Documente Academic

Documente Profesional

Documente Cultură

Grinding Mills SALA Leaflet 603 E, Sweden 1973

Încărcat de

Tsakalakis G. KonstantinosDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Grinding Mills SALA Leaflet 603 E, Sweden 1973

Încărcat de

Tsakalakis G. KonstantinosDrepturi de autor:

Formate disponibile

Mills

Leaflet 603 E

Application

Nowadays grinding mills are almost extensively used for

comminut1on of materials ranging from 5 mm to 40 mm

(3/ 16" -1 5/ 8" ) down to varying product sizes. They have

vast appl ications within di fferent branches of industry such

as for example the ore dressing, cement, lime, porcelain and

chemical industries and can be desi gned for continuous as

well as batch grind1ng.

Rod mills

The principal f ield of rod mil l usage is the preparation of

products in the 5 mm-0.4 mm (4 mesh to 35 mesh) range.

It may sometimes be recommended also for finer grinding.

Within these limits a rod mill is usually superi or to and

more effici ent than a ball mill. The basic principle for rod

grinding is reduction by line contact between rods ex-

tending the full length of the mill , resulting in selective

grinding carried out on the largest particle sizes. This

resul ts in a minimum production of extreme fines or slimes

and more effective grinding work as compared with a

ball mill. One stage rod mill grinding is therefore suitable

for preparation of feed to gravimetri c ore dressing methods,

certain flotat ion processes with sl ime problems and mag-

netic cobbing. Rod mills are frequently used as primary

mil ls to produce suitable feed to the second grinding stage.

Rod mills have usually a length/ diameter ratio of at least 1.4.

Fi g. 1. Rod mill , two-t ire type.

2

Ball mills

Ball mills can be used for coarse grinding as described

for the rod mill. They will , however, in that appl i cation

produce more fines and tramp oversize and will in any

case necessitate installation of e ~ f e c t i v e classification.

If finer grinding is wanted two or three stage grinding is

advisable as for instant primary rod mill with 75-100 mm

(3"-4" ) rods, secondary ballmillwith25-40mm(1"-11j

2

")

balls and possibly tertiary ball mill with 20 mm (3/ 4" ) ball::;

or cylpebs.

To obtain a close size distribution in the fine range the

specific surface of the grinding media should be as hi gh

as possible. Thus as small balls as possible should be

used in each stage.

Tube mills

Tube mills are m principle to be considered as ball mills,

the basic difference being that the length/ diameter ratio is

greater (3- 5) . They are commonly used for surface

cleaning or scrubbing action and f ine grinding in open

circuit.

Pebble mills

In some cases it i s suitable to use screened fract ions of

the materi al as grinding media. Such mills are usually

called pebble mills, but the working principle is the same

as for ball mills. As the power input is approximately

directly proportional to the volume wei ght of the grindi ng

media, the power input for pebble mills is correspondingly

smaller than f or a ball mill.

Wet or dry grinding

A dry process requires usually dry grinding. If the

feed is wet and sticky, it is often necessary to lower

the moisture content below 1 %. Grinding in front of

wet processes can be done wet or dry. In dry grind-

ing the energy consumption is higher, but the wear

of linings and charge is less than for wet grinding,

especially when treating highly abrasive and cor-

rosive material. When comparing the economy of wet

and dry grinding, the different costs for the ent1re

process must be considered.

Method of discharge

Overflow Rod Mill

Recommended for normal wet grinding in rod mills.

The diameter of the discharge trunnion is larger than

that of the feed trunnion giving an easy material

flow through the mill. The discharge trunnion can be

furnished with a trommel screen to remove rod frag-

ments, wooden chips etc. from the mill discharge.

Rod Mill with End Peripheral

Discharge

Used when a moderately coarse product is desired.

Rod Mill with Centre Preripheral

Discharge

Suitable for dry grinding at extremely high capaci-

ties and very coarse grinding, wet or dry. Also

applicable for very viscous material and humidities

of 3-15 % by weight.

Overflow Ball Mill

Suitable for almost all applications where a ball mill

is required. Simple and trouble-free grinding method.

The discharge trunnion can be furnished with trommel

screen.

Grate Discharge Ball Mill

This type of mill usually works with a high circulat-

ing load and thus produces very little extreme fines.

The specific power consumption is therefore less

than for an Overflow Mill. A Grate Discharge Mill

will also have 15-25 % higher capacity per volume

unit as compared with an Overflow Mill. The dis-

charge trunnion can be furnished with trommel

screen.

3

Mill speed

Mill speed is generally referred to as a percentage of critical ,

which is defined as the speed at which an infinitly small par-

ticle just follows a smooth shell lining in its motion.

n, =2.36 X NX lfD,

(n, 1.31 X N lfD,}

where n, is % of critical speed

D; is the mill diameter inside

shell lining in meters {feet) and

N is the mill speed rpm.

An increase in the mill speed will give a directly proportional

increase in mill power but there seems to be a square propor-

ti onal increase in the wear. Rod mills generally operate within

the range of 60-75 % of critical speed in order to avoid ex-

cecclve wear and tangled rods. Bal i and pebble mills are

usually operated at 70-85 % of crit ical speed. For dry grinding

the speed is usually somewhat !ower.

4

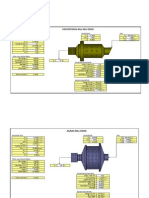

Fig. 2. Ball mill, dia. 2.7 X 6 m (9' X 21 ' )

100

90

10

1'0

60

so

30

20

IS

10

Ncrit rpm

.....

/' ~

/'

,

............ /' ......

~ v ....

~ ><

L

.......

1.0

22

/'./

f"': ....

"""

1/ ~

/'

......

!'-....

....... ~

10

Critical speed graph.

N m rp

20 II 16 10 12 10

,

./"

v ./"

....

~

"'

!""--

.......

Ncrtt

.....

~ ~ ~ t e r

1s 20 25 30 D1 feet

Example: A mill with 4.5 m dia (15' ) N ,;, obtained

= 20 rpm.

If N= 15 rpm nc obtained = 75 %.

Lining

The mill lining can be made of rubber or di fferent types of

steel (manganese or Ni-hard) with liner types according to

the customers requirements. For special appl ications we can

also supply porcelain, basalt and other linings.

Fi g. 3. Rubber lining, grate mill.

Charge volume

The mill power is approximately directly proportional to the

charge volume within the normal range. When calculating a

mill 40 % charge volume IS generally used. In pebble and

ball mills quite often charge volumes close to 50 % are

used. In a pebble mil l the pebble consumption ranges from

Sizing of mills

Factors influencmg the m11l size are :

1. Type, hardness and screen analysis of feed

2. Desired product size after grinding

3. Required capacity

In all cases the net energy consumpti on per ton

(kWh/ton) must be known either from previous

experience or laboratory tests before mill size

can be determined. The required mill net power

P kW ( = ton/h X kWh/ton) is obtained from

P= const. X :; X q X n, X L; X Dt

5

where an approximate fi gure for the constant is

3.5 for rod mill s, 4.0 for overflow ball or pebble

mill s and 4.5 for grate discharge ball or pebble

mills.

~ is specific gravity of grinding media (for rods

or balls normally 7.85)

q is the charge volume in fraction of mill volume

(40 %=0.40)

n c is the mill speed in fraction of critical speed

L; and D; are length and diameter inside shell

lining respecti vely (i n meters)

For a mill with more than 2.1 m (7') diameter the

total power is obtained by dividing net power by

0.85.

3-15 % and the charge has to be controlled automati cally

to maintain uniform power consumption.

The volumetric density of a rod and a ball charge is around

4.9 ton/ m

3

(31 0 lb/ cu.ft) corresponding to 37 % void space.

Fig. 4. Rod mill with max1mum rod charge.

5

Construction

Shell of steel plate quality B.S. En. 2 B arch welded, stress

relieved and with machined flanges. If desired the shell

can be provided wi th manholes.

Heads of S.G. iron (nodular) or steel castings with machin-

ed and drilled connection flanges to shell and trunnion.

Trunnions of S.G. iron or steel castings with machined

flange and bearing seat incl. device for dismantling the

bearings. For smaller mills the heads Dnd trunnions are

sometimes made in grey cast iron.

Bearings Dnd housings of SKF anti -friction type or self-

ali gning ball and socket type.

Gearing of spur type in S.G. iron or steel with cut teeth.

Pini on of steel quality B.S. En 43 with cut teeth and flame

hardened to suitable hardness.

Pinion Shaft of quality B.S. En 43, press fitted and key

locked to the pinion and carried in two SKF standard anti-

friction bearings. For bigger mills the pinion shaft is integral

with the pinion.

Speed Reducer with cast iron casing and shafts and gears

of speci al steel carried in anti -frict ion bearings.

Flexible Couplings provided between motor and speed re-

ducer as well as between speed reducer and pinion shaft.

6

Mills for laboratories

and pilot plants

For smaller capacities and laboratory use SALA manufac-

tures grinding mill s with sizes according to the table below.

These mill s are built on a steel frame, on which the

complete drive is also installed. The mill runs on rub-

berized rollers, which are driven via torque arm speed re-

ducers and rope drives from two standard squirrel-cage

motors. The speed reducers are of standard SALA type

running in oi l in dust-tight housings.

fhe mills can be used either for dry or wet, rod or bnll

grinding. By us1ng a separate attachment the discharge

end can be changed so that the mill s can be used for peri-

pheral instead of overflow discharge.

The lining is generally made as a plate of wear resistant

steel with welded on lifters. The heads are bolted onto the

shell which sim;:llifie:s the change of lining.

Fi g. 8. Mill s for pilot tests during assembly

in our workshop.

,,....,..,........,. ..

Fig. 6. Laboratory mill with peripheral discharge.

Fig. 7. Batch mill with water cooling jacket. Made in

stainless steel for grinding of tungsten.

7

H

A

L

T

D B

Arr. 1

L ... ....J,

barrel

.. .,

A

D L

mm

ft

mm ft

I

mm

1320 4'4" 1500--5000 5'-16' 5200- 9000

1500 5' 5'-17' 5500--9400

1800 6' 1800--5400 6'-18' 6200- 9800

2100 7' 21 ()()..-..&QO 7'-21' 6700-10900

2400 8' 2400-7200 8'-24' 7400-12400

2700 9' 2700--8100 9'-27' 7800-13600

3000 10' 3000-8100 10'-27' 6200-13600

3300 11' 3300-8100 11'-27' 8800-13700

3800 12' 3600-8100 12'-27' 9300-13800

3900 13' 3900--8100 13'-27' 9800-14600

4200 14' 4200-8100 14'-27' 10400-15600

4500 15' 4500--8100 15'-27' 1 2400-1 6200

1) Diameters and barrel lengths are manufactured with a

modulus of 300 mm (abt. 1 ') . Tube mills with greater

lengths than shown in the table can be delivered. For

calculations of power input and critical speed the dia-

meter and length should be reduced with the liner

thickness.

SA

SALA INTERNATIONAL AB

S-733 00 Sala Sweden Tel. 0224/132 20

Telegrams: Salamachine Telex 7536

ft

17'--3/J'

18'--31'

20'--32'

22'--36'

24'-.1'

26'-.&'

27'-.s'

28'-.s'

30'-.s'

32'-.&'

34'--51'

41'--53'

Arr. 2 Arr. 3

Arr. 4

"" . ; ...

.,,,

MdP)

Bmex H max

Total

-

Power

I

mm

I

ft

I

mm

I

ft

Hpl)

3500 11 '6" 2900 9'6" 35- 115

3500 11'6" 2900 9'6" 45- 150

4400 14'5" 3200 10'6" 90- 270

4800 15'9" 3500 1 1'6" 170- 510

6000 19'8" 4200 13'9'' 260- 780

6200 20'4" 5100 16'9" 415-1250

9300.)

30'6" 5100 16'9" 610-1650

9300) 30'6" 5100 16'9" 870-2100

9300) 30'6'' 5100 16'9'' 1200-2700

9600) 31'6" 5600 18'5" 1550-3250

10000) 32'10" 6100

20'

2000-3950

10700) 35'1" 6600 21'8" 2500-4500

2) Ball mill grate discharge w1th 40 % charge and speed

75 % of critical. For rod mills with 40 % charge and

60 % of critical multiply power figure by 0.60.

3) Drive motor with m1n. 10 % higher power should be

chosen.

*) Dual dnve as per arr. 4.

All measurements are for preliminary use only.

Sprl ngfeldt/VLT Civil Sweden 1973

S-ar putea să vă placă și

- Morgardshammar Grinding MillsDocument16 paginiMorgardshammar Grinding MillsTsakalakis G. Konstantinos100% (2)

- Nordberg Grinding Mills Ball Rod and PebbleDocument24 paginiNordberg Grinding Mills Ball Rod and PebbleTsakalakis G. Konstantinos100% (4)

- Ball MillDocument58 paginiBall MillFelipe CidÎncă nu există evaluări

- 47 NCPMillsDocument5 pagini47 NCPMillsraosp66Încă nu există evaluări

- Grinding Mills Ball Mill Rod Mill Design PartsDocument53 paginiGrinding Mills Ball Mill Rod Mill Design PartsRodrigo GarcíaÎncă nu există evaluări

- Crushing and GrindingDocument13 paginiCrushing and GrindingKumar NathanÎncă nu există evaluări

- Ball, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Document131 paginiBall, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Tsakalakis G. Konstantinos100% (7)

- Ball Mill Design & PowerDocument4 paginiBall Mill Design & PowerAlbert Eckersley100% (2)

- Modelling The Specific Grinding Energy and Ball Mill Scale-UpDocument7 paginiModelling The Specific Grinding Energy and Ball Mill Scale-UpTsakalakis G. KonstantinosÎncă nu există evaluări

- Bond, F.C. - 1958 - Grinding Ball Size Selection PDFDocument4 paginiBond, F.C. - 1958 - Grinding Ball Size Selection PDFvpgLion100% (1)

- Bond F.C., 1961. Crushing and Grinding CalculationsDocument17 paginiBond F.C., 1961. Crushing and Grinding Calculationsitapui86% (7)

- Grinding FundamentalsDocument49 paginiGrinding Fundamentalsalfonsopescador100% (7)

- Ball Milling - Final FinalDocument12 paginiBall Milling - Final FinalKrishna TejaÎncă nu există evaluări

- Rod and ball mill sizing using Bond Work IndexDocument5 paginiRod and ball mill sizing using Bond Work IndexzicoÎncă nu există evaluări

- Kobelco Grate - Kiln ProcessDocument11 paginiKobelco Grate - Kiln ProcessJb Koffi KadjoÎncă nu există evaluări

- Punjab University Lahore: Report On PcsirDocument32 paginiPunjab University Lahore: Report On Pcsirone_special89Încă nu există evaluări

- Scale-Up and Dynamics of Large Grinding Mills - A Case StudyDocument19 paginiScale-Up and Dynamics of Large Grinding Mills - A Case StudyTsakalakis G. KonstantinosÎncă nu există evaluări

- The Application of High Chrome Grinding Media at MMG Century Mine For Improved Grinding Media Consumption and Metallurgy PerformanceDocument15 paginiThe Application of High Chrome Grinding Media at MMG Century Mine For Improved Grinding Media Consumption and Metallurgy PerformanceYaser Mohamed Abas100% (1)

- Mechanical Flotation Equipment Selection GuideDocument13 paginiMechanical Flotation Equipment Selection Guidelouza8Încă nu există evaluări

- Design of Comminution Circuits Rowland 1982Document46 paginiDesign of Comminution Circuits Rowland 1982Eigen Galvez100% (1)

- High Pressure Grinding RollsDocument12 paginiHigh Pressure Grinding RollsJorge EduardoÎncă nu există evaluări

- 5 Ways to Improve Your Health and WellnessDocument112 pagini5 Ways to Improve Your Health and WellnessSegundo Colorado Villar89% (9)

- AIA Engineering Buy Rating on Strong Growth OutlookDocument34 paginiAIA Engineering Buy Rating on Strong Growth OutlookakshayÎncă nu există evaluări

- Pelletizing ذكيDocument8 paginiPelletizing ذكييوسف عادل حسانينÎncă nu există evaluări

- Mq45271 Ball Mill CalculationDocument130 paginiMq45271 Ball Mill CalculationAntonio Carlos de Angelis100% (1)

- Crushing and Grinding Calculations NewDocument20 paginiCrushing and Grinding Calculations NewTsakalakis G. Konstantinos100% (25)

- Basics in Mineral Processing-GeneralDocument18 paginiBasics in Mineral Processing-Generalmakedo33100% (7)

- MINE292 Lecture7 Energy Used in Comminution 2013Document87 paginiMINE292 Lecture7 Energy Used in Comminution 2013Waris La Joi Wakatobi100% (2)

- IsaMill CompendiumDocument660 paginiIsaMill Compendiumwenguo weiÎncă nu există evaluări

- 1581 GB 03Document11 pagini1581 GB 03hasan2525Încă nu există evaluări

- Mineral Processing A DasDocument36 paginiMineral Processing A DasYallarling NagureÎncă nu există evaluări

- Regrind Mills - Challenges of Scaleup (Final)Document15 paginiRegrind Mills - Challenges of Scaleup (Final)Edwar Villavicencio JaimesÎncă nu există evaluări

- Expert Systems in Mineral and Metal Processing-Elsevier LTD, Pergamon (1992)Document201 paginiExpert Systems in Mineral and Metal Processing-Elsevier LTD, Pergamon (1992)Nataniel LinaresÎncă nu există evaluări

- Sizing of Grinding Equipment 3Document9 paginiSizing of Grinding Equipment 3JazmínARÎncă nu există evaluări

- Ball MillDocument9 paginiBall MillTaufik AchmadÎncă nu există evaluări

- Grinding Mill Scale-Up Problems by CC Harris N ArbiterDocument4 paginiGrinding Mill Scale-Up Problems by CC Harris N ArbiterTsakalakis G. Konstantinos100% (3)

- Section 3C: GrindingDocument3 paginiSection 3C: GrindingLM100% (1)

- CH 12 Rod & Ball MillsDocument40 paginiCH 12 Rod & Ball Millsismael1806Încă nu există evaluări

- Sag MillingDocument21 paginiSag MillingNaren KumarÎncă nu există evaluări

- ErreDocument12 paginiErreErick LoÎncă nu există evaluări

- The Selection and Design of Mill LinersDocument11 paginiThe Selection and Design of Mill Linersluis martinezÎncă nu există evaluări

- Finding and Eliminating Bottlenecks in Flotation Plants: Rob Coleman - Account Director April 8, 2016Document35 paginiFinding and Eliminating Bottlenecks in Flotation Plants: Rob Coleman - Account Director April 8, 2016Philip Walker100% (1)

- Grinding FundamentalsDocument49 paginiGrinding FundamentalsanruloÎncă nu există evaluări

- Mill Lines by FlSmidthDocument4 paginiMill Lines by FlSmidthIrving Dirzo CarrilloÎncă nu există evaluări

- Rapid Determination of Bond Rod-Mill Work IndexDocument5 paginiRapid Determination of Bond Rod-Mill Work IndexCraig TaylorÎncă nu există evaluări

- Up-Scaling of Froth Flotation EquipmentDocument91 paginiUp-Scaling of Froth Flotation EquipmentChristine Sola Morrison100% (7)

- Drop Weight Test Parameters Help Predict Performance of Antamina Ore SamplesDocument23 paginiDrop Weight Test Parameters Help Predict Performance of Antamina Ore Samplesevizcardo4617Încă nu există evaluări

- The Modelling and Computer Simulation of Mineral TreatmentDocument25 paginiThe Modelling and Computer Simulation of Mineral TreatmentDirceu NascimentoÎncă nu există evaluări

- SAG & Ball Mill DimensioningDocument2 paginiSAG & Ball Mill DimensioningAngel Cuya100% (2)

- Fundamentals of Metallurgical Processes: International Series on Materials Science and TechnologyDe la EverandFundamentals of Metallurgical Processes: International Series on Materials Science and TechnologyEvaluare: 5 din 5 stele5/5 (1)

- Modeling and Simulation of Mineral Processing SystemsDe la EverandModeling and Simulation of Mineral Processing SystemsEvaluare: 5 din 5 stele5/5 (1)

- Rod MillDocument9 paginiRod MillupiekupittÎncă nu există evaluări

- Ball Mills & SeparatorsDocument91 paginiBall Mills & Separatorsvijay kumar100% (2)

- Cement Mill NotebookDocument32 paginiCement Mill NotebookNael92% (50)

- ComminutionDocument37 paginiComminutionDaniel ChamunorwaÎncă nu există evaluări

- BwiDocument8 paginiBwiHiresomannavar MahanteshÎncă nu există evaluări

- 05 - Crusher - Grinding MillsDocument63 pagini05 - Crusher - Grinding Millsmeenie99270100% (1)

- 4 MPDocument33 pagini4 MPSyed Shahzaib ShahÎncă nu există evaluări

- Heavy Media or Dense Media - PropertiesDocument2 paginiHeavy Media or Dense Media - PropertiesTsakalakis G. KonstantinosÎncă nu există evaluări

- DENVER Mineral CharacteristicsDocument8 paginiDENVER Mineral CharacteristicsTsakalakis G. Konstantinos100% (1)

- RI 7472 Graphical Method OutlierDocument15 paginiRI 7472 Graphical Method OutlierTsakalakis G. KonstantinosÎncă nu există evaluări

- Resins in Mine Roof Support - ΙΙ by D. C. Mclean and S. Α. McKayDocument11 paginiResins in Mine Roof Support - ΙΙ by D. C. Mclean and S. Α. McKayTsakalakis G. KonstantinosÎncă nu există evaluări

- Energy and Mineral Exploitation TechniquesDocument16 paginiEnergy and Mineral Exploitation TechniquesTsakalakis G. Konstantinos100% (1)

- Calcination Rates of LimestoneDocument2 paginiCalcination Rates of LimestoneTsakalakis G. KonstantinosÎncă nu există evaluări

- Theory, Applications, and Practical Operation of HydrocyclonesDocument15 paginiTheory, Applications, and Practical Operation of HydrocyclonesTsakalakis G. Konstantinos100% (2)

- Resins in Mine Roof Support - IDocument7 paginiResins in Mine Roof Support - ITsakalakis G. KonstantinosÎncă nu există evaluări

- Single Fracture of Brittle Spheres by N. Arbiter, C. C. Harris and G. A. StamboltzisDocument16 paginiSingle Fracture of Brittle Spheres by N. Arbiter, C. C. Harris and G. A. StamboltzisTsakalakis G. KonstantinosÎncă nu există evaluări

- Model Building Techniques For Mineral Treatment Processes, Whiten W. J.Document16 paginiModel Building Techniques For Mineral Treatment Processes, Whiten W. J.Tsakalakis G. KonstantinosÎncă nu există evaluări

- Chemistry of Hydration of Portland CementDocument44 paginiChemistry of Hydration of Portland CementTsakalakis G. KonstantinosÎncă nu există evaluări

- Relationship Between Particle Size Distributions by Number and Weight Harris - StamboltzisDocument3 paginiRelationship Between Particle Size Distributions by Number and Weight Harris - StamboltzisTsakalakis G. KonstantinosÎncă nu există evaluări

- Screen Motion AnalysisDocument3 paginiScreen Motion AnalysisTsakalakis G. KonstantinosÎncă nu există evaluări

- Horsepower To Drive Rotary Kilns, Cooler or Dryer by Allis ChalmersDocument4 paginiHorsepower To Drive Rotary Kilns, Cooler or Dryer by Allis ChalmersTsakalakis G. Konstantinos100% (2)

- Mining Activities in Ancient Greece From The 7th To The 1st Centuries BC John EconomopoulosDocument6 paginiMining Activities in Ancient Greece From The 7th To The 1st Centuries BC John EconomopoulosTsakalakis G. KonstantinosÎncă nu există evaluări

- The Simulation of Mineral Processing Machinery, W.J. WhitenDocument3 paginiThe Simulation of Mineral Processing Machinery, W.J. WhitenTsakalakis G. KonstantinosÎncă nu există evaluări

- Filling of Underground Cavities With FlyashDocument4 paginiFilling of Underground Cavities With FlyashTsakalakis G. KonstantinosÎncă nu există evaluări

- Grinding Mill Scale-Up Problems by CC Harris N ArbiterDocument4 paginiGrinding Mill Scale-Up Problems by CC Harris N ArbiterTsakalakis G. Konstantinos100% (3)

- Scale-Up and Dynamics of Large Grinding Mills - A Case StudyDocument19 paginiScale-Up and Dynamics of Large Grinding Mills - A Case StudyTsakalakis G. KonstantinosÎncă nu există evaluări

- Air Classifier ArticleDocument16 paginiAir Classifier ArticleTsakalakis G. Konstantinos100% (2)

- Bentonite C. W. Davis and H. C. VacherDocument54 paginiBentonite C. W. Davis and H. C. VacherTsakalakis G. KonstantinosÎncă nu există evaluări

- Coal Cleaning by Dense Medium Processes H.J. Ruff InprominDocument12 paginiCoal Cleaning by Dense Medium Processes H.J. Ruff InprominTsakalakis G. KonstantinosÎncă nu există evaluări

- Derivation of A Basic Efficiency Formula For Concentrating OperationsDocument17 paginiDerivation of A Basic Efficiency Formula For Concentrating OperationsTsakalakis G. KonstantinosÎncă nu există evaluări

- Recycled Aggregates Case Study (Production From Construction and Demolition Debris)Document8 paginiRecycled Aggregates Case Study (Production From Construction and Demolition Debris)Tsakalakis G. KonstantinosÎncă nu există evaluări

- Ball, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Document131 paginiBall, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Tsakalakis G. Konstantinos100% (7)

- Crushing and Grinding Calculations NewDocument20 paginiCrushing and Grinding Calculations NewTsakalakis G. Konstantinos100% (25)

- Modern Solutions To Screen NG Problems: Mogensen SizerDocument8 paginiModern Solutions To Screen NG Problems: Mogensen SizerTsakalakis G. KonstantinosÎncă nu există evaluări

- Modelling The Specific Grinding Energy and Ball Mill Scale-UpDocument7 paginiModelling The Specific Grinding Energy and Ball Mill Scale-UpTsakalakis G. KonstantinosÎncă nu există evaluări

- Inventory ManagementDocument60 paginiInventory Managementdrashti0% (1)

- Action Plan On GadDocument1 paginăAction Plan On GadCherish Devora ArtatesÎncă nu există evaluări

- DRM 25Document14 paginiDRM 25Anantha RajanÎncă nu există evaluări

- CommunicationDocument5 paginiCommunicationRyan TomeldenÎncă nu există evaluări

- Best Mesl StudoDocument15 paginiBest Mesl StudoJoenielÎncă nu există evaluări

- Ethanol: Safety Data SheetDocument19 paginiEthanol: Safety Data SheetNitika SinhaÎncă nu există evaluări

- A Hirshfeld Surface Analysis and Crystal StructureDocument8 paginiA Hirshfeld Surface Analysis and Crystal StructureLidiane MicheliniÎncă nu există evaluări

- COP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDocument4 paginiCOP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDavid CarrilloÎncă nu există evaluări

- DrdoDocument2 paginiDrdoAvneet SinghÎncă nu există evaluări

- CorentineDocument559 paginiCorentinejames b willardÎncă nu există evaluări

- Column and Thin Layer ChromatographyDocument5 paginiColumn and Thin Layer Chromatographymarilujane80% (5)

- ECE Laws and Ethics NotesDocument29 paginiECE Laws and Ethics Notesmars100% (1)

- Brochure Troysperse+CD1+Brochure+ (TB0112)Document8 paginiBrochure Troysperse+CD1+Brochure+ (TB0112)mario3312Încă nu există evaluări

- Tutorial Sim MechanicsDocument840 paginiTutorial Sim MechanicsHernan Gonzalez100% (4)

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pagini3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2Încă nu există evaluări

- Lab 1 Handout Electrical MachinesDocument23 paginiLab 1 Handout Electrical Machinesvishalsharma08Încă nu există evaluări

- Lolita An Intelligent and Charming Holstein Cow Consumes Only TwoDocument1 paginăLolita An Intelligent and Charming Holstein Cow Consumes Only Twotrilocksp SinghÎncă nu există evaluări

- 230kv Cable Sizing CalculationsDocument6 pagini230kv Cable Sizing Calculationsrajinipre-1Încă nu există evaluări

- Amber ToolsDocument309 paginiAmber ToolshkmydreamsÎncă nu există evaluări

- wt-and-fds-practical-slipsDocument32 paginiwt-and-fds-practical-slipsRohidas SapkalÎncă nu există evaluări

- Giljang - Bsn2-A10 - Sas 1-3Document7 paginiGiljang - Bsn2-A10 - Sas 1-3Cherylen Casul GiljangÎncă nu există evaluări

- Giraffe Juice GamesDocument32 paginiGiraffe Juice Gamesgwyn022100% (3)

- C172M QRH (VH-JZJ) v1.1Document49 paginiC172M QRH (VH-JZJ) v1.1alphaÎncă nu există evaluări

- The Critical Need For Software Engineering EducationDocument5 paginiThe Critical Need For Software Engineering EducationGaurang TandonÎncă nu există evaluări

- SEM 3037E Tower Piping.Document52 paginiSEM 3037E Tower Piping.Kodali Naveen KumarÎncă nu există evaluări

- Laser Module 5Document25 paginiLaser Module 5Luis Enrique B GÎncă nu există evaluări

- Information HandoutsDocument6 paginiInformation HandoutsPooja Marwadkar TupcheÎncă nu există evaluări

- MST 2 ReviewerDocument4 paginiMST 2 ReviewerAizha NarioÎncă nu există evaluări

- Manufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaDocument28 paginiManufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaSahil SundaÎncă nu există evaluări

- Technology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural ProductsDocument14 paginiTechnology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural Productslana del rey100% (1)