Documente Academic

Documente Profesional

Documente Cultură

Power Amplifiers For Proportional Valves: Amplifier Cards

Încărcat de

Fathi MusaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Power Amplifiers For Proportional Valves: Amplifier Cards

Încărcat de

Fathi MusaDrepturi de autor:

Formate disponibile

Vickers

Amplifier Cards

Power Amplifiers for Proportional Valves

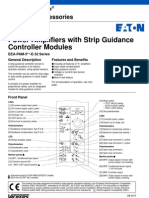

EEA-PAM-56*-A-14 Design

EEA-PAM-561-A-14 for use with valve types: KDG5V-5, 3* and KDG5V-7, 1* series EEA-PAM-568-A-14 for use with valve types: KDG5V-8, 1* series Analog command input signals can be non-inverting current, or non-inverting, inverting or differential voltages. The amplifier requires a power supply of 24V DC and is enabled by a 24V logic signal. The ramp is normally enabled but can be selectively disabled by suitable wiring to an external switch. The amplifier front panel contains LEDs showing the status of power, control supply and outputs. Potentiometers for adjusting ramp, deadband compensation and gain are also mounted in the front panel.

Features

F Basic valve amplifier F Voltage and current command signals F 1 ramp for acceleration and

deceleration

F 24V DC power supply F Pulse-width-modulated coil drives

General Description

This basic amplifier is designed for driving Vickers type KFDG5V-5/7/8, 2-stage proportional valves in applications requiring only one (adjustable) ramp setting for both acceleration and deceleration.

14-design Features

F Wider supply voltage range plus

increased tolerance to ripple

F Low supply voltage protection F Additional monitor points on edge

connector

F Gain re-positioned in circuitry to give:

Ramp setting unaffected by gain adjustment Constant trigger voltage for deadband compensation

Front Panel

LEDs [1] [2] [3] [4] [5] [6] [7] [8] Potentiometers [9] [10] [11] 24V power supply input, green 15V control supply output, green Output (solenoid) enabled, yellow Overload, red LVDT failure, red Output level to solenoid, yellow Deadband compensation; towards flow from main-stage service port (A or B) nearest LVDT Deadband compensation; towards flow from main-stage service port (B or A) furthest from LVDT Gain; flow from service port (A or B) nearest LVDT Gain; flow from service port (B or A) furthest from LVDT Ramp

24V 15V

[12] Monitor point J , conditioned command signal [13] Common ground (0V) J [14] Monitor point J , LVDT (spool) position

t t

J 2 (0.0787 dia.) sockets

Warning: Electromagnetic Compatibility (EMC) This product does not conform to the European Community directives for electromagnetic compatibility (EMC). It is only suitable for use within the European Economic Area in a sealed electromagnetic environment or as a spare for an existing machine. (Ref. UK Electromagnetic Compatibility Regulations 14 & 18, 1995.)

February 1996

GB-2101A

Valve Wiring Connections Solenoid Connections

Operating Data

Power (input) supply 20 to 34V DC x 40W max. 24V DC nominal <4V pk-to-pk ripple Amplifier shuts down below 19V z22 z2 b2 +15V x 50 mA max. in addition to LVDT demand +10V x 5 mA max. 10V x 5 mA max.

z26 (or z28) z28 (or z26)

No connection

Control (output) supplies:

Note: Connections not polarity sensitive LVDT Connections

Pin 3

Pin 1 Pin 2

Command signal inputs: Direct voltage pins b8, b6, z8, b10 Inverting voltage pin z10 Voltage range Input impedance (voltage) Current pin z6 Current range Input impedance (current) Standing solenoid current at zero command signal Note: A positive signal to a non-inverting signal pin reduces solenoid current Deadband compensation, separate controls for each direction from spool-centered position: Factory setting Adjustment per direction from centered position Gain, separate controls for each direction from spool-centered position: Factory setting Adjustment per direction from centered position Ramp time adjustment, linear: Factory setting Adjustment range

"10V 47 k "20 mA 100 1,4A

Pin 4 LVDT plug pin 1 2 3 4 Amplifier pin b14 z22 b16 Not connected

10% of max. stroke Y 0 to 50% of max. stroke Y

Max. spool stroke at 10V command signal Y 1,9 to 20% of max. spool stroke per 1 volt Y Max. time 50 ms to 2s, under pre-set deadband compensation and gain conditions specified above Factory-set 4 to 20 mA (100) Automatic reset when fault removed Apply 10 to 30V (6.8 k) Apply v0,8V or open circuit

Dither Feedback from LVDT to b14 Overload protection, factory-set Output enabled (power available to solenoid) z24 Output disabled (no power output to solenoid) z24 Ramp enabled (machine actuator acceleration and deceleration limited by ramp potentiometer) b12, b20

Y From spool-centered position

Open circuit between b20 and b12

Continued on next page

Ramp disabled (fastest acceleration and deceleration of machine actuator; ramp circuit bypassed) b12, b20 Command signal monitor point

Link b20 to b12 "5V full scale. Command signal conditioned by deadband compensation, gain and ramp functions "5V full scale 10 k Short-circuit protected >+6V when enabled <6V when disabled 0 to 50_C (32 to 122_F) 0,22 kg (0.48 lb) See catalogs: 2419 2460 2462 and 2315

Spool position monitor point front panel and z18 Monitor point impedance front panel and b18 Monitor point protection Output point to alarm indicator Ambient temperature range Mass Supporting products: Power supply unit options Electronic accessories Portable test equipment z12

Circuit and Connections

z2 b2 z22

+10V; 5 mA 10V; 5 mA +15V; 50 mA 24V 15V Output enable A B Overload low voltage Dither Voltage Ramp commands Gain

+24V Power zero

zbd32 zbd30 z12

24V DC power supply Monitor drive output Close to enable output

z6

Current command 100W

Output enable

z24

b6 47 kW b8 b10 z8 z10 Inv. voltage b4 z4

Power stage

z28 z26 Output

PWM Current sensing z22 b14

Control zero Deadband compensation Ramp enable b20 b12 b18 z18

b16 LVDT fail bz16 Cable screen

Link to disable ramp

Command signal monitor point (conditioned) on front panel

LVDT signal monitor point on front panel

Command Signals and Outputs Command signals Type Ref. Non-inverting g voltages g Non-inverting g current Inverting g voltage g z10 Differential voltage g b6/8/10 or z8 z6 Input pins Signal polarity ) * ) * * ) * ) One of b6/8/10 or z8 ) * Link one of b6/8/10 or z8 to bz4 One of b6/8/10 or z8 z10 bz4 P-B P-A P-B P-A P-B P-A P-B P-A P-B P-A Secondary pins ref. Valve flow

Installation Dimensions mm (inches)

Plug-in Unit of 3U Height, to IEC 297

3rd angle projection

DIN 41612 F48 male connector

7,92 (0.31)

M2,5 x 11 (0.43) long collar screws supplied with panel for fixing 2,5 (0.1)

z - pin row b - pin row d - pin row Components envelope

122,4 (4.82) Model designation 3 (0.12) 7,45 (0.29) 40,3 (1.59)

128,4 (5.06) 8 (0.31) 14,2 (0.56)

100 (3.94)

3 (0.12)

14 7,2 (0.28) (0.55)

175,24 (6.90)

S-ar putea să vă placă și

- Eea Pam 535 C 32 PDFDocument5 paginiEea Pam 535 C 32 PDFjorge130494Încă nu există evaluări

- Eea-Pam 561 A 12Document6 paginiEea-Pam 561 A 12Fathi MusaÎncă nu există evaluări

- Eea-Pam 32Document8 paginiEea-Pam 32Johnny Diaz VargasÎncă nu există evaluări

- 7225 AcDocument12 pagini7225 AcEdson AyalaÎncă nu există evaluări

- EN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated InductorDocument16 paginiEN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated Inductorcatsoithahuong84Încă nu există evaluări

- LCD221SD Service ManualDocument41 paginiLCD221SD Service Manual1cvbnmÎncă nu există evaluări

- AM5888SDocument10 paginiAM5888SproctepÎncă nu există evaluări

- VNH2SP30-E: Automotive Fully Integrated H-Bridge Motor DriverDocument26 paginiVNH2SP30-E: Automotive Fully Integrated H-Bridge Motor DriverIan LuksÎncă nu există evaluări

- Power Amplifiers For Proportional Valves: Amplifier CardsDocument5 paginiPower Amplifiers For Proportional Valves: Amplifier CardsFlávio ZarzarÎncă nu există evaluări

- Datasheet WS2801Document15 paginiDatasheet WS2801Nguyễn Trọng NghĩaÎncă nu există evaluări

- 5-channel BTL Driver for DVD player AM5868SDocument10 pagini5-channel BTL Driver for DVD player AM5868SnoileksirtÎncă nu există evaluări

- IHDx 60Document0 paginiIHDx 60MallickarjunaÎncă nu există evaluări

- B 15 A 20Document5 paginiB 15 A 20ElectromateÎncă nu există evaluări

- Boost Controller With Power Factor CorrectionDocument14 paginiBoost Controller With Power Factor CorrectionChiseledPrawnÎncă nu există evaluări

- Tca 965 BDocument18 paginiTca 965 BMichael WickertÎncă nu există evaluări

- Skhi 23 12Document11 paginiSkhi 23 12Shaun Dwyer Van HeerdenÎncă nu există evaluări

- MC 14053Document12 paginiMC 14053roozbehxoxÎncă nu există evaluări

- Recorp15m Rp15-4805saDocument4 paginiRecorp15m Rp15-4805saMario Suárez MelonÎncă nu există evaluări

- OB2269Document12 paginiOB2269Juan Ballon100% (1)

- ADC0831/ADC0832/ADC0834 and ADC0838 8-Bit Serial I/O A/D Converters With Multiplexer OptionsDocument33 paginiADC0831/ADC0832/ADC0834 and ADC0838 8-Bit Serial I/O A/D Converters With Multiplexer OptionsRoy Muy GolfoÎncă nu există evaluări

- 150KHz, 3A Step Down Voltage Switching Regulators DatasheetDocument10 pagini150KHz, 3A Step Down Voltage Switching Regulators DatasheetAlfredo Valencia RodriguezÎncă nu există evaluări

- DatasheetDocument10 paginiDatasheetCristina Nae0% (1)

- LM392Document6 paginiLM392Brzata PticaÎncă nu există evaluări

- LM1575/LM1575HV/LM2575/LM2575HV Series Simple Switcher 1A Step-Down Voltage RegulatorDocument23 paginiLM1575/LM1575HV/LM2575/LM2575HV Series Simple Switcher 1A Step-Down Voltage RegulatorOsman KoçakÎncă nu există evaluări

- Low Power Dual Operational Amplifiers Az358/358CDocument13 paginiLow Power Dual Operational Amplifiers Az358/358CMarissa ValdezÎncă nu există evaluări

- VFD-L Series AC Drive Instruction SheetDocument2 paginiVFD-L Series AC Drive Instruction SheetCongora PabloÎncă nu există evaluări

- PV proportional amplifier controls hydraulic solenoidDocument8 paginiPV proportional amplifier controls hydraulic solenoidRafael Torres SabalzaÎncă nu există evaluări

- 3ph Ac Motor ControlerDocument11 pagini3ph Ac Motor Controleradamkam1111Încă nu există evaluări

- Fully Integrated H-Bridge Motor Driver: VNH3SP30Document26 paginiFully Integrated H-Bridge Motor Driver: VNH3SP30Dan EsentherÎncă nu există evaluări

- 5V Disk Drive Spindle & VCM, Power & Control "Combo": General Bicmos TechnologyDocument17 pagini5V Disk Drive Spindle & VCM, Power & Control "Combo": General Bicmos Technologybenjoshu9031Încă nu există evaluări

- Data Sheet: TDA1558QDocument11 paginiData Sheet: TDA1558QMarco Tulio Da SilvaÎncă nu există evaluări

- 5-CH BTL DRIVER FOR DVD PLAYER WITH DISC BIDIRECTIONAL DRIVER AND TWO VARIABLE REGULATORSDocument8 pagini5-CH BTL DRIVER FOR DVD PLAYER WITH DISC BIDIRECTIONAL DRIVER AND TWO VARIABLE REGULATORSalbinicue1Încă nu există evaluări

- 150Khz, 3A PWM Buck DC/DC Converter Features General DescriptionDocument12 pagini150Khz, 3A PWM Buck DC/DC Converter Features General Descriptionpaulmx13Încă nu există evaluări

- Re30042 11.02Document6 paginiRe30042 11.02thierrylindoÎncă nu există evaluări

- IRS2092 DatasheetDocument18 paginiIRS2092 DatasheetSergio Daniel BarretoÎncă nu există evaluări

- LM2586 Simple Switcher 3A Flyback Regulator With Shutdown: General Description FeaturesDocument29 paginiLM2586 Simple Switcher 3A Flyback Regulator With Shutdown: General Description FeaturesJonny JohnÎncă nu există evaluări

- SM72441 Programmable Maximum Power Point Tracking Controller For Photovoltaic Solar PanelsDocument10 paginiSM72441 Programmable Maximum Power Point Tracking Controller For Photovoltaic Solar PanelsShahid SiddiqueÎncă nu există evaluări

- LTC1073fa DatasheetDocument16 paginiLTC1073fa DatasheetKushal KshirsagarÎncă nu există evaluări

- IC200MDD840 and 843 VersaMax Ten 24VDC Inputs Six Relay Outputs gfk2540 PDFDocument2 paginiIC200MDD840 and 843 VersaMax Ten 24VDC Inputs Six Relay Outputs gfk2540 PDFJosé Alexis Valero VillanuevaÎncă nu există evaluări

- AZ324Document10 paginiAZ324Franklim Miranda Dos SantosÎncă nu există evaluări

- Fet Controller Type 3Ch System Power Supply IcsDocument16 paginiFet Controller Type 3Ch System Power Supply IcsRohit SinghÎncă nu există evaluări

- General Description Features: Ezbuck™ 3A Simple Buck RegulatorDocument18 paginiGeneral Description Features: Ezbuck™ 3A Simple Buck RegulatorNielsen KaezerÎncă nu există evaluări

- Unisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersDocument7 paginiUnisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersNaresh KsÎncă nu există evaluări

- Precision Phase-Locked Loop: ... The Analog Plus CompanyDocument21 paginiPrecision Phase-Locked Loop: ... The Analog Plus Companykao08Încă nu există evaluări

- AP358 DatasheetDocument13 paginiAP358 DatasheetRafael OliveiraÎncă nu există evaluări

- DatasheetDocument13 paginiDatasheetkishore kumarÎncă nu există evaluări

- Fan 7316Document21 paginiFan 7316sontuyet82Încă nu există evaluări

- MC 14052 DatasheetDocument12 paginiMC 14052 DatasheetgrooyoÎncă nu există evaluări

- Isolated Flyback Switching Regulator W - 9V OutputDocument16 paginiIsolated Flyback Switching Regulator W - 9V OutputCasey DialÎncă nu există evaluări

- Atos E-BM-AC-05FDocument4 paginiAtos E-BM-AC-05FislamooovÎncă nu există evaluări

- 1395Document14 pagini1395Aurel-LucianNedaÎncă nu există evaluări

- High efficiency notebook computer power controllersDocument26 paginiHigh efficiency notebook computer power controllersВиола БорисовскаяÎncă nu există evaluări

- Description Power Range: Analog Servo DriveDocument7 paginiDescription Power Range: Analog Servo DriveElectromateÎncă nu există evaluări

- Data SheetDocument20 paginiData SheetLuis Fernando ChiavegatiÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe la EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsEvaluare: 3.5 din 5 stele3.5/5 (6)

- 110 Waveform Generator Projects for the Home ConstructorDe la Everand110 Waveform Generator Projects for the Home ConstructorEvaluare: 4 din 5 stele4/5 (1)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsDe la EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsÎncă nu există evaluări

- Presentation by Omar AlTurki - English PoetryDocument14 paginiPresentation by Omar AlTurki - English PoetryFathi MusaÎncă nu există evaluări

- Literature Approaches To Teaching LiteratureDocument14 paginiLiterature Approaches To Teaching LiteratureFathi Musa100% (1)

- Iic DK EX55 Oi SQ HM 8 Dkiz QL T6 yDocument12 paginiIic DK EX55 Oi SQ HM 8 Dkiz QL T6 yFathi MusaÎncă nu există evaluări

- 60617-3 1996Document24 pagini60617-3 1996Fathi MusaÎncă nu există evaluări

- 74 Ls 47Document3 pagini74 Ls 47Joelo D' CartonÎncă nu există evaluări

- Busbar SpecificationsDocument2 paginiBusbar SpecificationsFathi MusaÎncă nu există evaluări

- LAD9R1Document1 paginăLAD9R1Fathi MusaÎncă nu există evaluări

- Why Should Literature Be Used in The Language Classroom?: Nina Daskalovska, Violeta DimovaDocument5 paginiWhy Should Literature Be Used in The Language Classroom?: Nina Daskalovska, Violeta DimovaFathi MusaÎncă nu există evaluări

- Soft Start and Star Delta Trip Class by Application ChartDocument2 paginiSoft Start and Star Delta Trip Class by Application ChartFathi MusaÎncă nu există evaluări

- Product Data Sheet 6ES7232-4HA30-0XB0Document2 paginiProduct Data Sheet 6ES7232-4HA30-0XB0Fathi MusaÎncă nu există evaluări

- 74LS93Document11 pagini74LS93cocoxo13marÎncă nu există evaluări

- PLC or DCS PDFDocument12 paginiPLC or DCS PDFsafvanshaikhÎncă nu există evaluări

- Analog in Output ModulesDocument2 paginiAnalog in Output ModulesFathi MusaÎncă nu există evaluări

- Built-In Panel PC CP65xx: Installation and Operating Instructions ForDocument25 paginiBuilt-In Panel PC CP65xx: Installation and Operating Instructions ForFathi MusaÎncă nu există evaluări

- LV1 3RP15Document6 paginiLV1 3RP15Fathi MusaÎncă nu există evaluări

- PROFIBUS Guideline AssemblingDocument132 paginiPROFIBUS Guideline AssemblingSrikala VenkatesanÎncă nu există evaluări

- Low-Cost HDTV Satellite Set-Top Box Decoder For Microsoft VC-1, H.264 and MPEG-2Document4 paginiLow-Cost HDTV Satellite Set-Top Box Decoder For Microsoft VC-1, H.264 and MPEG-2Fathi MusaÎncă nu există evaluări

- Prolific PL2303HX Driver SettingsDocument11 paginiProlific PL2303HX Driver SettingsFathi MusaÎncă nu există evaluări

- PL 2303Document11 paginiPL 2303Fathi MusaÎncă nu există evaluări

- DATASHEETDocument4 paginiDATASHEETFathi MusaÎncă nu există evaluări

- DATASHEETDocument4 paginiDATASHEETFathi MusaÎncă nu există evaluări

- Production LevelsDocument4 paginiProduction LevelsT-money SloanÎncă nu există evaluări

- 41310Document14 pagini41310Fathi MusaÎncă nu există evaluări

- Price of OilDocument1 paginăPrice of OilFathi MusaÎncă nu există evaluări

- 170343626Document6 pagini170343626Fathi MusaÎncă nu există evaluări

- Counter HEF4510BDocument10 paginiCounter HEF4510BnnguyenQuangBa100% (1)

- Op Toc Rev7.1Document5 paginiOp Toc Rev7.1Fathi MusaÎncă nu există evaluări

- Siemens PLC Connection Manual for GP-PRO/PBIIIDocument52 paginiSiemens PLC Connection Manual for GP-PRO/PBIIIFathi MusaÎncă nu există evaluări

- ASR 1fDocument4 paginiASR 1fMadison MadisonÎncă nu există evaluări

- ERX Cable Pinouts GuideDocument8 paginiERX Cable Pinouts Guidedenilson.rodr1357Încă nu există evaluări

- Good PDSPDocument39 paginiGood PDSPJ HARSHA YADAVÎncă nu există evaluări

- ADT406-AP Technical ManualDocument55 paginiADT406-AP Technical ManualALEXANDER ROBLESÎncă nu există evaluări

- CPE 301 Logic Circuits & DesignDocument5 paginiCPE 301 Logic Circuits & DesignSiegrique Ceasar A. JalwinÎncă nu există evaluări

- CM OLTC Operating Instruction-HM0.460.301-EN PDFDocument52 paginiCM OLTC Operating Instruction-HM0.460.301-EN PDFDeegii DeegiiÎncă nu există evaluări

- InternalSlidingResult NWA PDFDocument25 paginiInternalSlidingResult NWA PDFEkansh DwivediÎncă nu există evaluări

- Esaote Mylab 25 30Document244 paginiEsaote Mylab 25 30DanielePironti50% (4)

- Ap9997gh-Hf Power Mosfet NDocument4 paginiAp9997gh-Hf Power Mosfet NVictorManuelBernalBlancoÎncă nu există evaluări

- Jerry Gordon's TecnNoteDocument101 paginiJerry Gordon's TecnNoteSteven CoelhoÎncă nu există evaluări

- Jadual Wim - Penjajaran Coptpa Cu, Wa, PPMPP, PPMPB Dan JPWDocument10 paginiJadual Wim - Penjajaran Coptpa Cu, Wa, PPMPP, PPMPB Dan JPWBakal JenazahÎncă nu există evaluări

- APC Back-UPS Pro 1300/1500: Product FeaturesDocument2 paginiAPC Back-UPS Pro 1300/1500: Product Featureswilliam Quispe BurgosÎncă nu există evaluări

- RF12B 434Mhz Transmitter PIC16F73Document23 paginiRF12B 434Mhz Transmitter PIC16F73calinsatÎncă nu există evaluări

- Manual Electric Heater Maxi HeatDocument5 paginiManual Electric Heater Maxi HeatSherif EmamÎncă nu există evaluări

- High-power NPN transistor specsDocument3 paginiHigh-power NPN transistor specsJavier Mendoza CastroÎncă nu există evaluări

- Lab Activity 3Document12 paginiLab Activity 3Jayvee Honorio0% (1)

- Nellcor NPB-290 - Service ManualDocument99 paginiNellcor NPB-290 - Service ManualSebastián Escobar MÎncă nu există evaluări

- Designing Bandgap Reference Sources With Cadence Virtuoso IC617Document12 paginiDesigning Bandgap Reference Sources With Cadence Virtuoso IC617carpet909Încă nu există evaluări

- Performance Availability GuaranteeDocument28 paginiPerformance Availability GuaranteeOmar GutierrezÎncă nu există evaluări

- EMX 11 G MKA - GA71 EA 012-R En-Generator ProtectionDocument40 paginiEMX 11 G MKA - GA71 EA 012-R En-Generator ProtectionRichardLemus100% (1)

- Data Sheet 6ES7214-1HF40-0XB0: General InformationDocument8 paginiData Sheet 6ES7214-1HF40-0XB0: General InformationZélia OrnelasÎncă nu există evaluări

- (GAS TURBINE MS 5001 PA) Volume IDocument159 pagini(GAS TURBINE MS 5001 PA) Volume Ihayder ahmed100% (2)

- Socomec Masterys BC & Delphys BCDocument2 paginiSocomec Masterys BC & Delphys BCsy4nÎncă nu există evaluări

- Ear Does Fourier AnalysisDocument14 paginiEar Does Fourier AnalysisLuckySharma SharmaÎncă nu există evaluări

- 8051 LAB Assignment QuestionsDocument5 pagini8051 LAB Assignment QuestionsMehul Patel0% (1)

- Thesis Proposal Sample For Electronics EngineeringDocument7 paginiThesis Proposal Sample For Electronics EngineeringCustomPaperSeattle100% (1)

- BJT Characteristic CurvesDocument7 paginiBJT Characteristic CurvesBhandari PrakashÎncă nu există evaluări

- Voltamp Transformers Limited: SR. NODocument2 paginiVoltamp Transformers Limited: SR. NOrohitshetyeÎncă nu există evaluări

- Basic Electronics (ECE 101) PDFDocument2 paginiBasic Electronics (ECE 101) PDFRahul PinnamaneniÎncă nu există evaluări

- 950H Elictrical Circuit DiagramDocument15 pagini950H Elictrical Circuit Diagramविशाल पुडासैनी100% (8)

- Manual Usuario Pipe Pro 300Document76 paginiManual Usuario Pipe Pro 300aromeroquirogaÎncă nu există evaluări

- IBM 1312 Serivce Parts Manual PDFDocument244 paginiIBM 1312 Serivce Parts Manual PDFMaria Luz Martinez SanzÎncă nu există evaluări