Documente Academic

Documente Profesional

Documente Cultură

51CrV4 10083 06 ENG 01

Încărcat de

ashkansoheylTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

51CrV4 10083 06 ENG 01

Încărcat de

ashkansoheylDrepturi de autor:

Formate disponibile

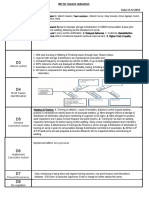

Alphanumeric designation

Numerical designation 1.8159

Standard reference Germany EN 10083-3:2006 France Italy

Correspondences 50CrV4 50CV4 50CrV4 S max

United Kingdom

Rev 01 51CrV4 Ni V

Date

12-02-07

51CrV4

Chemical composition ( % mass )

Spain United States Cr Mo -

Si max

Mn

P max

B -

heat product Young modulus [ N/mm2 ] 205000

0,47-0,55 0,4 0,7-1,1 0,035 0,035 0,9-1,2 0,45-0,57 0,43 0,66-1,15 0,04 0,04 0,85-1,25 PHYSICAL CHARACTERISTICS ( T=20C if not differently stated ) Poisson modulus 0,29 Bulk modulus [ N/mm2 ] 140000 Density [ kg/dm3 ] 7,85

0,1-0,25 0,08-0,27

Linear thermal expansion coefficient [ m/m C ] T=20C T=250C T=500C T=1000C -

2007 Granit Engineering www.graniteng.com ALL RIGHTS RESERVED for personal non commercial use

Heat treatment state SOFT ANNEALED ISOTHERMAL ANNEALED 16 16 < d 40 40 < d 100 100 < d 250 250< d 500 MECHANICAL CHARACTERISTICS ( T=20C if not differently stated ) Rod diameter Rm A5 Rp0.2 [ mm ] [N/mm2] [%] [N/mm2] 838 max 1080-1280 980-1180 880-1080 835-985 785-935 KCU [J] HB [N/mm2] 248 max 880 min 9 min 20 min 318-376 785 min 10 min 20 min 289-347 685 min 12 min 20 min 261-318 635 min 13 min 20 min 247-291 590 min 12 min 15 min 233-276 HARDENABILITY: MEDIUM/HIGH; steel available in the classes H;HH;HL

QUENCHED AND TEMPERED

DESCRIPTION/APPLICATIONS

Quench and tempering special CrV steel, equivalent to 50CrV4 standardized according to UNI 7874/7845, characterized by high tensile strength and medium/low toughness. It is suitable to the manufacture of components of maximum thickness equal to 50 mm meanly or strongly stressed (shafts, rollers, guide rollers, axles, levers, connecting rods, rocker arms). It lends itself in an optimum way to the manufacturing of springs, torsion bars, leaf springs. To improve the workability WELDABILITY : CRITICAL at the machines tools it can be booked with the addition of Ca or re-sulphurized (S0,1%). The use of re-sulphurized steels involves a worsening of the tensile strength characteristics along the transversal, of the impact strength and of the ADVISED WELDING PROCESSES fatigue strength. Advised austenitic grain dimension > 5 SMAW B (basic); GMAW; GTAW; PAW; LBW*; EBW* ( *on vacuum-sealed according to UNI 3245 (similar to ASTM E 112-82) outgased steels ) ADVISED WELDING PROCEEDINGS Surface hardening according to 1. f.m. at low C + Tp** + TB or PWHT INDUCTIONHARDNESS 1.x and LASERHARDNESS 1.x 2. austenitic f.m. + Tp ( 150 C ) Thermochemically manageable according to 3. f.m. Ni base alloy + Tp ( 150 C ) + PWHT CASEHARDENING 1.x GENERAL PRECAUTIONS Sizing and checking of effective multipass welding hardening thickness according to HD reduction ( 3 optimum ); hard reconditioning of electrodes DEEPHARDNESS 1.x and DEEPHARDNESS 2.x maximum edges cleaning Critical points : maximum reduction of the degree of the joint constraint Ac1 740 C maximum Rd reduction Ac3 790 C double layer buttering technique advised Ms 280 C LEGEND Tp : preheat minimum temperature[ C ] ; HD : diffusible hydrogen [ HEAT TREATMENT AND HOT PLASTIC ml/100g ]; Rd : dilution rapport [ % ] ; d : combined thickness [ DEFORMATION TEMPERATURES mm ] ; Q :heat input[ kJ/mm ] ; f.m. : filler metal; TB : temper beads ; Cooling PWHT : post-welding heat treatment TEMPERATURE C medium WARNING Hot plastic 850-1100 re-sulphurized grades not weldable deformation Normalization 870-900 air Soft annealing Isothermal annealing Hardening Tempering 680-720 Step 1 800-850 Step 700 820-860 540-680 air air oil air d [ mm ] 6 12 Tp** [ C ] 250 350 d [ mm ] 25 50 Tp** [ C ] 350 350

S-ar putea să vă placă și

- MIT Lockpicking GuideDocument49 paginiMIT Lockpicking GuideNarrowPathPilgrim100% (10)

- 4-Speed Transmission ManualDocument9 pagini4-Speed Transmission ManualashkansoheylÎncă nu există evaluări

- Total vehicle alignment guide for optimal tire performanceDocument7 paginiTotal vehicle alignment guide for optimal tire performancepvekzÎncă nu există evaluări

- GMAW Guide to MIG WeldingDocument52 paginiGMAW Guide to MIG WeldingGaddipati MohankrishnaÎncă nu există evaluări

- Surface Preparation Commentary GuideDocument32 paginiSurface Preparation Commentary Guidesflynn79100% (2)

- Durehete 950Document5 paginiDurehete 950ellisforheroes100% (1)

- Crgo MTCDocument4 paginiCrgo MTCGupta Gupta100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Prepration of ITP For Storage Tanks Fabrication & ErectionDocument27 paginiPrepration of ITP For Storage Tanks Fabrication & ErectionRamuAlagappan93% (15)

- Engineering Materials Data SheetDocument6 paginiEngineering Materials Data Sheetrajarao1234Încă nu există evaluări

- TDI33 Tank Inspection Suitaility For Service API 653 Sec 4Document29 paginiTDI33 Tank Inspection Suitaility For Service API 653 Sec 4Faizal SattuÎncă nu există evaluări

- BS MA 41 2 Tonne General Purpose Davits PDFDocument15 paginiBS MA 41 2 Tonne General Purpose Davits PDFMohamed Eid AbassÎncă nu există evaluări

- Week 8 Sheet Metal FormingDocument69 paginiWeek 8 Sheet Metal FormingashkansoheylÎncă nu există evaluări

- ASME Code Cases for Nuclear ComponentsN-71-18N-71-18N-122-2N-131-1N-133-3N-154-1N-155-2N-160-1N-192-3N-201-5N-208-1N-213N-243N-249-14N-253-14N-254N-257N-258-2Document14 paginiASME Code Cases for Nuclear ComponentsN-71-18N-71-18N-122-2N-131-1N-133-3N-154-1N-155-2N-160-1N-192-3N-201-5N-208-1N-213N-243N-249-14N-253-14N-254N-257N-258-2Biyong SantocildesÎncă nu există evaluări

- Weldwell Catalogue 2015Document8 paginiWeldwell Catalogue 2015jaganelrÎncă nu există evaluări

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe la EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceEvaluare: 5 din 5 stele5/5 (1)

- Design and MFG of Hydraulic PressesDocument54 paginiDesign and MFG of Hydraulic Pressesraghumn100% (3)

- Astm A106 Ts EnglDocument4 paginiAstm A106 Ts EnglxaviereduardoÎncă nu există evaluări

- Oil and Gas Transportation NetworkDocument79 paginiOil and Gas Transportation NetworkAbid Hussain100% (1)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesDe la EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesÎncă nu există evaluări

- AWS C5.7 (2000) - 2006r - Recommended Practices For Electrogas WeldingDocument65 paginiAWS C5.7 (2000) - 2006r - Recommended Practices For Electrogas WeldingPubcrawlÎncă nu există evaluări

- TWI Defects PDFDocument26 paginiTWI Defects PDFsukarlan98Încă nu există evaluări

- Erection Manual For Granulator 10.6.16 PDFDocument100 paginiErection Manual For Granulator 10.6.16 PDFdang2172014Încă nu există evaluări

- Tank in Service Inspection ChecklistDocument8 paginiTank in Service Inspection ChecklistAhmadiBinAhmad100% (3)

- D & H Equipment Booklet NewDocument21 paginiD & H Equipment Booklet NewHarsh Purohit100% (1)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDe la EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsEvaluare: 4 din 5 stele4/5 (6)

- Iagi Ingles PDFDocument30 paginiIagi Ingles PDFMatzelo ResetÎncă nu există evaluări

- Material spec sheet for 51CrV4 steelDocument3 paginiMaterial spec sheet for 51CrV4 steelanilÎncă nu există evaluări

- Hytrel Extrusion Manual PDFDocument28 paginiHytrel Extrusion Manual PDFashkansoheylÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw SmawDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- 34CrMo4 10083 06 ENG 01 PDFDocument1 pagină34CrMo4 10083 06 ENG 01 PDFMarcio CunhaÎncă nu există evaluări

- 36CrNiMo4 10083 98 ENG 01 PDFDocument1 pagină36CrNiMo4 10083 98 ENG 01 PDFanon_308531351Încă nu există evaluări

- Dörrenberg Edelstahl 1.7225 steel propertiesDocument0 paginiDörrenberg Edelstahl 1.7225 steel propertiesPavle StevanovicÎncă nu există evaluări

- 42CrMo4 10083Document5 pagini42CrMo4 10083DavindRa SoniÎncă nu există evaluări

- 1.2379 X153Crmov12 Cppu: Chemical CompositionDocument2 pagini1.2379 X153Crmov12 Cppu: Chemical CompositionAdrian Finichiu100% (1)

- UTOPEX2Document4 paginiUTOPEX2emregnesÎncă nu există evaluări

- 36NiCrMo16 10083 06 ENG 01Document1 pagină36NiCrMo16 10083 06 ENG 01Guru Raj9739Încă nu există evaluări

- 1.8550 - 34CRAlNi7sdfDocument2 pagini1.8550 - 34CRAlNi7sdfAdrian FinichiuÎncă nu există evaluări

- Material 1.2738 - 40CrMnNiMo8-6-4Document1 paginăMaterial 1.2738 - 40CrMnNiMo8-6-4johnnydoe90100% (1)

- UTOP Mo4 1.2345 - enDocument2 paginiUTOP Mo4 1.2345 - enGoran ErakovicÎncă nu există evaluări

- 1.4922 SteelDocument2 pagini1.4922 Steeldnageshm4n244Încă nu există evaluări

- 20240124091141-Dillimax 890 01 2024 eDocument4 pagini20240124091141-Dillimax 890 01 2024 enguyễn vanhuan211Încă nu există evaluări

- Data Sheet Res PDFDocument5 paginiData Sheet Res PDFToufani Rizal AlfarisiÎncă nu există evaluări

- 34 CR Ni Mo 6Document1 pagină34 CR Ni Mo 6Bogdan CraciunÎncă nu există evaluări

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 paginiKaiser Aluminum Shapes Soft Alloy PDFgerrzen64Încă nu există evaluări

- Power Metal Oxide Film Resistors: Electrical DataDocument2 paginiPower Metal Oxide Film Resistors: Electrical DatacorneloaieÎncă nu există evaluări

- ThyssenKrupp Steel Data Sheet P235GHDocument4 paginiThyssenKrupp Steel Data Sheet P235GHjaseerkannothÎncă nu există evaluări

- High Strength Structural Steel Data SheetDocument4 paginiHigh Strength Structural Steel Data SheetFernando Alonso Troncos MendivesÎncă nu există evaluări

- High Strength Fine Grained Structural Steel, Quenched and TemperedDocument6 paginiHigh Strength Fine Grained Structural Steel, Quenched and TemperedXQÎncă nu există evaluări

- X210CR12 GradeDocument3 paginiX210CR12 GradekartsoftÎncă nu există evaluări

- High Strength Fine Grained Structural Steel, Quenched and TemperedDocument6 paginiHigh Strength Fine Grained Structural Steel, Quenched and TemperedkazdanoÎncă nu există evaluări

- PK2SPDocument3 paginiPK2SPEmanuelValenciaHenaoÎncă nu există evaluări

- Domex 100 XF hot rolled steel data sheetDocument2 paginiDomex 100 XF hot rolled steel data sheetzubblwump5063Încă nu există evaluări

- 1.2714 55NiCrMoV7Document2 pagini1.2714 55NiCrMoV7Mogos PaulÎncă nu există evaluări

- Aisi 52100 SpecificationsubyuyDocument1 paginăAisi 52100 SpecificationsubyuyankitsarvaiyaÎncă nu există evaluări

- High Strength Fine Grained Structural Steel Quenched and TemperedDocument6 paginiHigh Strength Fine Grained Structural Steel Quenched and TemperedAugusto BerdetteÎncă nu există evaluări

- Quality 42crmo4: Lucefin GroupDocument1 paginăQuality 42crmo4: Lucefin GroupAnonymous Gbers2EÎncă nu există evaluări

- 10 1018Document1 pagină10 1018Uthayan SPÎncă nu există evaluări

- Tj-Ningbo - materialDesignUddLayout (Automatisch Gespeichert)Document79 paginiTj-Ningbo - materialDesignUddLayout (Automatisch Gespeichert)Hasta MahardikaÎncă nu există evaluări

- Multilayer Ceramic Capacitors Axial Leads MiniatureDocument1 paginăMultilayer Ceramic Capacitors Axial Leads Miniaturecataclg24Încă nu există evaluări

- Steel Grades and Surface TreatmentsDocument12 paginiSteel Grades and Surface TreatmentsGross Meltiade AlexanderÎncă nu există evaluări

- TDS P5300Document1 paginăTDS P5300Yavuz ÖzönderÎncă nu există evaluări

- MV Capacitor and Voltage Divider DsDocument4 paginiMV Capacitor and Voltage Divider DsCristiano BruschiniÎncă nu există evaluări

- Material Specification Sheet Saarstahl - 36crnimo4Document1 paginăMaterial Specification Sheet Saarstahl - 36crnimo4Anonymous rYZyQQot55Încă nu există evaluări

- 421 - Domex 700 MCDocument2 pagini421 - Domex 700 MClalamed21Încă nu există evaluări

- High-Wear Chromium SteelDocument1 paginăHigh-Wear Chromium SteelTürker AstarlioğluÎncă nu există evaluări

- 1.4112 X90Crmov18 R17X: Chemical CompositionDocument2 pagini1.4112 X90Crmov18 R17X: Chemical CompositionirajfarjiÎncă nu există evaluări

- Material 1.2767 - 45NiCrMo16Document1 paginăMaterial 1.2767 - 45NiCrMo16johnnydoe90Încă nu există evaluări

- OCR12VMDocument4 paginiOCR12VMcvgfgÎncă nu există evaluări

- 20160323093138-51CrV4 (50CrV4)Document1 pagină20160323093138-51CrV4 (50CrV4)P NAVEEN KUMARÎncă nu există evaluări

- Material 1.2379 - X153CrMoV12Document2 paginiMaterial 1.2379 - X153CrMoV12johnnydoe90Încă nu există evaluări

- CuAg0,1P PDFDocument8 paginiCuAg0,1P PDFirajfarji2481Încă nu există evaluări

- ASHU SHARMA'S PRESENTATION ON UPGRADED INSULATION SYSTEMSDocument125 paginiASHU SHARMA'S PRESENTATION ON UPGRADED INSULATION SYSTEMSpartha070Încă nu există evaluări

- FinDocument3 paginiFinTVP_contechÎncă nu există evaluări

- Conarc49 EngDocument2 paginiConarc49 Engdeepak2803Încă nu există evaluări

- Vishay Bccomponents: FeaturesDocument16 paginiVishay Bccomponents: FeaturesPetrutStefanVartolomeiÎncă nu există evaluări

- 4340Document1 pagină4340ralishÎncă nu există evaluări

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDe la EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášÎncă nu există evaluări

- Advances in Solid Oxide Fuel Cells XDe la EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffÎncă nu există evaluări

- Significantly Regulated Organizations Added in February 2017Document10 paginiSignificantly Regulated Organizations Added in February 2017ashkansoheylÎncă nu există evaluări

- Laboratory Glassware CatalogueDocument52 paginiLaboratory Glassware CatalogueashkansoheylÎncă nu există evaluări

- Self Tapping ScrewsDocument6 paginiSelf Tapping ScrewsashkansoheylÎncă nu există evaluări

- General Design Principles For Structural Design Formulae PDFDocument24 paginiGeneral Design Principles For Structural Design Formulae PDFkfarav100% (1)

- Hytrel Product Reference GuideDocument4 paginiHytrel Product Reference GuideashkansoheylÎncă nu există evaluări

- General Design Principles For Springs and Living HingesDocument2 paginiGeneral Design Principles For Springs and Living HingesashkansoheylÎncă nu există evaluări

- Hytrel Rheology Handling Product HandlingDocument8 paginiHytrel Rheology Handling Product HandlingROUSSMATÎncă nu există evaluări

- 154963guidance Consumer PDFDocument90 pagini154963guidance Consumer PDFashkansoheylÎncă nu există evaluări

- Minlon Zytel Design Info Module 2 PDFDocument62 paginiMinlon Zytel Design Info Module 2 PDFkfaravÎncă nu există evaluări

- Zytel LCPA Product Reference GuideDocument2 paginiZytel LCPA Product Reference GuideashkansoheylÎncă nu există evaluări

- Typical Processing Conditions For Engineering Polymers PDFDocument21 paginiTypical Processing Conditions For Engineering Polymers PDFkfaravÎncă nu există evaluări

- General Design Principles For Machining, Cutting and FinishingDocument8 paginiGeneral Design Principles For Machining, Cutting and FinishingashkansoheylÎncă nu există evaluări

- DelrinDocument65 paginiDelrind-fbuser-98630126100% (1)

- General Design Principles For BearingsDocument8 paginiGeneral Design Principles For Bearingsmehdi7891Încă nu există evaluări

- Crastin PBT and Rynite PET Design Info Module IV PDFDocument67 paginiCrastin PBT and Rynite PET Design Info Module IV PDFashkansoheyl100% (1)

- 2.injection MoldingDocument4 pagini2.injection Moldingmunishd_7Încă nu există evaluări

- Fit Tolerance For Plastic PartsDocument16 paginiFit Tolerance For Plastic PartsA_JANNESÎncă nu există evaluări

- Wheel DesignDocument4 paginiWheel Designmunishd_7Încă nu există evaluări

- Wheel DesignDocument4 paginiWheel Designmunishd_7Încă nu există evaluări

- Extrusion Applications PDFDocument23 paginiExtrusion Applications PDFashkansoheylÎncă nu există evaluări

- Delrin® Acetal Homopolymer Resin - Molding TipsDocument4 paginiDelrin® Acetal Homopolymer Resin - Molding TipsashkansoheylÎncă nu există evaluări

- Delrin Low Emissions For Auto ApplicationsDocument4 paginiDelrin Low Emissions For Auto ApplicationsashkansoheylÎncă nu există evaluări

- DuPont Delrin (R) Vs Acetal Copolymer White PaperDocument16 paginiDuPont Delrin (R) Vs Acetal Copolymer White Paperashkansoheyl0% (1)

- Otr Data Book 2005Document115 paginiOtr Data Book 2005jorgtedavidÎncă nu există evaluări

- AdtDocument6 paginiAdtashkansoheylÎncă nu există evaluări

- AE8009 Airframe Maintenance & RepairDocument24 paginiAE8009 Airframe Maintenance & RepairAeronaughtycs Hamdan0% (2)

- Cooperheat 6kanalniDocument2 paginiCooperheat 6kanalnier111poÎncă nu există evaluări

- Manual Español Econotig Miller PDFDocument32 paginiManual Español Econotig Miller PDFAngeles Pallares de PerezÎncă nu există evaluări

- OTC-6076-MS A New Approach To Designing Repair Clamps For Offshore StructuresDocument14 paginiOTC-6076-MS A New Approach To Designing Repair Clamps For Offshore StructuresAnil Chanana100% (1)

- PRC-0002 Current PDFDocument27 paginiPRC-0002 Current PDFOPAZOSCÎncă nu există evaluări

- Bahra Electric - EarthingDocument1 paginăBahra Electric - EarthingSalman JoÎncă nu există evaluări

- ISO 9606-3 1999 Qualification Testing of Welders-Fusion Welding Part 3 Copper and Copper AlloysDocument30 paginiISO 9606-3 1999 Qualification Testing of Welders-Fusion Welding Part 3 Copper and Copper AlloysJames HurtadoÎncă nu există evaluări

- Recommendations For Structural Design Criteria For Low Head Slide GatesDocument30 paginiRecommendations For Structural Design Criteria For Low Head Slide GatesNaresh AÎncă nu există evaluări

- (For PKG2 Only Applicable) : Uop Lines Applicable Post Heat RequirementDocument1 pagină(For PKG2 Only Applicable) : Uop Lines Applicable Post Heat RequirementMuhammad SawadÎncă nu există evaluări

- Welding Specification for Plant Piping SystemsDocument78 paginiWelding Specification for Plant Piping Systemsmasoud132Încă nu există evaluări

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 paginăTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarÎncă nu există evaluări

- ASTM A372-A372M-03 Standard Specification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsDocument5 paginiASTM A372-A372M-03 Standard Specification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsAarón Escorza MistránÎncă nu există evaluări

- Final Int RPT RVDocument58 paginiFinal Int RPT RVRudhra veena100% (1)

- Automated Drain Cleaner Design and Progress ReportDocument12 paginiAutomated Drain Cleaner Design and Progress ReportMohd Anwar83% (6)