Documente Academic

Documente Profesional

Documente Cultură

EC2-111 Universal Controller

Încărcat de

Maria DazaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

EC2-111 Universal Controller

Încărcat de

Maria DazaDrepturi de autor:

Formate disponibile

EC2-111 Universal Controller

Operating Instructions

GB

Contents:

Safety instructions: 1 Load Default Parameters: 2 Technical data: 1 Special Functions 2 Mounting 1 Indications On The Display 2 Electrical Installation 1 Parameter List 2 Setup and Parameter Modification Alarm Codes and Messages 2 using the Keypad 1 Visualising Data: LON Monitoring 2 Temporary Display of Data: 2 Note: This document contains short form instructions for experienced users. Use last column in List of Parameters to document your individual settings. More detailed information can be found in the User Manual.

The EC2-111 can be mounted in panels with a 71 x 29 mm cutout. See dimensional drawing below for space requirements including rear connectors. Push controller into panel cutout.(1) Make sure that mounting lugs are flush with outside of controller housing Insert allen key into front panel holes and turn clockwise. Mounting lugs will turn and gradually move towards panel (2) Turn allen key until mounting lug barely touches panel. Then move other mounting lug to the same position (3) Tighten both sides very carefully until controller is secured. Do not over tighten as mounting lugs will break easily.

Electrical Installation

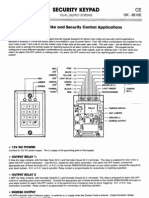

Refer to the electrical wiring diagram (below) for electrical connections. A copy of this diagram is labelled on the controller. Use connection wires/cables suitable for 90C operation (EN 60730-1)

Output2 Output4 Output3

L 8 7

The EC2-111 is a universal controller with LON interface with 2 digital inputs (1) (2), 3 temperature inputs (3) (4) (5) and 4 relay outputs (6) (7) (8) (9). EC2-211 is equipped with a FTT-10 transceiver type.

Network

6 7 8 9

11 10

Output1

3

24V AC/1A 2 1

EC2 Series

Therm./TXV

S1: Digital Input1 S2: Digital Input2 S3: Temp1 S4: Temp2 S5: Temp3

6(2) A 250V

EC2-11x

A B LON 22 23 24 25

12 13 14 15 16 17 18 19 20 21 22 23 24

S1

S2

S3

S4

1 2

3 4 5

Safety instructions:

Read installation instructions thoroughly. Failure to comply can result in device failure, system damage or personal injury. The product is intended for use by persons having the appropriate knowledge and skills. Ensure electrical ratings per technical data are not exceeded. Disconnect all voltages from system before installation. Keep temperatures within nominal limits. Comply with local electrical regulations when wiring

EC2 analog inputs are for dedicated sensors only and should not be connected to any other devices. Connecting any EC2 inputs to mains voltage will permanently damage the EC2. Important: Keep controller and sensor wiring well separated from mains wiring. Minimum recommended distance 30mm. Warning: Use a class II category transformer for 24VAC power supply (EN 60742). Do not ground the 24VAC lines. We recommend to use one transformer per EC2 controller and to use separate transformers for 3rd party controllers, to avoid possible interference or grounding problems in the power supply. Connecting any EC2 inputs to mains voltage will permanently damage the EC2.

S5 TCP/IP: RX+ TX+ RX- TX-

Setup and Parameter Modification Using the Keypad

For convenience, an infrared receiver for the optional IR remote control unit is build-in, enabling quick and easy modification of the system parameters when a computer interface is not available. Alternatively, the parameters can be accessed via the 4-button keypad. The configuration parameters are protected by a numerical password. The default password is 12. To select the parameter configuration: Press the PRG button for more than 5 seconds A flashing 0 is displayed Press or until 12 is displayed; (password) Press SEL to confirm password The first modifiable parameter code is displayed (/1). To modify parameters see Parameters modification below.

Technical Data

EC2 Series Controller Power supply Power consumption Communication Plug-in connector size Temperature storage operating Humidity Protection class Digital inputs Output relays 24VAC 10%; 50/60 Hz; Class II 4VA max. LonWorks Interface, FTT10, RJ45 connector Removable screw terminals wire size 0.14 1.5mm2 -20 +65C 0 +60C 080% r.h. non condensing IP65 (front protection with gasket) Volt free contacts, 5V / 0,1mA SPDT contacts, AgCdO Inductive (AC15) 250V/2A Resistive (AC1) 250V/6A; 12A total return current

Parameter Modification: Procedure

Press or to show the code of the parameter that has to be changed; Press SEL to display the selected parameter value; Press or to increase or decrease the value; Press SEL to temporarily confirm the new value and display its code; Repeat the procedure from the beginning "press or to show..." To exit and save the new settings: Press PRG to confirm the new values and exit the parameters modification procedure. To exit without modifying any parameter: Do not press any button for at least 60 seconds (TIME OUT). Press ESC on IR remote control.

(2) (4)

Mounting

Document Nr.: EC2-111_65078_EN_R00.doc

Replacement for 05

1/2

PCN: 864 917 21.06.2007

EC2-111 Universal Controller

Operating Instructions

GB

Special Functions:

The Special Functions can be activated by: Press and together for more than 5 seconds. A flashing 0 is displayed. Press or until the password is displayed (default = 12). If password was changed, select the new password. Press SEL to confirm password A 0 is displayed and the Special Function mode is activated. or to select the function. The number of special functions is dynamic Press and controller dependent. See list below. Press SEL to activate the function without leaving the special function mode. Press PRG to activate the function and leave the special function mode. Most of the Special Functions work in a toggle mode, the first call activates the function, and the second call deactivates the function. The indication of the function can only be displayed after exiting the special function mode. 0: Display test function 5: Resets all parameters to the factory default setting. The controller will indicate oF during the reset and the valve will close.

Display of Data:

The data to be shown on the display can be selected by the user. In case of an alarm, the alarm code is displayed alternately with the selected data. The user can inhibit the alarm code. Press the SEL button to scroll through all possible displayable data. The display will show for one second the numerical identifier of the data and then the selected data. After two minutes the display will return to the by parameter /1 selected data. It is possible to temporarily display the values of the different sensors. This is a useful feature when initially setting-up the system without the aid of the WebPages. Press the SEL sequentially. The value displayed on the screen corresponds to the number corresponding to the /1 parameter. Action only valid when parameter H2 = 3. IR LED Indication of relay 1 LON service LED Indication of relay 2 Indication of relay 3 Alarm condition

List Of Parameters

/ DISPLAY PARAMETERS Min Max Unit Def. /1 Value to show 0 7 0 0 = Value temperature sensor 1, Alignment factor /C will only work with this temperature display 1 = Value temperature sensor 1 2 = Value temperature sensor 2 3 = Value temperature sensor 3 10 = Status digital input 1: oF = open; on = closed circuit 11 = Status digital input 2: oF = open; on = closed circuit 4, 5, 6, 7, 8, 9 = not used /2 Alarm suppression (0 = off,1 = on) 0 1 n/a 0 /5 Temperature Unit (0 = C, 1 = F) 0 1 0 Note: This affects only data display. All configuration parameters except /C must be entered in C / K! /6 Decimal point 0 1 0 0 = yes, in the range -19.9 +19.9 1 = no /7 Display during defrost not used 0 2 0 Custom /C Temperature alignment for /1=0 Min Max Unit - 20 + 20 K / F Def. Custom 0.0

H OTHER PARAMETERS H2 Display access 0 3 3 0 = all disabled (Caution, access to controller only via LON network possible) 1 = Keyboard enabled 2 = IR remote control enabled 3 = Keyboard and IR remote control; Temporary data display and manual defrost enabled. 4 = Keyboard and IR remote control; Temporary data display disabled. Control setpoint with SEL key and manual defrost enabled. H3 IR access code 0 199 0 H5 Password 0 199 12

Alarm Codes

E2 E3 E4 Er Temperature sensor 1 failure Temperature sensor 1 failure Temperature sensor 1 failure. No sensor connected; sensor cable broken or short circuited Data error display - out of range Data send to the display is out of range. No data to display The display will show an --- at node start up and when no data is send to the display. Reset to default values activated The display will show an In when the factory default configuration data set is initialized. Wink request received The display will show a flashing Id when the wink request was received. The flashing Id will be shown on the display until the service button will be pressed, or a 30 min delay timer will expire or a second wink request is received. Node is offline The node is offline and no application is running. This is the result of a network management command and will happen for example during node installation. Digital input status: switch open Digital input status: switch closed

Visualising Data: LON Monitoring Server

The EC2-211 has a LON communication interface enabling the controller to be directly connected to a Monitoring Server. It can be connected by using the optional cable assembly to a LON network (ECC-014, order nr. 804 381, with RJ45 to open, cable length 3m).

Neuron ID / Service PIN:

The service pin is available on the display. It is used to identify the controller in a button for app. 1 second to send the Neuron ID. The LON network. Press the LED in the left upper corner will indicate the transmission of the Neuron ID. The default settings may be modified remotely from the Monitoring Server via the LON network. Consult the AMS__64074 user manual for more information. It is also possible to display live graphical data on the server or to log data containing the control temperature at defined intervals.

Messages

--In Id

OF

oF on

Emerson Electric GmbH & Co OHG is not to be held responsible for erroneous literature regarding capacities, dimensions, applications, etc. stated herein. Products, specifications and data in this literature are subject to change without notice. The information given herein is based on technical data and tests which ALCO CONTROLS believes to be reliable and which are in compliance with

technical knowledge of today. It is intended only for use by persons having the appropriate technical knowledge and skills, at their own discretion and risk. Since conditions of use are outside of ALCO'S control we cannot assume any liability for results obtained or damages occurred due to improper application. This document replaces all former versions

Emerson Electric GmbH & Co.OHG - Postfach 1251 - Heerstrae 111 - D-71332 Waiblingen - Germany - Phone +49-(0)7151-509-0 - Fax .49-(0)7151-509-200 www.eCopeland.com/alcoliterature.cfm Document Nr.: EC2-111_65078_EN_R00.doc Replacement for 05 2/2 PCN: 864 917 21.06.2007

S-ar putea să vă placă și

- EC2-712 Condenser ControllerDocument4 paginiEC2-712 Condenser ControllerMaria DazaÎncă nu există evaluări

- Digital LED Thermometer with Microcontroller AVR ATtiny13De la EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Evaluare: 5 din 5 stele5/5 (1)

- EC2-742 Condenser ControllerDocument4 paginiEC2-742 Condenser ControllerMaria DazaÎncă nu există evaluări

- EC2-512 Condensing Unit ControllerDocument4 paginiEC2-512 Condensing Unit ControllerMaria DazaÎncă nu există evaluări

- DHC100Document4 paginiDHC100Pablos AugoustisÎncă nu există evaluări

- EC3-D13 Alco controller για digital scrollDocument2 paginiEC3-D13 Alco controller για digital scrollLefti YMÎncă nu există evaluări

- Dixel: Instruction ManualDocument38 paginiDixel: Instruction ManualDavid SilvaÎncă nu există evaluări

- Manual: Monitoring, Control and Alarm SystemDocument38 paginiManual: Monitoring, Control and Alarm SystemSteve OliveiraÎncă nu există evaluări

- Pni CT36Document78 paginiPni CT36raduracheriuÎncă nu există evaluări

- Videx Vprox-100: (2 Door, 100 Key System)Document7 paginiVidex Vprox-100: (2 Door, 100 Key System)Christopher HenryÎncă nu există evaluări

- KFM Controlador PDFDocument8 paginiKFM Controlador PDFRodolfoAntonioLeónCárdenasÎncă nu există evaluări

- Protem d404pdf Rele Temperatura de TrafosDocument16 paginiProtem d404pdf Rele Temperatura de TrafosIvan FrancoÎncă nu există evaluări

- User Manual Control JT-901 Smart Eng ED 23.08.02Document28 paginiUser Manual Control JT-901 Smart Eng ED 23.08.02prueba12345100% (1)

- Freezer&Fridge KeypadDocument21 paginiFreezer&Fridge Keypadjohnwayne314Încă nu există evaluări

- CC !"#$ % & ' +) ,-.' ' +) , - c3'4/!!1564243) B@"Document7 paginiCC !"#$ % & ' +) ,-.' ' +) , - c3'4/!!1564243) B@"Kamrujjaman SakiÎncă nu există evaluări

- Dali GatewayDocument10 paginiDali GatewayUsman ZafarÎncă nu există evaluări

- Syl 151Document4 paginiSyl 151Boris KozjanÎncă nu există evaluări

- PID Temperatura EstDocument5 paginiPID Temperatura EstEektor BonillaÎncă nu există evaluări

- Ch402 - 403 - OPDocument2 paginiCh402 - 403 - OPhp691550% (2)

- DataKom 040 USERDocument45 paginiDataKom 040 USERsebastianÎncă nu există evaluări

- DATAKOM DK40 Installation ManualDocument45 paginiDATAKOM DK40 Installation ManualVykintas ImbrasasÎncă nu există evaluări

- Instrukcja XT 546 - WWW - Ebmia.plDocument3 paginiInstrukcja XT 546 - WWW - Ebmia.plAwdhesh Singh BhadoriyaÎncă nu există evaluări

- Daikin Remote Controller BRC1C62Document5 paginiDaikin Remote Controller BRC1C62oioizoii100% (1)

- 881NXDocument12 pagini881NXYogesh RamdasiÎncă nu există evaluări

- Contents:-: Temperature Sensor and ControlDocument34 paginiContents:-: Temperature Sensor and ControlTarun Gupta100% (4)

- Survey Technical Manual V 1.0Document28 paginiSurvey Technical Manual V 1.0snakeyvioÎncă nu există evaluări

- HL EH HB Desiccant Dryer Troubleshooting Guide Rev 2Document21 paginiHL EH HB Desiccant Dryer Troubleshooting Guide Rev 2Ramsi Edianta Sembiring100% (1)

- Pilot 1600 Manual-EnDocument22 paginiPilot 1600 Manual-EnBogdan BucataruÎncă nu există evaluări

- 0 Series ControllerDocument32 pagini0 Series ControllerNhan Sua CncÎncă nu există evaluări

- ELK38-240-C-R-2R DataSheetDocument14 paginiELK38-240-C-R-2R DataSheetAnna PopaÎncă nu există evaluări

- Fanuc: 0 Series ControllerDocument16 paginiFanuc: 0 Series ControllerHoangvinh Duong100% (1)

- InstructionsDocument4 paginiInstructionsMichael GiannakÎncă nu există evaluări

- Ic200cx QRG GBDocument58 paginiIc200cx QRG GBDouglasÎncă nu există evaluări

- Syl 2372Document8 paginiSyl 2372Ismael 8877Încă nu există evaluări

- TR-7570 Winding Temperature IndicatorManual PDFDocument30 paginiTR-7570 Winding Temperature IndicatorManual PDFkiran100% (5)

- Ic70cx enDocument24 paginiIc70cx enDCO FritempoÎncă nu există evaluări

- Zanotti Parameter SP SplitaggregatDocument17 paginiZanotti Parameter SP SplitaggregatSinan BulutÎncă nu există evaluări

- SG808 ManualDocument2 paginiSG808 ManualzzmeoneÎncă nu există evaluări

- Manual Falcon XLDocument7 paginiManual Falcon XLXavier OrtizÎncă nu există evaluări

- VT26 Series ManualDocument15 paginiVT26 Series ManualShivaramakrishna Challapalli0% (1)

- Vav Svn05b en 0704Document2 paginiVav Svn05b en 0704dino_pÎncă nu există evaluări

- MNL007 - ENG Rev.a - INGLESE SERVICE ECT-F - DMLPDocument32 paginiMNL007 - ENG Rev.a - INGLESE SERVICE ECT-F - DMLPP managerÎncă nu există evaluări

- 2116 and 2132 Multi Language User GuideDocument156 pagini2116 and 2132 Multi Language User GuideGerman Vasquez SepulvedaÎncă nu există evaluări

- CMS200 Product Manual Iss2Document62 paginiCMS200 Product Manual Iss2Anderson Celso59% (17)

- Dixell XR40CDocument4 paginiDixell XR40Cminhdung76np100% (1)

- 06-Heltun HE-TPS02 User ManualDocument26 pagini06-Heltun HE-TPS02 User ManualSarkis KaprelianÎncă nu există evaluări

- Automatic Door Opener With PIC12C508 CircuitDocument3 paginiAutomatic Door Opener With PIC12C508 CircuitLingaraj BeharaÎncă nu există evaluări

- CN-DP200 2Document6 paginiCN-DP200 2Sundar RamasamyÎncă nu există evaluări

- User's Manual: FDC 4100 / 7100 / 8100 / 9100 Auto-Tune Fuzzy / PID Process / Temperature ControllerDocument60 paginiUser's Manual: FDC 4100 / 7100 / 8100 / 9100 Auto-Tune Fuzzy / PID Process / Temperature ControllerkmpoulosÎncă nu există evaluări

- Pid Temperature Controller ManualDocument12 paginiPid Temperature Controller ManualraffaeleÎncă nu există evaluări

- I ThermDocument4 paginiI ThermAvneet MaanÎncă nu există evaluări

- AHE27 User Manual: PrefaceDocument16 paginiAHE27 User Manual: PrefaceDinh NguyenÎncă nu există evaluări

- Automatic Door Opener With PIC12C508Document3 paginiAutomatic Door Opener With PIC12C508Victoryback BackÎncă nu există evaluări

- Ethernet Controller User Manual: 1. Short DescriptionDocument13 paginiEthernet Controller User Manual: 1. Short DescriptionFantomasÎncă nu există evaluări

- 0 Series ControllerDocument13 pagini0 Series ControllerSuresh RamachandranÎncă nu există evaluări

- Engg. Manual TR-7570Document30 paginiEngg. Manual TR-7570Manish Gupta63% (8)

- UT130 Manual 1Document4 paginiUT130 Manual 1soka2030Încă nu există evaluări

- EC3-611 Rack Controller and ECD-000 Display UnitDocument8 paginiEC3-611 Rack Controller and ECD-000 Display UnitMaria DazaÎncă nu există evaluări

- TEC-8A-24V-PID-HC Operating ManualDocument21 paginiTEC-8A-24V-PID-HC Operating ManualSarah Joy ManimtimÎncă nu există evaluări

- Locator 3s Phasec 2s Phasec 2d: Technical Reference and Operating ManualDocument136 paginiLocator 3s Phasec 2s Phasec 2d: Technical Reference and Operating ManualMaria DazaÎncă nu există evaluări

- Phasec2d Data SheetDocument2 paginiPhasec2d Data SheetMaria DazaÎncă nu există evaluări

- H Im pcs1Document42 paginiH Im pcs1Maria DazaÎncă nu există evaluări

- H Im 68Document12 paginiH Im 68Maria DazaÎncă nu există evaluări

- H Im 67GDocument52 paginiH Im 67GMaria DazaÎncă nu există evaluări

- H Im 81eDocument28 paginiH Im 81eMaria DazaÎncă nu există evaluări

- H Im 65BDocument16 paginiH Im 65BMaria DazaÎncă nu există evaluări

- 06 CC AccessoriesDocument1 pagină06 CC AccessoriesMaria DazaÎncă nu există evaluări

- Bonh 1Document38 paginiBonh 1Maria DazaÎncă nu există evaluări

- CcarrierProduct Data Air Cooled Cond 09aw, Az-2pdDocument36 paginiCcarrierProduct Data Air Cooled Cond 09aw, Az-2pdrikechÎncă nu există evaluări

- 35391SSG Rev 07Document111 pagini35391SSG Rev 07Maria DazaÎncă nu există evaluări

- J Series ManualDocument144 paginiJ Series ManualMaria DazaÎncă nu există evaluări

- Process Control, Network Systems, and SCADADocument13 paginiProcess Control, Network Systems, and SCADASTÎncă nu există evaluări

- Attach 8 - CPDS Type 2ADocument401 paginiAttach 8 - CPDS Type 2AGlenn Adalia BonitaÎncă nu există evaluări

- Simulation of MPPT Techniques Using Quadratic Boost Converter For PV SystemDocument11 paginiSimulation of MPPT Techniques Using Quadratic Boost Converter For PV SystemTandin TshewangÎncă nu există evaluări

- RBFBBEDocument66 paginiRBFBBELauro RdzÎncă nu există evaluări

- 056-093 74xx MKI To 74xx MKII ConversionDocument2 pagini056-093 74xx MKI To 74xx MKII ConversiongilizaniniÎncă nu există evaluări

- Schneider Clipsal ESM32D20NADocument3 paginiSchneider Clipsal ESM32D20NAUmer Farooq100% (1)

- Pressure SwitchDocument2 paginiPressure Switchayyaz123Încă nu există evaluări

- Electrical Layout - Ground Floor Plan: Sheet No. InstructionsDocument1 paginăElectrical Layout - Ground Floor Plan: Sheet No. InstructionsAbhishek AjayÎncă nu există evaluări

- JH-HE3416 Guide v1.3.1 enDocument112 paginiJH-HE3416 Guide v1.3.1 enDavid Santiago Ortiz Rodriguez100% (2)

- pm21 2013Document222 paginipm21 2013MarioRossiÎncă nu există evaluări

- Problems 6 Circuit WileyDocument29 paginiProblems 6 Circuit WileyHelloWorldÎncă nu există evaluări

- Aeolian Vibration: Its Affects and Remedy On Transmission LinesDocument10 paginiAeolian Vibration: Its Affects and Remedy On Transmission LinesAsaduzzaman Khan0% (1)

- ToyotaDocument12 paginiToyotaJose F. SeguraÎncă nu există evaluări

- Introduction To The Arduino Microcontroller: Hands-On Research in Complex SystemsDocument11 paginiIntroduction To The Arduino Microcontroller: Hands-On Research in Complex SystemsRahmat KurniawanÎncă nu există evaluări

- Lecture Plan BE 8253 AutoDocument6 paginiLecture Plan BE 8253 Autoboomadev6321Încă nu există evaluări

- Pid Proton PDFDocument27 paginiPid Proton PDFfeyyazkurtÎncă nu există evaluări

- WM-E1S Family Quick Reference Guide ENG v2 00-1Document1 paginăWM-E1S Family Quick Reference Guide ENG v2 00-1Santiago MuñozÎncă nu există evaluări

- Hitachi - Energy - High K Dielectrics For SiC Power MOSFET TechnologyDocument8 paginiHitachi - Energy - High K Dielectrics For SiC Power MOSFET TechnologyApe DieÎncă nu există evaluări

- Transmission Lines PDFDocument44 paginiTransmission Lines PDFkajariÎncă nu există evaluări

- Tariel Kapanadze CoilDocument5 paginiTariel Kapanadze Coilharishkumarsingh0% (1)

- Advanced Data Communication For M.tech Communication SystemsDocument1 paginăAdvanced Data Communication For M.tech Communication Systemssrinath02Încă nu există evaluări

- High - K Dielectric Materials in MicroelectronicsDocument31 paginiHigh - K Dielectric Materials in MicroelectronicsAadil ShÎncă nu există evaluări

- UNITY2 MFC Series 2 Installation ManualDocument13 paginiUNITY2 MFC Series 2 Installation Manualntien6996Încă nu există evaluări

- DSP 1Document535 paginiDSP 1isarangadharanÎncă nu există evaluări

- 0513 Af 006564 - WithtagsDocument8 pagini0513 Af 006564 - WithtagsTHIAGO ROSAÎncă nu există evaluări

- Mechatronic System DesignDocument30 paginiMechatronic System DesignNor AzlanÎncă nu există evaluări

- 4x1 MUXDocument6 pagini4x1 MUXYash GuptaÎncă nu există evaluări

- Test - Practice On Wiring: Protection From ShockDocument4 paginiTest - Practice On Wiring: Protection From ShockShobu YarlagadaÎncă nu există evaluări

- BMI BRG-100RF X-Ray - Circuit Diagrams PDFDocument68 paginiBMI BRG-100RF X-Ray - Circuit Diagrams PDFeduardoÎncă nu există evaluări

- High-Efficiency Microwave BJT Power Amplifier Simulation: 24, Wright ofDocument4 paginiHigh-Efficiency Microwave BJT Power Amplifier Simulation: 24, Wright ofDania Largo JaimesÎncă nu există evaluări