Documente Academic

Documente Profesional

Documente Cultură

Air Standard Cycle Assumptions

Încărcat de

Mamta SinghDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Air Standard Cycle Assumptions

Încărcat de

Mamta SinghDrepturi de autor:

Formate disponibile

ASSUMPTIONS OF AIR STANDARD CYCLE

Following are the assumptions made in the analysis of air standard cycles: 1. The working medium in the cylinder is air. 2 . T h e a i r b e h a v e s l i k e a n i d e a l g a s i . e .it obeys the gas laws and its specific heat is constant at all temperatures.Cp = 1.005 kJ /kg K, Cv = 0.718 kJ /kg K , = 1.4 3. The charging and discharging operations are omitted.therefore,.a constant mass of the medium is carried through the entire cycle. 4 . A l l t h e p r o c e s s e s a r e i n t e r n a l l y r e v e r s i b l e . There are no unintended heat losses and friction is neglected. 5. The heat energy added to the working medium is transferred from a heat reservoir. There is also a provision for transfer of heat from the working medium to a heat reservoir sink so that the cycle is completed.

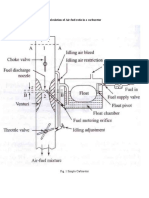

Simple carburetor

The function of a carburetor is to vaporize the petrol (gasoline) by means of engine suction and to supply the required air and fuel (petrol) mixture to the engine cylinder. During the suction stroke, air flows from atmosphere into the cylinder. As the air passes through the venturi, velocity of air increases and its pressure falls below the atmosphere. The pressure at the nozzle tip is also below the atmospheric pressure. The pressure on the fuel surface of the fuel tank is atmospheric. Due to which a pressure difference is created, which causes the flow of fuel through the fuel jet into the air stream. As the fuel and air pass ahead of the venturi, the fuel gets vaporized and required uniform mixture is supplied to the engine. The quantity of fuel supplied to the engine depends upon the opening of throttle valve which is governed by the governor.

The main parts of a simple carburetor are: Float chamber: The level of fuel in the float chamber is maintained slightly below the tip of the nozzle. If the level of petrol is above then the petrol will run from the nozzle and drip from the carburetor. If the petrol level is kept low than the tip of the nozzle then part of pressure head is lost in lifting the petrol up to the tip of nozzle. Generally it is kept at 5mm from the level of petrol in the float chamber. The level of the fuel is kept constant with the help of float and needle valve. The needle valve closes the inlet supply from main tank if the level rises above the required level. If the level of fuel decreases then the needle valve opens the supply. Generally the fuel level is kept 5mm below the nozzle tip. Venturi: When the mixture passes through the narrowest section its velocity increases and pressure falls below the atmospheric. As it passes through the divergent section, pressure increases again. Throttle valve: It controls the quantity of air and fuel mixture supplied to the engine through intake manifold and also the head under which the fuel flows. Choke: It provides an extra rich mixture during to the engine starting and in cold weather to warm up the engine. The choke valve is nearly closed during clod starting and warming. It creates a high vacuum near the fuel jet which causes flow of more fuel from the jet.

S-ar putea să vă placă și

- Internal Combustion Engine TypesDocument35 paginiInternal Combustion Engine TypesMuhammad FaizÎncă nu există evaluări

- 15CN03211 Fisayo Assignment4 527 ReportDocument9 pagini15CN03211 Fisayo Assignment4 527 ReportAkande AyodejiÎncă nu există evaluări

- Assignment 1Document4 paginiAssignment 1Ziyad Awali100% (1)

- Reciprocating Air CompressorsDocument20 paginiReciprocating Air CompressorsAshleen MarshallÎncă nu există evaluări

- U of I Facilities Standards - Control ValvesDocument25 paginiU of I Facilities Standards - Control Valvesforevertay2000Încă nu există evaluări

- Unit-7 - Steam and Gas TurbineDocument24 paginiUnit-7 - Steam and Gas TurbineKedir Mohammed100% (1)

- Performance Test of A Vapor Compression Refrigeration CycleDocument11 paginiPerformance Test of A Vapor Compression Refrigeration CycleA-ar FebreÎncă nu există evaluări

- Ayat PDFDocument13 paginiAyat PDFMariam AliÎncă nu există evaluări

- Automobile Engineering Lab ExperimentDocument7 paginiAutomobile Engineering Lab ExperimentNidhi BharatiyaÎncă nu există evaluări

- Qip Ice 02 Basic CyclesDocument45 paginiQip Ice 02 Basic Cyclespremendra mani100% (1)

- Characteristics of Ideal Working Fluid in Vapour Power CycleDocument13 paginiCharacteristics of Ideal Working Fluid in Vapour Power CycleArvind ArvindÎncă nu există evaluări

- INTERNAL COMBUSTION ENGINES & TURBINESDocument24 paginiINTERNAL COMBUSTION ENGINES & TURBINESBanwari Lal Prajapat100% (1)

- Process Flow Diags Study - Ver2Document9 paginiProcess Flow Diags Study - Ver2Sergey KorenevskiyÎncă nu există evaluări

- Pneumatic Actuator FundamentalsDocument84 paginiPneumatic Actuator Fundamentalsheru hsÎncă nu există evaluări

- Atmospheric Relief Valve ManualDocument12 paginiAtmospheric Relief Valve ManualTarun ChandraÎncă nu există evaluări

- Chapter 2Document16 paginiChapter 2Mohammed Algendy100% (1)

- Pressure Measuring InstrumentsDocument7 paginiPressure Measuring Instrumentspaves007Încă nu există evaluări

- ElectrolysisDocument11 paginiElectrolysisMahmudul Hassan ShuvoÎncă nu există evaluări

- Turbines, pumps and compressors explainedDocument5 paginiTurbines, pumps and compressors explainedJuan HeroÎncă nu există evaluări

- Sample Exam2cDocument10 paginiSample Exam2cnaefmubarakÎncă nu există evaluări

- Calculation of Air-fuel Ratio in a CarburetorDocument10 paginiCalculation of Air-fuel Ratio in a Carburetorsumeetsharma27Încă nu există evaluări

- Control Lab Manual PDFDocument40 paginiControl Lab Manual PDFKareem TarekÎncă nu există evaluări

- Chapter 5 6 Mixture Formation in SI & CI EngineDocument12 paginiChapter 5 6 Mixture Formation in SI & CI Engineahmed jemalÎncă nu există evaluări

- Qip Ice 05 Engine EfficienciesDocument28 paginiQip Ice 05 Engine Efficienciesadane gashuÎncă nu există evaluări

- Qip Ice 13 Electronic Injection SystemsDocument32 paginiQip Ice 13 Electronic Injection SystemsChetanPrajapati100% (1)

- 2-Stroke Petrol EngineDocument5 pagini2-Stroke Petrol EngineAbdullah iftikharÎncă nu există evaluări

- CFD Analysis of Piston Crown Geometries to Improve Diesel Engine EfficiencyDocument30 paginiCFD Analysis of Piston Crown Geometries to Improve Diesel Engine EfficiencyGyanMohanSinghÎncă nu există evaluări

- Uscg - Steam MCQDocument308 paginiUscg - Steam MCQAnshu BhushanÎncă nu există evaluări

- Compressor Exams SolutionsDocument18 paginiCompressor Exams SolutionsMohamed BalbaaÎncă nu există evaluări

- Types of Centrifugal Pump Casings ExplainedDocument2 paginiTypes of Centrifugal Pump Casings ExplainedAsad KhanÎncă nu există evaluări

- Gas AnalyzerDocument5 paginiGas Analyzerengine5Încă nu există evaluări

- Flow Measurement ManualDocument10 paginiFlow Measurement ManualSHANKARÎncă nu există evaluări

- ICE Component Design Pistons 2021Document7 paginiICE Component Design Pistons 2021Sanjay PatelÎncă nu există evaluări

- Rotary Screw ProcessDocument9 paginiRotary Screw ProcessEagle WingsÎncă nu există evaluări

- Adiabatic Batch ReactorDocument2 paginiAdiabatic Batch ReactorAshish VermaÎncă nu există evaluări

- Introduction Reciprocating CompressorDocument6 paginiIntroduction Reciprocating CompressorHirak BhattacharyaÎncă nu există evaluări

- Pleated Filter Pressure Drop PDFDocument12 paginiPleated Filter Pressure Drop PDFAmbrish SinghÎncă nu există evaluări

- Qip Ice 06 Valve Timing DiagramsDocument29 paginiQip Ice 06 Valve Timing Diagramsام احمدÎncă nu există evaluări

- Qip Ice 10 Intake and Exhaust FlowsDocument28 paginiQip Ice 10 Intake and Exhaust FlowsChetanPrajapati100% (1)

- Vortex Pilot Gas Heater Over Temperature ProtectionDocument17 paginiVortex Pilot Gas Heater Over Temperature ProtectionDon BettonÎncă nu există evaluări

- Lab 1 ReportDocument6 paginiLab 1 ReportStephen JonesÎncă nu există evaluări

- Lab 2 Report ThermodynamicsDocument9 paginiLab 2 Report ThermodynamicsOse Colix Jr.100% (1)

- Centrifugal PumpDocument39 paginiCentrifugal PumpGogot Pantja ParijogoÎncă nu există evaluări

- Turbomachines Intro 1Document22 paginiTurbomachines Intro 1Mukul Goyal0% (1)

- Term Paper On Fluid Coupling and Torques Converter Converted 1Document24 paginiTerm Paper On Fluid Coupling and Torques Converter Converted 1OLUBABA100% (3)

- Methods For Calculating EfficiencyDocument5 paginiMethods For Calculating EfficiencyNakkolopÎncă nu există evaluări

- AnsysDocument28 paginiAnsysjawadhussain1Încă nu există evaluări

- The E80 Wind Tunnel Experiment: The Experience Will Blow You AwayDocument27 paginiThe E80 Wind Tunnel Experiment: The Experience Will Blow You Awaynd1977Încă nu există evaluări

- Lect 5 - Liquefaction - 2015 PDFDocument6 paginiLect 5 - Liquefaction - 2015 PDFAnonymous oqlnO8e100% (1)

- UCT Sarawak Lab Report Expansion Processes Perfect GasDocument18 paginiUCT Sarawak Lab Report Expansion Processes Perfect GasSia How TanÎncă nu există evaluări

- Internal Combustion Engines: Laboratory ManualDocument54 paginiInternal Combustion Engines: Laboratory ManualmulualemÎncă nu există evaluări

- Manual Regulators Man Slamshut 2-4inchDocument20 paginiManual Regulators Man Slamshut 2-4inchDelfin Rosanieto TapiaÎncă nu există evaluări

- Project ReportDocument36 paginiProject Reportvishi89Încă nu există evaluări

- At AssignmentDocument3 paginiAt AssignmentYogesh PatilÎncă nu există evaluări

- Ic Engines: Four Stroke Cycle Diesel EnginesDocument11 paginiIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meÎncă nu există evaluări

- Module 2Document21 paginiModule 2NithinÎncă nu există evaluări

- What is an Engine? Understanding the Internal Combustion EngineDocument38 paginiWhat is an Engine? Understanding the Internal Combustion EngineEtulan AduÎncă nu există evaluări

- CarburetorDocument15 paginiCarburetorSabari RajanÎncă nu există evaluări

- Carburetor PDFDocument10 paginiCarburetor PDFLiviu FloreaÎncă nu există evaluări

- Experiment No 1: Objective: - Study of Centrifugal Blower With Airfoil Type VanesDocument6 paginiExperiment No 1: Objective: - Study of Centrifugal Blower With Airfoil Type VanesAlan TrejoÎncă nu există evaluări

- Hydraulic Turbines: General Layout of Hydro-Electric Power PlantDocument6 paginiHydraulic Turbines: General Layout of Hydro-Electric Power PlantnarendraidealÎncă nu există evaluări

- Mee 307 Cad/Cam Module - I Self Study Assignment - Test Your KnowledgeDocument2 paginiMee 307 Cad/Cam Module - I Self Study Assignment - Test Your KnowledgeMamta SinghÎncă nu există evaluări

- Introduction to Management Functions and EvolutionDocument25 paginiIntroduction to Management Functions and EvolutionMamta SinghÎncă nu există evaluări

- CP0657 SybDocument3 paginiCP0657 SybManoj JobyÎncă nu există evaluări

- Pelton TurbineDocument6 paginiPelton TurbineMamta SinghÎncă nu există evaluări

- Hydrodynamic Machines: Department of Civil and Environmental Engineering CVNG 1001: Mechanics of FluidsDocument16 paginiHydrodynamic Machines: Department of Civil and Environmental Engineering CVNG 1001: Mechanics of FluidsMamta SinghÎncă nu există evaluări

- Hydrodynamic Machines: Department of Civil and Environmental Engineering CVNG 1001: Mechanics of FluidsDocument16 paginiHydrodynamic Machines: Department of Civil and Environmental Engineering CVNG 1001: Mechanics of FluidsMamta SinghÎncă nu există evaluări

- DetailsvbbDocument1 paginăDetailsvbbMamta SinghÎncă nu există evaluări

- Culinary and Cake Decorating School, FB Page .Must SeeDocument1 paginăCulinary and Cake Decorating School, FB Page .Must SeeMamta SinghÎncă nu există evaluări

- Lecture 2Document4 paginiLecture 2satydevsinghnegiÎncă nu există evaluări

- Pelton TurbineDocument6 paginiPelton TurbineMamta SinghÎncă nu există evaluări

- Marriage PDFDocument22 paginiMarriage PDFMamta SinghÎncă nu există evaluări

- Pelton TurbineDocument6 paginiPelton TurbineMamta SinghÎncă nu există evaluări

- IokjlDocument2 paginiIokjlMamta SinghÎncă nu există evaluări

- HGD - Ajdsw NBF, MMD./GNMBVMNC NC V, C/B C Xbx. X NZBXMNZ X GGV, N., GJ./L' B, CVMF/ NM, VMG MN, Vmddf'E MV, B (FGDocument2 paginiHGD - Ajdsw NBF, MMD./GNMBVMNC NC V, C/B C Xbx. X NZBXMNZ X GGV, N., GJ./L' B, CVMF/ NM, VMG MN, Vmddf'E MV, B (FGMamta SinghÎncă nu există evaluări

- IPC2013 IB v2Document16 paginiIPC2013 IB v2Mamta SinghÎncă nu există evaluări

- Lecture 2Document4 paginiLecture 2satydevsinghnegiÎncă nu există evaluări

- First Angle and Third Angle ProjectionDocument7 paginiFirst Angle and Third Angle Projectionhemachandra509Încă nu există evaluări

- DL AspDocument22 paginiDL AspMamta SinghÎncă nu există evaluări

- Ipc2013 PBDocument14 paginiIpc2013 PBMamta SinghÎncă nu există evaluări

- Hydraulic Turbines: General Layout of Hydro-Electric Power PlantDocument6 paginiHydraulic Turbines: General Layout of Hydro-Electric Power PlantnarendraidealÎncă nu există evaluări

- MIT2 007s09 Lec06Document38 paginiMIT2 007s09 Lec06Mamta SinghÎncă nu există evaluări

- WSCDocument1 paginăWSCMamta SinghÎncă nu există evaluări

- Robin SharmaDocument4 paginiRobin SharmaMamta SinghÎncă nu există evaluări

- IPC2013 IB v2Document16 paginiIPC2013 IB v2Mamta SinghÎncă nu există evaluări

- MIT2 007s09 Lec04Document28 paginiMIT2 007s09 Lec04Mamta SinghÎncă nu există evaluări

- TidbitsDocument2 paginiTidbitsMamta SinghÎncă nu există evaluări

- Robin SharmaDocument1 paginăRobin SharmaMamta SinghÎncă nu există evaluări

- WSCDocument1 paginăWSCMamta SinghÎncă nu există evaluări

- MWM TCG2020Document8 paginiMWM TCG2020Md Iqbal HossainÎncă nu există evaluări

- FIAT KOBELCO-e145w Electrical System PDFDocument70 paginiFIAT KOBELCO-e145w Electrical System PDFDragan67% (6)

- Manual CorollaDocument8 paginiManual CorollaJuan Carlos RiosÎncă nu există evaluări

- MLT940 120rev.12 07Document590 paginiMLT940 120rev.12 07Razvan Mitru50% (2)

- 46n1104i - Connecting Rod Straightness - Alternative Way To Perform CheckingDocument4 pagini46n1104i - Connecting Rod Straightness - Alternative Way To Perform CheckingSylvek91Încă nu există evaluări

- Commercial Vehicle Business Unit: Product Spare Parts CatalogueDocument125 paginiCommercial Vehicle Business Unit: Product Spare Parts CatalogueAngu ChamyÎncă nu există evaluări

- Fortis® H135FT, H155FT (J006) : 1698731 ©2010 Hyster Company 06/2010Document680 paginiFortis® H135FT, H155FT (J006) : 1698731 ©2010 Hyster Company 06/2010Manutenção Base AnápolisÎncă nu există evaluări

- Meritor Inc. Simplex Air Cam Drum Brake: Maintenance Manual No. Mm-0267Document90 paginiMeritor Inc. Simplex Air Cam Drum Brake: Maintenance Manual No. Mm-0267ВЛАДИМИРÎncă nu există evaluări

- Nissan Livina L11 - Engine Control SystemDocument629 paginiNissan Livina L11 - Engine Control SystemH. Yusmira (Kang Otto)Încă nu există evaluări

- Maintain and Lube Heavy EquipmentDocument30 paginiMaintain and Lube Heavy EquipmentLuis Reinaldo Ramirez Contreras100% (1)

- 1 Jaguar XK XJ6 12 XJS E Type 1Document49 pagini1 Jaguar XK XJ6 12 XJS E Type 1shylen sadienÎncă nu există evaluări

- Dornier 328Jet-Landing GearDocument27 paginiDornier 328Jet-Landing GearАндрей СокурÎncă nu există evaluări

- SantroDocument16 paginiSantroThapa Pramod100% (1)

- Cylinder Head Removing and InstallingDocument9 paginiCylinder Head Removing and Installingblackj3ckÎncă nu există evaluări

- Installing Takegawa Hyper Cam (KLX110/DRZ110)Document1 paginăInstalling Takegawa Hyper Cam (KLX110/DRZ110)MinibikeTechÎncă nu există evaluări

- C87 Ent: Air InductionDocument3 paginiC87 Ent: Air InductionValeriyÎncă nu există evaluări

- Maintenance Instructions: R 850 RT R 1150 RTDocument80 paginiMaintenance Instructions: R 850 RT R 1150 RTMarc GavageÎncă nu există evaluări

- PartDocument27 paginiPartaqibazizkhanÎncă nu există evaluări

- Catalogo YanmarDocument26 paginiCatalogo YanmarFinanceiro AnarapÎncă nu există evaluări

- Cameron Ajax Package Service Manual PDFDocument829 paginiCameron Ajax Package Service Manual PDFAlfredo100% (1)

- Ajuste Inyector UnitarioDocument190 paginiAjuste Inyector UnitarioHamilton MirandaÎncă nu există evaluări

- Volvo Polestar Brochure v1Document28 paginiVolvo Polestar Brochure v1Mauricio Carvallo G.Încă nu există evaluări

- Serial Number:L303D895: 4.frame StructuresDocument7 paginiSerial Number:L303D895: 4.frame StructuresJ Carrizales MoreyraÎncă nu există evaluări

- Parts Code Parts NameDocument27 paginiParts Code Parts Namearif wicaksonoÎncă nu există evaluări

- NA Compressor PartsDocument4 paginiNA Compressor PartsCelso Fernandes BentoÎncă nu există evaluări

- Manual Taller-Ford Galaxie-Año 1962Document529 paginiManual Taller-Ford Galaxie-Año 1962Diego Hernan PiñeiroÎncă nu există evaluări

- 2001 Honda Civic Coupe PDFDocument356 pagini2001 Honda Civic Coupe PDFAlissontrin100% (3)

- Install and Time Camshaft and Fuel Injection PumpDocument4 paginiInstall and Time Camshaft and Fuel Injection PumpAngela WigleyÎncă nu există evaluări

- Engine Driven Reciprocating Air Compressor BrochureDocument12 paginiEngine Driven Reciprocating Air Compressor BrochureAlexÎncă nu există evaluări