Documente Academic

Documente Profesional

Documente Cultură

Hazard Audit Forms1

Încărcat de

Hamid AlilouDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hazard Audit Forms1

Încărcat de

Hamid AlilouDrepturi de autor:

Formate disponibile

KEMYA MAJOR PROJECTS AUDIT INDEX

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. WORKING ABOVE GRADE HAND PROTECTION RESPIRATORY PROTECTION MANUAL HANDLING DRIVING POWER AND HAND TOOLS HOUSEKEEPING HYDRAULIC PLATFORMS LADDERS AND STEPS GAS CYLINDERS CRANES EXCAVATIONS CUTTING AND WELDING RIGGING WORK ON SCAFFOLD MOBIL EQUIPMENT MACHINERY SCAFFOLDING

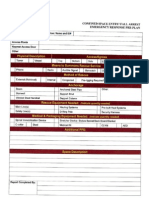

KEMYA MAJOR PROJECTS

OBSERVATION CHECKLIST NUMBER 1 WORKING ABOVE GRADE DATE: TIME SPENT: CHECK PEOPLE

Are they acting safely? Do they need harnesses? Are the weather conditions suitable?

LOCATION: OBSERVERS: YES NO COMMENT

WORKING POSITION/PLATFORM

Is there a record of inspection in place/current? Is the platform large enough? Is it in the right location? Guardrails and toe-boards in place? Is the platform near hazardous equipment? Is more than one escape route required? Is the platform tidy? Are there holes in the platform? Does the area below need to be roped off?

TOOLS

Are large tools roped off? Can anything fall to grade? Is any pulley systems safe? How are materials/tools lifted up?

LADDERS

Are the rungs and stiles in good condition? Are the feet/top secure? Does the ladder extend above the platform?

MOBILE PLATFORMS

Is grade level/firm? Is height to base ratio correct? Are the wheels locked? Are guardrails and toe-boards in place?

KEMYA MAJOR PROJECTS

OBSERVATION CHECKLIST NUMBER 2 HAND PROTECTION DATE: TIME SPENT: CHECK PEOPLE

Are they positioned correctly? Can they see both hands? What is the left hand doing? What is the right hand doing? Do they need assistance? Are they wearing gloves?

LOCATION: OBSERVERS: YES NO COMMENT

TOOLS

Do they need one? Is it right for the job? Is it in good condition? Is it being used properly?

HAZARDS

Is there a puncture hazard? Is there a cutting hazard? Is there a trapping hazard? Is there a crushing hazard? Is there an electrical hazard? Is there a chemical hazard? Is there a temperature hazard? Can the hazard be minimized ?

GLOVES

-

Are they the right type? Are they in good condition ?

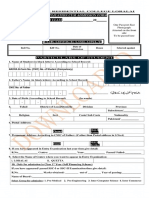

KEMYA MAJOR PROJECTS

Aluminized Asbestos Chain Mesh Kevlar Cotton Leather (thin) Leather (thick) PVC Neoprene Neoprene Nitrile for for for for for for for for for for heat resistance. knife cut protection. cut protection. general purpose. rough work. heat protection. Acids/Alkalis. oil work. Hydrofluoric Acid solvent and lube oil.

OBSERVATION CHECKLIST NUMBER 3 RESPIRATORY PROTECTION DATE: TIME SPENT: CHECK PEOPLE

Are they trained? Are they certified for this work? Are they confident with using the equipment? Is a confined space permit required? Is the permit in place?

LOCATION: OBSERVERS: YES NO COMMENT

EQUIPMENT/SELECTION

Risk from smoke and fumes? Risk from lack of oxygen? Risk from toxic gas? Risk from dust? Risk from chemical vapour? Are they using the right type?

EQUIPMENT CONDITION

Facepiece OK? Filter correct? Hoses and connections OK? Harness OK? Checklist completed?

KEMYA MAJOR PROJECTS

HAZARD MINIMISATION

Is a safety standby required? Is safety standby in place? Is rescue equipment available? Is log in/out sheet being used? Is gas/oxygen monitor required?

OTHER DANGERS

Is visibility restricted? Is escape route clear?

OBSERVATION CHECKLIST NUMBER 4 MANUAL HANDLING DATE: TIME SPENT: CHECK PEOPLE

Do they need to manhandle it? Do they know the weight of the load? Do they need assistance? Have they a secure grip on the load? Can they see where they are going? Are they wearing protective clothing i.e.: Gloves & Safety Footwear ? Are they lifting correctly:Straight back, knees bent ? Have they room to maneuver? Are there any obstructions on the route?

LOCATION: OBSERVERS: YES NO COMMENT

THE LOAD

Is it suitable for manual handling? Have sharp edges been removed or covered? Is it too hot/cold? Is it free from contamination? Is it stored in a safe place? Does it have a Hazchem label? Are there any special storage rules?

KEMYA MAJOR PROJECTS

Wheel barrows /Trolleys /Dolly

Is equipment suitable for the task? Are the ground conditions suitable? Are there any ramps or inclines, are they safe? Is the equipment under control at all times (wont run away)? Is the equipment in a good serviceable condition?

OBSERVATION CHECKLIST NUMBER 5 DRIVING DATE: TIME SPENT: CHECK PEOPLE

Wearing seat belts? Obeying speed limits? Reverse parking? Obeying road signs? Correct signals? Dipped headlights? Cut corners? Considerate to others? Drove past road barrier? Have they been assessed? Do they possess a current Driving Permit?

LOCATION: OBSERVERS: YES NO COMMENT

VEHICLES - Tyres in good condition?

Generally clean and tidy? Windscreen and windows clean? Exhaust system sound? Lights in working order? Load secure? Suitable towing hook? Indicators faulty? Is it suitable for the ground conditions?

KEMYA MAJOR PROJECTS

AREA

Is a permit required? Is the vehicle causing an obstruction to plant or safety equipment? Correctly parked?

Obscuring vision at road junction?

OBSERVATION CHECKLIST NUMBER 6 WORKING WITH POWER AND HAND TOOLS DATE: TIME SPENT: CHECK PEOPLE

- Have they selected the correct tool for the job? - Are they using the tool correctly? - Are they wearing the correct protective equipment? - Have they the skills to use the tool? - Do they need further training? - Do they recognize the hazards related to the tool? - Do they need a permit? - Did they disconnect the power supply prior to changing the cutting/operating bit? - Are they working aloft? If so are the tools secure from falling?

LOCATION: OBSERVERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

TOOLS

Are they in good working order? Do the safety devices work? Has the guard been removed? Is the hose connection sound? Has the electric cable insulation been damaged? Has the service period expired? Is the vice/holding jig secure? Is the hammerhead loose? Are the handles free from splinters? Is the spanner/wrench the correct type/size? Is the abrasive wheel suitable for the machine's speed? Are the appropriate regulations displayed? Is the cleaning tank labeled with cleaning agent and any hazard?

LOCATION

Is the area free from clutter? Is the lighting adequate? Are there any tripping hazards? Have spills been cleared up? Are any temporary hazards roped off? Are passers-by protected by screens?

OBSERVATION CHECKLIST NUMBER 7 HOUSEKEEPING DATE: TIME SPENT: CHECK PEOPLE - Are their work areas tidy?

Are they obstructing other people? Did they clean up after job completion? Have they returned tools and unused spare parts?

LOCATI ON: OBSER VERS: YES NO COMMENT

LOCATION General appearance of area? Lighting satisfactory? Unused pieces of equipment cluttering

KEMYA MAJOR PROJECTS

area? Oil spills or contamination? Scaffolds/Excavations taped or clearly marked? Areas under scaffolds - free from combustibles? Drums stored correctly? Gas cylinders stored correctly and secured? Is access open to fire hydrants/ monitors? Are walkways clear? Buildings - Fire Exits locked or blocked? Sub-Stores contents free from contamination/neatly stored? Chemicals/hazardous materials clearly labeled? Waste Bins overfull? Rigging equipment hung up where possible?

VEHICLES - Windows clean?

Cab Tidy? Exterior OK? Lights and indicators clean? (NB. rear lights) check

OBSERVATION CHECKLIST NUMBER 8 J.L.G. (MANLIFT) HYDRAULIC PLATFORMS DATE: TIME SPENT: CHECK PEOPLE

Has the operator been trained for this size of JLG? Is he wearing a safety harness? Should he have a safety standby? Can he see all around the vehicle from the job location? Does he know what to do in an Emergency?

LOCATI ON: OBSER VERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

LOCATION

Is a permit required? Lighting satisfactory? Are ground conditions suitable? Any overhead hazards -Electrical lines/Obstructions? Can the Operator be removed in an Emergency?

EQUIPMENT

Are the warning/instruction signs in good condition? Is the rated capacity exceeded? Is the platform supporting plant equipment? Are the check plates and hand holds free from oil/grease? Is the machine stable? Is it fitted with a spark arrestor?

OBSERVATION CHECKLIST NUMBER 9 PORTABLE LADDERS AND STEPS DATE: TIME SPENT: CHECK PEOPLE

Are the Ladders/Steps suitable for the job? Have they been examined for defects prior to use? Is the ladder secured (top & bottom)? Is there more than one person on the ladder? Have they spliced or lashed ladders

LOCATI ON: OBSER VERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

together? Are they working from a ladder with both feet on the rungs and a secure handhold? Are they working from steps higher than 6 feet? If near moving vehicles, have barriers been erected? If near a door, have they secured the door?

EQUIPMENT - Is a timber ladder painted?

Any undue wear or movement in the rungs? Metal tie-rods correctly positioned? If extension ladder, is there a 4-rung overlap? Is it free from oil? Is ladder at approx. 70 to the horizontal (4 in 1) Any makeshift repairs? Wooden steps - hinges sound and screws tight?

LOCATION

Does the ladder extend at least 3'6" above the landing place or the highest rung to be reached by the feet of the user?

OBSERVATION CHECKLIST NUMBER 10 GAS CYLINDERS DATE: TIME SPENT: CHECK PEOPLE - Have they secured the cylinders correctly?

Did they shut off the cylinders after use? Did they use a proper valve key? Are they rolling cylinders along the floor? Are they lifting it with a sling?

LOCATI ON: OBSER VERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

Is it being lifted using a cradle? Do they know what to do in an emergency; i.e. Leaking cylinder? Leaking and on Fire? Hot cylinder - no fire? Flashback ? Frozen regulator or valves?

EQUIPMENT - Are the oxygen and gas cylinders stored

separately? Are they protected from direct sunlight and heat? Empty cylinders of different gases segregated? All connections are free from oil and grease contamination? Hoses are free from defects? Flashback arrestors are fitted? Hoses in use are not wrapped around the cylinders?

OBSERVATION CHECKLIST NUMBER 11 CRANES DATE: TIME SPENT: CHECK PEOPLE

Is the Plant Operating Crew aware of the planned lift? Has a lifting plan been approved? Have the crane driver and rigger discussed the lift? Any overhead obstructions?

LOCATI ON: OBSER VERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

Is their sufficient clearance for the lift? Is there a permit for the crane? Is it clear who is controlling the lift? Are the signals understood? Is the Driver at the controls when the load is suspended?

LOCATION

Have underground checks been made under the outriggers? Lifting zone barriered off? Clearance around the counterweight/barriered off? If lifting over live plant, has risk analysis and procedure been carried out / approved? Are there any slew limitations?

EQUIPMENT

Has Crane Inspection Register been signed for the current week? Has overrun protection and a spark arrestor been fitted? Is rigging equipment registered and within date? Are there any sharp edges cutting into the slings? Should a load spreader have been used? Are the limit switches working?

OBSERVATION CHECKLIST NUMBER 12 EXCAVATIONS DATE: TIME SPENT: CHECK PEOPLE

Do they have a permit? Are they wearing correct protective clothing? Have they erected barriers? Do they have adequate means of ascent/descent? Do they know the locations of

LOCATI ON: OBSER VERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

underground services? Do they know what to do in an Emergency/gas alarm? Are warning lights provided?

EXCAVATION

Is general housekeeping adequate? Is excavation adequately shored? Or sloped Does the shoring project 18" above level of excavation? Have exposed lines or cables been supported? Is steel bridging in use where traffic is present?

PERMITS/PROCEDURES

Is the permit correctly filled in? Have checks for underground services been carried out, and markers positioned? Have steps been taken to safeguard personnel and to protect adjacent equipment? Is there a need to monitor gas and ventilation levels? Are special conditions being adhered to? Is the excavation registered in the control room?

OBSERVATION CHECKLIST NUMBER 13 WELDING AND BURNING DATE: TIME SPENT: CHECK LOCATI ON: OBSER VERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

PEOPLE

Do they have the correct and valid permit? Have they ensured that sparks will be contained? Do they understand what to do in an emergency? Have they the appropriate protective clothing? Are they using an exhaust ventilation system? Are they wearing respiratory protection? Have they erected screens to protect others? Are they competent to do the job? Did they turn off the bottles when leaving the job? Are they working in a confined space?

EQUIPMENT

Are the leads/hoses obstructing access ways? Flashback arrestors fitted? Hoses in good condition? Are hoses coiled around the cylinders? Hose clips in good condition? All hose connections tight? Welding cable connectors sound? Good earth connection made? Fire extinguisher within reach?

LOCATION

- Have drains been covered or sanded down?

Are there any combustibles under the working position? Is there adequate means of escape? Has the equipment to be welded or burnt been adequately prepared (gas freed)?

OBSERVATION CHECKLIST NUMBER 14 SLINGS, SHACKLES AND EYE BOLTS DATE: TIME SPENT: CHECK LOCATI ON: OBSER VERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

PEOPLE

Are they competent in sling selection? Do they know the safe working load of the slings? Have they ascertained/estimated the weight of the load? Did they examine the sling for defects? Have they protected the sling from damage by sharp edges/ corners on the load? Do they know the effect of sling angle on the load? Have they been trained to use the equipment? Have they a proper storage method to safeguard the slings from damage? Are they wearing gloves? Should they be using a Tag line to guide the load?

EQUIPMENT

Are the shackles/eye bolts etc in good condition and being used correctly? Is the lifting equipment due for testing? Is the SWL clearly marked? Any broken wires? Is the equipment suitable for the lift? Are slings secure on the hooks? Is the load secure? Have the slings been in contact with corrosive substances? Are the slings webbing/nylon? Have they any defects? Have they been exposed to high Temperatures? Is the hook fitted with a safety clip? When two or more slings are used are they of the same material? Does the load need special protection?

OBSERVATION CHECKLIST NUMBER 15 WORKING OFF SCAFFOLDING DATE: TIME SPENT: CHECK PEOPLE LOCATI ON: OBSER VERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

Are they acting safely? Are they using harnesses? Are the weather conditions suitable?

WORKING POSITION/PLATFORM

Is the scaffold complete and all the components in place? Is there a record of inspection? Is suitable ladder access provided? Are there loose or surplus materials on the platform? Is the scaffold suitable for the purpose? Are there any holes in the platform?

TOOLS

Are large tools roped off? Can anything fall to grade? Are the pulley systems safe? How are materials/tools lifted up?

LADDERS

Are the rungs and stiles in good condition? Are the feet/top secure? Does the ladder extend above the platform? Is the ladder tied off?

MOBILE PLATFORMS

Is grade level/firm? Is height to base ratio correct? Are the wheels locked? Are guardrails and toe-boards in place?

OBSERVATION CHECKLIST NUNBER l6 MOBILE EQUIPMENT DATE: TIME SPENT: CHECK ROADWORTHINESS

Tyre pressure and condition?

LOCATION: OBSERVERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

Towing assembly satisfactory? Lights and reflectors OK? Side panel clips secure?

OPERATIONAL SAFETY

General condition OK? Site inspection sticker required? Fuel system safe? Leaking? STOP button operational and clearly marked? Chalwyn valve fitted and operational? Spark arrestor fitted and operational? Combustible materials close to exhaust? Air tank and pipes rusted? Oil spills or contamination? Is Owner identified? Where is equipment refueled? Fan belt condition OK? Fire extinguisher fitted?

ELECTRICS

Wiring frayed? Battery connections tight? Battery clamps secure? Are external power cables in good condition? Fuses fitted and correct rating?

OBSERVATION CHECKLIST NUMBER 17 MACHINERY DATE: TIME SPENT: CHECK LOCATION

General location satisfactory? Does operator have sufficient access? Is it obstructing other people/machinery? Are walkways clear of tools, spares,

LOCATION: OBSERVERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

materials etc?

MECHANICAL CONDITION

General condition OK? Lighting satisfactory? Any makeshift repairs? Oil spills or contamination? Correct tools? Guards in place? Are basic operating instructions shown on the machine? Procedural/safety notice displayed? Tool condition OK? Electrical fail-safe device fitted and operable? STOP button operational and clearly marked? Fusebox/main switch accessible and clearly labeled? Correct fire extinguisher nearby? Other safety devices fitted are operational? Workpiece safely located? Goggles provided? All guards in place?

OPERATION

Being correctly used? Operator fully trained? Switched off when not in use? Waste Bins overfull? Swarf cleared away

Goggles provided?

OBSERVATION CHECKLIST NUMBER 18 SCAFFOLD STRUCTURE DATE: TIME SPENT: CHECK LOCATION

Are walkways, valves, plant or equipment clear and unrestricted? Can the ground or structure support the scaffold weight? Is the access to the working platform free

LOCATION: OBSERVERS: YES NO COMMENT

KEMYA MAJOR PROJECTS

of obstruction? Is the scaffold Tag/inspection record current and displayed?

STRUCTURAL CONDITION

Base boards and base plates supplied and properly bedded? Standards and ledgers level and secured with 90 couplers? Transoms correctly spaced and secured? Joints in standards and ledgers staggered no adjacent joints in same bay? Platforms fully decked boards correctly supported? Structure properly braced braces at the correct angle? Toe-boards on all working lifts? Guardrails at correct height? Ladders properly footed and at correct angle and securely tied? Ladder extends more than 1-meter (5 rungs) above landing? Platforms free of scrap and surplus materials? Is the work platform at the correct height for the task? Is the structure stable and physical ties in place? Is the structure suitable for the load? Is the scaffold a specialist structure, are Design calculations require?

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Scaffold Equipment GuideDocument27 paginiScaffold Equipment GuideHamid AlilouÎncă nu există evaluări

- Ogp Accident Guideline PDFDocument36 paginiOgp Accident Guideline PDFHamid AlilouÎncă nu există evaluări

- Chloroplast, PPTDocument21 paginiChloroplast, PPTSuchitra Sk88% (8)

- Safety WorkbookDocument24 paginiSafety WorkbookEsotericStone100% (1)

- Sample Fire Safety PlanDocument20 paginiSample Fire Safety PlanHamid Alilou0% (1)

- Emergency PlanningDocument58 paginiEmergency PlanningHamid AlilouÎncă nu există evaluări

- Disaster Manual 2003Document107 paginiDisaster Manual 2003Hamid AlilouÎncă nu există evaluări

- Steam BlowingDocument6 paginiSteam BlowingS V NAGESHÎncă nu există evaluări

- Chemical SpillsDocument28 paginiChemical SpillsHamid AlilouÎncă nu există evaluări

- WWTP Compliance PlanningDocument1 paginăWWTP Compliance PlanningHamid AlilouÎncă nu există evaluări

- Safety in AirportsDocument8 paginiSafety in AirportsHamid AlilouÎncă nu există evaluări

- Bupa International ApplicationDocument6 paginiBupa International ApplicationHamid AlilouÎncă nu există evaluări

- Safety in AirportsDocument8 paginiSafety in AirportsHamid AlilouÎncă nu există evaluări

- Task Risk Assessment Proforma Rev1 September 05Document5 paginiTask Risk Assessment Proforma Rev1 September 05Hamid AlilouÎncă nu există evaluări

- Presure Testing GuidanceDocument15 paginiPresure Testing GuidanceMahmood EijazÎncă nu există evaluări

- Battery Charging Room Design Review ChecklistDocument4 paginiBattery Charging Room Design Review ChecklistHyeong-Ho KimÎncă nu există evaluări

- Academy - HSE - Coordinator - Total Abu DhabiDocument3 paginiAcademy - HSE - Coordinator - Total Abu DhabiHamid AlilouÎncă nu există evaluări

- Hse PrinciplesDocument22 paginiHse PrinciplesHamid AlilouÎncă nu există evaluări

- Form HazidDocument1 paginăForm HazidHamid AlilouÎncă nu există evaluări

- Overpressure and Thermal ReliefDocument6 paginiOverpressure and Thermal ReliefHamid Alilou100% (1)

- Measuring Safety - Safety Related KpisDocument1 paginăMeasuring Safety - Safety Related KpisHamid AlilouÎncă nu există evaluări

- Cranesafe PDFDocument3 paginiCranesafe PDFHamid AlilouÎncă nu există evaluări

- Form HazidDocument1 paginăForm HazidHamid AlilouÎncă nu există evaluări

- Please Select The Applicable Method For Answering Each Question Qu - Questioning Ob - Observation Qu ObDocument2 paginiPlease Select The Applicable Method For Answering Each Question Qu - Questioning Ob - Observation Qu ObHamid AlilouÎncă nu există evaluări

- Rad Safety QuizDocument2 paginiRad Safety QuizHamid AlilouÎncă nu există evaluări

- FftacticssolarpowerDocument99 paginiFftacticssolarpowerdeepan_dreamer007Încă nu există evaluări

- Safety in AirportsDocument8 paginiSafety in AirportsHamid AlilouÎncă nu există evaluări

- Lifting SafelyDocument24 paginiLifting SafelyHamid AlilouÎncă nu există evaluări

- Rescue Plan English A3Document1 paginăRescue Plan English A3Hamid AlilouÎncă nu există evaluări

- Accident InvestigationDocument43 paginiAccident InvestigationHamid AlilouÎncă nu există evaluări

- 309-King Agar-110991 PDFDocument1 pagină309-King Agar-110991 PDFSneyder MurciaÎncă nu există evaluări

- Agoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticDocument6 paginiAgoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticAlejandro De la GarzaÎncă nu există evaluări

- Sansico Top Access Floor Trap - S3Document20 paginiSansico Top Access Floor Trap - S3Biggie ColdAngelÎncă nu există evaluări

- VOMGE Press Tool Design Course OverviewDocument11 paginiVOMGE Press Tool Design Course OverviewjanakÎncă nu există evaluări

- Sierra Gorda - Feasibility (2011)Document240 paginiSierra Gorda - Feasibility (2011)Nicolas CarrascoÎncă nu există evaluări

- Current Concepts in Orthopaedic Biomaterials and Implant FixationDocument24 paginiCurrent Concepts in Orthopaedic Biomaterials and Implant FixationS.EÎncă nu există evaluări

- ESSO Shaft Sealing Systems SpecificationDocument13 paginiESSO Shaft Sealing Systems SpecificationFlorin Daniel AnghelÎncă nu există evaluări

- Sybron Endo Sealapex Root Canal SealerDocument7 paginiSybron Endo Sealapex Root Canal Sealerenjoy enjoy enjoyÎncă nu există evaluări

- Role of DSS in RefineryDocument24 paginiRole of DSS in Refineryramadoss_alwar7307100% (1)

- Spot WeldingDocument5 paginiSpot WeldingRao MaazÎncă nu există evaluări

- Chemistry SBA7 ReportDocument6 paginiChemistry SBA7 ReportSam ChanÎncă nu există evaluări

- Admission Form All 2019 1Document8 paginiAdmission Form All 2019 1Riz WanÎncă nu există evaluări

- Omeprazole: by Jennica Mae V. CuicoDocument7 paginiOmeprazole: by Jennica Mae V. Cuicoジェンニカ メイÎncă nu există evaluări

- HP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced MaterialsDocument4 paginiHP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced Materialssirjole7584Încă nu există evaluări

- PVC FlamethrowerDocument21 paginiPVC FlamethrowerMike Nichlos100% (4)

- Cniai 34686 0003Document45 paginiCniai 34686 0003Nirosha Dilrangi PereraÎncă nu există evaluări

- (VESBO) Catalog en 100317Document55 pagini(VESBO) Catalog en 100317AnhNguyen100% (1)

- 1 s2.0 S2352179118302382 MainDocument5 pagini1 s2.0 S2352179118302382 MainIrfan IsdhiantoÎncă nu există evaluări

- Thermodynamics Chapter OverviewDocument40 paginiThermodynamics Chapter OverviewdeusleanÎncă nu există evaluări

- Rapid and Reliable HPLC Method For The Simultaneous Determination of Dihydroxyacetone, Methylglyoxal and 5-Hydroxymethylfurfural in Leptospermum HoneysDocument9 paginiRapid and Reliable HPLC Method For The Simultaneous Determination of Dihydroxyacetone, Methylglyoxal and 5-Hydroxymethylfurfural in Leptospermum Honeysasel ppÎncă nu există evaluări

- Alkaline Earth MetalDocument33 paginiAlkaline Earth MetalSup FansÎncă nu există evaluări

- ASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire ApparatusDocument3 paginiASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire Apparatusalin2005Încă nu există evaluări

- Organic Chem. Lab. M6 ACTIVITY SHEET PCCH103L Santos Ronzel ANgelo M.Document3 paginiOrganic Chem. Lab. M6 ACTIVITY SHEET PCCH103L Santos Ronzel ANgelo M.Akira SantosÎncă nu există evaluări

- Validation and Verification of Cleanning ProcessDocument42 paginiValidation and Verification of Cleanning ProcessEva Pa'e OÎncă nu există evaluări

- RN FDocument52 paginiRN Fhassan SardarÎncă nu există evaluări

- Bio HGHDocument19 paginiBio HGHapi-240332064Încă nu există evaluări

- 04 Gue SF7 Unit2 T1 T3Document44 pagini04 Gue SF7 Unit2 T1 T3Bill Wang100% (1)

- 2593Document9 pagini2593Zaid AhmadÎncă nu există evaluări

- Comparison of Triode and Diode Ion PumpDocument7 paginiComparison of Triode and Diode Ion PumpAarkayChandruÎncă nu există evaluări