Documente Academic

Documente Profesional

Documente Cultură

SIBOR Oxidation Protection

Încărcat de

Mohammed Abdul NaseerDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SIBOR Oxidation Protection

Încărcat de

Mohammed Abdul NaseerDrepturi de autor:

Formate disponibile

SIBOR

A New Oxidation-Protective Coating for Molybdenum Parts in the Glass Industry

PLANSEE is the worlds leading manufacturer of high performance powder metallurgical products. We develop and manufacture advanced products made of refractory metals and metallic composite materials. Guaranteed oxidation-protection of molybdenum

Due to their unique characteristics molybdenum and molybdenum alloys are used in the glass industry for glass melting electrodes, stirrers, gobbers, parts of glass tanks and other products for the manufacture of glass. Compared to ceramic materials molybdenum shows superior corrosion- and creep-resistance, leading to an increase in the service life of the components and improved glass quality. Unprotected molybdenum starts to react with oxygen at approximately 400 C / 752 F and forms a yellow, sublimating oxide at higher temperatures. This reaction excludes its use above temperatures of 500 C / 932 F in atmospheres containing oxygen. After years of intense research PLANSEE has developed a ground-breaking solution to the problem of how to protect molybdenum against oxidation: the patented SIBOR coating.

SIBOR allows the use of molybdenum over long periods in oxidizing atmospheres at temperatures of up to 1.700 C / 3092 F. Guaranteed oxidation-protection for isothermal lifetimes: 5000 h at 1250 C / 2282 F 500 h at 1450 C / 2642 F 50 h at 1600 C / 2912 F

xid no o

n n atio

ion t a r o scol i d o

n atio n i ntam o c no

Silica-forming coating with sealing effect

SIBOR is a silicon-based coating and builds a silica-surface layer on the protected component. The very hard and dense coating constitutes a diffusion barrier against the base material and creates a SiO2 sealing wherever it is exposed to air. As the uptempering of a glass tank takes place in an environment containing oxygen, SIBOR can reliably protect molybdenum parts against damage until the glass is molten.

Applications in glass melting

Whereas molybdenum is highly resistant to dissolution in molten glass, SIBOR dissolves within just a few days. This property is very useful in the heating-up of glass tanks, with SIBOR providing the protection against the oxidizing gas atmosphere until the molten glass covers the part. Coated glass melting electrodes can be fixed conveniently at their final positions in the cold glass melting tank before heating with burners starts. The same applies to SIBOR-coated molybdenum throats and front shields, which help to maintain an accurate and controlled glass flow over longer periods due to lower corrosion rates than unprotected ceramic blocks. Mo reinforcements for walls, bubble makers and doghouses are also regularly protected with SIBOR. SIBOR is dissolved by the molten glass within a short period of time so that effects such as glass discoloration or bubbleformation do not occur during normal melting operation.

Advantages of SIBOR

Compared to ceramic, intermetallic, platinum and other metal alloy solutions, SIBOR stands out with: - Versatile application possibilities at very high temperatures - Excellent long-term stability on oxidizing atmospheres - Quick dissolution in the glass - Prevention of oxidation at temperatures up to 1700 C / 3092 F (coating starts to soften above 1800 C / 3272 F) - Corrosion-protection against aggressive gases, salts, molten salts and molten metals - Allows fast heating and cooling processes without limitation (as SIBOR is a diffusion and compound layer) - Self-healing effect protecting parts against premature failure - No glass discoloration or bubble-formation during melting operation.

Micrograph of a cross section of as-coated SIBOR, thickness 150 m

SEM (BS-mode) of a heat-treated SIBOR coating; EDX: 1 - Si (molten SIBOR); 2 - Si, 4 - Mo, (Si); 3, 5 - Mo

SEM (BS-mode) cross section of an oxidized SIBOR coated Mo-sample (168 h in air at 1450C). EDX: 1 - SiO2; 2 - Mo, Si; 3 - Si, Mo; 4 - Mo, Si, B; 5 - Mo, (Si); 6 - Mo

SIBOR coating process

SIBOR is a highly efficient coating for molybdenum materials which is based on silicon and boron. It is applied by advanced coating technologies. The molybdenum surface is sandblasted before SIBOR is sprayed on by means of APS (Atmospheric Plasma Spraying) in combination with a robotic system. During the subsequent heat treatment, SIBOR reacts with the base material and forms a dense and stable layer (see micrographs) which, depending on the application, is 200 to 400 m thick and consists of molybdenum-silicide compounds with a SiO2 surface sealing. The surface is dark grey before, and distinctly brighter after the heat treatment process. Its structure is amorphous to polycrystalline before the heat treatment and composed of additional Mo-Si-B-containing diffusion zones afterwards. As molybdenum is unforgiving of any (even local) defect in the coating process, it is essential to thoroughly supervise and doublecheck the various manufacturing steps, including final inspection and measurement of the thickness (by eddy current method). Package, shipment, and unpacking have to be done with care.

Dimensions available

The maximum dimensions for SIBOR-coated parts are: 1000 x 640 x 600 mm. Larger assemblies can be produced by using a multi-part design.

Coating requirements

Molybdenum / SIBOR allows a wide variety of designs. Nevertheless, certain engineering and production principles must be observed. - The parts to be protected must be designed according to the coating requirement. Sharp edges and small bending radii have to be avoided. In the case of inner coatings the length/diameter ratio has to be checked. - All machining work must be completed before the coating is applied. However, the joining-together of already-coated parts is still possible. - In order to avoid chipping of the coating, only very limited bending of the finished parts is allowed. This procedure requires elevated temperatures and can only be done at PLANSEE.

Further application fields of SIBOR on molybdenum

Due to its outstanding mechanical properties at high temperatures in combination with the new type of protection against oxidation and corrosive media, SIBOR/ molybdenum has beneficial characteristics which are also used for applications in furnace industry and waste incineration. - SIBOR allows the use of high-temperature-resistant molybdenum materials in the high-temperature-processing and furnace industry at temperatures of up to 1700 C / 3092 F in atmospheres containing oxygen. Typical components are thermocouple protection tubes, gas lances, burner components and shielding. Even complex and joined components such as annealing boxes and rotary furnaces can be protected with SIBOR. - In waste incineration plants SIBOR-coated molybdenum parts are found in critical corrosion areas of the combustion chamber and boiler. The corrosion rate of molybdenum / SIBOR at 450 - 550 C / 842 - 1022 F in chloride-corrosion conditions is very low. Therefore it is possible to use molybdenum / SIBOR as anchors and hooks, nozzles and protection tubes or cladding material in the combustion or exhaust chamber.

PLANSEE products and service

PLANSEE provides a wide range of products and services for parts and components made of molybdenum and molybdenum alloys. A team of experienced engineers and application technicians supports our customers in matters of material selection and choice of appropriate design. All products are produced to the highest quality, meeting ISO 9001 standards, on state-of-the-art machinery.

Glass melting electrodes with SIBOR coating

Molybdenum throat channel protection fully coated with SIBOR

SIBOR-coated molybdenum plate electrode

APS spraying process

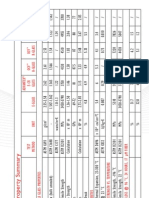

Properties of SIBOR on molybdenum

The following table presents application-relevant properties of as-deposited SIBOR on molybdenum (200 m SIBOR on 2 mm molybdenum sample, density of the coating approximately 80 %).

Physical properties of SIBOR

SIBOR Density [g/cm ]

3

Mo 10.22 5.3*10-6 (20 C / 68 F), 5.8*10-6 (1000 C / 1832 F), 6.5*10-6 (1500 C / 2732 F) 118 (100 C / 212 F), 110 (600 C / 1112 F) 220-280 HV10 (20 / 68 F) 0.26 (100 C / 212 F) and 0.28 (600C) 0.449 (100 C / 212 F), 0.357 (800 C / 1472 F) 0.1 (100 C / 212 F), 0.25 (1000 C / 1832 F)

2.2 3.3*10-6 (100 C / 212 F),

Coefficient of thermal expansion CTE [1/K ] 1

4.5*10-6 (600 C / 1112 F), 9.8*10-6 (1000 C / 1832 F), 8.9*10-6 (1200 C / 2192 F)

Thermal conductivity [W/(mK)] Hardness 2 Heat capacity cp [ J/(gK) ] Temperature conductivity [ cm2/s ] Specific electrical resistivity [ mWm ] 3

6.0 (100 C / 212 F), 5.9 (600 C / 1112 F) 486 50 HV0.1 (20 C / 68 F) 0.83 (100 C / 212 F) and 0.99 (600 C / 1112 F) 0.033 (100 C / 212 F), 0.025 (800 C / 1472 F) 3.2*10+5 (100 C / 212 F), 3.2*10+5 (1000 C / 1832 F)

1 2 3

according to our experience the system SIBOR on molybdenum can be heated to temperatures of about 1650 C / 3002 F without delamination. SIBOR is a brittle but strongly adherent coating; it should be treated like a glass coating. according to our customers experience SIBOR-coated glass melting electrodes work like uncoated ones during electrical heating of the glass melt.

Oxidation behavior and interaction with other materials

- oxidation behavior (Mo+SIBOR): SIBOR coated molybdenum can be heated slowly (as slow as about 5C hour) in annealed condition in oxidizing atmospheres. The lifetimes of the protective system under isothermal conditions after an initial ramp are: about 50 hours at 1600 C / 2912F about 500 hours at 1450 C / 2642 F and about 5000 hours at 1250 C / 2282 F. This outstanding behavior of SIBOR can be explained by the slow growth of a Mo-Si-B-phase with low diffuseness for Si in the Mo-coating-interface and the formation of a shock-resistant boron-modified SiO2 glass passivation layer on the surface of the coating. - interaction with other materials of glass-making equipment: Laboratory experiments and customers experience have so far revealed that direct contact with platinum must be avoided due to formation of low melting eutectics. Zirconmullite is the most appropriate ceramic material for longterm contact with SIBOR under oxidizing conditions. - interaction with molten glass (SIBOR): Immersion experiments in borosilicate glass at 1450 C / 2642 F show that dissolution is not yet complete after 200 hours; however, the generation of bubbles containing gaseous reaction-products (such as SiO) does strongly decrease after about 24 hours. Dissolution experiments under a.c. loading (1A cm2) showed the following results: in C-glass (1300 C / 2372 F) the SIBOR coating is dissolved within about 2 weeks, in green glass at 1400 C / 2552 F in about 1 week with formation of some bubbles. Bubbling and dissolution (H and CO) are mainly caused by the reaction of Si, B and C with hydroxyl groups within the glasses; In the case of the green glass the reaction of the sulfate and iron-III-oxide also makes a minor contribution. White glass (1400 C / 2552 F) is dissolved most quickly namely, within half a week, also with accompaniment of bubbling. In this case, it is mainly bubbles filled with CO2, N2, H2S and COS that are formed by the reaction of the sulfate with H2 / CO. The direct reaction of sulfate with SIBOR also contributes significantly to the dissolution of the coating.

S-ar putea să vă placă și

- Dental Investments and Refractory MaterialsDocument40 paginiDental Investments and Refractory MaterialsSusovan GiriÎncă nu există evaluări

- Protective CoatingsDocument20 paginiProtective Coatingsrahult19Încă nu există evaluări

- Coated Stud Bolts Protection GuideDocument3 paginiCoated Stud Bolts Protection Guidematteo2009Încă nu există evaluări

- Surface Corrosion Protection MethodsDocument10 paginiSurface Corrosion Protection MethodsmotiÎncă nu există evaluări

- Is 4736 1986Document15 paginiIs 4736 1986Vineeth BalakrishnanÎncă nu există evaluări

- Storage Silos: General CatalogueDocument32 paginiStorage Silos: General CatalogueNatarajan RavisankarÎncă nu există evaluări

- PTL 011-05-2021 BOP Handling Systems CatalogDocument13 paginiPTL 011-05-2021 BOP Handling Systems CatalogCamilo Andres Gonzalez RojasÎncă nu există evaluări

- Developments in High Temperature Corrosion Protection CoatingsDocument9 paginiDevelopments in High Temperature Corrosion Protection CoatingsRecep Vatansever100% (1)

- Corrective Action Process Flow ChartDocument3 paginiCorrective Action Process Flow ChartMohammed Abdul NaseerÎncă nu există evaluări

- Material Selection Guidelines for LNG Plant to Prevent Corrosion and CrackingDocument9 paginiMaterial Selection Guidelines for LNG Plant to Prevent Corrosion and CrackingVinothkumar KaliyamoorthyÎncă nu există evaluări

- 4.13.9 Typical Refractories in Industrial UseDocument8 pagini4.13.9 Typical Refractories in Industrial UsePalash SwarnakarÎncă nu există evaluări

- Coat Defects PDFDocument72 paginiCoat Defects PDFkirubha_karan2000100% (1)

- Advantage and Disadvantage of Raw MaDocument19 paginiAdvantage and Disadvantage of Raw MaNaelÎncă nu există evaluări

- Apv Phe PDFDocument23 paginiApv Phe PDFPatrascu MariusÎncă nu există evaluări

- Glass: Engr Muhammad Imran Hanif Assistant Professor Med CecosDocument33 paginiGlass: Engr Muhammad Imran Hanif Assistant Professor Med Cecoskhan janÎncă nu există evaluări

- Fastener Design ManualDocument30 paginiFastener Design ManualsmithworkÎncă nu există evaluări

- Brochure AluPeb EnglishDocument8 paginiBrochure AluPeb EnglishThi PhamÎncă nu există evaluări

- Refractorymaterials 150313053315 Conversion Gate01Document19 paginiRefractorymaterials 150313053315 Conversion Gate01tesfayregs gebretsadikÎncă nu există evaluări

- CUI Protective Coating Systems Part IDocument52 paginiCUI Protective Coating Systems Part Irty2Încă nu există evaluări

- Aluminum Oxynitride (Aka Transparent Aluminum) : Reported By: Lulab, Daisy Jane B. Reported By: Lulab, Daisy Jane BDocument20 paginiAluminum Oxynitride (Aka Transparent Aluminum) : Reported By: Lulab, Daisy Jane B. Reported By: Lulab, Daisy Jane BJet Espejon JavierÎncă nu există evaluări

- Oxyfuel BurnersDocument31 paginiOxyfuel BurnersMohammed Abdul NaseerÎncă nu există evaluări

- Manual - Phosphate and Black Oxide Coating of Ferrous MetalsDocument81 paginiManual - Phosphate and Black Oxide Coating of Ferrous MetalsVadim100% (2)

- H010ARDocument22 paginiH010ARMohammed ChaabateÎncă nu există evaluări

- ALAMARIN-JET OY Technical SpecificationDocument21 paginiALAMARIN-JET OY Technical SpecificationAndi PurwantoÎncă nu există evaluări

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe la EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Key Aluminum Nitride PropertiesDocument10 paginiKey Aluminum Nitride PropertiesMuhammad TanweerÎncă nu există evaluări

- Structural Ceramic Materials: Silicon Carbide - SicDocument12 paginiStructural Ceramic Materials: Silicon Carbide - SicMuthu BalajiÎncă nu există evaluări

- Mosi2 Heating Elements (MolyD or Molybdenum Disilicide Manufacturerd by SilcarbDocument10 paginiMosi2 Heating Elements (MolyD or Molybdenum Disilicide Manufacturerd by SilcarbA.K. RawatÎncă nu există evaluări

- Mosi2 Heating Elements (MolyD or Molybdenum Disilicide Manufacturerd by SilcarbDocument10 paginiMosi2 Heating Elements (MolyD or Molybdenum Disilicide Manufacturerd by SilcarbloritaÎncă nu există evaluări

- New Galvanizing TechnologyDocument4 paginiNew Galvanizing Technologywmaddoxmec100% (1)

- SGL PT Data Sheet Sic Heat ExchangersDocument2 paginiSGL PT Data Sheet Sic Heat Exchangerspippo2378793Încă nu există evaluări

- Zer CorDocument4 paginiZer CorVaibhav KhannaÎncă nu există evaluări

- SigmacoverDocument8 paginiSigmacoverHaresh BhavnaniÎncă nu există evaluări

- Ceramic Materials GuideDocument6 paginiCeramic Materials Guidejoel jÎncă nu există evaluări

- Anodizing 2Document25 paginiAnodizing 2Valeria Rueda100% (1)

- Recoatable Epoxy Systems For Maintenance and New Construction Recoatable Epoxy Systems For Maintenance and New ConstructionDocument8 paginiRecoatable Epoxy Systems For Maintenance and New Construction Recoatable Epoxy Systems For Maintenance and New ConstructionengindmecÎncă nu există evaluări

- Corrosione - Abstract From SchneiderDocument5 paginiCorrosione - Abstract From SchneiderMaxÎncă nu există evaluări

- The Raw Materials Required For To Make Clear Glass AreDocument4 paginiThe Raw Materials Required For To Make Clear Glass Arealiyah khalidÎncă nu există evaluări

- 3015 - Prefabrication PrimersDocument4 pagini3015 - Prefabrication PrimerseraswastaÎncă nu există evaluări

- What Is Silicone Conformal Coating For PCBDocument19 paginiWhat Is Silicone Conformal Coating For PCBjackÎncă nu există evaluări

- Ceramic MaterialsDocument8 paginiCeramic MaterialsCharidBecerraÎncă nu există evaluări

- Engineering Chemistry: Manufacturing of Portland CementDocument9 paginiEngineering Chemistry: Manufacturing of Portland CementShubham KhandelwalÎncă nu există evaluări

- Calorised Pipes Petrochemical W-UpDocument6 paginiCalorised Pipes Petrochemical W-UpSunil GuptaÎncă nu există evaluări

- SilcoTek Coating Overview Brochure WebDocument6 paginiSilcoTek Coating Overview Brochure WebIker MelladoÎncă nu există evaluări

- Canaleta de LucesDocument29 paginiCanaleta de LucesAriel MedranoÎncă nu există evaluări

- Usi SectionaleDocument18 paginiUsi SectionaleFlorian MihaleÎncă nu există evaluări

- Pekkan J. Mater. Sci. 2009Document8 paginiPekkan J. Mater. Sci. 2009errairachidÎncă nu există evaluări

- 2750 515-131 en Rev 1Document12 pagini2750 515-131 en Rev 1Abohicham AbhÎncă nu există evaluări

- 2.doc Semi Process TechnicalsDocument2 pagini2.doc Semi Process TechnicalsshreyeshÎncă nu există evaluări

- Anticorrosion Treatment AlucoastDocument7 paginiAnticorrosion Treatment Alucoastznim04Încă nu există evaluări

- 2023 Lesson 5 Glass (1)Document17 pagini2023 Lesson 5 Glass (1)laralor557Încă nu există evaluări

- Pipeclad-Product-Brochure-Sherwin-Williams-EnglishDocument12 paginiPipeclad-Product-Brochure-Sherwin-Williams-EnglishCésarÎncă nu există evaluări

- Lec 8 Insulation and Special BricksDocument17 paginiLec 8 Insulation and Special BricksSakunaPappuÎncă nu există evaluări

- Glaunach: Surface TreatmentDocument5 paginiGlaunach: Surface TreatmentRicky LuznyÎncă nu există evaluări

- DSM-0375.0 FeMoC CompDocument3 paginiDSM-0375.0 FeMoC CompApichitÎncă nu există evaluări

- Rms Polytechnic: Chemical Engineering Department 03 SemesterDocument11 paginiRms Polytechnic: Chemical Engineering Department 03 SemesterBhaumik ParmarÎncă nu există evaluări

- SERIE 700 Subproceso Asociado:: Esp. de Cliente Sistema:ISO 9000Document8 paginiSERIE 700 Subproceso Asociado:: Esp. de Cliente Sistema:ISO 9000Eliezer BarrantesÎncă nu există evaluări

- Preventing Scale Loss During Heat Treatment & Hot Forging - With ImagesDocument17 paginiPreventing Scale Loss During Heat Treatment & Hot Forging - With ImagesSrikar Shenoy100% (1)

- Manufacturing and Properties of Anti-Friction MaterialsDocument5 paginiManufacturing and Properties of Anti-Friction MaterialsMădălina ConstantinescuÎncă nu există evaluări

- Morgan Thermal Ceramics Product Data - Book - 2016Document179 paginiMorgan Thermal Ceramics Product Data - Book - 2016Alex MontielÎncă nu există evaluări

- Heat Resistant CeramicsDocument26 paginiHeat Resistant Ceramicsivy_oforiÎncă nu există evaluări

- 25% Cr Heat Resistant Stainless Steel SIRIUS 314Document4 pagini25% Cr Heat Resistant Stainless Steel SIRIUS 314Víctor SandovskyÎncă nu există evaluări

- White Paper - Mitigating Corrosion and Erosion in Waste To Energy and Biomass BoilersDocument20 paginiWhite Paper - Mitigating Corrosion and Erosion in Waste To Energy and Biomass BoilersmostafaÎncă nu există evaluări

- Cost Reduction in Heat Treatment With Protective CoatingsDocument7 paginiCost Reduction in Heat Treatment With Protective CoatingsAnand KesarkarÎncă nu există evaluări

- Tar ProductsDocument14 paginiTar ProductsShaival JhaÎncă nu există evaluări

- Magnesium Aluminate Spinel Refractory PropertiesDocument1 paginăMagnesium Aluminate Spinel Refractory PropertiesShaheer Ahmed KhanÎncă nu există evaluări

- Minimizing Heat Loss in High Temperature Industrial SystemsDocument7 paginiMinimizing Heat Loss in High Temperature Industrial SystemsTS WongÎncă nu există evaluări

- BoronizingDocument2 paginiBoronizingVishal Shirsat100% (1)

- Product Data Sheet: Direct Roving - Multi CompatibleDocument2 paginiProduct Data Sheet: Direct Roving - Multi CompatibleMohammed Abdul NaseerÎncă nu există evaluări

- Spray-Up 687 NewDocument2 paginiSpray-Up 687 NewMohammed Abdul NaseerÎncă nu există evaluări

- Chop Roving 605 NewDocument2 paginiChop Roving 605 NewMohammed Abdul NaseerÎncă nu există evaluări

- 14-2 Data FormsDocument12 pagini14-2 Data FormsMohammed Abdul NaseerÎncă nu există evaluări

- Guide To Using MinitabDocument14 paginiGuide To Using MinitabMohammed Abdul Naseer0% (1)

- Guide To Using MinitabDocument14 paginiGuide To Using MinitabMohammed Abdul Naseer0% (1)

- Sample Control of Nonconformances R1Document2 paginiSample Control of Nonconformances R1Mohammed Abdul NaseerÎncă nu există evaluări

- MicroscopeDocument6 paginiMicroscopeMohammed Abdul NaseerÎncă nu există evaluări

- Fiberex 408 DataSheetDocument1 paginăFiberex 408 DataSheetMohammed Abdul NaseerÎncă nu există evaluări

- Glass Fibers - PropertiesDocument2 paginiGlass Fibers - PropertiesMohammed Abdul NaseerÎncă nu există evaluări

- Bushing OperationDocument2 paginiBushing OperationMohammed Abdul NaseerÎncă nu există evaluări

- Low Cost Green Houses For Vegetable ProductionDocument19 paginiLow Cost Green Houses For Vegetable Productionqfarms100% (2)

- AF Animals Poultry IntroDocument10 paginiAF Animals Poultry IntroMamta KabraÎncă nu există evaluări

- Greenhouse Arid Regions IIMADocument11 paginiGreenhouse Arid Regions IIMATheScienceOfTimeÎncă nu există evaluări

- Boc G Oct04 QKDocument3 paginiBoc G Oct04 QKMohammed Abdul NaseerÎncă nu există evaluări

- Failures Due To Copper Sulphide in Transformer Insulation PDFDocument3 paginiFailures Due To Copper Sulphide in Transformer Insulation PDFOrcun CalayÎncă nu există evaluări

- 76 500cDocument4 pagini76 500cImam BukhoriÎncă nu există evaluări

- BoroBlock Linings - Glass Lining For InsulationDocument4 paginiBoroBlock Linings - Glass Lining For InsulationN P SrinivasaraoÎncă nu există evaluări

- HALAR ECTFE EPC ASIA Manual June 2005Document24 paginiHALAR ECTFE EPC ASIA Manual June 2005Vitor MirandaÎncă nu există evaluări

- Dampers: Air Chem Systems, IncDocument12 paginiDampers: Air Chem Systems, Inchector.pineda7111Încă nu există evaluări

- 1 Sealing and BondingDocument25 pagini1 Sealing and BondingCiddarthnÎncă nu există evaluări

- BS en 1096-2-2012 - (2022-08-18 - 04-11-29 Am)Document34 paginiBS en 1096-2-2012 - (2022-08-18 - 04-11-29 Am)Free MouseÎncă nu există evaluări

- Precision wire corrosion resistance Sandvik Sanicro 28Document2 paginiPrecision wire corrosion resistance Sandvik Sanicro 28Prasanna MuleyÎncă nu există evaluări

- Risk-Based Maintenance Planning of Subsea Pipelines Through Fatigue Crack Growth MonitoringDocument7 paginiRisk-Based Maintenance Planning of Subsea Pipelines Through Fatigue Crack Growth Monitoringdeepak16051988Încă nu există evaluări

- PD - TemperKote 850 PrimerDocument2 paginiPD - TemperKote 850 PrimerJosé MoránÎncă nu există evaluări

- Shade Sails InformationDocument8 paginiShade Sails InformationParmiss KiaÎncă nu există evaluări

- Deltashield C 1100: Product Data SheetDocument4 paginiDeltashield C 1100: Product Data SheetjoeÎncă nu există evaluări

- API 571 Flashcards - Quizlet GoodDocument18 paginiAPI 571 Flashcards - Quizlet Goodks_irdeÎncă nu există evaluări

- AMPCO Metal Welding Materials CatalogueDocument28 paginiAMPCO Metal Welding Materials Cataloguejhax90Încă nu există evaluări

- Structural Applications of AluminumDocument3 paginiStructural Applications of AluminumPrevoditeljski studijÎncă nu există evaluări

- 9 Chemistry Notes Unit 7 NewDocument7 pagini9 Chemistry Notes Unit 7 NewR.S.H100% (1)

- Diala S4 ZX-IDocument3 paginiDiala S4 ZX-IHenry UntirtaÎncă nu există evaluări

- SP0793-0000-1W05-003 Corrosion Protection - Rev0A (00D) - Sistemas de Pinturas de Barrick - Incluye Fabricante WEG Por Cada Sistemas (00C)Document46 paginiSP0793-0000-1W05-003 Corrosion Protection - Rev0A (00D) - Sistemas de Pinturas de Barrick - Incluye Fabricante WEG Por Cada Sistemas (00C)José Nicolás Valdéz BurgosÎncă nu există evaluări

- RocMaster Roc en PDFDocument24 paginiRocMaster Roc en PDFKKien VuÎncă nu există evaluări

- Pipeline Repair Product Data SheetDocument2 paginiPipeline Repair Product Data SheetCarlos MtzÎncă nu există evaluări

- Pipeline Operations - Petroleum & Natural GasDocument24 paginiPipeline Operations - Petroleum & Natural GasPriyo DjatmikoÎncă nu există evaluări

- Sensors ManualDocument232 paginiSensors ManualJuan ZaramaÎncă nu există evaluări

- Corrosion Testing of Aerosol ProductsDocument4 paginiCorrosion Testing of Aerosol ProductsEdgardo Ed RamirezÎncă nu există evaluări