Documente Academic

Documente Profesional

Documente Cultură

Flange Analysis - Traditional Method 14sep10

Încărcat de

Lava SatDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Flange Analysis - Traditional Method 14sep10

Încărcat de

Lava SatDrepturi de autor:

Formate disponibile

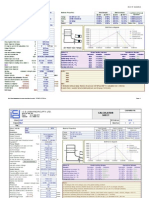

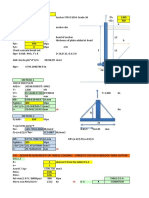

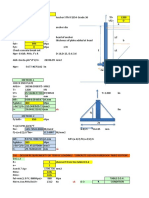

Flange Analysis for Internal Pressure - ASME Section VIII, Division 1, Appendices 2 and S - 2004 Edition

Job No. Client: Location: INPUT Flange Identification Flange Material: Facing: Bolting Material: Gasket: Test By: C.Y. Chkd: Appvd.: Date: Date: Date: 16-Jan-05

Blue = User Input

Taylor Forge M.F.D, Example 1 A105 1/16" Raised Face A193-B7 1/16" Compressed Asbestos PD = T= ca = ME = FE = 400 psig 500 0 0 0 F inches in-lb lb

Design Pressure (Internal): Design Temp.: Corrosion Allowance: External Moment External Force

Flange Data: See B16.5, B16.47, MSS SP 44 Outside Dia. A= 39.125 In Nom. Inside Dia. Bn = 32 In Min.Ring Thk. t= 2 In Hub Length h= 2.75 In Bolt Circle Dia C= 37 In Max Hub Dia. X= 34.25 In Thk @ Small end g0n = 0.5 In Gasket Data: See App. 2, Tables 2-5.1 and 2-5.2 N= 0.75 In b= 0.306 In G= 33.888 3700 2.75 36 0.551 in2 In psi y=

Allowable Stresses & Modulus of Elasticity Flange @ Design Temp: Flange @ Atm. Temp: Bolting @ Design Temp: Bolting @ Atm. Temp Flange Mod. of Elasticity, Design Flange Mod. of Elasticity, Atm. Sfo = Sfa = Sb = Sa = Efo = Efa = 17500 psi 17500 psi 25000 psi 25000 psi 29500000 psi 27300000 psi Bolt Data: No. of bolts Bolt Root Area

m= n= ab =

CALCULATIONS Peq due to ME = 16ME/G3 = Peq due to FE = 4FE/G2 = PD + PeqM + PeqF = Flange I.D, corroded Thk, small end, corroded Hub thk, large end, corroded

PeqM = PeqF = P= B= g0 = g1 =

0 psi 0 psi 400 psi 32 In 0.5 In 1.1250 In 1.375 In

Dim, C to outside of hub large end = R = Load and Bolt Calculations W m2 = bGy (Seating) Hp = 2bGmP H = G2P/4 W m1 = Hp + H (Operating) Am Ab W = >of W m2/Sa or W m1/Sb = nab = 0.5(Am + Ab)Sa = =

120537 71670 360779 432450

lb lb lb lb 2 17.30 in 2 19.84 in

464175 lb Load, Lb x 321699 71670 39080 464175 Lever Arm, Inches hD = R + 0.5g1 = hG = 0.5(C - G) = hT= 0.5(R + g1 + hG) = hG = 0.5(C - G) = = 1.938 1.556 2.028 1.556 Moment, Ft-Lb MD = HDhD = MG = HGhG MT = HThT Mg = WhG = = =

Condition HD = B2P/4 Operating HG = HP = W m1 - H HT = H - H D Operating Total Seating Hg = W =

623292 111519 79255 814066 722256

= = =

MO = MD+MG+MT =

K and Hub Factors K = A/B = T= Z= Y= U= g1 / go = ho = (Bgo)1/2 = Stress Long. Hub Stress Radial Flg. Stress Tang. Flg. Stress 1.223 1.830 5.041 9.773 10.740 2.250 4.000 Gasket Seating: fMg / Lg12B = SH = Mg / Lt2B = SR = YMg/t2B-ZSR = ST = d= h/ho = F= V= f= e = F/ho = hogo2U/V = = (1.33te)+1 Stress 20285 9734 6074 15009 13179 0.688 0.777 0.162 1.000 0.194 66.48 1.517 Allowable 26250 17500 17500 17500 17500 25000

L Factor (te + 1)/T + (t3/d) = L =

0.879 Index 0.845 0.881 Allow. Results 1.0 OK 1.0 OK

Flange Regidity (Appendix S): G.S.:(52.14MgV)/Lgo2hoK1Efa) = Jg = Op.: (52.14MOV)/Lgo2hoK1Efa) = Jo =

Operating: fMO / Lg12B = SH = MO / Lt2B = SR = YMO/(t2B)-ZSR = ST = .5(SH+SR) .5(SH+ST) (HD+HG+HT)/Ab = SB

Stress 22863 10972 6846 16917 14855 21801

Allowable 26250 17500 17500 17500 17500 25000

Results OK OK OK OK OK OK

Long.+Radial Stress .5(SH+SR) Long. + Tang.Stress .5(SH+ST) Bolt Stress

W m2/Ab

SBG = =

6077

S-ar putea să vă placă și

- BlindDocument3 paginiBlindSajal KulshresthaÎncă nu există evaluări

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 paginiSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Flange Pad CalcsDocument4 paginiFlange Pad CalcstomÎncă nu există evaluări

- Design of Flanges - Full-Face Gasket 2010Document29 paginiDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Flange CalculationsDocument3 paginiFlange CalculationssanjaysyÎncă nu există evaluări

- Bolted Flange Thickness CalculationDocument6 paginiBolted Flange Thickness Calculationshazan0% (1)

- Ring Flange CalculationDocument3 paginiRing Flange CalculationLuizÎncă nu există evaluări

- Design of Flanges - Loose Hub Type 2010Document58 paginiDesign of Flanges - Loose Hub Type 2010bakellyÎncă nu există evaluări

- FlangeCalc AS1210 v1.5Document28 paginiFlangeCalc AS1210 v1.5Ben100% (1)

- Flange From Plate - Asme 16.5Document1 paginăFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- FLANGEDocument1 paginăFLANGEscrbdgharavi50% (2)

- FlangeCalculationASMEVIII Version5Document13 paginiFlangeCalculationASMEVIII Version5madodandembe100% (3)

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 paginiASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Flange Calculation Sheet..Document2 paginiFlange Calculation Sheet..nguyenquoc198850% (2)

- Body Flange Design-Appx-2Document4 paginiBody Flange Design-Appx-2Matthieu100% (1)

- Reinforcement Pad DesignDocument3 paginiReinforcement Pad DesignAkshat JainÎncă nu există evaluări

- Flange CalculationsDocument5 paginiFlange CalculationsswapnavattemÎncă nu există evaluări

- Design of Flanges - Welded-On Integral Type 2010Document59 paginiDesign of Flanges - Welded-On Integral Type 2010bakellyÎncă nu există evaluări

- Design of Flat Head For HydrotestDocument12 paginiDesign of Flat Head For HydrotestSAGARÎncă nu există evaluări

- Body Flange Bolt TorqueDocument1 paginăBody Flange Bolt TorqueLcm Tnl100% (1)

- Finding Stresses at Junction of Cylinder and Reinforcing RingDocument4 paginiFinding Stresses at Junction of Cylinder and Reinforcing RingRey Fiedacan100% (1)

- Design of Flanges - Loose Type 2010Document53 paginiDesign of Flanges - Loose Type 2010bakellyÎncă nu există evaluări

- Pd5500 Flange CalculationDocument6 paginiPd5500 Flange CalculationMakrand SakpalÎncă nu există evaluări

- Leg CalculationDocument21 paginiLeg CalculationBahtiar Anak LaNangÎncă nu există evaluări

- Skirt Bracing Calc For Vertical Pressure VesselsDocument4 paginiSkirt Bracing Calc For Vertical Pressure Vesselsnagtummala100% (1)

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 paginiBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Lifting Lug Cal PDFDocument1 paginăLifting Lug Cal PDFveeru2906Încă nu există evaluări

- Saddle DesignDocument17 paginiSaddle Design9913489806Încă nu există evaluări

- Manhole DavitDocument2 paginiManhole DavitgaratetaÎncă nu există evaluări

- Nozzle Reinf Calc (Rough)Document12 paginiNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Expansion Loop Flexibility Analysis (Weaver)Document3 paginiExpansion Loop Flexibility Analysis (Weaver)bakelly100% (1)

- Blind Flange Design Calculations - by Abdel Halim GalalaDocument6 paginiBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 paginăChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanÎncă nu există evaluări

- Nozzle Neck CalculationDocument4 paginiNozzle Neck CalculationAkshat JainÎncă nu există evaluări

- Nozzle Loads WRC 107 Ver 1.1Document5 paginiNozzle Loads WRC 107 Ver 1.1Honey Tiwari75% (4)

- Davit CalcDocument6 paginiDavit Calcrustamriyadi100% (1)

- Lug Support DesignDocument3 paginiLug Support DesignSajal KulshresthaÎncă nu există evaluări

- FlangeCalculationASMEVIII Version5Document3 paginiFlangeCalculationASMEVIII Version5alvinchuan100% (1)

- 17 Asmeviii A-2 Reverse Integral FlangeDocument1 pagină17 Asmeviii A-2 Reverse Integral FlangepastylÎncă nu există evaluări

- Web Tapered Girder Design Based On AISC-ASD 9th, Appendix FDocument4 paginiWeb Tapered Girder Design Based On AISC-ASD 9th, Appendix FLivian TeddyÎncă nu există evaluări

- Connessione A Taglio EC3 IngleseDocument15 paginiConnessione A Taglio EC3 Inglesemihai_serban13Încă nu există evaluări

- Nozzle TempDocument2 paginiNozzle TempRakeshÎncă nu există evaluări

- Eyab AssignmentDocument8 paginiEyab AssignmentAbnet BeleteÎncă nu există evaluări

- Asme A-2 Reverse Flange CalculationDocument1 paginăAsme A-2 Reverse Flange CalculationpastylÎncă nu există evaluări

- Flange KOD Vessel Calculation - Actual ConditionDocument21 paginiFlange KOD Vessel Calculation - Actual ConditionPeter PerezÎncă nu există evaluări

- E4.5 Flange Cover CalcDocument10 paginiE4.5 Flange Cover CalcTanCM100% (1)

- Modification Thickness of A FlangeDocument3 paginiModification Thickness of A FlangePeter PerezÎncă nu există evaluări

- Calculo de Brida Segun ASMEDocument29 paginiCalculo de Brida Segun ASMEakarcz6731Încă nu există evaluări

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 paginiRean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionrbalmodalÎncă nu există evaluări

- UntitledDocument8 paginiUntitledmehrdad khoeiÎncă nu există evaluări

- SUPPL REINF Ver40Document9 paginiSUPPL REINF Ver40mehrdad khoeiÎncă nu există evaluări

- Inputs Astm A36 ASTM A193 Nitrile Rubber O-Ring Reference Document - (From Sec. VIII, Div. I) Gasket/'O-Ring' Type: ElastomerDocument10 paginiInputs Astm A36 ASTM A193 Nitrile Rubber O-Ring Reference Document - (From Sec. VIII, Div. I) Gasket/'O-Ring' Type: ElastomerRatnakar PatilÎncă nu există evaluări

- Brace Frame Connection ECBFDocument48 paginiBrace Frame Connection ECBFleonid48Încă nu există evaluări

- Suppl Reinf 2018 11Document9 paginiSuppl Reinf 2018 11mehrdad khoeiÎncă nu există evaluări

- Flange Asme ViiiDocument21 paginiFlange Asme Viiizahidwahla1Încă nu există evaluări

- Calculation For Sight Glass FlangeDocument4 paginiCalculation For Sight Glass FlangeOmil Rastogi0% (2)

- Skirt Support Analysis Per en 13445Document13 paginiSkirt Support Analysis Per en 13445karthik1amarÎncă nu există evaluări

- Potable Water Tank CalculationDocument37 paginiPotable Water Tank Calculationcamycax0% (1)

- 03 - Lifting Lug - 2nd Stage Separator (New)Document5 pagini03 - Lifting Lug - 2nd Stage Separator (New)Alessio BarboneÎncă nu există evaluări

- Solution Manual for an Introduction to Equilibrium ThermodynamicsDe la EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsÎncă nu există evaluări

- 3.2 Programming The Work: Created by Guy Henley, Last Modified by Mustafa Abusalah On Nov 20, 2014Document2 pagini3.2 Programming The Work: Created by Guy Henley, Last Modified by Mustafa Abusalah On Nov 20, 2014Lava SatÎncă nu există evaluări

- Oil and Gas FAQsDocument6 paginiOil and Gas FAQsLava SatÎncă nu există evaluări

- 3.4 Considerations in Developing The Conditions of ContractDocument4 pagini3.4 Considerations in Developing The Conditions of ContractLava SatÎncă nu există evaluări

- The Baseline of A Construction Contract: Created by Guy Henley, Last Modified by Mustafa Abusalah On Nov 20, 2014Document1 paginăThe Baseline of A Construction Contract: Created by Guy Henley, Last Modified by Mustafa Abusalah On Nov 20, 2014Lava SatÎncă nu există evaluări

- 3.3 Contract Price Information To Facilitate Evaluation of ChangesDocument1 pagină3.3 Contract Price Information To Facilitate Evaluation of ChangesLava SatÎncă nu există evaluări

- 1 PDFDocument2 pagini1 PDFSam ShahÎncă nu există evaluări

- Advanced 100% Solids Rigid Polyurethane Coatings Technology For Pipeline Field Joints and RehabilitationDocument14 paginiAdvanced 100% Solids Rigid Polyurethane Coatings Technology For Pipeline Field Joints and RehabilitationLava SatÎncă nu există evaluări

- Fabrication Sequence of JacketDocument37 paginiFabrication Sequence of JacketLava SatÎncă nu există evaluări

- 3 1Document3 pagini3 1Lava SatÎncă nu există evaluări

- Numerical Simulation of F Rost Heave in Soils Around The Buried Oil Pipeline in Island Talik Permafrost RegionDocument12 paginiNumerical Simulation of F Rost Heave in Soils Around The Buried Oil Pipeline in Island Talik Permafrost RegionLava SatÎncă nu există evaluări

- Introduction To Beam Theory Theory: Area Moments of Inertia, Deflection, and Volumes of BeamsDocument41 paginiIntroduction To Beam Theory Theory: Area Moments of Inertia, Deflection, and Volumes of BeamsDrAmit DuttaÎncă nu există evaluări

- AP Bearings For Industrial ApplicationsDocument79 paginiAP Bearings For Industrial Applicationsmikab25Încă nu există evaluări

- 3 1Document3 pagini3 1Lava SatÎncă nu există evaluări

- Icc Cricket World Cup 2015 Schedule With TimeDocument3 paginiIcc Cricket World Cup 2015 Schedule With TimeMuhammad NaeemÎncă nu există evaluări

- Short Term Pleasure vs. Long Term GainDocument31 paginiShort Term Pleasure vs. Long Term Gainunreal2Încă nu există evaluări

- Abaqus/CFD - Sample ProblemsDocument42 paginiAbaqus/CFD - Sample ProblemsLava SatÎncă nu există evaluări

- How To Select A Heat Shrink SleeveDocument2 paginiHow To Select A Heat Shrink SleeveLava SatÎncă nu există evaluări

- 7day PrimerDocument15 pagini7day PrimerGospodin Covek100% (5)

- Interpolating Tabular Data With MathcadDocument2 paginiInterpolating Tabular Data With MathcadLava SatÎncă nu există evaluări

- Non Linear Waves - Michael BrorsenDocument40 paginiNon Linear Waves - Michael BrorsenLava SatÎncă nu există evaluări

- Chainman Catalogue EditDocument57 paginiChainman Catalogue EditRem LaraziÎncă nu există evaluări

- Annex D - Stw-Comflow3Document45 paginiAnnex D - Stw-Comflow3Lava SatÎncă nu există evaluări

- Exercise Chart: PN 303731 © 2010 ICON Health & Fitness, Inc. All Rights Reserved. Specifications Subject To ChangeDocument1 paginăExercise Chart: PN 303731 © 2010 ICON Health & Fitness, Inc. All Rights Reserved. Specifications Subject To ChangeLava SatÎncă nu există evaluări

- Facets of HinduismDocument599 paginiFacets of HinduismLava Sat100% (1)

- Properties of British Universal Steel Columns and BeamsDocument4 paginiProperties of British Universal Steel Columns and BeamsLava SatÎncă nu există evaluări

- 107 Insert Control ButtonsDocument3 pagini107 Insert Control ButtonsLava SatÎncă nu există evaluări

- 1977 OTC 2827 The Design of Single Point MooringsDocument8 pagini1977 OTC 2827 The Design of Single Point MooringsLava SatÎncă nu există evaluări

- 107 Insert Control ButtonsDocument3 pagini107 Insert Control ButtonsLava SatÎncă nu există evaluări

- DRAFT Calculation Supposed To Be in Line With DNV-RP-F105 (Feb 2006) Sec. 3.5 and 3.6Document4 paginiDRAFT Calculation Supposed To Be in Line With DNV-RP-F105 (Feb 2006) Sec. 3.5 and 3.6Lava SatÎncă nu există evaluări

- Anchor ManualDocument187 paginiAnchor ManualAde Aris Satria100% (5)

- Lpalmer ResumeDocument4 paginiLpalmer Resumeapi-216019096Încă nu există evaluări

- Resume - Arun BhartiDocument3 paginiResume - Arun BhartiArun AbÎncă nu există evaluări

- Exterior Wall PrimerDocument2 paginiExterior Wall PrimerAsian PaintsÎncă nu există evaluări

- Unit 5.4 - Incapacity As A Ground For DismissalDocument15 paginiUnit 5.4 - Incapacity As A Ground For DismissalDylan BanksÎncă nu există evaluări

- Minimum Number of Thermocouples-Local PWHTDocument5 paginiMinimum Number of Thermocouples-Local PWHTPradip Goswami100% (1)

- Microporous WikiDocument2 paginiMicroporous WikiIris BalcarceÎncă nu există evaluări

- Secondary 1 Express English Paper 1 & 2Document15 paginiSecondary 1 Express English Paper 1 & 2Menon HariÎncă nu există evaluări

- Aits 2324 Ot I Jeea TD Paper 2 OfflineDocument14 paginiAits 2324 Ot I Jeea TD Paper 2 OfflineAshish SharmaÎncă nu există evaluări

- The Mystique of The Dominant WomanDocument8 paginiThe Mystique of The Dominant WomanDorothy HaydenÎncă nu există evaluări

- Maxs AdultDocument1 paginăMaxs Adultclark lopezÎncă nu există evaluări

- Process of Reinstatement Value Fire PoliciesDocument1 paginăProcess of Reinstatement Value Fire PoliciesvinaysekharÎncă nu există evaluări

- InfertilityDocument8 paginiInfertilityrivannyÎncă nu există evaluări

- Ahsan Menu KolachiDocument12 paginiAhsan Menu Kolachisalman GtrÎncă nu există evaluări

- Biology Lab ReportDocument5 paginiBiology Lab Reportapi-2576094460% (1)

- Period of Intuitive NursingDocument4 paginiPeriod of Intuitive NursingJhey-ar Toledo100% (1)

- Supply ForecastingDocument17 paginiSupply ForecastingBhavesh RahamatkarÎncă nu există evaluări

- Esc200 12Document1 paginăEsc200 12Anzad AzeezÎncă nu există evaluări

- How To Defend The Faith Without Raising Your VoiceDocument139 paginiHow To Defend The Faith Without Raising Your VoiceCleber De Souza Cunha100% (2)

- Data SheetDocument2 paginiData SheetsswahyudiÎncă nu există evaluări

- Here's HowDocument2 paginiHere's HowEden Dela CruzÎncă nu există evaluări

- Simple CASC StationsDocument74 paginiSimple CASC Stationssherief marouf100% (2)

- Non-Binary or Genderqueer GendersDocument9 paginiNon-Binary or Genderqueer GendersJuan SerranoÎncă nu există evaluări

- De Thi Chon HSGDocument10 paginiDe Thi Chon HSGKiều TrangÎncă nu există evaluări

- Quiz BowlDocument36 paginiQuiz BowlSherry GonzagaÎncă nu există evaluări

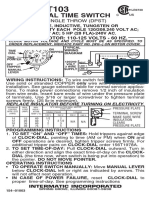

- T103 InstructionsDocument1 paginăT103 Instructionsjtcool74Încă nu există evaluări

- Guarantor Indemnity For Illness or DeathDocument2 paginiGuarantor Indemnity For Illness or Deathlajaun hindsÎncă nu există evaluări

- MLT IMLT Content Guideline 6-14Document4 paginiMLT IMLT Content Guideline 6-14Arif ShaikhÎncă nu există evaluări

- Polyken 4000 PrimerlessDocument2 paginiPolyken 4000 PrimerlessKyaw Kyaw AungÎncă nu există evaluări

- Fora Active Plus P 30 ManualDocument32 paginiFora Active Plus P 30 ManualBvcÎncă nu există evaluări

- LapasiDocument3 paginiLapasiWenny MellanoÎncă nu există evaluări