Documente Academic

Documente Profesional

Documente Cultură

STRUCTURAL CONCRETE WORK METHOD

Încărcat de

Roland Tio67%(3)67% au considerat acest document util (3 voturi)

2K vizualizări3 paginiWhen mixed in the correct amounts, concrete is a stable and versatile building medium which can be used in a variety of applications. Concrete is composed of cement, sand, aggregate (sized stone), and water. Versatility in building application is accomplished by altering the proportions of air and other variables in the mixture.

Descriere originală:

Titlu original

Method Statement - Concreting Work

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentWhen mixed in the correct amounts, concrete is a stable and versatile building medium which can be used in a variety of applications. Concrete is composed of cement, sand, aggregate (sized stone), and water. Versatility in building application is accomplished by altering the proportions of air and other variables in the mixture.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

67%(3)67% au considerat acest document util (3 voturi)

2K vizualizări3 paginiSTRUCTURAL CONCRETE WORK METHOD

Încărcat de

Roland TioWhen mixed in the correct amounts, concrete is a stable and versatile building medium which can be used in a variety of applications. Concrete is composed of cement, sand, aggregate (sized stone), and water. Versatility in building application is accomplished by altering the proportions of air and other variables in the mixture.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

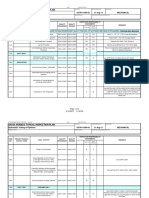

SENSASI ARMADA SDN. BHD.

METHOD STATEMENT STRUCTURAL CONCRETE WORK

INTRODUCTION Concrete is composed of cement, sand, aggregate (sized stone), and water. When mixed in the correct amounts, concrete is a stable and versatile building medium which can be used in a variety of applications ranging from roads, bridges and buildings, to septic tanks and even countertops for household use. The versatility in building application is accomplished by altering the proportions of air and other variables in the mixture. Strengthening materials such as re-bar, fiberglass strands, and plastic rods are then added. OBJECTIVE Method on how the concreting works are carried out safely. PLANT, MACHINERY AND EQUIPMENT Tower Crane / Mobile Crane, Concrete Pumps, Concreting Buckets, Vibrators, Wheelbarrows, etc. as applicable SAFETY REQUIREMENT The following personal protective equipments (PPE) are required: 1. Hard Hats 2. Rubber hand gloves 3. Rubber water boots 4. Safety Goggles 5. Safety Harness Applicable to working at height FORMWORK Formwork is the surface, supports and framing used to define the shape of concrete until the concrete is self-supporting. It includes the forms on which the concrete is poured, the supports to withstand the loads imposed by the forms and the concrete and any bracing added to ensure stability. WHEN USING CONCRETE FORMWORK 1. Certification of design must be provided by suitably qualified person (PE Practicing Engineer) 2. All framing must be completed so it complies with on site design documentation and manufacturers requirement. 3. Erection of formwork scaffold supports must be supervised by competent scaffolder registered with DOSH (Department of Occupational Safety and Health)

PREPARED BY: TIO KEAN HIN SAFETY AND HEALTH OFFICER REG. JKKP IS 127/438/2/1323

SENSASI ARMADA SDN. BHD.

PREPARATORY WORKS 1. Request for design mix based on the concrete grades specified on the structural drawings. 2. Submit the proposed design mix to client / clients representative for approval. 3. Carry out trial-mix of the design mix under the supervision of clients representative. 4. Prepare and conduct concrete test cube testing under the supervision of clients representative to determine the concrete design strength. Submit the results for approval. WORK METHODOLOGY This is a generic Work Method Statement. All works beyond the scope of this WMS shall be subject to a Job-Specific Job Safety Analysis (JSA). All construction workers engaged in the concrete pouring shall be inducted into the job-specific JSA. 1. Erection of scaffold supports for formworks supervised by a competent scaffolder in accordance with PEs design. All scaffold components supplied must be SIRIM approved. 2. Lay framings for beams and floor slabs as per PEs design. Ensure all framing timbers are of specified size in good condition free from defects. 3. As the floor installation is proceeding, it is imperative that the electrician follows closely behind, to install the various conduits/wiring. All conduits and similar service installations are to be placed under the top chord bar of the lattice.beam girder to ensure sufficient cover to the mesh reinforcement. Similarly, the plumber should be on-site to locate his service penetrations and fire collars, which should fall within the area of the void formers. 4. The specified mesh reinforcement is placed over and tied securely. 5. Reinforcing mesh fabric shall be lapped two (2) traverse wires Plus 50mm. and spacer chairs to be used in between layers of mesh. 6. After all reinforcement re-bars and mesh are placed and tied in accordance with design drawing and prior to concrete pouring, the formwork is given a final blowing and cleaning out the dirt and scraps. 7. Submit request for inspection of structural members with client / clients representative prior to concreting works using Structural Work (Reinforcement / Concrete) Inspection Checklist and Inspection and Test Plan. 8. Final inspections of formwork scaffold supports and props to be carried out and certified by competent person.

PREPARED BY: TIO KEAN HIN SAFETY AND HEALTH OFFICER REG. JKKP IS 127/438/2/1323

SENSASI ARMADA SDN. BHD.

9. After approval sought, formwork is ready to receive concrete pouring. Pour the concrete on designated locations using concrete pumps and / or crane assisted concrete buckets. 10. Pour concrete from the lowest point to the final concrete level in one operation in horizontal layers. 11. Compact concrete by mechanical vibrators. Ensure that concrete is worked into corners of the structural members. 12. After the concrete has set, carry out curing works by applying curing compound. RISK ASSESSMENT AND CONCLUSION During Erection of Formwork Scaffold Support 1. Falling Object Wear hard hat. 2. Fall from height Wear safety harness and proper working platform. 3. Human Error - Training and Safe Operating Procedure. During Formwork Framing and Decking 1. Fall from height Wear edge restrain safety harness and erect barricades. 2. Trip and Fall carry out regular housekeeping During Concrete Pouring 1. Chemical Contact Wear rubber hand gloves ,rubber boots and safety goggle 2. Hit by concrete bucket Safe Hoisting Procedure 3. Failure of Support site surveillance and monitoring.

Date Prepared: 18 February 2013 Reviewed By:

Lu Peng Khim - Project Manager

PREPARED BY: TIO KEAN HIN SAFETY AND HEALTH OFFICER REG. JKKP IS 127/438/2/1323

S-ar putea să vă placă și

- MOS - Concrete Works 07.18 R-0Document9 paginiMOS - Concrete Works 07.18 R-0RABIE EL MAGHWRY ABDELKHALEK ELGHAMRYÎncă nu există evaluări

- Method Statement FlooringDocument11 paginiMethod Statement Flooringmanish100% (1)

- Method Statement For ScaffoldingDocument3 paginiMethod Statement For Scaffoldingamg007100% (5)

- 3.method Statement of Structure Work-Eng PDFDocument85 pagini3.method Statement of Structure Work-Eng PDFSiampol Feepakphor100% (1)

- Method Statement of Concreting WorkDocument4 paginiMethod Statement of Concreting WorkChairul Fajri100% (10)

- Method Statement of Steel FabricationDocument15 paginiMethod Statement of Steel Fabricationjohney290% (10)

- Method Statement For Concrete Works (Rev.01)Document12 paginiMethod Statement For Concrete Works (Rev.01)EmadHassan0% (1)

- Method Statement for Parapet ConstructionDocument8 paginiMethod Statement for Parapet Constructionsonusweetyshobha100% (2)

- WMS (Method Statement For Formwork, Reinforcement and Concrete Works)Document9 paginiWMS (Method Statement For Formwork, Reinforcement and Concrete Works)PUI CHEE KHIAN100% (1)

- Method Statement Slab & Beam ConcretingDocument3 paginiMethod Statement Slab & Beam Concretingudithairesha100% (6)

- Method Statement For Retaining Wall Work ExecutionDocument3 paginiMethod Statement For Retaining Wall Work ExecutionSujeet SarukÎncă nu există evaluări

- Block Work-Method StatementDocument7 paginiBlock Work-Method StatementA1994486% (22)

- Method Statement for Backfilling WorkDocument4 paginiMethod Statement for Backfilling WorkEngr Muhammad SohailÎncă nu există evaluări

- P610 Beinn Eagagach Hydroelectric Scheme Construction MethodDocument14 paginiP610 Beinn Eagagach Hydroelectric Scheme Construction MethoddjgiumixÎncă nu există evaluări

- Method Statement Concrete Works PDFDocument18 paginiMethod Statement Concrete Works PDFdndudc95% (22)

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Document9 paginiMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepÎncă nu există evaluări

- Method Statement For Claustra Block Works.Document12 paginiMethod Statement For Claustra Block Works.sathiyaprasath80% (5)

- A Typical Method Statement For Roofing WorksDocument2 paginiA Typical Method Statement For Roofing Worksngian196250% (4)

- Method Statement of Brick WorksDocument2 paginiMethod Statement of Brick WorksMohamed Romeo Pixoto82% (11)

- Earthworks Method Statement - 1Document5 paginiEarthworks Method Statement - 1Liz LizzyÎncă nu există evaluări

- Method Statement FOR Acoustic Ceiling TilesDocument12 paginiMethod Statement FOR Acoustic Ceiling Tilesraks07010% (1)

- Method of Statement For PlasteringDocument6 paginiMethod of Statement For PlasteringScott Campbell100% (3)

- Method Statement For Formworks, Rebars, Cast-In-Situ ConcreteDocument28 paginiMethod Statement For Formworks, Rebars, Cast-In-Situ ConcreteAzhar Ali87% (15)

- Method Statement For Earth WorksDocument3 paginiMethod Statement For Earth WorksMin Min Soe0% (1)

- NUTL Building Formwork MethodDocument28 paginiNUTL Building Formwork MethodSimplicio Goncalves100% (1)

- Formwork Method StatementDocument3 paginiFormwork Method Statementsarathirv693% (14)

- Method Statement For Columns2Document5 paginiMethod Statement For Columns2Jasmine TsoÎncă nu există evaluări

- Method Statement For Ceramic Tile WorksDocument12 paginiMethod Statement For Ceramic Tile Worksprasath_subramanian100% (11)

- Method Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامDocument20 paginiMethod Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامM.ZEKEBA0% (1)

- Earth Work Method StatementDocument5 paginiEarth Work Method StatementToyEn MEgat100% (1)

- Construction Method Statement GuideDocument30 paginiConstruction Method Statement GuideEmad Rakat86% (7)

- Method Statement - Crack Control Joint For CCB RC WallDocument7 paginiMethod Statement - Crack Control Joint For CCB RC WallReza RosenoÎncă nu există evaluări

- Method Statement For Roadbase ConstructionDocument3 paginiMethod Statement For Roadbase ConstructionNordin Yunus93% (84)

- Method Statment (Structural Works)Document9 paginiMethod Statment (Structural Works)Hazem Shaker Abu Shaaban100% (2)

- 3) Method Statement For Formwork Steel & Concrete WorkDocument9 pagini3) Method Statement For Formwork Steel & Concrete WorkMukesh PrajapatÎncă nu există evaluări

- Construction of Dormitory & Housing compounds in NorochcholaiDocument33 paginiConstruction of Dormitory & Housing compounds in Norochcholaisaranga100% (1)

- Construction Method StatementDocument13 paginiConstruction Method StatementblackwellkidÎncă nu există evaluări

- Method Statement For Conventional Formwork BlogDocument9 paginiMethod Statement For Conventional Formwork BlogMohasin KhanÎncă nu există evaluări

- Renovations Method StatementDocument6 paginiRenovations Method StatementOfentse Ledwaba100% (1)

- Bulk Earthworks - Method StatementDocument4 paginiBulk Earthworks - Method Statementmemekenya0% (1)

- Method Statement of Soft-Landscape at PodiumDocument9 paginiMethod Statement of Soft-Landscape at PodiumFairuz100% (1)

- Method Statement of Concreting Pile Cap Rev02Document3 paginiMethod Statement of Concreting Pile Cap Rev02Mohd Hafizul Hj Tanalol75% (4)

- Method of Statement Column and Access With Water MarkDocument11 paginiMethod of Statement Column and Access With Water MarkManu MohanÎncă nu există evaluări

- Qatar Building Engineering Company Earthwork Inspection PlanDocument4 paginiQatar Building Engineering Company Earthwork Inspection PlanPageduesca RouelÎncă nu există evaluări

- Roof Truss InstallationDocument8 paginiRoof Truss InstallationSai Shankar LakshminarayananÎncă nu există evaluări

- Method Statement For Masonry WorksDocument10 paginiMethod Statement For Masonry WorksLabanKaruhangaÎncă nu există evaluări

- Method Statement for Concrete WorksDocument7 paginiMethod Statement for Concrete WorksArthur Ruhinda100% (1)

- Method Statement For Excavation and Backfilling WorksDocument2 paginiMethod Statement For Excavation and Backfilling WorksAnonymous wTTx1L86% (22)

- Uganda Entebbe International Airport Upgrading and Expansion Project Steel Work Method StatementDocument14 paginiUganda Entebbe International Airport Upgrading and Expansion Project Steel Work Method StatementAkatwijuka AllanÎncă nu există evaluări

- MS For MasonryDocument23 paginiMS For MasonryThimira Bandara EkanayakeÎncă nu există evaluări

- T211 Method Statement - RC SlabDocument11 paginiT211 Method Statement - RC SlabStephen David GozunÎncă nu există evaluări

- CONSTRUCTION DRAINAGE WORKS STATEMENTDocument5 paginiCONSTRUCTION DRAINAGE WORKS STATEMENTYin Mohd100% (4)

- Method Statement For Slab On GradeDocument3 paginiMethod Statement For Slab On Grademustafa75% (4)

- Method of Statement For The Construction of RC Pipe Support - R0Document3 paginiMethod of Statement For The Construction of RC Pipe Support - R0Cornelius AnthonyÎncă nu există evaluări

- R.C.C. Columns and Shear Walls Construction Method StatementDocument2 paginiR.C.C. Columns and Shear Walls Construction Method StatementVVRAO100% (1)

- Mos For Gypsum PartitionsDocument8 paginiMos For Gypsum PartitionsCamlockÎncă nu există evaluări

- Method Statement For Construction of Compound WallDocument12 paginiMethod Statement For Construction of Compound Walljones71% (7)

- Residential Apartment ConstructionDocument21 paginiResidential Apartment ConstructionNAVEENGKSÎncă nu există evaluări

- Waterproofing Screed Installation GuideDocument5 paginiWaterproofing Screed Installation Guideramtsan100% (2)

- Gargoyle Arctic SHC NHDocument1 paginăGargoyle Arctic SHC NHtribolasÎncă nu există evaluări

- BME Unit IV Machine ToolsDocument41 paginiBME Unit IV Machine ToolsArvind BhosaleÎncă nu există evaluări

- KF 006 Grid CouplingsDocument30 paginiKF 006 Grid CouplingsShravan VogulamÎncă nu există evaluări

- Plumbing: Wholesale CatalogDocument92 paginiPlumbing: Wholesale CatalogTan Kang YaoÎncă nu există evaluări

- Erucic Acid PDFDocument3 paginiErucic Acid PDFVivek VikramÎncă nu există evaluări

- ECOM6008 12 Project GuidelineDocument4 paginiECOM6008 12 Project GuidelinerierunaruÎncă nu există evaluări

- Satip A 004 03Document3 paginiSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Operations Management Assignment PDFDocument4 paginiOperations Management Assignment PDFanteneh tesfaw0% (2)

- Airlight Energy Vue D'ensemble Projet CSPDocument11 paginiAirlight Energy Vue D'ensemble Projet CSPusinemaroc100% (2)

- Fundamentals of Maintenance ManagementDocument161 paginiFundamentals of Maintenance Managementwessamalex100% (3)

- Chapter-5 Design of Welded JointsDocument15 paginiChapter-5 Design of Welded JointsVarshaÎncă nu există evaluări

- Electrical Discharge MachiningDocument16 paginiElectrical Discharge MachiningRizwan MrnÎncă nu există evaluări

- Chapter 1 PDFDocument12 paginiChapter 1 PDFAdoree RamosÎncă nu există evaluări

- Codes Standards For On Site Testing LaboratoryDocument7 paginiCodes Standards For On Site Testing LaboratoryVipin Kumar ParasharÎncă nu există evaluări

- Mr. A. Panchariya Dept. of Mech. Engg. MNIT JaipurDocument143 paginiMr. A. Panchariya Dept. of Mech. Engg. MNIT JaipurAnand KumarÎncă nu există evaluări

- Absorption and Variable CostingDocument8 paginiAbsorption and Variable CostingGerard Beltran ArcaÎncă nu există evaluări

- Chap 5 8 Reviewer PDFDocument20 paginiChap 5 8 Reviewer PDFriiiÎncă nu există evaluări

- 2016 Osprey Skate CatalogueDocument84 pagini2016 Osprey Skate CatalogueDarkangelcaliÎncă nu există evaluări

- Taiwan Turnkey-Project Information - Aluminum Alloy Wheel Making PlantDocument1 paginăTaiwan Turnkey-Project Information - Aluminum Alloy Wheel Making PlantFelicia Wagner100% (1)

- Smart Gas Lift ValveDocument8 paginiSmart Gas Lift ValveAhmed MamdouhÎncă nu există evaluări

- Multiple Hearth Furnaces B3Document3 paginiMultiple Hearth Furnaces B3Ossy DewintaÎncă nu există evaluări

- Flat Type+epoxy+floor+coatingDocument3 paginiFlat Type+epoxy+floor+coatingRuano Andreola StumpfÎncă nu există evaluări

- Is 4454 1 2001 PDFDocument15 paginiIs 4454 1 2001 PDFSunitSGalimathÎncă nu există evaluări

- Effect of Powder Mixed Electric Discharge Machining (PMEDM) On Various Materials With Different Powders: A ReviewDocument6 paginiEffect of Powder Mixed Electric Discharge Machining (PMEDM) On Various Materials With Different Powders: A ReviewIJIRSTÎncă nu există evaluări

- Designated Trade DivisionsDocument9 paginiDesignated Trade Divisionschi hin choyÎncă nu există evaluări

- p5 p6 m3 Industrial Robots and Flexible Manufacturing Systems in Engineering2Document5 paginip5 p6 m3 Industrial Robots and Flexible Manufacturing Systems in Engineering2hi_am_balajiÎncă nu există evaluări

- Cat 320D Excavator PDFDocument28 paginiCat 320D Excavator PDFtomaustinÎncă nu există evaluări

- Fixing Procedure For FRP-GRP PipesDocument5 paginiFixing Procedure For FRP-GRP Pipesvenka07100% (1)

- Minh Viet HR - ProfileDocument23 paginiMinh Viet HR - ProfileAriesNhaÎncă nu există evaluări

- 06 - 1 Cutting Tools - 2013 - LRDocument17 pagini06 - 1 Cutting Tools - 2013 - LRBaggerkingÎncă nu există evaluări