Documente Academic

Documente Profesional

Documente Cultură

Dts

Încărcat de

Ruby SmithDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dts

Încărcat de

Ruby SmithDrepturi de autor:

Formate disponibile

SRM UNIVERSITY FACULTY OF ENGINEERING & TECHNOLOGY

Department of Mechanical Engineering

MODEL EXAMINATION Sub Code: PME405 Sub Name: Design of Transmission System Course/Year/Sem: B.Tech/III / V Answer ALL Questions (Usage of PSG Design Data Book is permitted) 1. What is done to accommodate initial sag in chain drive? 2. How is a wire rope specified?

ODD Date: 29.08.2011 Time: 180minutes Total Marks: 100

3. Label (a) Addendum (b) Flank in a simple sketch of a gear tooth 4. What are the commonly used gear tooth profiles? 5. When bevel gears are used? 6. In worm gear drive, only wheel is designed. Why? 7. State important properties of bearing materials. 8. Distinguish between a shaft and an axle. 9. What do you mean by ray diagram? 10.What are preferred numbers? Part B - ( 5 x 16 = 80 marks )

11. A V-belt drive is required to transmit 16 kW power to a compressor. The

motor speed is 1440 rpm and the speed reduction ratio is 3.6. Design the belt drive. Sketch the details of pulley. (16 marks) Or 12. A truck equipped with a 9.5 kW engine uses a roller chain as final drive to the rear axle. The driving sprocket runs at 900 rpm and the driven sprocket at 400 rpm with a center distance of approximately 600 mm. Select the roller chain.

13. A motor shaft running at 1440 rpm has to transmit 30 KW power to a low speed shaft rotating at 480 rpm. The pinion has 25 teeth. Both pinion and gear are made of C45 steel. Design a suitable spur gear drives. (16 marks) Or 14. Design a pair of helical gears to transmit 30 kW at a speed reduction ratio of 4:1. The input shaft runs at 2000 rpm. Both pinion and gear are l5Ni2crlMo15 under carburized Condition. (16 marks)

15. Design a bevel gear drive to transmit 7.36 kW at 1440 rpm for the following data: Gear ratio = 3, Material for pinion an gear C45 surface hardened (16 marks) Or 16. Design a worm gear drive for the following data: Power to be transmitted : 20 kW, Worm speed: 1440 rpm, Speed reduction: 24: 1. (16 marks)

17. Design a 9 speed gear box for the following data: Minimum speed: 100 rpm, Step ratio: 1.25. The input is from a 4 kW, 1400 rpm motor. Draw the speed diagram and indicate the number of teeth on each gear in a kinematic diagram (16 marks) Or 18. Design a shaft to transmit power from an electric motor to a lathe head stock through a pulley by means of a belt drive. The pulley weighs 200 N and is located at 300 mm from the centre of the bearing. The diameter of the pulley is 200 mm and the maximum power transmitted is 1 kW at 120 r.p.m. The angle of lap of the belt is 180 and coefficient of friction between the belt and the pulley is 0.3. The shock and fatigue factors for bending and twisting are 1.5 and 2.0 respectively. The allowable shear stress in the shaft may be taken as 35 MPa. (16 marks)

19. Design a journal bearing for a centrifugal pump from the following data: Load on the journal=20000 N, Speed of the journal = 900rpm, Type of oil is SAE10, for which the absolute viscosity at 55C = 0.017kg/m-s, Ambient temperature of oil = 15.5C, Maximum bearing pressure for the pump=1.5N/mm2. Calculate also mass of the lubricating oil required for artificial cooling, If the rise of temperature, if the rise of temperature of oil be limited to 10C heat dissipation coefficient=1232W/m2/C (16 marks) Or

20. A shaft is supported on the bearing A and B 800 mm between the centers. A 20 straight tooth spur gear having 600 mm pitch diameter is located 200 mm to the right of left hand bearing A and a 700 mm diameter pulley is mounted on 250 mm towards the left of bearing B. the gear is driven by a pinion with a downward tangential force. While the pulley is driven by the belt horizontally having 180 angle of warp. The pulley is also serve as a flywheel and weighs 2000 N. the maximum belt tension is 3000 N and the tension ratio is 3:1. Determine the necessary shaft diameter if the allowable shear stress of the material is 40 MPa. (16 marks)

S-ar putea să vă placă și

- Me 1352Document6 paginiMe 1352arunramakrishnanÎncă nu există evaluări

- Me 2352 - DTS Q BankDocument5 paginiMe 2352 - DTS Q Bankpaul_jaikumarm27530% (1)

- ME2352 Design of Transmission Question BankDocument4 paginiME2352 Design of Transmission Question BankKarthik SubramaniÎncă nu există evaluări

- Dts Important Ques 2 16 MarksDocument5 paginiDts Important Ques 2 16 MarksBas RamuÎncă nu există evaluări

- Design of Transmission ElementDocument42 paginiDesign of Transmission ElementVenkatesh MohanÎncă nu există evaluări

- Jeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Document3 paginiJeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Balu phoenixÎncă nu există evaluări

- 8th Sem - Assignment - MD II (2962108)Document5 pagini8th Sem - Assignment - MD II (2962108)rishabhk28995Încă nu există evaluări

- Design of Transmission SystemsDocument6 paginiDesign of Transmission SystemsSelva KumarÎncă nu există evaluări

- AT8611 Lab QuestionsDocument9 paginiAT8611 Lab QuestionsChirpiÎncă nu există evaluări

- 181505-181902-MD - IiDocument2 pagini181505-181902-MD - IiSiddharth PanchalÎncă nu există evaluări

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pagini2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusÎncă nu există evaluări

- Projects For Lab BDocument91 paginiProjects For Lab BPeter AshrafÎncă nu există evaluări

- Sathyabama University: Register NumberDocument3 paginiSathyabama University: Register NumberSecret SecretÎncă nu există evaluări

- Dme 2 QP CombinedDocument9 paginiDme 2 QP CombinedPrasinÎncă nu există evaluări

- Dts Model Que Type B 2018-19Document2 paginiDts Model Que Type B 2018-19rammit2007Încă nu există evaluări

- Iii Me Ii Sem Q.bank 2016-17Document32 paginiIii Me Ii Sem Q.bank 2016-17Abhishek SakatÎncă nu există evaluări

- Question Paper Code:: (10×2 20 Marks)Document3 paginiQuestion Paper Code:: (10×2 20 Marks)PradeepÎncă nu există evaluări

- Supp Nov 2009Document10 paginiSupp Nov 2009prk74Încă nu există evaluări

- Design of Transmission Systems - Important QuestonsDocument5 paginiDesign of Transmission Systems - Important QuestonsPost BoxÎncă nu există evaluări

- DTS QBDocument19 paginiDTS QBHem KumarÎncă nu există evaluări

- I.C.E Assig.Document3 paginiI.C.E Assig.sherifkazem20100% (1)

- DTS ND06-QPDocument3 paginiDTS ND06-QPsrajapratyÎncă nu există evaluări

- Machine Design - LDocument2 paginiMachine Design - LNilesh Mistry (Nilesh Sharma)Încă nu există evaluări

- Design of Transmission SystemsDocument14 paginiDesign of Transmission SystemsmechfameÎncă nu există evaluări

- Eighth Semester B.Tech. Degree Examination, November 2008 (2003 Scheme) Branch: Production 03.804: Machine Tool Design (P)Document3 paginiEighth Semester B.Tech. Degree Examination, November 2008 (2003 Scheme) Branch: Production 03.804: Machine Tool Design (P)Jithesh VÎncă nu există evaluări

- AAAAAAAAAAAAAADocument16 paginiAAAAAAAAAAAAAASriramulu JaichandarÎncă nu există evaluări

- UNit-2 Numerical ProblemsDocument16 paginiUNit-2 Numerical ProblemsMarthandeÎncă nu există evaluări

- Unit3 Premodel1Document2 paginiUnit3 Premodel1T.V.B.BabuÎncă nu există evaluări

- Design of Transmission Systems 1key 1Document2 paginiDesign of Transmission Systems 1key 1srajapratyÎncă nu există evaluări

- Design of Transmission Systems 3Document2 paginiDesign of Transmission Systems 3srajapratyÎncă nu există evaluări

- UPTU 2013-14 Machine Design - II EME 602Document4 paginiUPTU 2013-14 Machine Design - II EME 602nitin_johriÎncă nu există evaluări

- Design of Transmission System-QbDocument5 paginiDesign of Transmission System-QbGanapathi SekaranÎncă nu există evaluări

- Assignment No4Document2 paginiAssignment No4Jai SharmaÎncă nu există evaluări

- 05-04 Machine Design & Cad-II (Me)Document2 pagini05-04 Machine Design & Cad-II (Me)Abdul AhadÎncă nu există evaluări

- AECD QuestionsDocument7 paginiAECD QuestionssbkÎncă nu există evaluări

- Design of Transmission SystemsDocument3 paginiDesign of Transmission SystemsSaravanan KumarÎncă nu există evaluări

- R8 Nov-Dec-2015Document3 paginiR8 Nov-Dec-2015Hari VenkitÎncă nu există evaluări

- ACFrOgA5tUgRDZJXHXmL8 Tw5dcxYJxiOIwOU5Eo4HonpVpoFZFJo3FpR3jkEpxVlzSr4SlTPfwEhXU2oUrUpctlLPK5aDrEIjX Z49543n2D8VZdCWCJYobCVtHeuFv-2Hje7s8XnE4FiVLAx-HDocument3 paginiACFrOgA5tUgRDZJXHXmL8 Tw5dcxYJxiOIwOU5Eo4HonpVpoFZFJo3FpR3jkEpxVlzSr4SlTPfwEhXU2oUrUpctlLPK5aDrEIjX Z49543n2D8VZdCWCJYobCVtHeuFv-2Hje7s8XnE4FiVLAx-HDept of MechanicalÎncă nu există evaluări

- Question Paper Code:: (10×2 20 Marks)Document3 paginiQuestion Paper Code:: (10×2 20 Marks)PradeepÎncă nu există evaluări

- DMM Ii (2015)Document35 paginiDMM Ii (2015)gorijalaÎncă nu există evaluări

- DTSDocument7 paginiDTSmithundme659Încă nu există evaluări

- Design of Transmission Systems 10Document2 paginiDesign of Transmission Systems 10srajapratyÎncă nu există evaluări

- Question Bank For Machine DesignDocument3 paginiQuestion Bank For Machine DesignSachin KumbharÎncă nu există evaluări

- Me 7 Sem Design of Mechanical Drives 3560 Summer 2019Document2 paginiMe 7 Sem Design of Mechanical Drives 3560 Summer 2019djniksthehearteditorÎncă nu există evaluări

- Question Paper - Design of Machine Elements 2 Oct-19-October - 2019Document2 paginiQuestion Paper - Design of Machine Elements 2 Oct-19-October - 2019ChanduÎncă nu există evaluări

- MSD Question BankDocument24 paginiMSD Question BanknithreeÎncă nu există evaluări

- Md-Ii 2Document11 paginiMd-Ii 2Vishal ZalaÎncă nu există evaluări

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Document3 paginiB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PÎncă nu există evaluări

- DTS Model PaperDocument3 paginiDTS Model PaperrajkumardotcomÎncă nu există evaluări

- Problems For Presentation On Spur GearDocument1 paginăProblems For Presentation On Spur GearSomnath SomadderÎncă nu există evaluări

- 15A03602 Design of Machine Members - IIDocument2 pagini15A03602 Design of Machine Members - IIJagannath CherkuÎncă nu există evaluări

- Fourth Year - Mechanical Power Eng. Dept. First Term - 2016/2017 Internal Combustion EnginesDocument5 paginiFourth Year - Mechanical Power Eng. Dept. First Term - 2016/2017 Internal Combustion EnginesMohamed SamyÎncă nu există evaluări

- 07a6ec05 Designofmachinemembers IIDocument11 pagini07a6ec05 Designofmachinemembers IIzahid_polyÎncă nu există evaluări

- Designn of Tranmission SystemDocument4 paginiDesignn of Tranmission Systemsathiskumar411Încă nu există evaluări

- Upto 2010 KomDocument36 paginiUpto 2010 KomRajueswarÎncă nu există evaluări

- r05320305 Design of Machine Members IIDocument11 paginir05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- Motorcycle, Solo (Harley-Davidson Model WLA)De la EverandMotorcycle, Solo (Harley-Davidson Model WLA)Încă nu există evaluări

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationDe la EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationÎncă nu există evaluări

- Deferential EquationsDocument58 paginiDeferential EquationsShivan BiradarÎncă nu există evaluări

- InvtDocument15 paginiInvtRuby SmithÎncă nu există evaluări

- Analytic Geometry Formulas PDFDocument4 paginiAnalytic Geometry Formulas PDFKaranbir RandhawaÎncă nu există evaluări

- Formula Sheet GeometryDocument2 paginiFormula Sheet Geometrykssuhasreddy_3743947Încă nu există evaluări

- Retail Banking ProjectDocument39 paginiRetail Banking ProjectRuby SmithÎncă nu există evaluări

- ERP NotesDocument40 paginiERP Notesprakash83% (6)

- Analytic Geometry Formulas PDFDocument4 paginiAnalytic Geometry Formulas PDFKaranbir RandhawaÎncă nu există evaluări

- Topic Page No: 1. Introduction ..1-4Document3 paginiTopic Page No: 1. Introduction ..1-4Ruby SmithÎncă nu există evaluări

- Zebpad 7t100Document5 paginiZebpad 7t100Ruby SmithÎncă nu există evaluări

- Zebpad 7c UpgradeDocument5 paginiZebpad 7c UpgradeRuby SmithÎncă nu există evaluări

- Zebpad 7t100Document5 paginiZebpad 7t100Ruby SmithÎncă nu există evaluări

- Data BookDocument60 paginiData BookgcldesignÎncă nu există evaluări

- RL 34350Document12 paginiRL 34350Ruby SmithÎncă nu există evaluări

- ME0405Document5 paginiME0405Ruby SmithÎncă nu există evaluări

- Accountancy Is The Process of Communicating Financial: Einstein College of EngineeringDocument21 paginiAccountancy Is The Process of Communicating Financial: Einstein College of EngineeringJackson JeevarajÎncă nu există evaluări

- An Unpretentious View of Technical Drawings Historic Evolution Managerial Approach 2169 0316.1000108 PDFDocument5 paginiAn Unpretentious View of Technical Drawings Historic Evolution Managerial Approach 2169 0316.1000108 PDFRuby SmithÎncă nu există evaluări

- The Factories Act, 1948Document91 paginiThe Factories Act, 1948Sudhi SudhiÎncă nu există evaluări

- Factories Act 1948Document39 paginiFactories Act 1948albusvijayÎncă nu există evaluări

- Factories Act 1948Document69 paginiFactories Act 1948P VenkatesanÎncă nu există evaluări

- Holistic Design Solutions FactoriesDocument6 paginiHolistic Design Solutions FactoriesRuby SmithÎncă nu există evaluări

- InvstudyDocument5 paginiInvstudyRuby SmithÎncă nu există evaluări

- Economic Analyses For Business PDFDocument105 paginiEconomic Analyses For Business PDFRebeccaÎncă nu există evaluări

- Statergic Human Resource ManagementDocument249 paginiStatergic Human Resource Managementnaveenkumar193100% (2)

- Solvedproblems PFMDocument75 paginiSolvedproblems PFMstratgy0% (3)

- Abs Brake PDFDocument81 paginiAbs Brake PDFRuby SmithÎncă nu există evaluări

- Lecture NotesDocument140 paginiLecture NotesRavi GajenthranÎncă nu există evaluări

- Components PDFDocument1 paginăComponents PDFNilabjo Kanti PaulÎncă nu există evaluări

- Steam Turbine Q & ADocument47 paginiSteam Turbine Q & Asrikanth9555100% (1)

- AutoCAD Tutorial 002 PDFDocument54 paginiAutoCAD Tutorial 002 PDFskannanmecÎncă nu există evaluări

- Ug RegulationDocument12 paginiUg RegulationRuby SmithÎncă nu există evaluări

- 11.trouble Shooting For TMDocument9 pagini11.trouble Shooting For TMfrezgi birhanuÎncă nu există evaluări

- Brevini EvoMax Series PDFDocument196 paginiBrevini EvoMax Series PDFJorge RuizÎncă nu există evaluări

- MATChapter 57ATFundamentalsDocument27 paginiMATChapter 57ATFundamentalsDwy Bagus NÎncă nu există evaluări

- Gear TrainDocument26 paginiGear TraingowthamarajÎncă nu există evaluări

- Bevel GearDocument5 paginiBevel GearKrestle Charmy VistoÎncă nu există evaluări

- Vol 0015Document4 paginiVol 0015FranciscoOliveiraÎncă nu există evaluări

- Automatic Transaxle (A4AF3) PDFDocument200 paginiAutomatic Transaxle (A4AF3) PDFClaudio Godoy Gallegos100% (4)

- LV12 - Drive Shafts - Issue 1Document19 paginiLV12 - Drive Shafts - Issue 1Đức HòangÎncă nu există evaluări

- Boite Seamless XtracDocument13 paginiBoite Seamless Xtracdudule01Încă nu există evaluări

- List of Lubricants ZF AstronicDocument14 paginiList of Lubricants ZF AstronicBroCactusÎncă nu există evaluări

- 2 Chain DrivesDocument35 pagini2 Chain DrivesMohammad UmairÎncă nu există evaluări

- Atb 935Document5 paginiAtb 935Raul Rodriguez JuarezÎncă nu există evaluări

- 72 10 PDFDocument46 pagini72 10 PDFPanca Xp100% (1)

- Gear SystemDocument57 paginiGear SystemWilson LimÎncă nu există evaluări

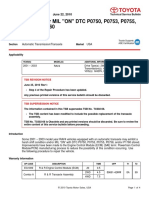

- Harsh Shift And/or MIL "ON" DTC P0750, P0753, P0755, P0758 And/or P1760Document4 paginiHarsh Shift And/or MIL "ON" DTC P0750, P0753, P0755, P0758 And/or P1760Thomas AndersonÎncă nu există evaluări

- SM 92Document381 paginiSM 92VIDAL ALEJANDRO GARCIAVARGASÎncă nu există evaluări

- T.E. (Mechanical Engineering) Semester VDocument5 paginiT.E. (Mechanical Engineering) Semester Vmanil patilÎncă nu există evaluări

- CSA PM Calculation - 07.2019 - FormuleDocument45 paginiCSA PM Calculation - 07.2019 - FormulejogremaurÎncă nu există evaluări

- Mech 203 Term Project Automobile Differential and TransmissionDocument29 paginiMech 203 Term Project Automobile Differential and TransmissionYugi SupriatnaÎncă nu există evaluări

- Torque Converter - WikipediaDocument6 paginiTorque Converter - Wikipediaajo zinzoÎncă nu există evaluări

- Transit StatusDocument100 paginiTransit StatusSurjeet Singh SaranÎncă nu există evaluări

- VTU Exam Question Paper With Solution of 18ME62 Design of Machine Elements-II Aug-2022-Manikandan HDocument43 paginiVTU Exam Question Paper With Solution of 18ME62 Design of Machine Elements-II Aug-2022-Manikandan HFusion gaming100% (1)

- DL RD m760 2 PDFDocument1 paginăDL RD m760 2 PDFtudor-72Încă nu există evaluări

- ZF Vector Drive ConceptsDocument48 paginiZF Vector Drive ConceptsConcept of ReasoningÎncă nu există evaluări

- Cincinnati Dividing Head ChartDocument26 paginiCincinnati Dividing Head ChartNewton LoÎncă nu există evaluări

- Allison 5000/6000 Series Off-Highway Transmissions Parts CatalogDocument3 paginiAllison 5000/6000 Series Off-Highway Transmissions Parts CatalogFilipposÎncă nu există evaluări

- Steering and BrakeDocument170 paginiSteering and BrakeWahyu Beleng100% (1)

- 2010 - Baja Sae CatalogDocument15 pagini2010 - Baja Sae Catalogedubarbier100% (1)

- QB 1Document2 paginiQB 117TUME135 NAVEEN KUMAR.S100% (1)

- Gearbox Data Sheet: in Line Right AngleDocument1 paginăGearbox Data Sheet: in Line Right Anglepenulis kata penulis kataÎncă nu există evaluări