Documente Academic

Documente Profesional

Documente Cultură

A Coples

Încărcat de

arrancatetasDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Coples

Încărcat de

arrancatetasDrepturi de autor:

Formate disponibile

-- TAPER GRID COUPLING --------------------------------------------

TAPER GRID COUPLING

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

1.

(Characteristic

WCC Taper Grid Steel Flexble Coupling

& Merit)

We can get more favorable convinience and cost

down by using the WCC Taper Grid Steel Flexble

Coupling.

1)

1) PARALLEL

Grease

The movement of the grid in

the lubricated grooves accommodates parallel misalignment

and steel permits full functioning of the grid-groove action in

damping out shock and

vibration.

Grid

.(

2)

2 ~ 3)

2) ANGULAR

(2 ~

3

)

Hub

(Groove), Grid

Under angular misalignment,

the grid groove design permits

a rocking and sliding action of

the lubricated grid and hubs

without any loss of power

through the resilient grid.

, .

3)

3) AXIAL

End Float for both driving and

Hub

Grease

driven members is permitted

Grid

because the grid slides freely in

the lubricated grooves.

4)

4) TORSIONAL FLEXIBILITY

..

Torsional flexibility is the advantage of WCC Taper

Grid

Grid Coupling, Providing flexible accommodation

Grid

Tooth

.

Taper Grid Coupling

to changing load conditions.

WCC

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

Light Load

Grid

Grid Hub Tooth

The grid bears near the outer edges

of the hub teeth. The long span

between the points of contact

remains free to flex under load

(Load)

Grid

Tooth

Shocking

Vibration

Normal Load

G r i d

Hub

Tooth

Grid

(Bending)

As the load increases, the distance

between the contact points on the

hub teeth is shortened, but a free

span still remains to cushion shock

loads

Shock Load

G r i d

The coupling is flexible within its

Hub Tooth

rated

Grid

capactity.

Under

extreme overloads, the grid bears

(Torsion)

fully on the hub teeth and transmits

power

full load directly.

Starting .

WCC Taper Grid coupling demonstrate the excellent

performance as shown below.

(Virbration absorption)

---------------------WOO CHANG COUPLING

(Shock load absorption)

-- TAPER GRID COUPLING --------------------------------------------

:Vibration

& Shock

INPUT

:30%

OUTPUT

MERITS

1.

Grid Cutting

Shaft

2. Center

Shearing

3.

(Mechanical

4.

Grid

Tooth

Seal),

2

(Bearing)

, ,

5.

shearing Grid or Tooth.

3. The life of parts(Mechanical Seal and Bearing, etc)

can be extends to twice or more.

4. Quick installation and easy maintenance reduce

5. WCC Grid coupling is interchangeable with

international industry standard.

6.

100%

6. It always transmits the power full(100%) under

low noise.

.

.

relating machine is protected by the virtue of

labor cost and down-time costs.

7.

breaking of the shaft or machinery part connected.

2. When the parallel misalignment is too servere, the

1. When overload occur, grid breaks and prevents

7. You can use it continually at cheaper replacement

cost by changing damaged parts only.

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

2.

(Application)

Flange

Chain Coupling

Pin-Bush Flange coupling and Chain couplings have

Taper Grid Coupling

usually used, but now using the WCC Taper Grid

, Wcc

1. .

2.

under-end floating.

machinery parts under over load.

7.

angular misalignment.

5. When we need to prevent breaking of the

6. .

underline misalignment.

4. When we need adequate power transmission

5.

load.

3. When we need adequate power transmission

4.

1. When we need to reduce vibration and shock

2. When we need adequate power transmission

3.

Coupling we will get many benefits.

6. When reverse revolution is required.

7. When we need smooth starting.

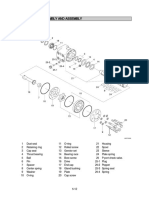

3.

(Structure)

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

4.

(Designation)

WCC

1020

T H

Cover (Horizontal split cover)

Coupling(Taper Grid Coupling)

(Coupling Size)

(Woo Chang Coupling)

TV. : Vertical split cover

TFS: Full spacer type(Horizontal split cover)

THS: Half spacer type(Horizontal split cover)

TBW: Brake wheel type(Horizontal split cover)

5.

(Selection

1)

Method)

1) S e l e c t i o n P r o c e s s

By using the following formula, obtain Design

Torque required.

Torque

T = 97,400 H

N S F

T = Torque(Kg cm)

H= (kw)

H = (HP)

N = (rpm)

S F =

Torque

T = Design Torque(Kg cm)

H= Power(kw)

H = Power(HP)

N = Working revolution(rpm)

S F = Recommended service factor

Size basic

Shaft Coupling

Torque

Select the size with the same or with the greater

value at the Basic Torque column. Refer to the

maximum speed allowed to the size selected,

T = 71,620 H S F

N

and then compare the shaft diameters of the

application with the max. Bore dia of the size

selected. If the coupling bore size is not suitable,

select the larger coupling size.

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

Special requirements

a. on calculating the torque required, use the

lowest operating speed(N) of the application.

b. If there are reverse motions repeatedly or

a.N

b.

2

frequent irregular load changes, make service

factor twice.

2)

2) Example

30 . 1,750 Motor Rotary Type Pump

.

1,750rpm motor to rotary type pump. Motor shaft

58page Pump

1.8

30 .

Torque(kg cm) = 3071,6201.8 =2,210

1,750

Cover

transmitting power is 30HP

Torque(kg cm) =

3071,6201.8 =2,210

1,750

44mm

torque 2210kg

1060 2

1060

Normal

1040

factor of pump is 1.8(Refer to page 58).

The coupling size 1040 accepts the calculated

service

1 1040

2,210kg

57mm

dia is 48mm and pump s 52mm.

cm

Torqiue

When you select a Coupling to connect a 30HP,

1,750 1060

TH TV

cm.

And then compare the

application shaft size(52mm) to the maximum bore

of the selected coupling size 1040(43mm).

You will select the coupling size 1060 accepting

upto 55mm shaft diameter. The size also accept the

application motor speed 1750rpm. Either TH or TV

cover is available. Finally, the coupling size 1060 is

selected

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

6.

(Instruction

Coupling

for Installation)

.

.

TH Type Taper Grid Coupling

Taper Grid Coupling

Gauge( Dial Gauge)

1) TH Type

Feeler

.

The performance and the life of the coupling depend

on how you install and service them. This page helps

you how to assemble the coupling for the best

performance and for the trouble free operation.

TH Taper Grid Coupling is designed to be operate in

either the horizontal or vertical position without

modification.

Simple standard mechanical tools such as

wrenches, a straight edge and feeler gauge or

dial guage are required to install the Taper Grid

Coupling.

1) In case of TH Type

Oil Seal Grease

Hub Shaft

Clean all metal parts using

nonflammable solvent. Lightly

coat seals with grease and place

on shaft, before mounting hub

Mounting hubs on the shafts.

Gap

Using a spacer bar, equal in

thickness to the normal gap. The

difference in maximum measurements must be not exceed the

angular limit.

90

3

Align so that a straight edge

rests squarely on both hubs as

shown fig. And also at 90interval. The clearance must not exce

ed the limit specified in table 3.

Hub Tooth Grease

Grid

After greasing the tooth of

groove hub, fix the Grid in the

same direction.

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

Grid Grease

Oil

Grease fully upon the Grid. Place oil

Seal cover

seals on the hubs, put gaskets and

Gasket

fasten the cover halves correctly by

Cover

Cover

** Coupling

Coupling

bolts.

Match Mark

Grid

Grid

.

Coupling

** Coupling disassembly and Grid

removal.

Whenever it is necessary to disconnect

the coupling, remove the cover halves

and grid. A round rod or screw driver

can be a convenient tool to remove

the grid.

3 (Table

Size

1020

1030

1040

1050

1060

1070

1080

1090

1100

1110

1120

1130

1140

1150

1160

1170

1180

1190

1200

3 - misalignment capacity)

(Unit:mm)

Normal

Recommended installation

Operating

Parallel Angular(1/16

) Parallel Angular(1/ 4

) Gap

10%

Offset p

X -Y

Offset p

X -Y

0.15

0.06

0.3

0.24

3

0.15

0.07

0.3

0.29

3

0.15

0.08

0.3

0.32

3

0.20

0.10

0.4

0.39

3

0.20

0.11

0.4

0.45

3

0.20

0.12

0.4

0.50

3

0.20

0.15

0.4

0.61

3

0.20

0.17

0.4

0.70

3

0.25

0.20

0.5

0.82

4.5

0.25

0.22

0.5

0.90

4.5

0.28

0.25

0.56

1.01

6

0.28

0.30

0.56

1.19

6

0.28

0.33

0.56

1.34

6

0.30

0.39

0.6

1.56

6

0.30

0.44

0.6

1.77

6

0.30

0.50

0.6

2.00

6

0.38

0.56

0.76

2.26

6

0.38

0.61

0.76

2.44

6

0.38

0.68

0.76

2.72

6

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

1) TV Type

1) In case of TV Type

Oil Seal Grease

Hub

Shaft

nonflammable solvent. Lightly

Cover

Clean all metal parts using

coat seals with grease and place

on shaft, before mounting hub

Mounting hubs on the shafts.

Gap

Using a spacer bar, make the

gap between the hubs equal to

the value stated in the table #3

Align so that a straight edge

90

rests squarely on both hubs as

shown fig. And also at 90inter-

12

val. The clearance must not exce

ed the limit specified in page 12

table #3.

Hub Tooth Grease

Grid

After greasing the tooth of

groove hub, fix the Grid in the

same direction.

Grid

Grease

Cover Grease 180

.(Size

Gasket

1150

90

Grease fully upon the grid.

Place oil seals on the hubs, put

gaskets and fasten the vertical

halves, locating lube plug at 180

.)

degree. (note : 90from the size

1150)

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

1) TFS THS Type

Flange Hub Shaft

Flange Shaft

1) In case of TFS THS Type

Mount flange hubs on the sfafts

to be aligned correctly.

Oil Seal

Spacer Hub

Flange Hub

Bolt

~ Page11 TH

spacer on the concave-convex

and fasten bolts

~ Refer to the instruction of

installation of TH Grid Coupling as shown

on Page 11.

Carefully position each half

After

assembly.

Adequate

Coupling

lubrication is essential for a

successful operating and ensure

long life.

.

Cover Match

Mark

You can mount vertically or

horizontally.

As per the application.

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

**Spacer Coupling(THS,TFS)/

Hub Bolt 2

Remove all bolts except two

fasteners. Loosening the two

bolts every 5mm, tap them with a

Spacer Coupling

Spacer Coupling

Flange Hub

TFS Type

Bolt

mallet to disengage, Spacer

Gap

7.

2 Bolt

1) Replacement of spacer

apart from the shaft hubs.

Insert spacer tightly between

shaft hubs. Refer to

of TFS

type installation.

..

Bolt

(Selection

of Puller Holes)

CPLG B.C.D. Bolt

Size (mm) Size

1070

74

M8

1080 89.5

M8

1090 106

M10

1100 121.5 M10

1110 136.5 M10

1120 150.5 M12

1130 185

M16

---------------------WOO CHANG COUPLING

CPLG B.C.D. Bolt

Size (mm) Size

1140

205

M16

1150 227.5 M20

1160

260

M20

1170

306

M24

1180

341

M30

1190

393

M30

1200

414

M30

-- TAPER GRID COUPLING --------------------------------------------

8.

(Lubrication

WCC Taper Grid Coupling

and handling)

You should choose the high quality lubricant for a

good performance and long life.

1) Grease

Grid Hub Grease Cover

Grease Grease

.

2)

Grease 3, 240~250

3, 4,000

Coupling

Grease .

3) Grease

Grease ?17 ~ 70

C 5

rpm .

1) Grease Lubrication

Grease on the grid before assembling covers. Fill up

grease through the lube plugs after assembled

coupling.

2) Supplement and Replacement

Every three months or every 240 ~ 250 hours

operating, you should add grease, Every 3 months,

or every 4,000 hours operating, you should replace

all the deteriorated grease.

3) Selection

You can choose grease according to the ambient

temperature range in table 5.

Common Industraial Lubricants(NLGI Grade #2)

Table 5

Ambient Temperature Range:

0

F to 150

F(-18 to 66 )

-30

F to 100(-34 to 38 )

Amolith Grease #2

Amolith Grease #2

Amoco Oil Co.

Litholene HEP 2

Litholene HEP 2

Atlantic Richfield co.

Chevron Dura - Lith EP-2

Chevron Dura - Lith EP 2

Chevron U.S.A Inc.

Citgo HEP-2

Citgo HEP 2

Cities Service Co.

EP Conolith #2

EP Conolith #2

Conoco Inc.

Ronex MP

Ronex MP

Exxon Company, USA

Gulfcrown Grease #2

Gulfcrown Grease #2

Gulf Oil Corp.

Cosmolube #2

Cosmolube #1

E.F.Houghton & Co.

Esso MP Grease H

Lotemp EP

Ompenrial Oil Corp.

#84 Light

Keystone Div.(Pennwalt) #81 Light

Mobil Oil Corp.

Mobilux EP111

Mobilux #1

Phillips Petroleum Co.

IB & RB Grease

Philube IB & RB Grease

Shell Oil Co.

Alvania Grease #2

Alvania Grease #2

Standard Oil Co.(OH0

Factran #2

Factran #2

Sun Oil Company

Prestige 42

Prestige 42

Texaco Lubricants

Starplex HD2

Multifak EP2

Union Oil Co.(CA)

Union Unoba #2

Union Unoba #2

Valvoline Oil Co.

Val - Lith EP #2

Val - Lith EP #2

** Note : Check with lube manufacture for approved lubricants to use in the food processing industry

Manufacturer

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

9.

(Dimensions)

Type TH (Horizontal Split Aluminum Cover)

Coupling ( Coupling weight, without bore machining )

HP Max. Basic

Bore

Cplg

Dimensions(mm)

Gap(mm)

Per

Size 100 Speed Torque Dia(mm)

Wt

(rpm)

(kg.cm)

(kg)

rpm

Max. Min. A

B

C

D

E

Min. Nor Max.

1020 0.68 4500 486

30 12

101.6 98.0 47.5 39.7 66.5 1.5 3

4.5 1.9

1030 1.93 4500 1383

35 12

110.0 98.0 47.5 49.2 68.3 1.5 3

4.5 2.6

1040 3.22 4500 2304

43 12

1175 104.6 50.8 57.1 70.0 1.5 3

4.5 3.4

1050 5.63 4500 4033

50 12

138.0 123.6 60.3 66.7 79.5 1.5 3

4.5 5.4

1060 8.85 4350 6337

55 19

150.5 130.0 63.5 76.2 92.0 1.5 3

4.5 7.3

1070 13 4125 9217

65 19

161.9 155.4 76.2 87.3 95.0 1.5 3

4.5 10

1080 27 3600 19010 78 27.0 194.0 180.8 88.9 104.8 116.0 1.5 3

4.5 18

1090 48 3600 34564 95 27.0 213.0 1999.8 98.4 123.8 122.0 1.5 3

6

25

1100 81 2400 58183 107 41

250.0 245.7 120.6 142.0 155.5 1.5 3

6

42

1110 121 2250 86411 117 41

270.0 258.5 127.0 160.3 161.5 1.5 4.5 9.5 54

1120 177 2025 126736 136 60

308.0 304.4 149.2 179.4 191.5 1.5 4.5 9.5 81

1130 257 1800 184343 165 67

346.0 329.8 161.9 217.5 195.0 1.5 6

12.5 121

1140 370 1650 264993 184 67

384.0 371.6 182.8 254.0 201.0 1.5 6

12.5 178

1150 515 1500 368686 203 108 453.1 371.8 182.9 269.2 271.3 1.5 6

12.5 234

1160 724 1350 518465 228 120.7 501.4 402.2 198.1 304.8 278.9 1.5 6

12.5 317

1170 965 1225 691286 279 133.4 566.4 437.8 215.9 355.6 304.3 1.5 6

12.5 448

1180 1338 1100 958584 311 152.4 629.9 483.6 238.8 393.7 321.1 1.5 6

12.5 619

1190 1770 1050 1267358 339 152.4 675.6 524.2 259.1 436.9 325.1 1.5 6

12.5 776

1200 2413 900 1728216 361 177.8 756.9 564.8 279.4 497.8 355.6 1.5 6

12.5 1.057

---------------------WOO CHANG COUPLING

Lube

Wt

(kg)

0.03

0.03

0.05

0.05

0.09

0.11

0.17

0.25

0.43

0.51

0.73

0.91

1.13

1.95

2.81

3.49

3.76

4.40

5.62

-- TAPER GRID COUPLING --------------------------------------------

Type TV (Vertical Split Steel Cover)

Coupling ( Coupling weight, without bore machining )

HP Max. Basic

Bore

Cplg

Dimensions(mm)

Gap(mm)

Dia(mm)

Size Per

Speed

Torque

Wt

100 (rpm) (kg.cm)

(kg)

rpm

Max. Min. A

B

C

D

E

Min. Nor Max.

1020 0.68 6000 486

30 12.7 111.1 98.0 47.5 39.7 24.2 1.5 3

4.5 2.0

1030 1.93 6000 1383

36 12.7 120.0 98.0 47.5 49.2 25.0 1.5 3

4.5 2.6

1040 3.22 6000 2304

44 12.7 128.5 104.6 50.8 57.1 25.7 1.5 3

4.5 3.4

1050 5.63 6000 4033

50 12.7 147.6 123.6 60.3 66.7 31.2 1.5 3

4.5 5.4

1060 8.85 6000 6337

57 19.1 162.0 130.0 63.5 76.2 32.2 1.5 3

4.5 7.3

1070 13 5500 9217

65 19.1 173.0 155.4 76.2 87.3 33.7 1.5 3

4.5 10.4

1080 27 4750 19010 79 27.0 200.0 180.8 88.9 104.8 44.2 1.5 3

4.5 17.7

1090 48 4000 34564 95 27.0 231.8 1999.8 98.4 123.8 47.7 1.5 3

6

25.4

1100 81 3250 58183 107 41.3 266.7 245.7 120.6 142.0 60.0 1.5 3

6

42.2

1110 121 3000 86411 117 41.3 285.8 258.5 127.0 160.3 64.2 1.5 4.5 12.5 54.4

1120 177 2700 126736 136 60.3 319.0 304.4 149.2 179.4 73.4 1.5 4.5 12.5 81.6

1130 257 2400 184343 165 66.7 377.8 329.8 161.9 217.5 75.1 1.5 6

12.5 122.5

1140 370 2200 264993 184 66.7 416.0 371.6 182.8 254.0 78.2 1.5 6

12.5 180.1

1150 515 2000 368686 203 108.0 476.3 371.8 182.9 269.2 106.9 1.5 6

12.5 230.0

1160 724 1750 518465 228 120.7 533.4 402.2 198.1 304.8 114.3 1.5 6

12.5 321.1

1170 965 1600 691286 279 133.4 584.2 437.8 215.9 355.6 119.4 1.5 6

12.5 448.2

1180 1338 1400 958584 311 152.4 630.0 483.6 238.8 393.7 130.0 1.5 6

12.5 591.0

1190 1770 1300 1267358 339 152.4 685.0 524.2 259.1 436.9 135.0 1.5 6

12.5 761.0

1200 2413 1100 1728216 361 177.8 737.0 564.8 279.4 497.8 145.0 1.5 6

12.5 1021

---------------------WOO CHANG COUPLING

Lube

Wt

(kg)

0.03

0.03

0.05

0.05

0.09

0.11

0.17

0.25

0.43

0.51

0.73

0.91

1.13

1.95

2.81

3.49

3.76

4.40

5.62

-- TAPER GRID COUPLING --------------------------------------------

Size

1020

1030

1040

1050

1060

1070

1080

1090

1100

1110

1120

1130

1140

1150

1160

1170

1180

1190

1200

Type TFS (Full Spacer), THS (Half Spacer)

HP

Per

100

rpm

0.68

1.93

3.22

5.63

8.85

13

27

48

81

121

177

257

370

515

724

965

1338

1770

2413

Max. Basic

Speed Torque

(rpm) (kg.cm)

3600

3600

3600

3600

3600

3600

3600

3600

2400

2250

2025

1800

1650

1500

1350

1225

1100

1050

900

486

1383

2304

4033

6337

9217

19010

34564

58183

86411

126736

184343

264993

368686

518465

691286

958584

1267358

1728216

* BE Shaft

BE

.

Bore

Dia(mm)

Max.

36

44

57

64

79

83

95

108

127

149

165

178

203

254

279

330

330

362

381

Min.

12.7

12.7

12.7

12.7

19.1

19.1

27.0

27.0

38.1

50.8

63.5

76.2

88.9

101.6

114.3

127.0

101.6

114.3

127.0

A

101.6

110.0

1175

138.0

150.5

161.9

194.0

213.0

250.0

270.0

308.0

346.0

384.0

453.1

501.4

566.4

629.9

675.6

756.9

B

35

41

54

60

73

79

89

102

90

104

119

135

152

173

186

220

249

276

305

Dimensions(mm)

BE(TFS) BE(THS)

Min Max Min Max

89 203 45

102

89 216 45

109

89 216 45

109

112 216 57

109

127 330 64

166

127 330 64

166

184 406 93

204

184 406 93

204

203 406 103 205

210 406 106 205

246 406 125 205

257 406 130 205

267 406 135 205

345 371 175 187

356 406 180 205

384 445 194 224

400 490 202 247

411 530 207 267

445 575 224 289

N

52

59

78

87

103

109

122

142

171

196

225

238

266

334

366

425

451

508

530

F

86

94

113

126

145

153

178

210

251

277

319

346

386

425

457

527

591

660

711

Gap

5

5

5

5

5

5

5

5

6.5

6.5

9.5

9.5

9.5

9.5

9.5

9.5

9.5

9.5

9.5

Flange Lube

Bolt Wt

No. (kg)

4

8

8

8

8

12

12

12

12

12

12

12

12

14

14

16

16

18

18

0.03

0.03

0.05

0.05

0.09

0.11

0.17

0.25

0.43

0.51

0.73

0.91

1.13

1.95

2.81

3.49

3.76

4.40

5.62

* BE means the distants between shaft

ends. Do not miss to tell on ordering

---------------------WOO CHANG COUPLING

-- TAPER GRID COUPLING --------------------------------------------

Type TBW (Brake Wheel)

Standard Brake Wheel

Cplg

Size Motor Power Brake Torque

(40%ED KW)

(kg . m)

1020

1030

1040

2.2

5

1050

5.5

10

1060 5.5 7.5 11 10 14 21.2

1070

15

30

1080

30

53

1090 75

90 63 80

1100

45

132

1110 75

90

180

1020 110 132

335

1130 160 200 400 475

1140 160 200 400 475

* Motor

Brake

wheel

Size

AB JB

Crane

Max

Bore Dia

Lube

Brake

Dimensions(mm)

(mm)

wt

Size Rating

of

C

D

E

F

H

I

J

Gap (kb)

CPLG Max Min A

1020 110

30 12.7 102 48 39.6

3

0.03

1030 359

36 12.7 111 48

49

3

0.03

160 80 1040 663

44 12.7 117 51

57 145 140 40 12 28

3

0.05

200 100 1050 1202 50 12.7 138 60

66 184 178 50 17 33

3

0.05

200 100 1060 2129 57 19.1 151 63

76 184 178 50 17 33

3

0.09

250 125 1070 3373 68 19.1 162 76

87 230 224 62. 22 40.5 3

0.11

315 160 1080 6497 82 27.0 194 89 105 292 285 80 23 57

3

0.17

355 180 1090 11060 95 27.0 213 98 124 330 320 90 26 64

3

0.25

400 200 1100 19355 107 41.3 251 121 142 374 362 100 28 72

5

0.43

450 224 1110 29032 117 41.3 270 127 160 422 410 112 32 80

5

0.51

500 250 1120 44240 136 60.3 308 149 179 462 445 125 35 90

6

0.73

560 280 1130 66212 165 66.7 346 162 218 516 495 140 45 95

6

0.91

560 280 1140 89862 184 66.7 384 184 253 516 495 140 45 95

6

1.13

Firstly, determine the brake size of you coupling and then check the W dimensions from the above chart

---------------------WOO CHANG COUPLING

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Catalogo de Metales Cigueñal-Biela PDFDocument43 paginiCatalogo de Metales Cigueñal-Biela PDFAlex Xavier Malasquez LeónÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Cummins n14 2015 LR PDFDocument28 paginiCummins n14 2015 LR PDFGutierrez Efrain100% (1)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Pipe GuideDocument231 paginiPipe GuidegeorgD2010100% (1)

- 6 Spd. Automatic Transmission 09L All Wheel DriveDocument452 pagini6 Spd. Automatic Transmission 09L All Wheel DriveNP100% (1)

- Suzuki 2017-2019 Sv650 Service ManualDocument681 paginiSuzuki 2017-2019 Sv650 Service ManualMaxim KovalenkoÎncă nu există evaluări

- 2017 TRB CatalogDocument760 pagini2017 TRB CatalogBrion Bara IndonesiaÎncă nu există evaluări

- Essential MATLAB For Engineers and Scientists - Brian D. Hahn & Daniel T. ValentineDocument102 paginiEssential MATLAB For Engineers and Scientists - Brian D. Hahn & Daniel T. Valentinegagansingh87Încă nu există evaluări

- QUIZ 1 LG With AnswerDocument6 paginiQUIZ 1 LG With Answermellon3duwenÎncă nu există evaluări

- TKE-GEC-24 - Códigos de Falhas e Alertas-PortuguêsDocument6 paginiTKE-GEC-24 - Códigos de Falhas e Alertas-PortuguêsValdo100% (1)

- Oxy Miser SeriesDocument4 paginiOxy Miser SeriesKarla ChumbiaucaÎncă nu există evaluări

- John Crane Type 8-1 PDFDocument6 paginiJohn Crane Type 8-1 PDFHoang DungÎncă nu există evaluări

- Clow FittingsDocument21 paginiClow Fittingsnjsmith5Încă nu există evaluări

- Clow FittingsDocument21 paginiClow Fittingsnjsmith5Încă nu există evaluări

- Tuercas MariposaDocument1 paginăTuercas MariposaarrancatetasÎncă nu există evaluări

- TYPE 1/1B: Elastomer Bellows SealsDocument6 paginiTYPE 1/1B: Elastomer Bellows SealsWalter TeránÎncă nu există evaluări

- ASM BP 221 Stion V6Document3 paginiASM BP 221 Stion V6arrancatetasÎncă nu există evaluări

- Idas ForjDocument43 paginiIdas ForjJose Luis PintoÎncă nu există evaluări

- GWS 1-08-Att.1-R1Document7 paginiGWS 1-08-Att.1-R1solrac4371Încă nu există evaluări

- Materials Compatibility Reference - ChartsDocument2 paginiMaterials Compatibility Reference - ChartsarrancatetasÎncă nu există evaluări

- AeroGO SystemDocument2 paginiAeroGO SystemarrancatetasÎncă nu există evaluări

- SOLUTIONS Software Corporation Enterprise, FL 32725 USA: Chemical / Material CompatibilityDocument34 paginiSOLUTIONS Software Corporation Enterprise, FL 32725 USA: Chemical / Material CompatibilityarrancatetasÎncă nu există evaluări

- Crane BronzeValve CatalogDocument53 paginiCrane BronzeValve CatalogarrancatetasÎncă nu există evaluări

- Index PDFDocument28 paginiIndex PDFarrancatetasÎncă nu există evaluări

- Bolts and NutsDocument144 paginiBolts and Nutskeo85Încă nu există evaluări

- Material Compatibility Guide 3 PDFDocument8 paginiMaterial Compatibility Guide 3 PDFarrancatetasÎncă nu există evaluări

- AbbreviationsDocument3 paginiAbbreviationsarrancatetasÎncă nu există evaluări

- Piping ManualDocument1 paginăPiping ManualarrancatetasÎncă nu există evaluări

- Material Compatibility GuideDocument18 paginiMaterial Compatibility GuidearrancatetasÎncă nu există evaluări

- ContentsDocument2 paginiContentsarrancatetasÎncă nu există evaluări

- Preface: Pages A1 To A14Document1 paginăPreface: Pages A1 To A14arrancatetasÎncă nu există evaluări

- Material Compatibility Guide 3Document8 paginiMaterial Compatibility Guide 3arrancatetasÎncă nu există evaluări

- 15-5 PH Data Bulletin PDFDocument12 pagini15-5 PH Data Bulletin PDFAndres Camilo BenitezÎncă nu există evaluări

- PP OPM3ExecGuideDocument5 paginiPP OPM3ExecGuidejainjorÎncă nu există evaluări

- Material Compatibility Guide 2Document2 paginiMaterial Compatibility Guide 2arrancatetasÎncă nu există evaluări

- Astm A204 GRBDocument1 paginăAstm A204 GRBarrancatetasÎncă nu există evaluări

- Train SLK r171 IntroDocument98 paginiTrain SLK r171 IntroIvo AlmeidaÎncă nu există evaluări

- 2012-2013 Specifications v010 enDocument222 pagini2012-2013 Specifications v010 enMário CorreiaÎncă nu există evaluări

- 5-3 Group 3 Disassembly and AssemblyDocument25 pagini5-3 Group 3 Disassembly and Assemblystefan corjucÎncă nu există evaluări

- BS en 14399-2-2015 - TC - (2021-05-23 - 05-16-50 PM)Document51 paginiBS en 14399-2-2015 - TC - (2021-05-23 - 05-16-50 PM)EmreÎncă nu există evaluări

- Yz 250 F-2006Document69 paginiYz 250 F-2006AdolfoÎncă nu există evaluări

- Post Test OLD - Attempt Review Steering and BrakeDocument16 paginiPost Test OLD - Attempt Review Steering and BrakeJean DickmaÎncă nu există evaluări

- 580L RadiadorDocument2 pagini580L RadiadorFernando Garcia Prepa en LineaÎncă nu există evaluări

- Https WWW - Google.com Amp S WWW - Engineeringtoolbox.Document7 paginiHttps WWW - Google.com Amp S WWW - Engineeringtoolbox.BelalNorÎncă nu există evaluări

- Hutch Suspension 240-261Document22 paginiHutch Suspension 240-261fullkuleÎncă nu există evaluări

- Bauer PilecoParts Book D46Document32 paginiBauer PilecoParts Book D46W MoralesÎncă nu există evaluări

- Arctic Cat 2009 250 Utility DVX 300 Service ManualDocument10 paginiArctic Cat 2009 250 Utility DVX 300 Service Manualandrew100% (48)

- NEC CHAPTER 3 QUIZ With AnswersDocument20 paginiNEC CHAPTER 3 QUIZ With AnswersAbdul RaheemÎncă nu există evaluări

- Despiece-Mototaxi Re4sDocument112 paginiDespiece-Mototaxi Re4sCristian HiguitaÎncă nu există evaluări

- 4012 Tag2 2aDocument2 pagini4012 Tag2 2awidiÎncă nu există evaluări

- Evinrude Carburetor Group Parts For 1966 18hp 18602 Outboard MotorDocument8 paginiEvinrude Carburetor Group Parts For 1966 18hp 18602 Outboard MotorWouter GrootÎncă nu există evaluări

- Explosion Proof Cable Glands Prysmian Barrier Glands (424TX) For SWB Steel Wire Braided CableDocument2 paginiExplosion Proof Cable Glands Prysmian Barrier Glands (424TX) For SWB Steel Wire Braided CablerocketvtÎncă nu există evaluări

- Parts Manual: CascadeDocument17 paginiParts Manual: CascadeIntercambio de ManualesÎncă nu există evaluări

- Finisher Sr4030d374-57parts Location and ListDocument58 paginiFinisher Sr4030d374-57parts Location and ListEdmundo SanchezÎncă nu există evaluări

- Terminal SizeDocument6 paginiTerminal SizeThanis SribovornmongkolÎncă nu există evaluări

- CORTEC Compact Valves - Critical ServiceDocument2 paginiCORTEC Compact Valves - Critical ServiceAndresÎncă nu există evaluări

- 51599Document14 pagini51599Bo ClarkÎncă nu există evaluări

- Sullair 10B-40HDocument84 paginiSullair 10B-40HLuis Eduardo Albarracin RugelesÎncă nu există evaluări

- Vdocument - in Caterpillar Cat 225 Excavator Prefix 76u Service Repair Manual 76u00694 01199 1586296486Document28 paginiVdocument - in Caterpillar Cat 225 Excavator Prefix 76u Service Repair Manual 76u00694 01199 1586296486Amel AlidraÎncă nu există evaluări