Documente Academic

Documente Profesional

Documente Cultură

Piping Fabrication and Design

Încărcat de

Reyz CroewDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Piping Fabrication and Design

Încărcat de

Reyz CroewDrepturi de autor:

Formate disponibile

Fabrication and design 1.

A flange to nozzle joint for vessel design for lethal subtances may be type 1, 2 or slip on? B. False (UW-11 a) 2. If pipe is ordered by its nominal wall thickness?c. The manufacturing undertolerance on wall thickness shall taken into account (UG-16 d) 3. Joint permitted by the code, in which joint efficiency may be improved though the performance of radiography are limited to?b. Type 1 or 2 (UW 12) 4. Impact testing is required for SA 516 gr 65 material when nominal thickness is 0.75 and MDMT 0 oF? B. False (UG-20f) 5. Plastic Deformation occurs when stress is? B. Above the elastic limit 6. AI not required to make visual inspection on root of joint type 3? A. True 7. The edge of material shall be examined to detect the presence of? UG 93 d 1 (Lamination, shearing crack) 8. On a 7/8 thickness of head made from SA 516 grade 70 it is found that the extreme elongation fiber is 7%, it is need to PWHT as per UCS 56? No. Refer to UCS 79 9. What is the nominal thickness to be used in table UCS 56 when joining 1.5 and 1 inch thick material by full penetration butt joint? C. 1 inch (UW40 f 5) 10.Single welded butt joint without backing not verified as meting UW 35 are joint? C. Type 3 (UW 12) 11.The original marking may be transfered provided? C. If covered by written quaality system (UG-77a) 12.A flange to nozzle joint is category? C (UW-3) 13.Pemitted joint detail for nozzle to shell connection for vessel to contain lethal substance?a. as figure UW 16 a-f (UW 2, lethal substance = full penetration, type 1) 14.For a 48 nominal inside diameter head the maximum dviation outside of the specific shape is? 0.6 (UG-81 a) 1.25% ID 15.Type 3 joint may be use to weld circumferential and longitudinal on 20 OD and 0.5 thickness PV? False. (UW 12) 16.24 cylindrical shell with 6 nominal inside diameter nozzle. The maksimum out of roundness at a cross section passing through the opening is? 0.36 (UG-80)

17.Weld indication by spot radiography where roundd indication in excess of specified in App 4 RT shall be considered unacceptable? Yes (UW 51) 18.The minimum thickness for shell after forming of PV used for compressed air service is? C. 3/32 exclusive CA (UG 16 4) 19.Is it allowed by ASME VIII to use welded pipe supplied by pipe mill for shell? Yes (UG-9) 20.Is manufacturee rquired ASME VIII to maintained traceability included heat number of pipe material used for pressure part? Yes (UG-77) 21.When youare performing material receiving inspection you found that the surface of an 100 elipsoidal head has deviated inside due to mechanical reason by 0.5. Is this acceptable? Yes (UG 80-2) 22.Is it permitted to attached NPS 2 to nozzle not comply with UG-37 on category A without additional requirement? No (UW-14) 23.The governing thickness be used to determining MDMT of material for nozzle to shell joint (without reinforcing pad is)? Thickness of material and thickness of shell 24.The requirement to make vessel production test is not applicable for joint category B provided that joint is made by using the same WPS as per joint category A? True (UG-84 i) 25.Tapered, UW 9 c

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Research Topics For Economics Thesis in PakistanDocument7 paginiResearch Topics For Economics Thesis in PakistanStacy Vasquez100% (2)

- 2017 Lecture 3 Metal Carbonyls PDFDocument28 pagini2017 Lecture 3 Metal Carbonyls PDFMahnoor FatimaÎncă nu există evaluări

- LAB - Testing Acids & BasesDocument3 paginiLAB - Testing Acids & BasesRita AnyanwuÎncă nu există evaluări

- PESTEL AnalysisDocument2 paginiPESTEL AnalysisSayantan NandyÎncă nu există evaluări

- Sears Canada: Electric DryerDocument10 paginiSears Canada: Electric Dryerquarz11100% (1)

- Software Requirements CompressDocument9 paginiSoftware Requirements CompressApni Duniya100% (1)

- Electrochemistry DPP-1Document2 paginiElectrochemistry DPP-1tarunÎncă nu există evaluări

- Paper 5Document4 paginiPaper 5hbyhÎncă nu există evaluări

- Comparative ApproachDocument12 paginiComparative ApproachSara WongÎncă nu există evaluări

- Advertisement For Recruitment of Non-Teaching StaffDocument3 paginiAdvertisement For Recruitment of Non-Teaching StaffGoogle AccountÎncă nu există evaluări

- Problem Sheet 3 - External Forced Convection - WatermarkDocument2 paginiProblem Sheet 3 - External Forced Convection - WatermarkUzair KhanÎncă nu există evaluări

- What Is NanoWatt TechnologyDocument1 paginăWhat Is NanoWatt Technologyfolk_sharathÎncă nu există evaluări

- BE 503 - Week 1 - Analysis 7.18.11Document6 paginiBE 503 - Week 1 - Analysis 7.18.11dwoodburyÎncă nu există evaluări

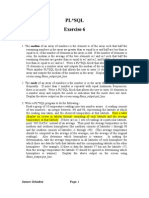

- PL SQL Exercise6Document2 paginiPL SQL Exercise6Nishant AndhaleÎncă nu există evaluări

- Lecture Notes 1 - Finance - Principles of Finance Lecture Notes 1 - Finance - Principles of FinanceDocument7 paginiLecture Notes 1 - Finance - Principles of Finance Lecture Notes 1 - Finance - Principles of FinanceKim Cristian MaañoÎncă nu există evaluări

- Thinking Out LoundDocument2 paginiThinking Out LoundExita ConiaÎncă nu există evaluări

- Mil Tos (1ST Quarter)Document3 paginiMil Tos (1ST Quarter)Rhea Carillo100% (14)

- Design Report of STOL Transport AircraftDocument64 paginiDesign Report of STOL Transport Aircrafthassan wastiÎncă nu există evaluări

- Shakespeare Ubd Unit PlanDocument16 paginiShakespeare Ubd Unit Planapi-239477809Încă nu există evaluări

- Swot Ananlysis of Fintech CompaniesDocument7 paginiSwot Ananlysis of Fintech CompaniesUyen Le VuÎncă nu există evaluări

- Getting Started HANADocument86 paginiGetting Started HANAAr RazaÎncă nu există evaluări

- Awareness On Stock MarketDocument11 paginiAwareness On Stock MarketBharath ReddyÎncă nu există evaluări

- Barista TestDocument7 paginiBarista Testwinnie chanÎncă nu există evaluări

- Effect of Spent Engine Oil On The Internal Structure of Corchorus OlitoriusDocument55 paginiEffect of Spent Engine Oil On The Internal Structure of Corchorus Olitoriusanon_568621284Încă nu există evaluări

- Differentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2Document186 paginiDifferentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2integrationbyparths671Încă nu există evaluări

- Pre-Colonial Philippine ArtDocument5 paginiPre-Colonial Philippine Artpaulinavera100% (5)

- Balfour Castle EstateDocument20 paginiBalfour Castle EstatejahumphriesÎncă nu există evaluări

- OMNI OptixDocument4 paginiOMNI OptixFelipe MoyaÎncă nu există evaluări

- Jibachha's Textbook of Animal Health Volume-IIDocument16 paginiJibachha's Textbook of Animal Health Volume-IIjibachha sahÎncă nu există evaluări

- EWC 662 English Writing Critical Group Work Portfolio: Submitted ToDocument31 paginiEWC 662 English Writing Critical Group Work Portfolio: Submitted ToNurul Nadia MuhamadÎncă nu există evaluări