Documente Academic

Documente Profesional

Documente Cultură

Vortex Tube Manufacturing

Încărcat de

Sameer JainDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Vortex Tube Manufacturing

Încărcat de

Sameer JainDrepturi de autor:

Formate disponibile

SIR PADAMPAT SINGHANIA UNIVERSITY (UDAIPUR) PROJECT SYNOPSIS AIR CONDITIONING BY COMPRESSED AIR (TEMPERATURE CHANGE) Project Mentor:

Mr. Deepak Paliwal Project Leader: Naman Chaturvedi E-mail ID : Contact No. : Objective: To prepare a air conditioning as well as air warming device by the use of compressed air and use of exhaust air. Aim : - Our aim is to make a device which can be used in following ways

It can be used in a house in place of air conditioning. Place where vortex tube is not sufficient for cooling there we can use COVT. It can also used for removing dust particles. Where we required less amount of cool and hot air.

Introduction: Vortex Tube: The vortex tube, also known as the Ranque-Hilsch vortex tube, is a mechanical device that separates a compressed gas into hot and cold streams. It has no moving parts. Principal: Pressurized gas is injected tangentially into a swirl chamber and accelerated to a high rate of rotation. Due to the conical nozzle at the end of the tube, only the outer shell of the compressed gas is allowed to escape at that end. The remainder of the gas is forced to return in an inner vortex of reduced diameter within the outer vortex.

Technical Details:

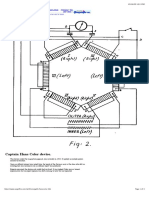

vortex tube Parts of Vortex Tube: Body Washer Valve Sleeve Generator O ring Cold cap

Dimensions: Inside Diameter: D Length of the hot pipe: 32D Length of the cold pipe: 20D Diameter of the Washer: 1.5D Valve: 1.5D Diameter of O ring: 2D Length of Sleeve: 5D Methodology: Working of Vortex Tube: Compressed air is injected into the vortex tube at extremely high speeds and that creates a cyclone, or vortex, spinning a million revolutions per minute. Part of the air is forced to spin inward to the center and travels up a long tube where a valve turns the spinning column of air inside itself. The inside column of air gives up its heat to the outside column. The cold air is directed out the cold end of the Vortex Tube and the hot air is directed out the other end of the Vortex Tube. The air flow and temperature are totally controllable. And since there are no moving parts there is little need for maintenance. Manufacturing of Vortex Tube: Firstly we make the parts of the vortex tube as per the dimensions (given above) .Firstly we join the hot pipe with the washer and join the generator sleeve ,which goes inside it because of smaller in diameter.Then we join it with the generator which helps to support vortex creation.At the one end we place conical nozzle inside the tube and we place cold cap at that place which return the hot air from where we get the cold air by the valve connected at the end of the pipe from outside.At the other end get the hot air by the other valve.By this way the hot air and the cold air is separated by the valves. we can also utilise the exhaust air in different places.

Benefits : Vortex Tubes Benefits: Vortex Tubes use only compressed air- no electricity or refrigerants are required Vortex Tubes are maintenance free - Since Vortex Tubes have no moving parts there is no maintenance required Vortex Tubes are Exceptionally reliable Vortex Tubes are Compact and lightweight

Applications: Vortex Tube Applications: Vortex Tubes have a very wide range of application for industrial spot cooling on machines, assembly lines and processes.

Cool Machining Operations Cool heat seal operations Thermal test sensors and choke units Temperature cycle parts Combination Of Vortex Tube (COVT) : It is a combination of more than one vortex tube.It has a collecting chambers in which hot and cold air is collected and supply to the desired place. It can be used for the larger use where we require more hot and cold air.

Target users:

It is basically inexpensive so it can be used by common man. Its exhaust gases are not harmful for the people. Exhaust gases are also utilised for the people in other works. People can use it easily.

S-ar putea să vă placă și

- Starlite PDFDocument35 paginiStarlite PDFPuturrú De FuáÎncă nu există evaluări

- GEET Fuel Processor Plans: WARNING: This Information Is Clasified As EXPERIMENTAL!Document10 paginiGEET Fuel Processor Plans: WARNING: This Information Is Clasified As EXPERIMENTAL!John BlackÎncă nu există evaluări

- Build A 3-Band Shortwave Converter For Your CarDocument2 paginiBuild A 3-Band Shortwave Converter For Your CarbobbyunlockÎncă nu există evaluări

- Simple HHO Boosters Improve Fuel EfficiencyDocument29 paginiSimple HHO Boosters Improve Fuel EfficiencyLudovicÎncă nu există evaluări

- Hybrid Tech Eat On Fuel CellDocument13 paginiHybrid Tech Eat On Fuel CellhhojonÎncă nu există evaluări

- (PANTONE STIRLING GEET SPAD) Thesis - Simple Gas Turbine Engine DesignDocument130 pagini(PANTONE STIRLING GEET SPAD) Thesis - Simple Gas Turbine Engine DesignTri KurniawanÎncă nu există evaluări

- Shawyer EM Drive TheoryDocument14 paginiShawyer EM Drive TheoryPabloSilveira100% (1)

- Dony WatssDocument49 paginiDony WatssvbugaianÎncă nu există evaluări

- Externally Fired Microturbine FlyerDocument1 paginăExternally Fired Microturbine FlyerPaulFerry100% (1)

- High Voltage GenerationDocument6 paginiHigh Voltage Generationdp500100% (1)

- The Inventions of CaptainDocument3 paginiThe Inventions of CaptainAngela0220Încă nu există evaluări

- Car PlansDocument11 paginiCar Planslaurlos100% (2)

- Reduce Fuel Costs Up To 28% With Fuel EnergizerDocument26 paginiReduce Fuel Costs Up To 28% With Fuel EnergizerAmal JithÎncă nu există evaluări

- Geet Reactor RodDocument11 paginiGeet Reactor RodthenjhomebuyerÎncă nu există evaluări

- Power Generation by Foot Step Method - Rack and PinionDocument13 paginiPower Generation by Foot Step Method - Rack and Pinionprem53100% (2)

- Motionless Free Energy: Because It Opposes Itself, It Can Never Be More Than 100% Efficient. We AreDocument6 paginiMotionless Free Energy: Because It Opposes Itself, It Can Never Be More Than 100% Efficient. We AreRolling76Încă nu există evaluări

- Nuclear BatteryDocument22 paginiNuclear BatteryPrayag P NairÎncă nu există evaluări

- Barbosa 150426021227 Conversion Gate01Document6 paginiBarbosa 150426021227 Conversion Gate01zac2351Încă nu există evaluări

- Practical Guide to Free-Energy Devices Chapter 16 Q&ADocument44 paginiPractical Guide to Free-Energy Devices Chapter 16 Q&AAleksa Nataša RančićÎncă nu există evaluări

- Bob BoyceDocument47 paginiBob BoyceDmitryRussuÎncă nu există evaluări

- Generator Bushing DesignsDocument10 paginiGenerator Bushing DesignsPradeep_VashistÎncă nu există evaluări

- Design and Testing of an Autorotative Payload Delivery SystemDocument11 paginiDesign and Testing of an Autorotative Payload Delivery SystemvictorÎncă nu există evaluări

- Manual Book HHO GENERATOR Fuel EfficientDocument56 paginiManual Book HHO GENERATOR Fuel EfficientLuis Enrique Jarquin AramburoÎncă nu există evaluări

- Thermodynamics 2Document7 paginiThermodynamics 2riez24Încă nu există evaluări

- FleetDocument5 paginiFleetEdmundo Macias ArenasÎncă nu există evaluări

- Generation of Electricity Using Fan PDFDocument4 paginiGeneration of Electricity Using Fan PDFAmruta KageÎncă nu există evaluări

- Covid Economics: Vetted and Real-Time PapersDocument82 paginiCovid Economics: Vetted and Real-Time PapersbehnazÎncă nu există evaluări

- The Making of The Källe-GasifierDocument15 paginiThe Making of The Källe-GasifierMarky Maypo100% (1)

- Axial Flux Permanent Magnet Generators For Pico-HydropowerDocument8 paginiAxial Flux Permanent Magnet Generators For Pico-HydropowerEngineers Without Borders UKÎncă nu există evaluări

- Slayer Exciter: by Ivan WilbergDocument7 paginiSlayer Exciter: by Ivan Wilbergapi-408463795Încă nu există evaluări

- Ambient Background EnergyDocument1 paginăAmbient Background EnergyBruce A. PerreaultÎncă nu există evaluări

- Microwave TubesDocument58 paginiMicrowave TubesDhyey DesaiÎncă nu există evaluări

- Ferrite T PuDocument4 paginiFerrite T PunanarÎncă nu există evaluări

- Nikola Tesla Notes On A Unipolar Generator The Electrical EngineerDocument10 paginiNikola Tesla Notes On A Unipolar Generator The Electrical EngineerDiego Betancourt MejiaÎncă nu există evaluări

- Vortex Tube - Yunpeng XueDocument121 paginiVortex Tube - Yunpeng XueVladan MilojevićÎncă nu există evaluări

- Transformers PDFDocument6 paginiTransformers PDFVasileSpireaÎncă nu există evaluări

- HV GeneratorDocument6 paginiHV GeneratorNatasaBugaianÎncă nu există evaluări

- Bill Williams Gas Splitter Dry CellDocument4 paginiBill Williams Gas Splitter Dry CellCiprian ALÎncă nu există evaluări

- ERR Power Station Project BookletDocument18 paginiERR Power Station Project BookletAnonymous C0KBah6TEqÎncă nu există evaluări

- Motionless Electromagnetic GeneratorDocument9 paginiMotionless Electromagnetic GeneratorViswa TejaÎncă nu există evaluări

- A Simple Inverter For Flour..Document8 paginiA Simple Inverter For Flour..Daniel Vladimir MaciucaÎncă nu există evaluări

- Bedini Monopole 3 Group ExperimentDocument5 paginiBedini Monopole 3 Group Experimentnadirma66Încă nu există evaluări

- Airborne Wind Turbine: A turbine in the air without a towerDe la EverandAirborne Wind Turbine: A turbine in the air without a towerÎncă nu există evaluări

- Molecular Beam Epitaxy: Applications to Key MaterialsDe la EverandMolecular Beam Epitaxy: Applications to Key MaterialsÎncă nu există evaluări

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinDe la EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinÎncă nu există evaluări

- Study of a reluctance magnetic gearbox for energy storage system applicationDe la EverandStudy of a reluctance magnetic gearbox for energy storage system applicationEvaluare: 1 din 5 stele1/5 (1)

- Aluminum-Air Batteries The Ultimate Step-By-Step GuideDe la EverandAluminum-Air Batteries The Ultimate Step-By-Step GuideÎncă nu există evaluări

- Safe Energy Forever: + Pure water for the world and a cure for cancerDe la EverandSafe Energy Forever: + Pure water for the world and a cure for cancerÎncă nu există evaluări

- From the Letters and Journals of Robert Murray-SmithDe la EverandFrom the Letters and Journals of Robert Murray-SmithEvaluare: 5 din 5 stele5/5 (1)

- Applied Superconductivity: Volume IIDe la EverandApplied Superconductivity: Volume IIVernon L. NewhouseÎncă nu există evaluări

- Wild American Ginseng: Lessons for Conservation in the Age of HumansDe la EverandWild American Ginseng: Lessons for Conservation in the Age of HumansÎncă nu există evaluări

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsDe la EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsÎncă nu există evaluări

- Scientific American Supplement, No. 613, October 1, 1887De la EverandScientific American Supplement, No. 613, October 1, 1887Încă nu există evaluări

- Induction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryDe la EverandInduction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryEvaluare: 5 din 5 stele5/5 (2)

- List of Imp Books For GateDocument1 paginăList of Imp Books For GateSameer JainÎncă nu există evaluări

- Indian Air Force: Notification For MenDocument2 paginiIndian Air Force: Notification For MenTrcStaffÎncă nu există evaluări

- Yamaha Motors CSR ReportDocument24 paginiYamaha Motors CSR ReportSameer JainÎncă nu există evaluări

- Summer Training Report at RSMM on Mining OperationsDocument2 paginiSummer Training Report at RSMM on Mining OperationsSameer JainÎncă nu există evaluări

- Hindustan Zinc Project ReportDocument22 paginiHindustan Zinc Project ReportSameer JainÎncă nu există evaluări

- NFPA 15 SummaryDocument13 paginiNFPA 15 SummarySam Low100% (2)

- Centrifugal Compressor P&ID GuideDocument4 paginiCentrifugal Compressor P&ID Guidenaveenbaskaran1989100% (1)

- Processing Units DetailDocument49 paginiProcessing Units DetailAnonymous HjB1bhmÎncă nu există evaluări

- HB 605-10 enDocument34 paginiHB 605-10 enmaxz123Încă nu există evaluări

- AQV18&24VBE Service Manual PDFDocument100 paginiAQV18&24VBE Service Manual PDFstefanovigano8579Încă nu există evaluări

- SLG Chem3 LG 2.14 Application (Environment in Focus)Document7 paginiSLG Chem3 LG 2.14 Application (Environment in Focus)Lorraine CalacsanÎncă nu există evaluări

- API6A Trim Material RatingsDocument6 paginiAPI6A Trim Material RatingsFredy ReyesÎncă nu există evaluări

- Miscible Displacement ProcessesDocument24 paginiMiscible Displacement ProcessesrarahahaÎncă nu există evaluări

- Gujarat Technological UniversityDocument2 paginiGujarat Technological UniversityChavda jayesh laljibhaiÎncă nu există evaluări

- Spring Loaded Safety ValvesDocument16 paginiSpring Loaded Safety ValvesUdit Kumar Sarkar0% (1)

- Ramana Prasad Intro ImpDocument10 paginiRamana Prasad Intro ImpVijayalakshmi R.Încă nu există evaluări

- Fluid MechanicsDocument4 paginiFluid MechanicsAngelicaÎncă nu există evaluări

- AQT MSV 1 Suavizador Manual UnlockedDocument8 paginiAQT MSV 1 Suavizador Manual UnlockedEdgar CastroÎncă nu există evaluări

- Pressure Loss Due To Friction in DuctsDocument13 paginiPressure Loss Due To Friction in DuctsMohsen HassanÎncă nu există evaluări

- of Hydraulic Accumulator PDFDocument39 paginiof Hydraulic Accumulator PDFSANTOSH RATHODÎncă nu există evaluări

- MAAE 3300 PA Session 4 Pipe Flow ProblemsDocument4 paginiMAAE 3300 PA Session 4 Pipe Flow ProblemsPadmassun IxznziÎncă nu există evaluări

- Es Igual en Lama 1: Codigo Material Cant. Descripcion / Especificacion / CondicionesDocument8 paginiEs Igual en Lama 1: Codigo Material Cant. Descripcion / Especificacion / CondicionesraulÎncă nu există evaluări

- QUIZ-Hazardous Area ClassificationDocument2 paginiQUIZ-Hazardous Area ClassificationPillai Sreejith100% (4)

- New Correlation For Z-Factor Using Genet PDFDocument9 paginiNew Correlation For Z-Factor Using Genet PDFFreddy Mendoza CoronelÎncă nu există evaluări

- Tower Internals: Design PracticesDocument67 paginiTower Internals: Design PracticesTala RamezaniÎncă nu există evaluări

- In The Partial Fulfillment of The Requirement For The Diploma in Mechanical Engineering Submitted ToDocument11 paginiIn The Partial Fulfillment of The Requirement For The Diploma in Mechanical Engineering Submitted To225 Shashi GavhaneÎncă nu există evaluări

- ScheduleDocument2 paginiSchedulecbcyouthygnÎncă nu există evaluări

- Fundamentals of FirefightingDocument6 paginiFundamentals of FirefightingArman PinedaÎncă nu există evaluări

- Fire Pump Questions - Churn PressureDocument5 paginiFire Pump Questions - Churn Pressurenapster386Încă nu există evaluări

- Chap15 - MBalDocument38 paginiChap15 - MBalSlim.BÎncă nu există evaluări

- Owner's Manual CH640, CH730, CH740: Liquefi Ed Petroleum Gas (LPG) or LPG/Natural Gas (NG) FueledDocument12 paginiOwner's Manual CH640, CH730, CH740: Liquefi Ed Petroleum Gas (LPG) or LPG/Natural Gas (NG) FueledMatthew BurkhalterÎncă nu există evaluări

- ATP Creeping FlowDocument4 paginiATP Creeping FlowLikhithÎncă nu există evaluări

- Requirements for Branch Connections to Flare HeadersDocument3 paginiRequirements for Branch Connections to Flare Headersgpskumar22Încă nu există evaluări

- LurgiDocument28 paginiLurgiMisha Manohar100% (2)

- Vessel Inspection PDFDocument18 paginiVessel Inspection PDFAhmed Imtiaz Rao100% (1)