Documente Academic

Documente Profesional

Documente Cultură

Delo Extended Life Coolant Antifreeze 5050

Încărcat de

Ravi SekhonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Delo Extended Life Coolant Antifreeze 5050

Încărcat de

Ravi SekhonDrepturi de autor:

Formate disponibile

DELO EXTENDED LIFE COOLANT/ANTIFREEZE

Coolant/Antifreeze, Prediluted 50/50, Prediluted 60/40 (all with and without Bitterant); Extender

PRODUCT NUMBER 227804 (MSDS 10391) DELO EXTENDED LIFE COOLANT/ANTIFREEZE PRODUCT NUMBER 227808 (MSDS 10652) DELO EXTENDED LIFE COOLANT/ANTIFREEZE -B

Delo Extended Life Coolant/Antifreeze (Delo ELC) concentrate is ethylene glycol based and contains Chevron's patented carboxylate technology. This product does not contain conventional inhibitors like silicates, nitrates, amines, phosphates or borates. Delo ELC concentrate can be used for initial fill or top up but it must diluted. It should be used full strength for freeze point adjustment.

PRODUCT NUMBER 227018 (MSDS 10644) DELO EXTENDER

Delo Extender should be added to Delo ELC at 500,000 miles/10,000 hours/4 years to reach a coolant service life of 1,000,000 miles/20,000 hours/8 years. The amount of Extender needed is based on the volume of the cooling system. Extender should only be added once during the service life of Delo ELC. Delo Extender contains nitrite and molybdate.

PRODUCT DESCRIPTION AND FEATURES

Delo Extended Life Coolant/Antifreeze products are heavy duty engine coolants that use a patented organic corrosion inhibitor technology called carboxylates. The product line consists of Delo Extended Life Coolant/Anti-Freeze Concentrate, Delo Extended Life Prediluted 50/50 Coolant/Antifreeze, Delo Extended Life Prediluted 60/40 Coolant/Antifreeze and Delo Extender. Delo ELC products contain nitrite and molybdate for added protection against cavitation and erosion.

PRODUCT NUMBER 227805 (MSDS 10400) DELO EXTENDED LIFE PREDILUTED 50/50 COOLANT/ANTIFREEZE PRODUCT NUMBER 227811 (MSDS 10673) DELO EXTENDED LIFE PREDILUTED 50/50 COOLANT/ANTIFREEZE - B

Delo Extended Life Prediluted 50/50 Coolant/Antifreeze is a 50/50 mixture of Delo Extended Life Coolant/ Antifreeze concentrate with deionized water for freeze protection down to -34F (-37C) and boil over protection to 264F (129C) with a 15 lb pressure cap. Delo ELC Prediluted 50/50 is recommended for top up and can be used for initial fill.

CUSTOMER BENEFITS

Delo Extended Life Coolant/Antifreeze products delivers value through: Improved profitability Eliminates the cost of SCAs (supplemental coolant additives), test strips and the manpower required to test coolant and add SCAs. 750,000 miles on-road use (8 years or 12,000 hours off-highway use) on initial fill with no Extender needed 1,000,000 miles/20,000 hours/8 years with a Delo Extender addition at 500,000 miles/10,000 hours/4 years. Reduced operating costs Effective, long term corrosion protection of all cooling system components Reduced hard water scale Superior protection at high operating temperatures Protects against winter freeze up and minimizes the chance of summer boil over Outstanding hot surface aluminum protection

4 March 2008 COOL-40

PRODUCT NUMBER 275117 (MSDS 23605) DELO EXTENDED LIFE PREDILUTED 60/40 COOLANT/ANTIFREEZE PRODUCT NUMBER 275111 (MSDS 10725) DELO EXTENDED LIFE PREDILUTED 60/40 COOLANT/ANTIFREEZE - B

Delo ELC 60/40 is a 60% glycol/40% deionized water mixture of Delo Extended Life Coolant/Antifreeze concentrate for use where freeze protection down to -62F (-52C) is needed. Product number 27511 contains a bitterant.

2008 Chevron Products Company. San Ramon, CA. All rights reserved. All trademarks are the property of Chevron Intellectual Property LLC.

Delo Extended Life Coolant/Antifreeze Continued

Improved heat transfer that reduces down time due to non silicate containing formula. Improved water pump life due to reduced water pump seal wear resulting from fewer dissolved solids Reduced inventory costs One product for all applications including onroad, off-road and stationary No inventory of SCA filters or liquids needed. No test strip inventory needed Storage stable for a minimum of 8 years due to non-silicate containing formula

Boiling and Freezing Protection for Delo Extended Life Coolant/Antifreeze

Using a 15 lb Radiator Cap Coolant/ Water Ratio 50/50 60/40 40/60 Freeze Point -34F (-36.7C) -62F (-52.2C) -12F (-24C) Boil Over Protection +265F (129.4C) +270F (132.2C) +224F (107C)

Delo Extended Life Coolant System is recommended for all heavy duty and natural gas engines including

APPLICATIONS

The patented carboxylate technology in Delo ELC can be used in on-road, off-road and stationary engine applications. Delo ELC protects all cooling system components and has proven over years of field testing and customer use to improve water pump life and improve heat transfer. The inhibitors in Delo ELC do not readily deplete and for this reason there is no need to add SCAs or test the coolant/antifreeze as is required when using conventional coolants requiring SCA additions if correct top-up practices are followed. In service Delo ELC is recommended for use out to 750,000 miles/15,000 hours/8 years. If even longer service intervals are desired then the addition of Delo Extender at 500,000 miles/10,000 hours/4 years will extend the service life to 1,000,000 miles/20,000 hours/8 years. When using Delo ELC it is not recommended that supplemental coolant additives be used. If an accidental addition of SCAs should happen it will not create any operational issues. Additions of SCAs to Delo ELC increases the overall cost of maintenance and adds inhibitors that are not needed for ELC to perform at maximum levels of protection. Delo ELC products are dilution tolerant up to 25% percent with other nonDelo ELC products or water. Dilution of more then 25% will reduce the extended life properties of this product. When using Delo ELC it is recommended that the product freeze point be maintained between -12F and -62F. If the freeze point is higher or lower than the range specified it is an indication that water or concentrated coolant has been added to the system. To adjust freeze point for over or under concentration use the tables at the end of this document. Note: These products are not to be used to protect the inside of potable water systems against freezing.

Caterpillar, Navistar, Cummins, Detroit Diesel, Mack, MTU, and other original equipment

manufacturers (OEMs). Delo Extended Life Coolant System is also recommended for use in the cooling systems of all types of industrial internal combustion engines using various types of fuels. Delo Extended Life Coolant/Antifreeze products meet or exceed the requirements of the following: ASTM D 6210 ASTM D 3306 TMC RP 329, 302A, 351 (color) Phosphate-free requirement of European OEMs Silicate-free requirement of Japanese OEMs Caterpillar EC-1 Navistar B1

CORROSION PROTECTION

Delo Extended Life Coolant/Antifreeze products have been tested against all ASTM standards for heavy duty and light duty coolants. ASTM 1384 results are as follows. Note that negative numbers show a weight gain versus a weight loss. Delo Extended Life Coolant/Antifreeze ASTM D 1384 Glassware Corrosion Test ASTM Limit Copper Solder Brass Steel Iron Aluminum

*

Weight loss, mg per coupon* 2 0 -1 -1 -1 3

10 max 30 max 10 max 10 max 10 max 30 max

Negative indicates net gain 4 March 2008 COOL-40

2008 Chevron Products Company. San Ramon, CA. All rights reserved.

Delo Extended Life Coolant/Antifreeze Continued

PHYSICAL PROPERTIES OF DELO ELC

Traditional coolants containing phosphate and borate exhibit high pH and reserve alkalinity (RA) when compared with Delo Extended Life Coolant/Antifreeze. This comparison cannot be used to make conclusions about relative corrosion protection since the definition of RA is based upon the buffering curve of inhibitors that are not present in the coolant. Delo Extended Life Coolants unique corrosion inhibitor system is designed to protect aluminum and other system metals at lower pH levels than conventional coolants. A comparison of Delo Extended Life Coolant/Antifreeze with traditional coolants is shown below: Delo Extended Life Coolant/ Antifreeze Typical pH Typical RAa (mL) 8.3 6.0 Traditional Coolant/ Antifreeze 10.5 12.0

Delo Extended Life Coolant Prediluted 60/40 as needed for freeze protection. Using these three simple steps will keep Delo ELC performing at maximum protection levels and provide a service life of 750,000 miles/15,000 hours/8 years. If a longer service interval is desired addition of Delo Extender as per chart below at 500,000 miles/10,000 hours/4 years will result in total coolant service life of 1,000,000 miles/20,000 hours/8 years.

Delo Extender has been specially formulated to double the life of Delo Extended Life Prediluted 50/50 Coolant Antifreeze. It should only be added at 500,000 miles/10,000 hours/4 years.

Quantity of Delo Extender needed at 500,000 miles of on-road use (4 years or 10,000 hours of off-highway use) Cooling System Capacity, liters 22-30 30-49 49-83 83-114 114-155 155-197 197-243 Delo Extender Quantity, liters 0.5 1 1.5 2 3 4 5

a. RA is defined as the amount in milliliters (mL), of 0.1 normal hydrochloric acid required to reduce the pH of 10 ml of antifreeze to 5.5.

Delo ELC has low pH and RA relative to traditional coolants. The pH change profile in service is a more important performance measure than the RA level. Delo Extended Life Coolant/Antifreeze shows a typical pH reduction of less than 1.5 units in 160,000 kilometer fleet tests compared with a pH reduction of up to 3 units for traditional coolants. The American Society for Testing Materials (ASTM) has eliminated RA Level requirements in both key antifreeze specifications: ASTM D 3306 for automotive and ASTM D 4985 for heavy-duty engines. This action by the ASTM acknowledges that coolants that are not based on phosphate and borate can provide excellent corrosion protection for cooling system metals.

Delo Extender should only be used with Delo Extended Life Coolants.

TYPICAL TEST DATA

Product Number MSDS Number Appearance Specific gravity 15/15C

Delo Extended Life Coolant/Antifreeze 227804 10391 Red 1.130 -37 8.3 6.0 None

Freezing point, C1, ASTM D 1177 pH2, ASTM D 1287 Reserve alkalinity3, ASTM D 1121 Silicate, %4

HOW TO MAINTAIN DELO ELC

There are three simple steps to maintaining Delo Extended Life Coolant while in service: 1. Check the coolant color and insure the product is bright red, contains no debris or any signs of oil at every PM. 2. Test the freeze point of Delo ELC at least two times per year. Maintain freeze point between -12F and -62F. Use of a refractometer is recommended. 3. Keep cooling system at full levels by topping-up using Delo Extended Life Coolant Prediluted 50/50 or

Typical test data are average values only. Minor variations which do not affect product performance are to be expected in normal manufacturing.

1 2 3 4

50 vol % aqueous solution 1:2 dilution with water as received as anhydrous alkali metasilicate

2008 Chevron Products Company. San Ramon, CA. All rights reserved.

4 March 2008 COOL-40

Delo Extended Life Coolant/Antifreeze Continued

Delo Extended Life Extender Product Number MSDS Number Appearance Specific gravity Silicate, % 227018 10644 Red 1.06 None

HANDLING PRACTICES

All coolants, including extended life coolants should be stored in such a manner that package integrity is maintained. It is recommended that all coolants be agitated before use to insure inhibitors have not separated in storage. The primary limiting factor in the shelf life of a coolant is silicate instability. Since silicate will eventually polymerize to silicate gel, all traditional silicate-based coolants have a shelf life of about 18 months. Delo Extended Life Coolant System is silicate-free and, therefore, can be stored for extended periods (up to 8 years) provided the integrity of the container is maintained. All coolants should be disposed of in compliance with all laws, rules and regulations applicable to the this product line.

Typical test data are average values only. Minor variations which do not affect product performance are to be expected in normal manufacturing.

2008 Chevron Products Company. San Ramon, CA. All rights reserved.

4 March 2008 COOL-40

Delo Extended Life Coolant/Antifreeze Continued

FREEZE POINT ADJUSTMENT CHARTS

FREEZE POINT ADJUSTMENT CHART FOR UNDERCONCENTRATED SYSTEMS

UNDER CONCENTRATED

TESTED FREEZE PROTECTION %AF IN COOLANT

(Use this chart to adjust your freeze point up to -35F)

For use with ethylene glycol based fluids

7-GAL 8-GAL 9-GAL TOTAL COOLANT SYSTEM VOLUME 10-GAL 11-GAL 12-GAL 13-GAL 14-GAL 15-GAL

VOLUME TO DRAIN AND REPLACE WITH COOLANT CONCENTRATE

25 20 15 10 5 0 -5 -10 -15 -20 -25 -30 -35

10 16 21 25 29 33 36 39 42 44 46 48 50

3 2-3/4 2-1/2 2-1/4 2 1-3/4 1-1/2 1-1/4 1 3/4 1/2 1/4 0

3-1/2 3-1/4 3 2-3/4 2-1/4 2 1-3/4 1-1/2 1 3/4 1/2 1/4 0

4 3-3/4 3-1/4 3 2-3/4 2-1/4 2 1-1/2 1-1/4 1 3/4 1/4 0

4-1/2 4 3-3/4 3-1/4 3 2-1/2 2-1/4 1-3/4 1-1/2 1 3/4 1/2 0

5 4-1/2 4 3-3/4 3-1/4 2-3/4 2-1/2 2 1-1/2 1-1/4 3/4 1/2 0

5-1/4 4-3/4 4-1/2 4 3-1/2 3 2-3/4 2-1/4 1-3/4 1-1/4 1 1/2 0

5-3/4 5-1/4 4-3/4 4-1/4 3-3/4 3-1/4 2-3/4 2-1/4 1-3/4 1-1/2 1 1/2 0

6-1/4 5-3/4 5-1/4 4-3/4 4-1/4 3-1/2 3 2-1/2 2 1-1/2 1 1/2 0

6-3/4 6 5-1/2 5 4-1/2 3-3/4 3-1/4 2-3/4 2 1-1/2 1 1/2 0

Using a refractometer measure freeze point of coolant. Match reading with a value under the Tested freeze point protections column. Determine cooling system volume and using chart, determine volume of coolant to drain from cooling system. Replace drained volume with coolant concentrate.

2005 ChevronTexaco Products Company. San Ramon, CA. All rights reserved.

USE REFRACTOMETER TO CHECK FREEZE PROTECTION

O VER CONCENTRATED

FREEZE PROTECTION OF SAMPLE MIXED 50/50 WITH WATER %AF IN COOLANT

FREEZE POINT ADJUSTMENT CHART FOR OVERCONCENTRATED SYSTEMS

(Use this chart to adjust your freeze point down to -35F)

TOTAL COOLANT SYSTEM VOLUME 10-GAL 11-GAL 12-GAL

7-GAL

8-GAL

9-GAL

13-GAL

14-GAL

15-GAL

VOLUME TO DRAIN AND REPLACE WITH DEIONIZED WATER

+10 +7 +5 0 -5 -6 -12 -18 -23 -29 -34

50 55 60 65 70 75 80 85 90 95 100

0 3/4 1-1/4 1-3/4 2 2-1/4 2-3/4 3 3 3-1/4 3-1/2

0 3/4 1-1/4 1-3/4 2-1/4 2-3/4 3 3-1/4 3-1/2 3-3/4 4

0 3/4 1-1/2 2-1/4 2-3/4 3 3-1/2 3-3/4 4 4-3/4 4-1/2

0 1 1-3/4 2-1/4 2-3/4 3-1/4 3-3/4 4-1/4 4-1/2 4-3/4 5

0 1 1-3/4 2-1/2 3-1/4 3-3/4 4-1/4 4-1/2 5 5-1/4 5-1/2

0 1-1/4 2 2-3/4 3-1/2 4 4-1/2 5 5-1/4 5-3/4 6

0 1-1/4 2-1/4 3 3-3/4 4-1/4 5 5-1/2 5-3/4 6-1/4 6-1/2

0 1-1/4 2-1/4 3-1/4 4 4-3/4 5-1/4 5-3/4 6-1/4 6-3/4 7

0 1-1/2 2-1/2 3-1/2 4-1/4 5 5-3/4 6-1/4 6-3/4 7-1/4 7-3/4

If refractometer reading is off scale or shows a freeze point for the sample lower than -62F, use the chart above to adjust the freeze point to -35F. To do this, take the coolant sample and dilute it 50/50 with water. Take a new refractometer reading and match this value to the reading under the Freeze protection of sample mixed 50/50 with water column. Determine your cooling system volume and based on the chart above, drain the recommended amount of coolant and relace that volume with water. Recheck freeze point.

2005 ChevronTexaco Products Company. San Ramon, CA. All rights reserved.

USE REFRACTOMETER TO CHECK FREEZE PROTECTION

2008 Chevron Products Company. San Ramon, CA. All rights reserved.

4 March 2008 COOL-40

S-ar putea să vă placă și

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDe la EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingEvaluare: 5 din 5 stele5/5 (3)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe la EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Desitherm BrochureDocument8 paginiDesitherm BrochureBrandon FordÎncă nu există evaluări

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisDe la EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisEvaluare: 5 din 5 stele5/5 (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe la EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- Retainning WallDocument14 paginiRetainning Wallahamedtouhid899Încă nu există evaluări

- PM High Strength Magnetic Alloys PDFDocument13 paginiPM High Strength Magnetic Alloys PDFSAMIT JAINÎncă nu există evaluări

- General: ASTM A351 Gr. CF3MDocument1 paginăGeneral: ASTM A351 Gr. CF3MPipeline EngineerÎncă nu există evaluări

- Delo® XLC Antifreeze-CoolantDocument5 paginiDelo® XLC Antifreeze-CoolantAymanSayedElantableeÎncă nu există evaluări

- Coolant Texaco 7997Document4 paginiCoolant Texaco 7997m_najmanÎncă nu există evaluări

- Cat CoolantDocument4 paginiCat CoolantMaqsood Ahmad100% (1)

- Ha Vol in Ed Ex CoolDocument4 paginiHa Vol in Ed Ex Coolsudhir5441Încă nu există evaluări

- Havoline Extended Life Antifreeze CoolantDocument6 paginiHavoline Extended Life Antifreeze CoolantNegru P. PlantatieÎncă nu există evaluări

- Product Data: Antifreeze NFDocument5 paginiProduct Data: Antifreeze NFJaya PranataÎncă nu există evaluări

- Calflo Heat Transfer FluidDocument4 paginiCalflo Heat Transfer FluidderekfisherÎncă nu există evaluări

- Diesel Exhaust Fluid (Def) : Aqueous Urea Solution For Your SCR Nox Reduction SystemsDocument2 paginiDiesel Exhaust Fluid (Def) : Aqueous Urea Solution For Your SCR Nox Reduction SystemsSonthiMÎncă nu există evaluări

- ELC DexCool PDSDocument3 paginiELC DexCool PDSMyOpel PartsÎncă nu există evaluări

- Zerex Extended Life Antifreez & Coolant (Valvoline)Document2 paginiZerex Extended Life Antifreez & Coolant (Valvoline)anibal_rios_rivasÎncă nu există evaluări

- Coolant For EngineDocument27 paginiCoolant For EnginemunhÎncă nu există evaluări

- Mobil Delvac Extended Life CoolantDocument2 paginiMobil Delvac Extended Life CoolantAnibal RiosÎncă nu există evaluări

- Tellus s2 MDocument3 paginiTellus s2 MSeindahNyaÎncă nu există evaluări

- How Much Do You Know About Heavy Duty CoolantDocument5 paginiHow Much Do You Know About Heavy Duty CoolantengrsurifÎncă nu există evaluări

- ES COMPLEAT™ AntifreezeCoolant - LT15548Document2 paginiES COMPLEAT™ AntifreezeCoolant - LT15548Cesar G.Încă nu există evaluări

- Características Líquido de ArrefecimentoDocument2 paginiCaracterísticas Líquido de ArrefecimentoMarcelo Hein da LuzÎncă nu există evaluări

- Fluid Recommendations ###Document5 paginiFluid Recommendations ###benjir shuvoÎncă nu există evaluări

- PDSDetail PageDocument4 paginiPDSDetail Pagemgamal1080Încă nu există evaluări

- Cat ElcDocument4 paginiCat ElcDoru IonÎncă nu există evaluări

- Absorption Chillers 07Document52 paginiAbsorption Chillers 07Sujadi Cherbond100% (1)

- S3 V46 DatasheetDocument3 paginiS3 V46 DatasheetNazim SalehÎncă nu există evaluări

- Shell Tellus S2 M 68 (en-GB) TDSDocument3 paginiShell Tellus S2 M 68 (en-GB) TDSJasmine TsoÎncă nu există evaluări

- Cooltreat Al EngDocument3 paginiCooltreat Al EngironiteÎncă nu există evaluări

- Tellus 46Document3 paginiTellus 46Vani YolganÎncă nu există evaluări

- FDbrochureDocument13 paginiFDbrochureAyman Mohammed Ibrahim AbdouÎncă nu există evaluări

- Cat Deac: Prevents Freezing While Providing Superior Component ProtectionDocument2 paginiCat Deac: Prevents Freezing While Providing Superior Component ProtectionEbied Yousif AlyÎncă nu există evaluări

- Dectron DSV Series CatalogDocument4 paginiDectron DSV Series Catalogbluemojo0% (2)

- Color Changing Antifreeze/Coolant: Montreal Toronto Edmonton VancouverDocument2 paginiColor Changing Antifreeze/Coolant: Montreal Toronto Edmonton VancouverDarmawan Putranto0% (1)

- Compatibilidad - SB - TB03-05-2Document2 paginiCompatibilidad - SB - TB03-05-2Cesar G.Încă nu există evaluări

- GEA KME Brochure Evaporadores SearleDocument12 paginiGEA KME Brochure Evaporadores SearleCarlos Labra FierroÎncă nu există evaluări

- DEUTCH Coolant PDSDocument2 paginiDEUTCH Coolant PDSHestySulistyaÎncă nu există evaluări

- Peak Final Charge 50-50Document2 paginiPeak Final Charge 50-50andymoreÎncă nu există evaluări

- Pakelo TDS - 2456.00 - ENGDocument3 paginiPakelo TDS - 2456.00 - ENGOrshanetzÎncă nu există evaluări

- Shell Tellus S2V 46Document3 paginiShell Tellus S2V 46mehmetaliozgurÎncă nu există evaluări

- AFC Compact Systems: GEA Searle KEC Air Cooler: Top-Level Engineering SolutionsDocument12 paginiAFC Compact Systems: GEA Searle KEC Air Cooler: Top-Level Engineering SolutionsJt LoutfiÎncă nu există evaluări

- Shell Tellus V: Industrial Hydraulic Fluid For Wide Temperature RangeDocument4 paginiShell Tellus V: Industrial Hydraulic Fluid For Wide Temperature RangeAxel Mahya AvichenaÎncă nu există evaluări

- Mercedes Benz Anti-Freeze TechDocument10 paginiMercedes Benz Anti-Freeze TechRahim HilmiÎncă nu există evaluări

- Dispelling The MythsDocument31 paginiDispelling The MythsViji55555Încă nu există evaluări

- Shell Tellus S2 M 46 (En) TDSDocument3 paginiShell Tellus S2 M 46 (En) TDSAnonymous oAbjbl4HÎncă nu există evaluări

- Shell Rotella ELC Libre de Nitrito Prediluido 50-50Document3 paginiShell Rotella ELC Libre de Nitrito Prediluido 50-50Jorge Arrieta TorresÎncă nu există evaluări

- GulfSea BD Hydraulic OilsDocument3 paginiGulfSea BD Hydraulic OilsObydur RahmanÎncă nu există evaluări

- ELC Data SheetDocument2 paginiELC Data SheetFabio Junior100% (1)

- Inbound 8675972274567913345Document4 paginiInbound 8675972274567913345Ñâü ĐáÎncă nu există evaluări

- Atlas Copco: P PA AR R E EG GDocument2 paginiAtlas Copco: P PA AR R E EG GHoang Minh HungÎncă nu există evaluări

- Technical Bulletin 019999011156 en KhlszstemschutzDocument13 paginiTechnical Bulletin 019999011156 en KhlszstemschutzIvarson SilvaÎncă nu există evaluări

- ELC Data Sheet PEHP9557Document4 paginiELC Data Sheet PEHP9557Суйунбай Солпуев100% (1)

- Clavus ABDocument2 paginiClavus ABDarmawan NugrohoÎncă nu există evaluări

- Automotive Coolant - General Information: Austech AC-10 Austech AC-9 Austech AC-2 Austech AC-1Document2 paginiAutomotive Coolant - General Information: Austech AC-10 Austech AC-9 Austech AC-2 Austech AC-1senthilkumar rangarajÎncă nu există evaluări

- Manual PN 51852 Aquavaire SupplementDocument20 paginiManual PN 51852 Aquavaire SupplementengenhariaÎncă nu există evaluări

- NALCOOL 2000 Nitrite Based Diesel Engine Corrosion & Scale Inhibitor - ChemEqualDocument1 paginăNALCOOL 2000 Nitrite Based Diesel Engine Corrosion & Scale Inhibitor - ChemEqualChemEqualÎncă nu există evaluări

- Use and Maintenance Guidelines Extended-Life (OAT and NOAT) CoolantsDocument4 paginiUse and Maintenance Guidelines Extended-Life (OAT and NOAT) CoolantsjahoohaÎncă nu există evaluări

- 56 Gpcdocxcbe24855key1400020442836623.pdf 4c8de734dde65Document3 pagini56 Gpcdocxcbe24855key1400020442836623.pdf 4c8de734dde65Robert GanÎncă nu există evaluări

- Boiler AUTOTREAT - 25 LTRDocument2 paginiBoiler AUTOTREAT - 25 LTRBINIT SINGHÎncă nu există evaluări

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe la EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsEvaluare: 5 din 5 stele5/5 (1)

- Whirlpool Awe 6515 WDocument41 paginiWhirlpool Awe 6515 WCoryl BlueÎncă nu există evaluări

- C-9 Fender SystemDocument31 paginiC-9 Fender Systemanupbhansali2004Încă nu există evaluări

- PDF Partees PrincipalesDocument13 paginiPDF Partees Principalesguapo86Încă nu există evaluări

- H2O2 Passivation ProcedureDocument8 paginiH2O2 Passivation ProcedureLim SenglinÎncă nu există evaluări

- WEG CFW 09 Ebc1 Board Guide 0899.4973 Installation Guide EnglishDocument16 paginiWEG CFW 09 Ebc1 Board Guide 0899.4973 Installation Guide EnglishEvandro LhpÎncă nu există evaluări

- Drilling Rig Selection - Guidelines Only)Document79 paginiDrilling Rig Selection - Guidelines Only)Edo Gawa77% (13)

- Project Report On GearsDocument40 paginiProject Report On Gearsjai70% (27)

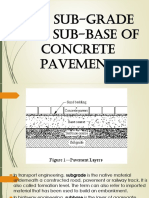

- The Sub-Grade and Sub-Base of Concrete PavementDocument16 paginiThe Sub-Grade and Sub-Base of Concrete PavementPatrick TaylorÎncă nu există evaluări

- GH 961Document1 paginăGH 961ÄhmêdÄBdulhåqÎncă nu există evaluări

- 11.asphalt Mix CuringDocument3 pagini11.asphalt Mix CuringGiorgos Siorentas100% (1)

- Yhj (K) E 12 To 24 Zjmexcorx: High Wall Inverter R-410A 60HzDocument6 paginiYhj (K) E 12 To 24 Zjmexcorx: High Wall Inverter R-410A 60HzAbraham AlvarezÎncă nu există evaluări

- Paint Master Bonding Liquid - TDSDocument2 paginiPaint Master Bonding Liquid - TDSMichael JoudalÎncă nu există evaluări

- Double Freq TransientDocument22 paginiDouble Freq TransientMelissa Miller100% (1)

- CH 02Document7 paginiCH 02hedayatullahÎncă nu există evaluări

- Sb70491atosh9 PDFDocument1 paginăSb70491atosh9 PDFCarlosÎncă nu există evaluări

- Check ValveDocument10 paginiCheck ValvekutecoolÎncă nu există evaluări

- Ammonia Synthesis CatalystsDocument16 paginiAmmonia Synthesis CatalystsSaqib Ali0% (1)

- Prashant Mishra ReportDocument27 paginiPrashant Mishra ReportPrashant MishraÎncă nu există evaluări

- MGO Chiller 120kW Cooling Spec. - PDFDocument7 paginiMGO Chiller 120kW Cooling Spec. - PDFAlexandros KritsotakisÎncă nu există evaluări

- Hindalco Rolled - Products - Cold - Rolleds PDFDocument4 paginiHindalco Rolled - Products - Cold - Rolleds PDFamitkdewÎncă nu există evaluări

- WEG Weg Automation Reference Codes Controls 50058173 Quick Guide EnglishDocument24 paginiWEG Weg Automation Reference Codes Controls 50058173 Quick Guide EnglishSergio Ricardo IbañezÎncă nu există evaluări

- Ch04 Design Calculation of Structures and Fatigue BehaviourDocument20 paginiCh04 Design Calculation of Structures and Fatigue Behaviourmostafa mostafaÎncă nu există evaluări

- Wall Treatments: Arshpreet Kaur Matharoo L-2015-HSC-10-BIDDocument38 paginiWall Treatments: Arshpreet Kaur Matharoo L-2015-HSC-10-BIDAISXOXOÎncă nu există evaluări

- Is 7001 1989Document14 paginiIs 7001 1989Kevin100% (1)

- 05 Fuel SystemDocument109 pagini05 Fuel SystemUtomo BudidarmoÎncă nu există evaluări

- Guide To Epoxy Grouting: Foundation Preparation FormingDocument2 paginiGuide To Epoxy Grouting: Foundation Preparation FormingerleosÎncă nu există evaluări

- Pages From DESIGN OF STEEL STRUCTURES (NORSOK) - 4Document6 paginiPages From DESIGN OF STEEL STRUCTURES (NORSOK) - 4dunglxÎncă nu există evaluări