Documente Academic

Documente Profesional

Documente Cultură

5 - Whole Metallurgy (Part I)

Încărcat de

Antonio C. KeithDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

5 - Whole Metallurgy (Part I)

Încărcat de

Antonio C. KeithDrepturi de autor:

Formate disponibile

I.

Metals

Light metals Heavy metals High melting Brittle Ductile

Non metals

Inert gases

Noble

Low melting

From the periodic table, it can be found that: Metals are on the left side. Nonmetals are on the right side. Metalloids or semiconductors are at the boundary between metals and nonmetals; e.g. Carbon, Silicon and Boron.

Properties of metals:

1- Ionized positively. 2- Crystalline solids at room temperature, except Hg and Ga. 3- Opaque and lustrous. 4- Thermally ad electrically conductors. 5- Hardness, melting and boiling points. 6- Density. 7- Ductile and malleable. 8- Melting range. 9- White in color except Au and Cu.

Pure metals in dentistry:

1- Au and Pt foils Restorations.

2- Pt foils

Porcelain.

3- Au and Sn

Ceramo metal restorations.

4- Ag and Cu

Electroplated dies.

5- Hg

Amalgam.

6- Ti

Implantology, Cr and Br (Procera).

Shaping of metals:

a) Casting: Liquid metal Crystalline solid

Solidification and thermal shrinkage 4-6%

b) Plastic forming (Cold working): Cast metal rod, wire, tube,

c) Sintering (Powder metallurgy): Powder

Heat Solid Pressure

Accompanied by Shrinkage, Density and Porosity

d) Electroforming: Ag and Cu electroplating.

C:\Documents

and

Settings\Mostafa

A.

Latif\My

Documents\My

Pictures\Dr.Azza\Metallurgy\078_Electroplating.mov

Solidification of metals:

A Liquid Temperature Plateau L+S Tf B B\ Supercooling C Solid D

Time Time temperature cooling curve for a pure metal

1- Nucleus formation: Liquid metal atomic aggregates embryos embryos

Penetration of super cooling

temp. Latent heat

2- Crystallization: Nuclei of crystallization Homogeneous

Dendrites Crystals Solid metal

Heterogeneous

Grains and grain boundaries:

Poly crystalline material Crystals with various orientation Crystals or grains have: Shape Size Orientation Distribution Grain Proper Boundary Grain boundary: - Transition zone (1-2 atomic distances). - Indicates discontinuity of space lattices planes. - Nearly noncrystalline. - Of higher energy. - Greater rate of diffusion. - Greater concentration of impurities. - More readily attacked by chemicals.

Microstructural variables of a single phase material

Grain size: - Size - Size

1

Number and location of nuclei. Grain boundary - area.

Control of grain size: Size Physical properties.

1 e.g. Y .S . r

1- Amount and rate of supercooling (Control number of grains and nuclei). 2- Rate of crystallization and rate of nucleation. 3- Nucleating agents.

Wrought metal Deformation

Cast Wrought

Recovery Grain growth Recrystallization

Cast metal Deformation of metals:

wrought metal Elastic Plastic

Elastic

Plastic

Lattice imperfections: a- Point defects: Vacancies

b- Line defects: Dislocations

Edge Dislocation

Screw Dislocation

Mixed Dislocation

c- Plane defects: Boundaries

Strain hardening: [Cold working] [Work hardening]: Dislocation is inhibited by: 1- Point defects. 2- Collision of 2 dislocation. 3- Foreign atom lattice. 4- Grain boundaries. Dislocation build up Stresses needed to proceed deformation So, Hardness, Strength and P.L.

Meanwhile, Ductility and Corrosion resistance

Annealing: It reverses the effects of cold working It involve three stages: 1- Recovery. 2- Recrystallization. 3- Grain growth. Factors affecting grain size and shape: 1- Rate of cooling. 2- Nucleating agents. 3- Cold working. 4- Annealing a) Recrystallization b) Grain growth.

Recovery

Tm (for few minutes) Relief of stresses

Recrystallization

0.3-0.6 Tm

Grain growth

Further annealing

Nucleation of stress free grains Growth of grains. at boundaries. .

and

St., P.L., and Hardness Ductility

Cold worked Recovery

and

Recryst.

St., P.L. Ductility

Grain growth

Tensile strength

A) Cold worked B) Recovery C) Recrystallization D) Grain growth

Ductility

S-ar putea să vă placă și

- ALLEN, S.M. & THOMAS, E.L. The Structure of MaterialsDocument7 paginiALLEN, S.M. & THOMAS, E.L. The Structure of MaterialsPaula Brokate33% (6)

- Basic Mettalurgy of The Precious Metal Part IDocument38 paginiBasic Mettalurgy of The Precious Metal Part ILinda LindawatiÎncă nu există evaluări

- Santa Fe Symposium: Basic Metallurgy of Precious MetalsDocument33 paginiSanta Fe Symposium: Basic Metallurgy of Precious MetalsaripÎncă nu există evaluări

- MSM M 1& 2 Imp QnsDocument18 paginiMSM M 1& 2 Imp Qnssangei2093Încă nu există evaluări

- Properties of MetalsDocument10 paginiProperties of MetalsKawaii SamaÎncă nu există evaluări

- BY Dr. Bibin BhaskaranDocument51 paginiBY Dr. Bibin BhaskarannvemanÎncă nu există evaluări

- Metals: Igcse O LevelDocument21 paginiMetals: Igcse O LevelLeniÎncă nu există evaluări

- METALS NON METALS TheoryDocument23 paginiMETALS NON METALS TheoryweyiÎncă nu există evaluări

- Metals and Non-Metals NE (L)Document21 paginiMetals and Non-Metals NE (L)Aryan BhuraÎncă nu există evaluări

- Metallugy BasicDocument62 paginiMetallugy Basicatique islamÎncă nu există evaluări

- MetalDocument16 paginiMetalEdgar Apaza HuallpaÎncă nu există evaluări

- CPE 601-Corrosion Week 5Document74 paginiCPE 601-Corrosion Week 5Nur AqilahÎncă nu există evaluări

- Class 12 Chemistry PPT D Block Chemistry July 2023Document17 paginiClass 12 Chemistry PPT D Block Chemistry July 2023Sheetal TrivediÎncă nu există evaluări

- TDK ... P CORROSION & IGC ........ Add ........ B4TDocument21 paginiTDK ... P CORROSION & IGC ........ Add ........ B4Tdwi sutiknoÎncă nu există evaluări

- Project and Facility ManagementDocument26 paginiProject and Facility ManagementKumaResan SubramaniamÎncă nu există evaluări

- Chapter - 8 MetalDocument12 paginiChapter - 8 Metalamit_idea1Încă nu există evaluări

- Chemistry 1000 Lecture 10: Metals and Crystal Structures: Marc R. RousselDocument17 paginiChemistry 1000 Lecture 10: Metals and Crystal Structures: Marc R. RousselShahid KhanÎncă nu există evaluări

- MetalDocument9 paginiMetaldjtomcraftÎncă nu există evaluări

- Grade X - Teaching Notes: Metals and Non-Metals GlossaryDocument25 paginiGrade X - Teaching Notes: Metals and Non-Metals GlossaryAkshith KottaÎncă nu există evaluări

- Anglais ScientifiqueDocument4 paginiAnglais Scientifiqueali BourenaneÎncă nu există evaluări

- Metal and Alloy 24 Nov.2023Document28 paginiMetal and Alloy 24 Nov.2023lvvjkhpoggpskjzcpwÎncă nu există evaluări

- Metals Used in ProsthodonticsDocument43 paginiMetals Used in ProsthodonticsnavneetkhanÎncă nu există evaluări

- Manufacturing Science and MetallurgyDocument47 paginiManufacturing Science and MetallurgyAppu bjÎncă nu există evaluări

- Chapter+4+ +Imperfections+in+CrystalsDocument25 paginiChapter+4+ +Imperfections+in+Crystalspramod_kÎncă nu există evaluări

- Publication 3 26810 199 PDFDocument11 paginiPublication 3 26810 199 PDFnagarajÎncă nu există evaluări

- Manufacturing Processes: Dra. Martha P. Guerrero Mata Dra. Adriana Salas ZamarripaDocument67 paginiManufacturing Processes: Dra. Martha P. Guerrero Mata Dra. Adriana Salas ZamarripaBrayan AlvarezÎncă nu există evaluări

- Chapter 2Document70 paginiChapter 2劉德信Încă nu există evaluări

- HGHFFDocument2 paginiHGHFFJob ShortsÎncă nu există evaluări

- Chemistry Endurance Race 5070Document29 paginiChemistry Endurance Race 507024avesh.kumarÎncă nu există evaluări

- Metaullargy NotesDocument14 paginiMetaullargy Noteswama ojhaÎncă nu există evaluări

- CHE882Unit3 L15Document8 paginiCHE882Unit3 L15Ms Mayank YadavÎncă nu există evaluări

- Metal PropertiesDocument17 paginiMetal PropertiesParag AlamyanÎncă nu există evaluări

- CorrosionDocument15 paginiCorrosionSohila A. MabroukÎncă nu există evaluări

- Corrosion Protection 7.1 Causes of Corrosion:: (2) Combined StateDocument10 paginiCorrosion Protection 7.1 Causes of Corrosion:: (2) Combined Stateحاتم غيدان خلفÎncă nu există evaluări

- GoldDocument7 paginiGoldHammad zia 32Încă nu există evaluări

- Metals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument43 paginiMetals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDheeraj KumarÎncă nu există evaluări

- 06 - Uet FM LecDocument48 pagini06 - Uet FM LecAbcÎncă nu există evaluări

- Unit 1Document280 paginiUnit 1Abhishek ChavanÎncă nu există evaluări

- Structure, Properties, Process, and Aplications of GoldDocument10 paginiStructure, Properties, Process, and Aplications of GoldMahfud EffendiÎncă nu există evaluări

- Non Ferrous-Metal - Group-2 - Written-Report - ME3Document11 paginiNon Ferrous-Metal - Group-2 - Written-Report - ME3ELLIEÎncă nu există evaluări

- Ceramics: Classification and Properties of Ceramic MaterialsDocument36 paginiCeramics: Classification and Properties of Ceramic MaterialsMadhumita KumarÎncă nu există evaluări

- Alkali Metals: MetalDocument8 paginiAlkali Metals: MetalKaitlynRanaÎncă nu există evaluări

- Lesson 7 Metals and Non MetalsDocument5 paginiLesson 7 Metals and Non MetalsSoham AÎncă nu există evaluări

- METALSDocument4 paginiMETALSAyan BarbonÎncă nu există evaluări

- CHEM 252 Lecture 1Document18 paginiCHEM 252 Lecture 1Adjei DanielÎncă nu există evaluări

- Alloys: I) IntroductionDocument12 paginiAlloys: I) IntroductionNikhil ShelarÎncă nu există evaluări

- Occurrence of MetalsDocument24 paginiOccurrence of MetalsPamo CaytanoÎncă nu există evaluări

- Class 2 Materials in Metal Manufacturing: Crystalline StructureDocument5 paginiClass 2 Materials in Metal Manufacturing: Crystalline StructureAlef BergÎncă nu există evaluări

- Metallic Structure: Group 2: Ngo Giang Nam Trinh Hoang Minh Nguyen Phu HuyDocument30 paginiMetallic Structure: Group 2: Ngo Giang Nam Trinh Hoang Minh Nguyen Phu HuyhuycanphuÎncă nu există evaluări

- Unit 1-Constitution of AlloyDocument51 paginiUnit 1-Constitution of Alloyvenkatesan palaniÎncă nu există evaluări

- Corrosion 15012019 PDFDocument61 paginiCorrosion 15012019 PDFDeepak SainiÎncă nu există evaluări

- 4.5 Alloy 2023Document21 pagini4.5 Alloy 2023Zahrani AssyifaÎncă nu există evaluări

- Metallurgy 5th Ed 1977 PDFDocument483 paginiMetallurgy 5th Ed 1977 PDFanon_435115635Încă nu există evaluări

- By:-Utsah Sharma - at Crazy ScienceDocument21 paginiBy:-Utsah Sharma - at Crazy ScienceUtsah SharmaÎncă nu există evaluări

- Worksheet 6.1Document1 paginăWorksheet 6.1annnyyyaaaaaÎncă nu există evaluări

- Bahan Konstruski Dan Korosi - Pertemuan 2Document40 paginiBahan Konstruski Dan Korosi - Pertemuan 2sri utariÎncă nu există evaluări

- The Disintegration of An Engineered Material Into Its Constituent AtomsDocument41 paginiThe Disintegration of An Engineered Material Into Its Constituent Atomsanudeep009Încă nu există evaluări

- Dental Casting Alloys FinalDocument175 paginiDental Casting Alloys FinalNiaz Ahammed0% (1)

- Extractive Metallurgy 1: Basic Thermodynamics and KineticsDe la EverandExtractive Metallurgy 1: Basic Thermodynamics and KineticsÎncă nu există evaluări

- Underground Treasures: How and Where to Find Them: A Key for the Ready Determination of All the Useful Minerals Within the United StatesDe la EverandUnderground Treasures: How and Where to Find Them: A Key for the Ready Determination of All the Useful Minerals Within the United StatesÎncă nu există evaluări

- The Impact of Technology On Modern Architecture #ABC123Document4 paginiThe Impact of Technology On Modern Architecture #ABC123Antonio C. KeithÎncă nu există evaluări

- The Evolution of Urban Design: From The Ancient World To The Modern Metropolis #GHI789Document4 paginiThe Evolution of Urban Design: From The Ancient World To The Modern Metropolis #GHI789Antonio C. KeithÎncă nu există evaluări

- Preserving The Past: The Role of Historic Preservation in Architecture #MNO345Document5 paginiPreserving The Past: The Role of Historic Preservation in Architecture #MNO345Antonio C. KeithÎncă nu există evaluări

- Redefine 101Document6 paginiRedefine 101Antonio C. KeithÎncă nu există evaluări

- Mix 456Document6 paginiMix 456Antonio C. KeithÎncă nu există evaluări

- EcoSphere 4321Document6 paginiEcoSphere 4321Antonio C. KeithÎncă nu există evaluări

- FuturaVista 8165Document6 paginiFuturaVista 8165Antonio C. KeithÎncă nu există evaluări

- Pardigmas 2Document5 paginiPardigmas 2Antonio C. KeithÎncă nu există evaluări

- Urban Oasis-6934Document6 paginiUrban Oasis-6934Antonio C. KeithÎncă nu există evaluări

- Horizon 123Document10 paginiHorizon 123Antonio C. KeithÎncă nu există evaluări

- Dingledy The Corpus Juris Civilis A Guide To Its History and Use Accepted Manuscript VersionDocument41 paginiDingledy The Corpus Juris Civilis A Guide To Its History and Use Accepted Manuscript VersionAntonio C. KeithÎncă nu există evaluări

- Norm 456Document6 paginiNorm 456Antonio C. KeithÎncă nu există evaluări

- Play 789Document6 paginiPlay 789Antonio C. KeithÎncă nu există evaluări

- Civitai ApiDocument17 paginiCivitai ApiAntonio C. KeithÎncă nu există evaluări

- Export Codex Ashburnham Facsimile PDFDocument1 paginăExport Codex Ashburnham Facsimile PDFAntonio C. KeithÎncă nu există evaluări

- Information Codes of Mutant Forms: Arch. Bojan BaleticDocument15 paginiInformation Codes of Mutant Forms: Arch. Bojan BaleticAntonio C. KeithÎncă nu există evaluări

- Pedsim: Quick Start GuideDocument6 paginiPedsim: Quick Start GuideAntonio C. KeithÎncă nu există evaluări

- CopperToxicity PDFDocument7 paginiCopperToxicity PDFAntonio C. KeithÎncă nu există evaluări

- UltraDry Spool Holders - Instructions PDFDocument15 paginiUltraDry Spool Holders - Instructions PDFAntonio C. KeithÎncă nu există evaluări

- CopperToxicity PDFDocument7 paginiCopperToxicity PDFAntonio C. KeithÎncă nu există evaluări

- StarCraft II A New Challenge For Reinforcement LearningDocument20 paginiStarCraft II A New Challenge For Reinforcement LearningAntonio C. KeithÎncă nu există evaluări

- tp132 c2 PDFDocument9 paginitp132 c2 PDFAntonio C. KeithÎncă nu există evaluări

- Discrete Shells: Eurographics/SIGGRAPH Symposium On Computer Animation (2003) D. Breen, M. Lin (Editors)Document7 paginiDiscrete Shells: Eurographics/SIGGRAPH Symposium On Computer Animation (2003) D. Breen, M. Lin (Editors)Antonio C. KeithÎncă nu există evaluări

- DA PAM 415 28 Guide To Army Real Property Category CodesDocument483 paginiDA PAM 415 28 Guide To Army Real Property Category CodesAntonio C. Keith100% (1)

- History of CAD - CAE CompaniesDocument5 paginiHistory of CAD - CAE CompaniesAntonio C. KeithÎncă nu există evaluări

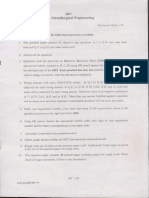

- GATE Metallurgical Engineering 2007Document15 paginiGATE Metallurgical Engineering 2007RATHIRAM NAIKÎncă nu există evaluări

- Tribology InternationalDocument6 paginiTribology InternationalAch KitevarzÎncă nu există evaluări

- Defects in Liquid Crystals - Maurice KlemanDocument101 paginiDefects in Liquid Crystals - Maurice KlemanAlexCooksÎncă nu există evaluări

- Creep and High Temperature Failure: OutlineDocument6 paginiCreep and High Temperature Failure: OutlineAravind PhoenixÎncă nu există evaluări

- Niels Hansen. Metallurgical Transactions 16A (1985) - P. 2167-2190.Document24 paginiNiels Hansen. Metallurgical Transactions 16A (1985) - P. 2167-2190.Bruna OliveiraÎncă nu există evaluări

- Effect of Strain Rate On Bake Hardening Response of BH220 SteelDocument5 paginiEffect of Strain Rate On Bake Hardening Response of BH220 SteelTC Tugay DoğanÎncă nu există evaluări

- Strengthening MechanismsDocument17 paginiStrengthening Mechanismspkn_pnt9950Încă nu există evaluări

- Metallurgy Interview Questions and Answers 105Document14 paginiMetallurgy Interview Questions and Answers 105PK NanavatiÎncă nu există evaluări

- Mechanical Engineering Branch: B.Tech. Degree CourseDocument92 paginiMechanical Engineering Branch: B.Tech. Degree CoursetonykptonyÎncă nu există evaluări

- Accoustic Emmision Technique (I)Document52 paginiAccoustic Emmision Technique (I)MACLIN JOHN VASANTH K100% (1)

- Catastrophic Plate Tectonics The PhysicsDocument10 paginiCatastrophic Plate Tectonics The PhysicsDANAYRI SUSETTE HERNANDEZ MARTINEZÎncă nu există evaluări

- 06 Strengthening MechanismsDocument63 pagini06 Strengthening MechanismsMURALIGOCAM_29070605100% (1)

- Introduction To Acoustic Emission Testing 2Document20 paginiIntroduction To Acoustic Emission Testing 2Ashutosh SinghÎncă nu există evaluări

- Skin PassDocument14 paginiSkin PassamanciotrajanoÎncă nu există evaluări

- Magnetoplastic Effect in Nonmagnetic MaterialsDocument8 paginiMagnetoplastic Effect in Nonmagnetic MaterialsSeindahNyaÎncă nu există evaluări

- Atomistic Simulations of Ductile Failure in A B.C.C. High Entropy AlloyDocument33 paginiAtomistic Simulations of Ductile Failure in A B.C.C. High Entropy Alloyhk esatonÎncă nu există evaluări

- Recent Progress in The Development of Gamma Titanium Aluminide AlloysDocument22 paginiRecent Progress in The Development of Gamma Titanium Aluminide AlloysMahdi abanÎncă nu există evaluări

- Chapter 3: Dislocations in Crystals: Young's ModulusDocument67 paginiChapter 3: Dislocations in Crystals: Young's Modulusjohn parkerÎncă nu există evaluări

- Effect of Interstitial Solutes On The Strength and Ductility of Titanium-Conrad1981Document281 paginiEffect of Interstitial Solutes On The Strength and Ductility of Titanium-Conrad1981Alejandro Z.Încă nu există evaluări

- Effect of Hydrogen On Creep of ZN-2.5%Nb AlloyDocument31 paginiEffect of Hydrogen On Creep of ZN-2.5%Nb AlloyshyamÎncă nu există evaluări

- EMTL 250 Module 2 2017Document27 paginiEMTL 250 Module 2 2017Mwongera MwaraniaÎncă nu există evaluări

- Previous Year Question Papers of GATE Metallurgical Engineering-3Document12 paginiPrevious Year Question Papers of GATE Metallurgical Engineering-3Smruti PattanayakÎncă nu există evaluări

- Metallography in Failure Analysis PDFDocument300 paginiMetallography in Failure Analysis PDFAbhinandan Admuthe100% (4)

- Engineering Physics NotesDocument69 paginiEngineering Physics NotesSaipavan Seelamsetty86% (7)

- MT 2022Document36 paginiMT 2022Jag Parvesh DahiyaÎncă nu există evaluări

- Defects in CrystalsDocument19 paginiDefects in CrystalszeroÎncă nu există evaluări

- ESO 205 Nature and Properties of MaterialsDocument26 paginiESO 205 Nature and Properties of MaterialsAkshayVaidyaÎncă nu există evaluări

- Bouaziz Et Al. - An Extension of The Kocks-Mecking Model of Work Hardening To Include Kinematic Hardening and Its Application To SolutesDocument9 paginiBouaziz Et Al. - An Extension of The Kocks-Mecking Model of Work Hardening To Include Kinematic Hardening and Its Application To SolutesYWUÎncă nu există evaluări

- Consideration of Orowan Strengthening Effect in Particulate-Reinforced Metal Matrix Nanocomposites A Model For Predicting Their Yield StrengthDocument6 paginiConsideration of Orowan Strengthening Effect in Particulate-Reinforced Metal Matrix Nanocomposites A Model For Predicting Their Yield Strengthirajfarji2481Încă nu există evaluări