Documente Academic

Documente Profesional

Documente Cultură

Hazop Study

Încărcat de

Adeel AhmedDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hazop Study

Încărcat de

Adeel AhmedDrepturi de autor:

Formate disponibile

Chapter 8

Hazop Study

CHAPTER - 8

HAZOP STUDY

HAZOP stands for hazards & operability studied. A HAZOP survey is one of the most common and widely accepted methods of systematic qualitative hazard analysis. It is used for both new or existing facilities and can be applied to a whole plant, a production unit, or a piece of equipment It uses as its database the usual sort of plant and process information and relies on the judgment of engineering and safety experts in the areas with which they are most familiar. The end result is, therefore reliable in terms of engineering and operational expectations, but it is not quantitative and may not consider the consequences of complex sequences of human errors. The objectives of a HAZOP study can be summarized as follows: 1) 2) To identify (areas of the design that may possess a significant hazard potential. To identify and study features of the design that influence the probability of a hazardous incident occurring. To familiarize the study team with the design information available. To ensure that a systematic study is made of the areas of significant hazard potential. To identify pertinent design information not currently available to the team. To provide a mechanism for feedback to the client of the study teams detailed comments.

3) 4) 5) 6)

A HAZOP study is conducted in the following steps: 1) Specify the purpose, objective, and scope of the study. The purpose may he the analysis of a yet to be built plant or a review of the risk of UN existing unit. Given the purpose and the circumstances of the study, the objectives listed above can he made more specific. The scope of the study is the boundaries of the physical unit, and also the range of events and variables considered. For example, at one time HAZOP's were mainly focused on fire and explosion endpoints, while now the scope usually includes toxic release, offensive odor, and environmental end-points. The initial establishment of purpose, objectives, and scope is very important and should be precisely set down so that it will be clear, now and in the future, what was and was 108

Chapter 8

Hazop Study not included in the study. These decisions need to be made by an appropriate level of responsible management.

2)

Select the HAZOP study team. The team leader should be skilled in HAZOP and in interpersonal techniques to facilitate successful group interaction. As many other experts should be included in the team to cover all aspects of design, operation, process chemistry, and safety. The team leader should instruct the team in the HAZOP procedure and should emphasize that the end objective of a HAZOP survey is hazard identification; solutions to problems are a separate effort. Collect data. Theodore16 has listed the following materials that are usually needed: Process description Process flow sheets Data on the chemical, physical and toxicological properties of all raw materials, intermediates, and products. Piping and instrument diagrams (P&IDs) Equipment, piping, and instrument specifications Process control logic diagrams Layout drawings Operating procedures Maintenance procedures Emergency response procedures Safety and training manuals

3)

Economics and Environmental Study of the Plant

The final choice of the plant site usually involves a presentation of the economic factors for several quality attractive sites. The exact site of economic study of plant locations will vary with the each company making the study. It should include the following; The limitations of preliminary plant location cost studies should be pointed out to management. No matter how carefully a survey is prepared, future trends such as population and marketing shifts, development of competitive processes and the advent of new industries. Services and transportation facilities cannot be reliably predicted.

Plant Location and Site Selection

The location of the plant has a crucial effect on the profitability of the project and the scope of the future expansion. Many factors are considered when selecting a suitable site. A brief explanation of each factor is given below; I) Raw Material Supply

109

Chapter 8

Hazop Study

Probably location of the raw material of an industry contributes more towards the choice of a plant site than any other factor. This is especially noticeable in those in which the raw material is inexpensive and bulky and is made more compact and obtains a high bulk value during the process of manufacturing. ii) Marketing Area For materials that are produced in bulk quantities, such as minerals, cement, acids and fertilizers, where the cost of the product per ton is relatively low and cost of transportation has a significant fraction of the sale price. The plant should be located close to the primary market. This consideration will be less important for low volume production, high price product such as pharmaceuticals. iii) Transportation Facilities The transport of material and the product from the plant will be over riding consideration in site selection. If practicable, a site should be selected that is close to at least two major forms of transport, road, rail, water way (canal or river) or a sea port. Road transport is being increasingly used and is suitable for local distribution from a central ware house. Rail transportation will be cheaper for long distance transport of bulk chemicals. Air transport is convenient and efficient for the movement and personnel and essential equipment and supplies and proximity of the site to a major airport should be considered. iv) Sources of Power Power for chemical industry is preliminary from coal, water and oil; these fuels supply the most flexible and economical sources, in as much as they provide for generation of steam both for processing and electricity production, power can be economically developed as a byproduct in most chemical plants. If the needs are great enough, since the process requirements generally call for low-pressure steam. The turbines of engines used to generate electricity can be operated non-condensing and supply exhaust steam for processing purposes. v)

Availability of Labor

Labor will be needed for construction of the plant and its operation. Skilled construction workers will usually be brought in from outside the site area, but there should be an adequate pool of unskilled labor available locally, and labor suitable for training to operate plant. Skilled tradesmen will be needed for plant maintenance. Local trade union customs and restrictive practices will have to be considered when assessing the availability and suitability of local labor for equipment and training. Vi) Water Supply Water for industrial purposes can be obtained from one of two general sources; the plants own source or municipal supply. If the demand of water is large, it is more economical for the industry to supply its own water. Such a supply may be obtained from drilled wells, rivers, lakes, dammed streams or other supplies. Before a company enters upon any project, it 110

Chapter 8

Hazop Study

must ensure itself of a sufficient supply of water for all industrial, sanitary and fire demands, both for present and future. vii)

Effluent Disposal

All industrial processes produce waste products and full consideration must be given to difficulties and cost of their disposal. The disposal of toxic and harmful effluents will be recovered by local regulations and the appropriate authorities must be consulted during the initial state of survey to determine the standards that must be met. viii) Local Community Considerations The proposed plant must fit in and be acceptable to local community. Full consideration must be given to the safe location of the plant so that it does not impose a significant additional risk to the community. On a new site, the local community must be able to provide adequate facilities for, the plant personnel; school, banks, housing, recreational and cultural facilities. ix) Land Considerations Sufficient suitable land must be available for the proposed plant and for future expansion. The land should ideally be flat, well drained and have suitable load-bearing characteristics. A full site evaluation should be made to determine the need for piling or other special foundations. x) Climate Adverse climatic conditions at a site will increase costs. Abnormally low temperature will require the provisions for additional insulation and special heating for equipment and pipe runs. Stronger strictures will be needed at locations subjected to strong winds (cyclone hurricane areas) or earthquakes. Xi) Political and Strategic Considerations Capital grants, tax concessions, and other inducements are often given by governments direct new investment to preferred locations such as areas of high unemployment. The availability of such grants can be the over-riding consideration in site selection.

Table - HAZOP Guide Words and Meanings Guide Words Meaning No Negation of design intent Less Quantitative decrease More Quantitative increase Part of Qualitative decrease As well as Qualitative Increase Reverse Logical opposite of the intent Other than Complete substitution 111

Chapter 8

Hazop Study

4)

Conduct the study. Using the information collected, the unit is divided into study "nodes" and the sequence diagrammed in Figure, is followed for each node. Nodes are points in the process where process parameters (pressure, temperature, composition, etc.) have known and intended values. These values change between nodes as a result of the operation of various pieces of equipment' such as distillation columns, heat exchanges, or pumps. Various forms and work sheets have been developed to help organize the node process parameters and control logic information.

When the nodes are identified and the parameters are identified, each node is studied by applying the specialized guide words to each parameter. These guide words and their meanings are key elements of the HAZOP procedure. They are listed in Table (10.1). Repeated cycling through this process, which considers how and why each parameter might vary from the intended and the consequence, is the substance of the HAZOP study. 5) Write the report. As much detail about events and their consequence as is uncovered by the study should be recorded. Obviously, if the HAZOP identifies a not improbable sequence of events that would result in a disaster, appropriate follow-up action is needed. Thus, although risk reduction action is not a part of the HAZOP, the HAZOP may trigger the need for such action.

The HAZOP studies are time consuming and expensive. Just getting the P & ID's up to date on an older plant may be a major engineering effort. Still, for processes with significant risk, they are cost effective when balanced against the potential loss of life, property, business, and even the future of the enterprise that may result from a major release. HAZOP Study of Storage Tank for Di-ethanol amine A HAZOP study is to be conducted on MEA storage tank, as presented by the piping and instrumentation diagram show in figure. In this scheme, MEA is unloaded from tank trucks into a storage tank maintained under a slight positive pressure until it is transferred to the process. Application of the guide words to the storage tank is shown in Table along with a listing of consequences that results from process deviation. Some of the consequences identified with these process deviations have raised additional questions that need resolution to determine whether or not hazards exist.

112

Chapter 8

Hazop Study

Di-ethanol amine Storage Tank

Figure- : Piping and instrumentation diagram [20]

113

Chapter 8

Hazop Study

Deviations from operating conditions Level: Less

What event could cause this deviation

Consequences of this deviation on item of equipment under consideration Pump cavities Reagent released Reagent released Reagent released Reagent released Tank overfills Tank overfills

Process indications

Tank runs dry Rupture of discharge line V-3 open or broken V-1 open or broken Tank rupture (busting of vessel)

LIA-1 FICA-1 LIA-1, FICA-1 LIA-1 LIA-1 LIA-1 LIA-1 LIA-1

More

Unload too much from column Reverse flow from process

Temperature: Less More

Temperature of inlet is colder than normal Possible vacuum Temperature of inlet is hotter than normal Region released External fire Tank fails

114

S-ar putea să vă placă și

- Chemical and Petrochemical IndustryDocument6 paginiChemical and Petrochemical IndustryjeevaÎncă nu există evaluări

- Hazop StudyDocument18 paginiHazop StudyChaudhary KashifÎncă nu există evaluări

- PROJECT STANDARDS AND SPECIFICATIONS Fla PDFDocument12 paginiPROJECT STANDARDS AND SPECIFICATIONS Fla PDFAsif Haq100% (1)

- Chemical Process Plant SafetyDocument37 paginiChemical Process Plant Safetyvenky437Încă nu există evaluări

- Railway Presentation Cement With FlyashDocument13 paginiRailway Presentation Cement With FlyashPraveen GargÎncă nu există evaluări

- Jaipur Oil Depot Fire 2009 Project ReportDocument17 paginiJaipur Oil Depot Fire 2009 Project Reportcharu kohliÎncă nu există evaluări

- Various Considerations in Equipment Layout in The Equipment and Plot PlanDocument12 paginiVarious Considerations in Equipment Layout in The Equipment and Plot PlanThiruvengadam100% (1)

- PESO Approval ProcessDocument8 paginiPESO Approval ProcesssanthoshkumarplÎncă nu există evaluări

- Explosive SafetyDocument41 paginiExplosive SafetyRonelie Mendoza VenerayanÎncă nu există evaluări

- Explosives Act 1884 summaryDocument76 paginiExplosives Act 1884 summaryA D SharmaÎncă nu există evaluări

- Hazop-Gas Processing ComplexDocument2 paginiHazop-Gas Processing ComplexjavadÎncă nu există evaluări

- Lab 11 - Carbon Footprint CalculationDocument13 paginiLab 11 - Carbon Footprint CalculationAmy HollingsworthÎncă nu există evaluări

- Materials Handling Chapter 1 and 2Document9 paginiMaterials Handling Chapter 1 and 2Edel Quinn Madali100% (1)

- Materials System SpecificationDocument8 paginiMaterials System SpecificationGOSP3 QC MechanicalÎncă nu există evaluări

- Aviation Biofuel Is A Growing IndustryDocument6 paginiAviation Biofuel Is A Growing IndustryCarl FreerÎncă nu există evaluări

- Oisd192 PDFDocument68 paginiOisd192 PDFpmcmbharat264Încă nu există evaluări

- Safety & Health Issue in Textile IndustryDocument4 paginiSafety & Health Issue in Textile Industrythongtn2007Încă nu există evaluări

- List OISD StandardsDocument6 paginiList OISD StandardsAmol changoleÎncă nu există evaluări

- Brochure Petrochemical IndustryDocument8 paginiBrochure Petrochemical IndustryrogarditoÎncă nu există evaluări

- Oisd 115Document71 paginiOisd 115Rishabh Das100% (2)

- 40 CFR 112 SpillDocument90 pagini40 CFR 112 SpillGrady HopkinsÎncă nu există evaluări

- Principles Hazop Fta Eta FmeaDocument2 paginiPrinciples Hazop Fta Eta FmeaDidier Hung Leung SangÎncă nu există evaluări

- Hazan & HazopDocument5 paginiHazan & HazopAasif EqubalÎncă nu există evaluări

- Fire and Explosion NoteDocument56 paginiFire and Explosion NoteLevine98100% (1)

- Small Scale NGLDocument45 paginiSmall Scale NGLNoirchevalÎncă nu există evaluări

- Inputsupporting Data For Hazop StudyDocument10 paginiInputsupporting Data For Hazop Studydebu1985Încă nu există evaluări

- Central Pollution Control Board Guidelines For Poultry Farms in Haryana - Naresh KadyanDocument6 paginiCentral Pollution Control Board Guidelines For Poultry Farms in Haryana - Naresh KadyanNaresh Kadyan100% (3)

- VEL2164 CAT Filter Separator For Aviation Fuel HandlingDocument28 paginiVEL2164 CAT Filter Separator For Aviation Fuel HandlingULISES MONTANOÎncă nu există evaluări

- Colour Coding Is 9404Document8 paginiColour Coding Is 9404dhoops1988Încă nu există evaluări

- Oil and GasDocument14 paginiOil and GasTarun N. O'Brain GahlotÎncă nu există evaluări

- Desgning Sop 4 Haier IndiaDocument74 paginiDesgning Sop 4 Haier IndiaChandra GuptaÎncă nu există evaluări

- JSW Report PDFDocument65 paginiJSW Report PDFKiran Varghese KÎncă nu există evaluări

- Tank TruckDocument80 paginiTank Truckjacobpm2010Încă nu există evaluări

- Mines Act RulesDocument30 paginiMines Act RulesGanesh KumarÎncă nu există evaluări

- InsulationDocument10 paginiInsulationJyotiÎncă nu există evaluări

- A Project Report On Study On Foundry Industry BelgaumDocument60 paginiA Project Report On Study On Foundry Industry BelgaumBabasab Patil (Karrisatte)100% (1)

- IS 15394.2003 Fire Safety in Petroleum RefineriesDocument16 paginiIS 15394.2003 Fire Safety in Petroleum RefineriesnpwalÎncă nu există evaluări

- Basic Introduction of Coal Handling SystemDocument7 paginiBasic Introduction of Coal Handling SystemHerman AbdullahÎncă nu există evaluări

- TCC LTDDocument17 paginiTCC LTDjithukpÎncă nu există evaluări

- OGP437Document156 paginiOGP437tommyliangÎncă nu există evaluări

- Petronet LNG LTD., India: Investment in LNG Terminals & Future For The Downstream IndustriesDocument26 paginiPetronet LNG LTD., India: Investment in LNG Terminals & Future For The Downstream Industriesjan.pa87534Încă nu există evaluări

- Process Safety Overview - Dr. Wisdom Enang (FNSE)Document25 paginiProcess Safety Overview - Dr. Wisdom Enang (FNSE)Tony IsodjeÎncă nu există evaluări

- TGE Brochure 2010Document12 paginiTGE Brochure 2010ankeshkatochÎncă nu există evaluări

- Risk Analysis and Modeling Construction and Operation of Gas Pipeline Projects in PakistanDocument24 paginiRisk Analysis and Modeling Construction and Operation of Gas Pipeline Projects in PakistanJuanCarlosVilchisDuránÎncă nu există evaluări

- 2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankDocument19 pagini2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankAdnan AliÎncă nu există evaluări

- HCL Maubhandar, Project ReportDocument57 paginiHCL Maubhandar, Project ReportRahul Raj Yaduvanshi100% (1)

- HPCL - Palanpur Terminal EIADocument130 paginiHPCL - Palanpur Terminal EIAKalai SelvanÎncă nu există evaluări

- Is.6994.1.1973 Leather Hand GlovesDocument25 paginiIs.6994.1.1973 Leather Hand GlovesSovan ChakrabortyÎncă nu există evaluări

- 01the Gujarat Factories Rules 1963Document365 pagini01the Gujarat Factories Rules 1963Siddhrajsinh Zala100% (1)

- Equipment Process Data Sheet ChecklistDocument1 paginăEquipment Process Data Sheet Checklistankur2061Încă nu există evaluări

- Isi Safety Codes ListDocument7 paginiIsi Safety Codes ListDrGuru PrasadÎncă nu există evaluări

- 10.3 Ventilation Surveys - Air Quality and Quantity SurveysDocument11 pagini10.3 Ventilation Surveys - Air Quality and Quantity SurveysDeepakKattimaniÎncă nu există evaluări

- Safety in The Oil and Gas IndustryDocument40 paginiSafety in The Oil and Gas IndustryMeg CariñoÎncă nu există evaluări

- Tank Lorry Filling GantryDocument21 paginiTank Lorry Filling GantrySiddharth BarmanÎncă nu există evaluări

- Technical FeasibilityDocument5 paginiTechnical FeasibilityMelody ArgenteraÎncă nu există evaluări

- Lecture 2Document22 paginiLecture 2Sana taÎncă nu există evaluări

- ChemPlantDesign-General Plant ConsiderationDocument32 paginiChemPlantDesign-General Plant ConsiderationAiman SyazwanÎncă nu există evaluări

- 7.0 Plant Location and Site SelectonDocument14 pagini7.0 Plant Location and Site SelectonVikas KumarÎncă nu există evaluări

- Plant Location and Site SelectionDocument34 paginiPlant Location and Site SelectionNaik LarkaÎncă nu există evaluări

- Process Intensification: Engineering for Efficiency, Sustainability and FlexibilityDe la EverandProcess Intensification: Engineering for Efficiency, Sustainability and FlexibilityÎncă nu există evaluări

- National Maritime Oil/HNS Spill Contingency PlanDocument36 paginiNational Maritime Oil/HNS Spill Contingency PlanAdeel AhmedÎncă nu există evaluări

- DM Technical Guideline No.11 - Transportation-and-Handling-of-Hazardous-WasteDocument14 paginiDM Technical Guideline No.11 - Transportation-and-Handling-of-Hazardous-WastekatageriguruÎncă nu există evaluări

- Reference 2Document6 paginiReference 2Adeel AhmedÎncă nu există evaluări

- Bauxite Residue Management - Best Practice PDFDocument31 paginiBauxite Residue Management - Best Practice PDFJohn GiannakopoulosÎncă nu există evaluări

- BP7 Safe Cleaning of Freight ContainersDocument19 paginiBP7 Safe Cleaning of Freight ContainerskhtibÎncă nu există evaluări

- InfoBulletin 3 2021 Hazardous and Non Hazardous Waste Processing and Rec...Document17 paginiInfoBulletin 3 2021 Hazardous and Non Hazardous Waste Processing and Rec...Adeel AhmedÎncă nu există evaluări

- OpTransactionHistory PDF18!06!2021Document1 paginăOpTransactionHistory PDF18!06!2021Adeel AhmedÎncă nu există evaluări

- 2-Ethyl Hexanol: Cautionary Response InformationDocument2 pagini2-Ethyl Hexanol: Cautionary Response InformationAdeel AhmedÎncă nu există evaluări

- Accident Reporting FairdealDocument34 paginiAccident Reporting FairdealAdeel AhmedÎncă nu există evaluări

- Sokalan RO: Every Drop CountsDocument6 paginiSokalan RO: Every Drop CountsAdeel AhmedÎncă nu există evaluări

- RFP 1100085103 - Clarification Note 1Document1 paginăRFP 1100085103 - Clarification Note 1Adeel AhmedÎncă nu există evaluări

- 3-Emergency PreparednessDocument50 pagini3-Emergency PreparednessAdeel AhmedÎncă nu există evaluări

- EnviroSEP - Oil & Water SeparatorDocument4 paginiEnviroSEP - Oil & Water SeparatorAdeel AhmedÎncă nu există evaluări

- DocumentDocument14 paginiDocumentKhalid AwanÎncă nu există evaluări

- Safety Induction EssentialsDocument42 paginiSafety Induction EssentialsAdeel Ahmed100% (2)

- DNI Information - Introduction and HazardsDocument32 paginiDNI Information - Introduction and HazardsAdeel Ahmed85% (13)

- Personal Protective EquipmentDocument41 paginiPersonal Protective EquipmentAdeel AhmedÎncă nu există evaluări

- Heat StressDocument15 paginiHeat StressAdeel AhmedÎncă nu există evaluări

- Strain Gauge Transducer OnlyDocument4 paginiStrain Gauge Transducer OnlyAdeel AhmedÎncă nu există evaluări

- 2 - Slips Trips & FallsDocument33 pagini2 - Slips Trips & FallsAdeel AhmedÎncă nu există evaluări

- TOB - Cat 1Document3 paginiTOB - Cat 1Adeel AhmedÎncă nu există evaluări

- Oxygen Gas Producing PlantDocument29 paginiOxygen Gas Producing PlantAdeel Ahmed0% (1)

- Mass Balance (Final)Document26 paginiMass Balance (Final)Adeel AhmedÎncă nu există evaluări

- Essay Writing FinDocument7 paginiEssay Writing FinAdeel AhmedÎncă nu există evaluări

- Accident - Incident InvestigationDocument7 paginiAccident - Incident InvestigationAdeel AhmedÎncă nu există evaluări

- Accident - Incident InvestigationDocument7 paginiAccident - Incident InvestigationAdeel AhmedÎncă nu există evaluări

- Asbestos Removal ContractDocument1 paginăAsbestos Removal ContractAdeel AhmedÎncă nu există evaluări

- Risk Assessment Action PlanDocument1 paginăRisk Assessment Action PlanAdeel AhmedÎncă nu există evaluări

- Census2006 RawMasterDocument1.567 paginiCensus2006 RawMasterAdeel AhmedÎncă nu există evaluări

- Template For PaperDocument3 paginiTemplate For PaperAdeel AhmedÎncă nu există evaluări

- 6 Contoh HazopDocument139 pagini6 Contoh HazopJoko SetiawanÎncă nu există evaluări

- C-23 Life Cycle of Process Plants PDFDocument9 paginiC-23 Life Cycle of Process Plants PDFnike_y2k100% (1)

- Hazard Identification ChapterDocument78 paginiHazard Identification ChapterRobert WilsonÎncă nu există evaluări

- DRAFT WSH Guidelines On Process Hazards Analysis - For Public Consultation (6 Jun - 4 Jul 2016)Document38 paginiDRAFT WSH Guidelines On Process Hazards Analysis - For Public Consultation (6 Jun - 4 Jul 2016)m_saminathanÎncă nu există evaluări

- Hazop Hazard and Operability StudyDocument44 paginiHazop Hazard and Operability StudyAshish PawarÎncă nu există evaluări

- What If-Checklist ExampleDocument3 paginiWhat If-Checklist ExampleltroncosÎncă nu există evaluări

- SHEPHERD RISK Hazards & Effects Management Process 01 Day TrainingDocument3 paginiSHEPHERD RISK Hazards & Effects Management Process 01 Day TrainingMuhammad.SaimÎncă nu există evaluări

- Hazop Procedures Kenny SampleDocument178 paginiHazop Procedures Kenny Sampleayuzme123100% (1)

- Hazard and Operability (HAZOP) & Hazard Analysis TrainingDocument106 paginiHazard and Operability (HAZOP) & Hazard Analysis TrainingShainu Govindankutty100% (8)

- Hazop ProcedureDocument14 paginiHazop ProcedureAnh Hai100% (1)

- Chemtech Pharmacon - Engineering ServicesDocument2 paginiChemtech Pharmacon - Engineering ServicesDilip KatekarÎncă nu există evaluări

- Training Report of PolyelectrolytesDocument10 paginiTraining Report of PolyelectrolytesJaveed802100% (1)

- Adil CV LatestDocument4 paginiAdil CV LatestBurhanÎncă nu există evaluări

- Process Safety Capability Studies PDFDocument51 paginiProcess Safety Capability Studies PDFmaurya888Încă nu există evaluări

- Chemical Engineering - Instrumentation (Improving Plant Operation, Safety and Control) - Volume 2 PDFDocument149 paginiChemical Engineering - Instrumentation (Improving Plant Operation, Safety and Control) - Volume 2 PDFsw100% (1)

- Fatal Risk Control Protocol Issue 2 Jan 2005Document44 paginiFatal Risk Control Protocol Issue 2 Jan 2005Luis Fernando Giraldo OspinaÎncă nu există evaluări

- Process Control CompleteDocument71 paginiProcess Control CompleteJanusÎncă nu există evaluări

- OSHA Module 2Document16 paginiOSHA Module 2Varsha G100% (1)

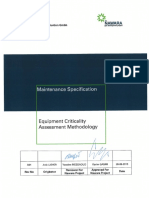

- NA-OTP-PMT-000-OR-STA-00001 Equipment Criticality Assessment MethodologyDocument11 paginiNA-OTP-PMT-000-OR-STA-00001 Equipment Criticality Assessment MethodologyKechaou100% (1)

- Hazard-Identification Petroleum Safety and Major Hazards FacilityDocument20 paginiHazard-Identification Petroleum Safety and Major Hazards FacilityFilipÎncă nu există evaluări

- AIPS Guide - Element 7 HEMP Rev 2Document9 paginiAIPS Guide - Element 7 HEMP Rev 2mahamed medlamineÎncă nu există evaluări

- crr91026 (CHAZOP)Document40 paginicrr91026 (CHAZOP)pneuma110100% (1)

- Supplier VDR Master ListDocument59 paginiSupplier VDR Master Listwendypost73Încă nu există evaluări

- Importance of Inter Discipline Check or IDC PDFDocument3 paginiImportance of Inter Discipline Check or IDC PDFSurabhi SolankiÎncă nu există evaluări

- Accuracy in QRADocument8 paginiAccuracy in QRAJohm Robert taylor100% (1)

- Hazard and Operability (HAZOP) & Hazard Analysis TrainingDocument106 paginiHazard and Operability (HAZOP) & Hazard Analysis TrainingBeste Ardıç Arslan100% (4)

- 2017 India Conference Presentation Pack Early Bird Dekra PDFDocument205 pagini2017 India Conference Presentation Pack Early Bird Dekra PDFChitikala RajeshÎncă nu există evaluări

- CV BuiKhoiNguyenDocument4 paginiCV BuiKhoiNguyenBui Khoi NguyenÎncă nu există evaluări

- SA JER CNAAA TPIT 500016 - Rev00Document45 paginiSA JER CNAAA TPIT 500016 - Rev00Amar DhasÎncă nu există evaluări

- PE-D-CO-PRO-001-00 Project Commissioning, Start - Up and Handover ProcedureDocument38 paginiPE-D-CO-PRO-001-00 Project Commissioning, Start - Up and Handover Proceduremarin cristian0% (1)