paginiTurbochargersudheeshÎncă nu există evaluări

- Heating & Cooling LoadsDocument66 paginiHeating & Cooling LoadsAbdullah Maqsood50% (2)

- Avalanches, Facts and InformationDocument1 paginăAvalanches, Facts and InformationAiled Basurto AlvarezÎncă nu există evaluări

- Graphene Based TextileDocument10 paginiGraphene Based TextileTaofiqur Rahman ShochchoÎncă nu există evaluări

- 105mm Enhanced GunDocument38 pagini105mm Enhanced Gungrindormh53100% (1)

- Ruukki Double Grade S420MH S355J2H RectangularDocument6 paginiRuukki Double Grade S420MH S355J2H Rectangularhooky1Încă nu există evaluări

- Electrostatic AnalyzerDocument6 paginiElectrostatic AnalyzerKcirtap ZkethÎncă nu există evaluări

- 7.7 High Pressure Vapour Liquid Equilibria: V L I IDocument7 pagini7.7 High Pressure Vapour Liquid Equilibria: V L I IayushÎncă nu există evaluări

- Determining Wicking of Fibrous Glass Fiber Blanket Insulation (Aircraft Type)Document3 paginiDetermining Wicking of Fibrous Glass Fiber Blanket Insulation (Aircraft Type)Ahmed AlzubaidiÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Nitrogen RejectionDocument7 paginiNitrogen RejectionOmar TocmoÎncă nu există evaluări

- Efa FitnetDocument20 paginiEfa FitnetQuoc VinhÎncă nu există evaluări

- NEET-Exam-2022 With SolutionDocument78 paginiNEET-Exam-2022 With SolutionNIKHIL BISHNOIÎncă nu există evaluări

- Solutions Manual Chapter13Document42 paginiSolutions Manual Chapter13Daeyoung KimÎncă nu există evaluări

- Column Thumb RulesDocument4 paginiColumn Thumb RulesAnand.5100% (1)

- CV - Tony BroccoliDocument25 paginiCV - Tony BroccolitbroccoliÎncă nu există evaluări

- Materi MatrikulasiDocument72 paginiMateri MatrikulasiAyziffyÎncă nu există evaluări

- 4PH0 2PR Que 20170616Document20 pagini4PH0 2PR Que 20170616aya abdulfattahÎncă nu există evaluări

- Lec6 TorsionDocument26 paginiLec6 TorsionJordan DavidsonÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)