Documente Academic

Documente Profesional

Documente Cultură

Fabrication Technology Subject List

Încărcat de

chetanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fabrication Technology Subject List

Încărcat de

chetanDrepturi de autor:

Formate disponibile

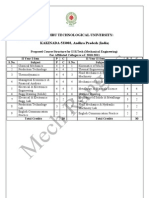

Sem Subject Code Subject

Credit Grade Internal Grade 4 4 2 2 6 5 CC CD BC BC CC CD CC AB Internal Grade

1 1 1 1 1 1 1 1

310015 310034 310002 310041 310029 310030 310031 310018

Communication Skill Mathematics-I Applied Science-I [Physics] Engineering Measurements-I Engineering Drawing Engineering Mechanics

Essentials of Environment and Seismic Engineering 3 Computer Applications Subject 4

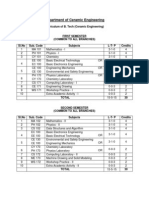

Sem Subject Code

Credit Grade

2 2 2 2 2 2 2 2 2 2 2 2 2

320001 320001 320002 320002 320055 320055 320007 320007 320004 320004 320056 320056 320005

Mathematics-II Mathematics-II Applied Science-II [Chemistry] Applied Science-II [Chemistry] Work-shop Work-shop Elements of Civil Engineering Elements of Civil Engineering Fundamentals of Electrical Engineering Fundamentals of Electrical Engineering Engineering Measurements-II Engineering Measurements-II Non Conventional Energy Sources

3 3 2 2 4 4 4 4 5 5 2 2 3

BC BC CC CC BB BB DD DD DD DD BB BB BC BC BC AB AB

2 2 2

320005 320015 320015

Non Conventional Energy Sources Mechanical Structure and Piping Drafting Mechanical Structure and Piping Drafting

3 6 6

BC CD CD CC CC

Sem

Subject Code

Subject

Credit

Grade Internal Grade

3 3 3 3 3 3 3 4

330001 335501 335502 335503 335504 335505 335506 345501

HUMAN RESOURCE MANAGEMENT MECHANICAL TECHNOLOGY MATERIALS and METALLURGY WELDING TECHNOLOGY - 1 FABRICATION TECHNOLOGY - 1 WELDING TECHNOLOGY PRACTICES - 1 FABRICATION TECHNOLOGY PRACTICES - 1 INSTRUMENTATION CONTROL and QUALITY ASSURANCE

3 7 7 3 2 4 4 6

AA AB BC AB BB AB AA AB AB AA

4 4 4 4 4 4

345502 345503 345504 345505 345506 345507

SHEET METAL FABRICATION PLANT EQUIPMENT MAINTENANCE and ERACTION WELDING TECHNOLOGY - II FABRICATION TECHNOLOGY - II PRACTICES IN WELDING TECHNOLOGY - II PRACTICES IN FABRICATION TECHNOLOGY - II

5 6 3 2 4 4

AA AB BC AB AB BB

Sem

Subject Code

Subject

Credi Grad Internal t e Grade

355501

Fabrication design Piping Engineerin g Welding

BC

355502

CC

355503

BB

Metallurgy 5 355504 Industrial Mngt and Org. Behaviour Welding Inspection and Testing Welding Metallurgy (practice) Proffesiona l practices1 5 BC

355505

BC

355506

AB

355507

AB

Mr. Ghanshyam D Acharya, Head, Fabrication Technology Dept., Sir Bhavsinhji Polytechnic Institute, Bhavnagar

9824566946

gdacharya@rediffmail.com/ gdacharya@gmail.com

GOA: 5.7 FABRICATION TECHNOLOGY & ERECTION ENGINEERING DEPTT.: 5.7.1 This sandwich course was started in the year 1973 with an intake of 30 students. It is a 4 year course and the pass out students play a pivotal role in the erection and fabrication of steel structures at various industries. 5.7.2 The curriculum aims at providing technical manpower to the fabrication industries at the middle level management. It is a sandwich pattern course with industrial training in two phases at V and VIII Terms as a part of the curriculum. The first and second terms includes basic engineering courses including compulsory industrial visit. The higher terms consists of Fabrication Engineering curriculum dealing mostly with welding and fabrication process, erection and commissioning of structures. 5.7.3 The Department would be able to help in controlling quality to ISI specifications industries. It can help in erection of machines, trusses, cranes, towers. Welding quality inspection for different structures can be taken up

S-ar putea să vă placă și

- B.E. Civil EngineeringDocument94 paginiB.E. Civil EngineeringgerogevkÎncă nu există evaluări

- 4 Curriculum StructureDocument19 pagini4 Curriculum StructurealiyazahirÎncă nu există evaluări

- Civil Syl Lab Us 200708Document142 paginiCivil Syl Lab Us 200708Gaddam KalpanaÎncă nu există evaluări

- DIPLOMA SEM-II Exam Scheme &subject CodeDocument8 paginiDIPLOMA SEM-II Exam Scheme &subject CodeccritamÎncă nu există evaluări

- Cem 2011Document1 paginăCem 2011Bishoy EmileÎncă nu există evaluări

- GTU Harmonized Syllabus For SPFU CollegesDocument5 paginiGTU Harmonized Syllabus For SPFU CollegesPiyush PatelÎncă nu există evaluări

- Ic3 8Document62 paginiIc3 8Akshay TanotraÎncă nu există evaluări

- Programme Structure and Course ContentDocument15 paginiProgramme Structure and Course ContentZyla RosfazillahÎncă nu există evaluări

- Diploma in Mechanical EngineeringDocument3 paginiDiploma in Mechanical Engineeringidforemon6898Încă nu există evaluări

- Courses of Study v3Document101 paginiCourses of Study v3Samarth KumarÎncă nu există evaluări

- 2850 L3 Diploma Qualification Handbook IVQ v1Document230 pagini2850 L3 Diploma Qualification Handbook IVQ v1damnsexybeast100% (1)

- List of Courses Offered 12015Document10 paginiList of Courses Offered 12015Anok BilisÎncă nu există evaluări

- Sathyabama University Mech Syllabus (Highlighted Copy)Document109 paginiSathyabama University Mech Syllabus (Highlighted Copy)Reginald YesuthasanÎncă nu există evaluări

- 1ST TO 3RD SEM Teaching Scheam in Gtu Diploma EnggDocument1 pagină1ST TO 3RD SEM Teaching Scheam in Gtu Diploma EnggKartik PatelÎncă nu există evaluări

- Btech Computer Science and Engg Semester I To Vi Semester Vii and Viii Old Sys CbcegsDocument132 paginiBtech Computer Science and Engg Semester I To Vi Semester Vii and Viii Old Sys CbcegsJasmine SinghÎncă nu există evaluări

- BTech Mech Curriculum & Syllabi (2008-09 Onwards)Document105 paginiBTech Mech Curriculum & Syllabi (2008-09 Onwards)Raghav SarinÎncă nu există evaluări

- Diploma in Civil Engineering - Direct EntryDocument4 paginiDiploma in Civil Engineering - Direct EntrydhwaniÎncă nu există evaluări

- B (1) .Tech Detailed SyllabiDocument159 paginiB (1) .Tech Detailed SyllabiJynt RjÎncă nu există evaluări

- 4th Mech - BakDocument17 pagini4th Mech - BakKumarItžMëÎncă nu există evaluări

- 6th Mech - BakDocument23 pagini6th Mech - Bakshiva shakthyÎncă nu există evaluări

- M.Tech Structural Engineering Degree National Institute of Technology TiruchirappalliDocument2 paginiM.Tech Structural Engineering Degree National Institute of Technology Tiruchirappallinira365Încă nu există evaluări

- M.tech. (Mechanical Engineering) Part-Time (Semester System)Document37 paginiM.tech. (Mechanical Engineering) Part-Time (Semester System)Sarabjeet SinghÎncă nu există evaluări

- Bachelor of Science in Civil EngineeringDocument7 paginiBachelor of Science in Civil EngineeringGuillermo O. BernabeÎncă nu există evaluări

- DMX3206 - Tma 1Document2 paginiDMX3206 - Tma 1Thushith WithanageÎncă nu există evaluări

- CurriculumDocument1 paginăCurriculumRob MercadoÎncă nu există evaluări

- Lbs BulletinDocument38 paginiLbs BulletinSirajuddeen MujahidÎncă nu există evaluări

- BTech Metallurgical CurriculumDocument32 paginiBTech Metallurgical CurriculumiyomasaÎncă nu există evaluări

- The PE Exam Survival GuideDocument41 paginiThe PE Exam Survival GuideTABIBI11Încă nu există evaluări

- Bs in Materials Minor in Business: A Track of 9 Credits Is PossibleDocument1 paginăBs in Materials Minor in Business: A Track of 9 Credits Is PossibleLuisaGomesÎncă nu există evaluări

- JNTU Hyderabad BTech ME 2005-2006 syllabusDocument48 paginiJNTU Hyderabad BTech ME 2005-2006 syllabuschepurthi100% (2)

- Bs Mechanical EngineeringDocument4 paginiBs Mechanical EngineeringsknarengopiÎncă nu există evaluări

- Mechanical Engineering Programme StructuresDocument9 paginiMechanical Engineering Programme StructuresReen ZulkifleeÎncă nu există evaluări

- JNTUK - Proposed Course Structure For B.tech II YearDocument1 paginăJNTUK - Proposed Course Structure For B.tech II YearNaveen SuryaÎncă nu există evaluări

- B.Tech Chemical Engineering CurriculumDocument51 paginiB.Tech Chemical Engineering CurriculumShambhu Singh RathoreÎncă nu există evaluări

- FEE2015 Fundamentals of Engineering ExaminationDocument40 paginiFEE2015 Fundamentals of Engineering ExaminationFu AunÎncă nu există evaluări

- Syllabus Copy R15 II To IVDocument124 paginiSyllabus Copy R15 II To IVJeet Niren ShahÎncă nu există evaluări

- Program Code, Department and Year Details for B.Tech Mechanical and Production EngineeringDocument8 paginiProgram Code, Department and Year Details for B.Tech Mechanical and Production EngineeringPallav AnandÎncă nu există evaluări

- Auto - Syallbus - R2008Document96 paginiAuto - Syallbus - R2008gowrisankar32Încă nu există evaluări

- Course Curriculum For The New Programme (B.Tech.) W.E.F. 2013 BatchDocument9 paginiCourse Curriculum For The New Programme (B.Tech.) W.E.F. 2013 Batchteju1996coolÎncă nu există evaluări

- Automobile Eng 07 08 EtDocument95 paginiAutomobile Eng 07 08 EtNeha SharmaÎncă nu există evaluări

- Mechanical CurriculumDocument103 paginiMechanical CurriculumPremsai Tadisetti100% (1)

- MECHANICAL ENGINEERING STUDY PROGRAMMESDocument22 paginiMECHANICAL ENGINEERING STUDY PROGRAMMESPolycarp H TomÎncă nu există evaluări

- Syllabus 4Document33 paginiSyllabus 4microsoftkarthiÎncă nu există evaluări

- B Tech ME Scheme and Syllabus 2023Document40 paginiB Tech ME Scheme and Syllabus 2023NIHANÎncă nu există evaluări

- ElectronicsDocument2 paginiElectronicsSwapnil SangodkarÎncă nu există evaluări

- VR10 Ug CseDocument169 paginiVR10 Ug CseLakshmi TharunÎncă nu există evaluări

- Mechanical EngineeringDocument36 paginiMechanical EngineeringChandan Kumar SahuÎncă nu există evaluări

- Maharshi Dayanand University Rohtak: Syllabus and Courses of Reading For M.Tech (Mechanical Engineering)Document22 paginiMaharshi Dayanand University Rohtak: Syllabus and Courses of Reading For M.Tech (Mechanical Engineering)Ramesh PandaÎncă nu există evaluări

- Curriculum of Industrial EngineeringDocument2 paginiCurriculum of Industrial EngineeringMai MohamedÎncă nu există evaluări

- University of the Punjab course schedules for Metallurgy & Materials Engineering, Electrical Engineering, and Chemical Engineering programsDocument2 paginiUniversity of the Punjab course schedules for Metallurgy & Materials Engineering, Electrical Engineering, and Chemical Engineering programsWaqar DarÎncă nu există evaluări

- EENGDocument4 paginiEENGrbÎncă nu există evaluări

- 3 MDM Curriculum AsOn 04nov2011Document25 pagini3 MDM Curriculum AsOn 04nov2011Vamsi KrishnaÎncă nu există evaluări

- Transcript of MarksDocument2 paginiTranscript of MarksKiranPadman50% (2)

- B.tech Mechanical With Specilization in Chemical Process EnggDocument100 paginiB.tech Mechanical With Specilization in Chemical Process EnggvandhanaÎncă nu există evaluări

- Pipeline and Energy Plant Piping: Design and TechnologyDe la EverandPipeline and Energy Plant Piping: Design and TechnologyEvaluare: 5 din 5 stele5/5 (2)

- Engineering Applications: A Project Resource BookDe la EverandEngineering Applications: A Project Resource BookEvaluare: 2.5 din 5 stele2.5/5 (1)

- Electrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyDe la EverandElectrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyEvaluare: 4 din 5 stele4/5 (1)

- Abstract For Int. Con Green Welding Technologies - ShanghaiDocument2 paginiAbstract For Int. Con Green Welding Technologies - ShanghaichetanÎncă nu există evaluări

- Sydem VenturiDocument3 paginiSydem VenturichetanÎncă nu există evaluări

- IIW 2017 manuscript submission guidelinesDocument3 paginiIIW 2017 manuscript submission guidelineschetanÎncă nu există evaluări

- Abstract For Int. Con Green Welding Technologies - Shanghai PDFDocument2 paginiAbstract For Int. Con Green Welding Technologies - Shanghai PDFchetanÎncă nu există evaluări

- Tqe Flyer PDFDocument2 paginiTqe Flyer PDFchetanÎncă nu există evaluări

- Tqe Inspection Fives CombustionDocument1 paginăTqe Inspection Fives CombustionchetanÎncă nu există evaluări

- Releiveing Letter VJTI Two Week STTP 16 19 and 12 To 17Document1 paginăReleiveing Letter VJTI Two Week STTP 16 19 and 12 To 17chetanÎncă nu există evaluări

- 3 Fold Flyer MakarpuraDocument2 pagini3 Fold Flyer MakarpurachetanÎncă nu există evaluări

- Draw Elevation From X Direction Plan and LH SV In1 Angle Projection MethodDocument10 paginiDraw Elevation From X Direction Plan and LH SV In1 Angle Projection MethodchetanÎncă nu există evaluări

- Chetan Somani teaching schedule July 3-7Document1 paginăChetan Somani teaching schedule July 3-7chetanÎncă nu există evaluări

- Releiveing Letter From IIWDocument1 paginăReleiveing Letter From IIWchetanÎncă nu există evaluări

- Tech-Quest Engineers: Training Certifica-Tion Level-Iii ServicesDocument2 paginiTech-Quest Engineers: Training Certifica-Tion Level-Iii ServiceschetanÎncă nu există evaluări

- Releiveing Letter VJTIDocument1 paginăReleiveing Letter VJTIchetanÎncă nu există evaluări

- Inverse Square Law Calculation Exposure-Distance CalculationDocument2 paginiInverse Square Law Calculation Exposure-Distance CalculationchetanÎncă nu există evaluări

- Time Table 22 Feb To 27 Feb 16Document2 paginiTime Table 22 Feb To 27 Feb 16chetanÎncă nu există evaluări

- Weekly Timetable for ClassesDocument2 paginiWeekly Timetable for ClasseschetanÎncă nu există evaluări

- VJTI Mastud ConfirmationDocument1 paginăVJTI Mastud ConfirmationchetanÎncă nu există evaluări

- Technical Committee Welding MachineDocument1 paginăTechnical Committee Welding MachinechetanÎncă nu există evaluări

- Weld Joint Model PDFDocument1 paginăWeld Joint Model PDFchetanÎncă nu există evaluări

- VJTI Mastud ConfirmationDocument1 paginăVJTI Mastud ConfirmationchetanÎncă nu există evaluări

- Welding Positions - Welding AnswersDocument5 paginiWelding Positions - Welding AnswerschetanÎncă nu există evaluări

- Weekly Class ScheduleDocument2 paginiWeekly Class SchedulechetanÎncă nu există evaluări

- SAW and GTAW welding angles and passes diagramDocument1 paginăSAW and GTAW welding angles and passes diagramchetanÎncă nu există evaluări

- Weld Joint ModelDocument1 paginăWeld Joint ModelchetanÎncă nu există evaluări

- DArch Architectural AssistantshipDocument5 paginiDArch Architectural AssistantshipchetanÎncă nu există evaluări

- Exp Report RatnamaniDocument2 paginiExp Report RatnamanichetanÎncă nu există evaluări

- 63.32... 88 NosDocument2 pagini63.32... 88 NoschetanÎncă nu există evaluări

- AXIAL PUMP Senator. LibyaDocument40 paginiAXIAL PUMP Senator. Libyasenator.libyaÎncă nu există evaluări

- Ndes 2013 Regis001Document1 paginăNdes 2013 Regis001chetanÎncă nu există evaluări

- P15340-CYD-PI-SP-0006 - Rev.1 (Specification For Fabrication, Erection & Testing of Piping System)Document43 paginiP15340-CYD-PI-SP-0006 - Rev.1 (Specification For Fabrication, Erection & Testing of Piping System)Saiful AmreeÎncă nu există evaluări

- Codap 2010 Division 1 Amp 2 SNCTDocument4 paginiCodap 2010 Division 1 Amp 2 SNCTAbdullahÎncă nu există evaluări

- Aws WJ 201409Document166 paginiAws WJ 201409German Favela100% (2)

- Foundation TypesDocument203 paginiFoundation Typesmecha.turq100% (2)

- Guided By: Prof. Laukik RautDocument8 paginiGuided By: Prof. Laukik RautShrvan HirdeÎncă nu există evaluări

- Itp For SSDP Project Rev CDocument9 paginiItp For SSDP Project Rev CRachel FloresÎncă nu există evaluări

- SFR 582018Document36 paginiSFR 582018Milos KosticÎncă nu există evaluări

- Piping Fabrication and Erection ProcedureDocument15 paginiPiping Fabrication and Erection ProcedureMuhammadChabibi83% (6)

- IC Design and Manufacturing Update Spring 2020Document28 paginiIC Design and Manufacturing Update Spring 2020Stewart PrinceÎncă nu există evaluări

- Tacom Weld Code SteelDocument165 paginiTacom Weld Code SteelAles Kubat0% (1)

- PVC SpecificationDocument17 paginiPVC SpecificationDavid Ruelas50% (2)

- Prefabrication Structural ProcedureDocument10 paginiPrefabrication Structural ProcedureMiky AndreanÎncă nu există evaluări

- Method Statement For Pipe Support Fabrication and Installation 6423dp420 00 0030000 Rev01 PDFDocument21 paginiMethod Statement For Pipe Support Fabrication and Installation 6423dp420 00 0030000 Rev01 PDFfurkanÎncă nu există evaluări

- CV. Muhammad Zubair - Rev-02Document6 paginiCV. Muhammad Zubair - Rev-02Muhammad Zubair100% (1)

- Weldments Training Courses For Autodesk Inventor - I GET ITDocument6 paginiWeldments Training Courses For Autodesk Inventor - I GET ITVeLuisÎncă nu există evaluări

- Design of GateDocument29 paginiDesign of Gateramkumar121Încă nu există evaluări

- Steel Girder Fabrication RequirementsDocument11 paginiSteel Girder Fabrication RequirementsAnkur Tayal100% (1)

- Process Tank Fabrication Work StepsDocument4 paginiProcess Tank Fabrication Work StepsMuhammad ZubairÎncă nu există evaluări

- Manual Cutting Machine 1Document4 paginiManual Cutting Machine 1H 5895Încă nu există evaluări

- Mini Projects For Mechanical 10Document12 paginiMini Projects For Mechanical 10ZEESHANA001Încă nu există evaluări

- SP 41 05Document14 paginiSP 41 05donyaÎncă nu există evaluări

- QCP - PP Insulation Using Wire MeshDocument5 paginiQCP - PP Insulation Using Wire MeshBurning TrainÎncă nu există evaluări

- Proposal CNC Panel Marking & Cutting PDFDocument60 paginiProposal CNC Panel Marking & Cutting PDFZaneta ZhafirahÎncă nu există evaluări

- Rahul Industries: ISO 9001 Manufacturer of Automotive & Industrial ComponentsDocument12 paginiRahul Industries: ISO 9001 Manufacturer of Automotive & Industrial ComponentsRocky Green0% (1)

- MC Check Sheet Unit - 2Document2 paginiMC Check Sheet Unit - 2SURJIT SINGHÎncă nu există evaluări

- Design and Fabrication of Horizontal and Vertical Tiles CleanerDocument8 paginiDesign and Fabrication of Horizontal and Vertical Tiles CleanerDANIEL DASÎncă nu există evaluări

- Site Erection Procedure For Piping InstallationDocument10 paginiSite Erection Procedure For Piping InstallationIrsan HaeruddinÎncă nu există evaluări

- Fastshapes: SystemDocument4 paginiFastshapes: SystemJimmy MyÎncă nu există evaluări

- 2 Nov 15 Guidelines On Supervision of Steelworks Fabricated Overseas PDFDocument12 pagini2 Nov 15 Guidelines On Supervision of Steelworks Fabricated Overseas PDFSadok KzadriÎncă nu există evaluări

- Top Steel Fabrication Companies in DubaiDocument5 paginiTop Steel Fabrication Companies in DubaiRashid AlminÎncă nu există evaluări