Documente Academic

Documente Profesional

Documente Cultură

Shubham Reportmn, MN

Încărcat de

Ajit JainTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Shubham Reportmn, MN

Încărcat de

Ajit JainDrepturi de autor:

Formate disponibile

1

SUMMER TRAINING AT PANKI THERMAL POWER STATION

PTPS

KANPUR

UPRVUNL

SUBMITTED BY: SHAILENDRA PRATAP SINGH B.TECH, 3rd YEAR MECHANICAL ENGINEERING (MPD)PTPS,KANPUR(U.P) ROLL NO. : 1004540046

SUBMITTED TO: Mr. T.C.GUPTA EXECUTIVE ENGINEER MAINTENANCE AND PLANNING DIVISON

HARCOURT BUTLER KANPUR-208002

TECHNOLOGICAL INSTITUTE,

ACKNOWLEDGEMENT

I am extremely thankful to the members of Panki Thermal Power Station (PTPS), Kanpur for their kind support and co-operation during my 4 weeks of training period. I would like to acknowledge Mr. T.C.Gupta(Assistant Engineer, Maintainance and Planning divison (MPD IV) for giving me this fortunate chance to learn the various applications of mechanical engineering in real life. I express my sincere gratitude towards him for his wonderful guidance in the department and making me understand the various stages of thermal power generation.I also express my respectful gratitude towards all other engineers and technical staff at MPD for their help and guidance during my training period. Finally, I thank all those who have helped me in the success of my training program. They have added a lot to my knowledge.

SHAILENDRA PRATAP SINGH B.Tech 3rd year Mechanical Engineering HBTI Kanpur

CERTIFICATE

It is certified that SHAILENDRA PRATAP SINGH, student of 3rd B.Tech Mechanical Engineering H.B.T.I. Kanpur has worked on the Project on PTPS Kanpur under my guidance and supervision. He has shown sincere efforts and keen interest during preparation of this project report. My best wishes are with him, his efforts and his future endeavours. Mr. T.C.GUPTA Assistant Engineer MPD IV PTPS Kanpur

INDEX

S. NO. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Acknowledgement Index Introduction Organisational Set-up Various divisions for effective working of PTPS Water Treatment Plant Boiler and Boiler auxiliaries system Oil Handling Plant Coal Handling Plant Milling System Coal firing system in the boiler furnace Details of Boiler at PTPS Specifications of the boiler Steam generating units and auxiliaries Technical specifications of the Milling Plant and Fuel Firing System CONTENTS PAGE NO. 2 4 6 8 11 13 15 15 16 17 19 20 23 25 28

15.

Turbine Maintenance Department (TMD) Compounding of the steam turbines Governing system of turbine Turbine protection testing Turbine oil pressure regulating system Specifications of 110 MW Turbine Important features of Turbine

30 31 31 31 32 33 34 34 35 35 36 36 37 38 38 38 38 39 42 43 44 44 44 45 45 46 48 50 52

16. 17.

Electronic instruments useful for the plant Training in Electrical Maintenance Division (TMD) Rating of Transformers of Unit 3 and Unit 4 Current Transformer (CT) Potential Transformer (PT) Generator and Exciter Introduction to Switch gears, Circuit Breakers and Relays Devices used for circuit breaking (making) Fuse and Iron Clad Switches Isolators Circuit Breakers Thermal Relays Grid Substation Wave Trap Switch Yard Tracks for Transformer Control & Instrumentation Division Various instruments of the C & I department Turbo Supervisory equipments Water Pollution Control Air Pollution Control Conclusion

18.

19.

INTRODUCTION

In India there is a very long chain of thermal power project including the project in UP. Some of the power projects under Uttar Pradesh Rajya Vidyut Utpadan Nigam Ltd. (UPRVUNL) are as follows: S.No. Name of Power Project 1 Harduaganj A 2 Harduaganj B 3 Harduaganj C 4 Panki, Kanpur 5 Obra 6 Obra ext. 7 Anpara 8 Anpara ext. 9 Pariksha No. of Units 3 4 3 2 8 5 3 2 2 Capacity(MW) 90 210 230 210 550 1000 630 1000 220

Panki Thermal Power Station:

With the industrial development of Kanpur, a thermal power station was established at the banks of river Ganga, in the year 1923, which was known as Riverside Power House (RPH). In the year 1947, RPH was taken over by the Government of UP under the name of Kanpur Electricity Supply Administration (KESA). In 1962, RPH reached its maximum capacity of 100 MW leaving no scope of future development. Government of India approved setting up of power station having capacity of 64 MW (2x32 MW). The new plant was inaugurated on 17 Sep 1968 by the Prime Minister, Smt. Indira Gandhi. In the year 1976, two units of 110 MW each were installed to meet the increasing power demand. These units were inaugurated on 30 Jun 1976, by the Chief Minister of UP, Mr. N.D.Tiwari.

At present 2x32 MW units are not operating due to not having the suitable Pollution control machinery. The Central government has commissioned a 210 MW unit at Panki Power Station. At PTPS, 2x105 MW BHEL made coal fired turbo generating units are presently in operation. These 105 MW machines were manufactured, supplied and commissioned by M/s BHEL, during 1976-77 with features of reheating and regenerative feed heating. The Steam Generator is balanced draft, radiant, dry bottom, single drum, natural circulation, vertical water tube type construction with skin casing and semi direct type of firing system. Apart from the above 105 MW units, 2x32 MW Russia made turbo generating units were also installed at PTPS in 1967-68, however these units have become obsolete and permanently closed now after running for about 30 years. Location: PTPS is located in the West Kanpur in between Kalpi Road & the famous Grand Trunk Road and is 16 km distant from the Kanpur Central Railway Station. It is situated on the banks of lower Ganga canal and is connected with the Panki railway station for the easy transportation of coal. Availability of Raw Material at PTPS: The main raw materials used in the plant are as follows: Raw Material Water Coal Petroleum Products Source Lower Ganga Canal Jharia Mines of Coal India Ltd., Bihar Indian Oil Corporation Ltd., Kanpur

ORGANISATIONAL SET-UP

CHAIRMAN DIRECTORS GENERAL MANAGER

DGM (1) Operation & Maintenance

DGM (2) Electrical

DGM (3) Coal Handling Stare & Civil

DGM (4) Headquarters

DGM(I)

Operation Group

Maintenance Group

EE

GP(A)

EE

GP(B)

EE

GB(C)

EE

GP(D)

EE

TMD

EE

BMD

EE

OPERATION GENERAL

AE AE

AE AE

AE AE

AE AE

AE AE

AE AE

9 AE AE AE AE AE AE AE AE AE AE AE AE OG1 AE AE OG2 AE AE

DGM (2) (ELECTRICAL)

Control & Instrumentation

EMD

EDD

Central Purchase Division

EE

EE

EE

EE

AE AE AE AE

AE AE AE AE AE

AE AE AE

AE AE AE

DGM (3)

EE

EE EFFI Division

EE TRM

Transport Division

Central Purchase Division

AE AE

AE

AE

EE

AE AE

AE

10

HQ

Store Division AE AE AE Power House Dispensary Civil Maintenance Division AE AE AE AE AE

ADMINISTRATIVE STRUCTURE OF PTPS Employee of factory Circle officer Divisional officer Sub-divisional officer Staff : : : : : GM Superintending Engineer Executive Engineer Assistant Engineer Operators, Technicians & 4th class employee

The whole set up of management is known as a circle. The total number of employees in PTPS is 1536.

11

VARIOUS DIVISIONS FOR EFFICIENT WORKING OF PTPS

Water Treatment Plant (WTP): This division separates the physical and chemical impurities of water. Coal Handling Division (CHD): This division takes care of efficient supply of coal and oil fuel to the power plant. Boiler Maintenance Division (BMD): This division looks after the efficient working and performance of boiler, its mounting, its accessories, feed pump, milling system etc. Turbine Maintenance Division (TMD): This division looks after the efficient working of turbine and its accessories. Electrical Maintenance Division (EMD): This division takes care of the electrical networks and its elements in the power station. Control and Instrumentation Division (C & I): This division takes care of various instruments fitted in the power plants for controlling the generation of electricity. Electrical Distributors Division: This division looks after the distribution of produced electricity to the grid. Civil Maintenance Division: This division looks after the construction and maintenance of various structures in the power plant. Operation General Division (OG 1): This division takes care of the sanitation and cleaning etc of the power plant.

12

Operation General Division (OG 2): This division is responsible of the management of the power station. It deals with the salaries of employees, recording and sending data related to the performance of the power plant to the Head Office. Store and Purchase Division: This division deals with the storage and supply of various spare parts requires in the power house along with their purchase. Transportation Division: This division looks after the transportation of coal.

13

WATER TREATMENT PLANT

The water treatment plant is required as the water from canal cannot be directly used in the boiler because it contains physical and chemical impurities which have an adverse effect on plant operation. The turbidity of this canal water is 80. The water used in the boiler is Demineralised water (i.e. DM water). Water from the canal is drawn by the pump house where large physical impurities are operated by a screen having a net. This water is converted into DM water in the following stages: Flculator Plant: In this plant the alum is added to water to precipitate dust particles in water. Aluminium in alum neutralizes charge dust particles and dust particles become very heavy and settle down. Bleaching powder and limestone is also added to remove temporary hardness along with chlorine (liquid), which removes bacteria and organic matter. Chlorine dosing is must during rainy days. The process of sedimentation is applied to remove heavier particles. Water is now stored in CST (Condensate Storage Tank). Note: PAC (Poly Aluminium Chloride) is used instead of alum, when the impurities in the canal water are more than a reasonable limit, especially during the rainy season. Clarifying Pump House: It consists of five clarifying pumps, four service water pump and two dividing pumps. Form the clarify pump house, the water goes to the condenser and the sand filter. Sand Filter: These stages are put across the flow of water so as to remove other suspended particles, if any. Now the turbidity of water is 2-3.

14

Activated Carbon Filter: This filter is employed for removal of bacteria and organic matter through oxidation. It uses anthracite coal for filter. The turbidity of the water obtained here is 1-2. Cation exchanger: At this stage, the ions (Ca, Mg, Fe) are absorbed by an ion exchange method liberating H+ ions. HCl and resin (-ve) are principal ingredients of chemical filters present here. Here the hardness of the water is removed. Weak base anion exchanger: Here the weak bases (acetic acid, carboxylic acid etc.) are absorbed by carefully releasing OH- ions. Degasser: Here the gases like CO2, O2 and H2 are removed. Strong base anion exchanger: Here a resin is used which absorbs strong anions like SO 42-, Cl2-, phosphate ion, silica etc. and releases OH-. Mixed Bed Exchanger: Here the remaining ions are extracted through both cation and anion resin. The demineralised water is now ready which has the following specifications: Conductivity : 0.004 siemens/cm2 pH : 8.5-9 The desired pH in clear water is between 8.5 and 9. Phosphate dosing is done at the end for this purpose. The total capacity of water treatment plant is to provide 60 tonnes of water per hour.

15

BOILER & BOILER AUXILIARIES SYSTEM

Fuel Handling System (Coal & Oil) Milling System Air & Flue gas System Water & Steam circuits Turbine Steam Flow System Condensate System Feed Water System Turbine bled steam & Drip Drain System Turbine Lubricating Oil System Turbine Gland Sealing System Turbine Vacuum System Generator Seal Oil System Generator Gas Cooling System Power Generation & Transmission Solution Auxiliaries

OIL HANDLING PLANT

In Thermal power stations fuel oil play vital role. Oil burners besides initial lighting up are also used to provide effective ignition of the coal associated with P.F. burners and to stablise the flame. The burners can provide enough heat to carry on boiling operation of the boilers for initial starting period. It can provide 10 15 % of the maximum load. At lean period or when it is desired to run the boilers at off load condition oil burners are used. Fuel oils used in power station are: Heavy furnace oil (HFO) Light diesel oil (LDO) High speed diesel oil (HSD)

16

Low sulphur High stock oil (LSHS)

COAL HANDLING PLANT

A simple schematic diagram of the coal handling plant of PTPS is as shown. The raw coal (bituminous coal) is brought to the power plant by the means of railways. The wagon tripplers transfer it into the wagon triple hoppers (WTH) which empties the coal from the wagons. The wagon capacity is around 50-60 tonnes. From WTH the coal is transferred to the vibrators, it separates the stone boulders from the coal from where it is then passed to the conveyors. The length of the belt is 1000m and speed is approximately 7.2 km/hr. The conveyor carries around 500 tonnes of coal per hour to crusher house where the big pieces of coal are separated in a screen and sent to crusher through conveyor from where the crushed pieces are transferred to other conveyors. These are smaller particles of size ranging from 20 mm to 40 mm or below. Then conveyor takes coal from where trippler transfer the coal to raw coal bunker (RCB). There are two suspension magnets present over conveyor just before crusher house. These magnets remove any metallic impurities in the coal moving on the conveyor belt. The whole process described is valid when the coal brought by the trains directly feed the RCB. When there is no train available then the coal comes from the coal yard. The coal from the coal yard is dropped with the help of bulldozers in the hopper from where it is transferred to the conveyors and the process is repeated to carry the coal to the RCB. When RCBs are full then the coal coming from the wagon trippler hopper, after being crushed in the crusher house is transferred to conveyor which carries it to the stacker that spreads the coal in the coal yard with the help of boom conveyor. The boom conveyor can rotate 360 times on the stacker which moves itself on a track laid over the length of the coal yard.

17

Thus the coal gets stored in the coal yard, which can be used when the train carrying coal are unavailable. In PTPS, more than one lakh tonnes of coal can be stored in coal yard. The coal handling plant also takes care of the storage purification and supply of fuel oil, which is used for initial lighting up of the boiler furnace, and generation of constant temperature in the furnace during normal operation. Mode of operation in Coal Handling Plant: 1. Bunker filling operation: Coal flow from wagon trippler to boiler house bunker 2. Reclaim operation: Coal flow from stockyard to boiler house bunker 3. Stacking: Coal flow from wagon trippler to stockyard 4. Bunker filling and reclaiming simultaneously

MILLING SYSTEM

A layout of the milling system at the PTPS is as shown in the figure. In a thermal power plant pulverized coal is used for producing heat in the furnace. This is because the burning of this state of coal takes place completely and also there is lesser problem in ash handling. The coal pieces of size 20 mm to 40 mm are taken from the RCB and through raw coal chain feeder (RCF) their coal pieces are fed to the ball mills. In the ball mills, there are steel balls of size 40, 50 and 60 mm and with a net weight of nearly 52 tonnes. These mills rotate about their axis and this makes the balls collide with the coal pieces to break them into pulverized form. Ball mills are provided with flue gases at about 300 o C that helps drying the coal and raises its temperature to about 85-90o C. There is a fan in the circuit called as vapour fan, this fan solves three purposes: It creates vacuum in the circuit so that the pulverised coal is sucked out of ball mill with air. If due to any reasons the supply of coal to the ball mill is broken and flue gasses are continuously supplied then the temperature of the ball mill will rise excessively high. To avoid this vapour fan thus recirculates pulverized coal to the ball mill and so temperature of the ball mill comes down.

18

For cooling dry cold air is also supplied while recirculation. Cooling is must because if the temperature becomes higher enough then the coal can catch fire. Micro particles of coal are directly sucked by the vapour fan with air and supplied to the furnace chamber for combustion. The pulverised coal from the ball mills is passed through a classifier that acts as a screen separating out the bigger particles from the pulverized coal and returning them back to the ball mill. From the classifiers the coal goes to the cyclone separators where coal particles are separated from the air. The vapour fan pumps out the air and the coal particles go to warm conveyor via turnicates. The warm conveyor delivers the coal to be stored in pulverized coal bunker (PCB). From PCB the coal goes to pulverized coal feeder that feeds the coal to the furnace with the help of primary air fan (PAF). This fan takes air from primary air heater and pushes the pulverized coal from all four corners of the chamber. Secondary air fan (SAF) supplies hot air (taken from secondary air heater) to the chamber for combusting the coal properly. Coal is supplied from the all sides to have a uniform and complete combustion. In PTPS there are three ball mills and four PCBs for each unit of 110 MW. From ball mill A, coal can be directly given to PCB A and PCB B via turnicates. Similarly from mill B to PCB B & PCB C and from mill C to PCB C & PCB D. For any different combination of ball mill and from those stated above, warm conveyor is used.

19

COAL FIRING SYSTEM IN THE BOILER FURNACE

The steam generating unit has been designed for firing coal and oil at low loads for stablisation. The fuel firing equipment is designed such that the rated parameters would be reached when the fuel is fired. The burners are located at corners of the furnace tangential to the imaginary circles, having their centers co-axial with the center of the combustion chamber. At each corner, there are nine compartments arranged as mentioned below. There are four coal burner nozzles, three vapour burners and two oil burners at each corner. The four coal nozzles are provided with air packets, which flow around the coal fuel system. Each of the engine compartments is provided with independent air dampers. All the adjustable tips are of stainless steel to withstand high temperature. Coal Bunkers: Total bunkers Manufacturer Capacity Type : 16 : BHEL : 3.65 ton/hr : Tilting tangentially

Pulverised coal fired boiler: With the increase in the size of the turbines, the boiler work also increases. They have to supply steam at a high temperature & pressure and in a bulk quantity. In such type of the boiler coal is fired in pulverized form, which has the following advantages: 1. Unlimited output capacity. 2. Even low grade coal can be burned. 3. Even very fine boiler output control is possible. 4. High efficiency. 5. Less possibility if unburned coal. Fuel Oil System: In the pulverized fuel fired oil boiler firing is used for safe and quick start up of boiler ignition of pulverized coal and to bring stability to coal flame under low output with eight flexible oil guns, two in each corner. The oil guns are located at the top and bottom of secondary air nozzles and in between coal nozzles. The oil guns are of pressure atomizing type.

20

DETAILS OF BOILER AT PTPS

21

A boiler is a closed vessel in which water under pressure is converted into steam. It is one of the major components of a power plant. It is always designed to transfer maximum amount of heat to the boiler water by all the three modes of transformer: convection, conduction and radiation. Boilers can be classified as water tube boiler and fire tube boiler. a. Fire tube boiler: In this type of boiler, products of combustion pass through tubes which are surrounded by water. Depending on whether the tubes are horizontal tube boilers they may be internally or externally fed. An internally fed boiler has grate and combustion chamber enclosed including furnace. The grate is separate and distinct from the boiler shell. A fire tube boiler is simple, compact and rugged in construction. Its initial cost is low. A vertical fire tube boiler occupies less floor space. However, they are economical only for low pressure and therefore available in small sizes having steam capacity of about 15,000 kg/hr. b. Water tube boiler: In this boiler, water flows inside the tubes and hot gases flow outside the tube. The tubes are interconnected to common water channels and to steam outlet. Water tube boilers are classified as vertical, horizontal and inclined. The number of drums may be one or more. The circulation of water in the boiler may be natural (due to difference in density between cold and hot water) or forced through the action pumps. Forced circulation has the advantages: 1. Lesser weight of boiler and cheaper foundation. 2. Lighter tubes. 3. Freedom from scaling problems. 4. Greater freedom in configuration of furnace, tubes etc. 5. Uniform heating of all parts. 6. Better control of temperature. 7. Increased efficiency of boiler. 8. Quick response to load changes. In view of all these modern boilers use forced circulation. However, forced circulation means higher investment, more costly maintenance and increase

22

in auxiliary power consumption. The unit is designed for minimum continuous value of 375 tonnes/hr, at a pressure of 135 kg/sq. cm and a temperature of 540o C. The reheat system steam flows at MCR. The feed water temperature of the MCR is 240o C. The unit is balanced draft radiant dry bolt on single drum, natural circulation, vertical tube type construction with casing and a single reheat system. The furnace is arranged for dry ash discharge and is filled with burners located at the four pipes. Each corner burner is supplied with coal, vapour, and oil filled secondary air components. The unit is provided with three ball pipes and arranged to operate with intermediate coal power. The steam super heaters consist of four stages which are ceiling, primary S/H, platen and final super heaters. The ceiling terms the root of furnace and horizontal pass and finishes as the rear wall of the second pass. The primary super heater is made up of horizontal bands located at the second pass while the platens are located at furnace exits. The portion above the furnace too encloses the super heaters. The control of super heater steam is achieved by two stages of spray attempration which are located before the platen super heater and the other located before the final super heater. The re-heaters are in two stages. First and triplex heat exchanges located at the second pass which absorbs heat from super heater a steam as well as from flue gases. In the second stage exists re-heater located in the horizontal pass as penitent tabular loop. Reheated steam temperature control valves and the other emergency conditions by an attemprator located in the cold reheat lines. In order to ensure reliable and continuous operation ample soot blow equipment is provided. There are start retractable steam soot blower provided at the top of the furnace fully retractable steam soot blowers are arranged for the horizontal re-heater and super heater in the rear pass. The steam soot blowers are electrically operated.

SPECIFICATIONS OF THE BOILER

23

Manufacturer Maximum continuous rating Maximum rating without stabilization Rated steam pressure at super heater outlet Rated steam temperature at upper heater outlet Rated temperature of feed water at economizer inlet Rated steam flow through reheater Rated steam temperature at reheater inlet Efficiency of the boiler Design pressure of the boiler drum Design pressure of the reheater Motor for FD Fan: Type : EL Motor Rated output : 330 KW Full load current : 44 A

: BHEL : 375 ton/hr : 240 ton/hr : 139 kg/sq. cm : 540o C : 240o C : 324 ton/hr : 360o C : 86 % : 161 kg/sq. cm : 42 kg/sq. cm

Induced Draft Fans (ID FANS): It is a continuous type draft fan and its two units are used for each boiler. The type is BHEL oxiall-430-2240. The induced draught fan does the function of sucking the gas from the furnace, making the gas to flow through the various heating surfaces & dust collecting equipment and sending the gas out through the chimney with required velocity. The ID fan handles the hot flue gases and sends the fly ash causing rapid erosion of impeller; enough care is taken at the design stage to select the fan for the worst condition. Number : two per boiler Capacity : 367200 m3/hr Temperature of flue gases : 1215o C Speed : 990 rpm Motor for ID (Induced Draft) Fans: Type : EL motor Rated output : 440 KW Full load current : 127 A Fan design ratings: Capacity Total head developed Maximum temperature of medium : 44.6x10 e-4 mm/hr : 410 mm : 145o C

24

Specific weight of medium Fan speed Fan direction of rotation Blade type Type of regulation Drive motor: Manufacturer Frame size Design Power: Rated Actual power required Rated voltage No. of phases Voltage & frequency: Full load rpm Full load current Full load frequency Torque Frequency Terminal Connections: Type Number

: 863 Cp/cm : 990 rpm : clockwise : laminated curved blade : inlet valve regulation : MEEP, Haridwar : 15-5-00-p : Codena : 1000 KW : 740 KW : 6600 :3 : 990 rpm : 104 A : 94 % : 4.63 : 50 Hz : star :6

Note: The 6 leads taken out in the terminal box and connected on 4 brushes, form a star.

STEAM GENERATING UNITS AND AUXILIARIES

25

Supporting structure: It serves for arranging the suspending water wall system, steam super heaters, re-heaters, economizers, air pre-heaters, galleries insulation and sheet casing.

26

Galleries and stairways: These provide access for maintenance like root blowers, valve burners, dampers ant to various main & view holes. Boiler drum and drum internals: Boiler drum is made of alloy steel plate of thickness and has a diameter of 1800 mm. The drum is of fusion welded on hemispherical dished ends. The function of the drum internals is to reduce the dissolved solid content with the steam to a prescribed limit. Rough mountings: These contents of access doors into the combustion regions of super heater, economizers and air burners as well as observation pots, explosion doors etc. The rough mountings are made of cast iron or are of fabricated design. Water walls: The combustion chamber is formed of water wall tubes on four side diameters 60.3 mm set, at a pitch of 52 mm. In the corner where the pulverized coal burners are located, the tubes are bent suitably to provide opening for the sending of the tilting tangential burners. Re-heaters: The steam re-heaters having a total surface area of 255.1 sq. mm are made of pendant and horizontal tabular loops and are in two stages. The first stage of horizontal tabular arrangements and the peripheral if tabular is used. The steam for super heater flows through bigger tubes outside diameter of 85 mm while the steam to be reheated flows outside the tube through bigger tubes outside with a diameter of 70 mm. The super heated steam from the triflux is drawn through three-way valve arranged in a connecting pipe between the outlet of platen super heater and inlet of final super heater. The second stage of super heater is suspended in the horizontal pass of the boiler as pendant tabular loops. The reheater tubes are welded to the inlet and exit heater. Economiser: The economizer with a heating surface of 4950 sq. cm made of steamless tabular loops. The tubes of outside diameter of 32 mm are welded by means of stubs to the inlet and outlet heater. The heater and horizontal loops rest on supporting structure of second pass of the boiler with provision for free expansion. The economizer blocks are arranged, with a second pass of the heat recovery zone of the boiler so as to achieve recovery of heat in a very common economic manner.

27

Safety valves: The boiler is equipped with two spring loaded safety valves mounted on the drum, two spring loaded safety valves mounted on super heater, outlet heater, two spring loaded safety valves mounted on cold reheat line at reheater inlet. Two spring safety valves are mounted on hot reheat line at reheater outlet. Safety valves mounted on at boiler drum are of 1859 WA and 1930 WA type dressed industrial valve and instrumentation division USA. The sizes are 3 and 2.5. The total dissolved quantity is 290 tonnes/hr and the design temperature and pressure are 347o C and 161 kg/sq. cm respectively. The set pressure for the 3 and 2.5 valves are respectively 161 kg/sq. cm and 1636 kg/sq. cm. Air preheater: They are of tabular type having a total effective area of 107.2 sq. cm. They are made up of ERW tubes of outside diameter 40 mm. The ends of this are expanded into plates. The air preheater is divided into stages having eight heater blades and second stage having four blocks by using expansion joints. The air heater is designed such that flue gas passes through the tubes in the vertical direction while the air to be heated flow outside the tubes in a direction perpendicular that of flue gas. Skin casing: a. Insulation and outer casing: The furnace walls are arranged in tangent tube construction and are completely skin-cased with light insulation outside covered by ripped aluminium sheets. Skin casing to prevent air leakage is also adopted on the front and rear walls and cooling of second pass. The ceiling above the secondary super heater and the final reheater has tight refractory and insulation. The temperature of outside surface of the insulator and casing will be low enough from the point of the safety of operation personnel. b. Cold and hot ducts: These include ducts working from forced draught fans to air reheater, interconnecting ducts between air heater blocks, the duct into primary fan, hot air duct to burner and air distribution box. Flue ducts: These include the duct between the air reheater, air heater economizers, the duct enclosing economizer blocks, the duct below the reheater and the duct between the block boiler, the reheater and chimney. The layout of the flue gas extraction ducting commences at the point of extraction of the hot flue gases from the heat recovery zone of the boiler and ends at the raw coal

28

inlet. The flue gases extraction ducting is made of alloy steel plate in view of the fact that the hot gases will be around nozzles. Soot Blower: Below root in the furnace a top region the super-heater a reheater zone and the economizer coils. Steam is used as the medium. The steam is tapped from the pulled of the plate super-heater and the system includes are on the reduction valves or safety valves. Four box type soot blowers at the trifler reason and simple feed type root blower for economizers are also provided.

TECHNICAL SPECIFICATIONS OF THE MILLING PLANT AND FUEL FIRING SYSTEM

Pulverising Mill: Type Number of mills Rated capacity Type of drive Speed Motor capacity : drum mill 800/575 : three : 20 tonnes/hr. : electric motor : 990/990/171 and 170/175/170 rpm : 6030 KW, 6.6 KV : 22 l/min : 80 psi : 350 l

Lubricating system: Discharge pump Pressure of oil at pump Quality of lubricated oil reqd. /mill Oil Cooler: Cooling water required Raw Coal Feeder: Type No. of boiler Type of drive

: 7.5 com. /hr at 230o C : chain feeder R600 : three : elect motor 7.5 KW

29

Coal Burner: Total no. of feeder Manufacturer Capacity Type Oil Burners: Number per boiler Type Capacity Position of burner Cyclone Separator: Type Diameter of unit Efficiency Vapour Fan: Type Type of inlet control No. of inlet Runner Speed Motor: Manufacturer Type Rated output Rating Weight

: 16 : BHEL : 3.65 ton/hr : tilting tangentially : 8 mm to tier : manual with mechanized atomisation : 800 kg/hr : at furnace corner : SEA 1600/2 : 1600 mm : 82% : DL-1600-60 : damper : one : 1800 mm : 1480 rpm : BHEL, Haridwar : DA 2014-64-67, TPEC : 630 KW, 230 rpm : 6.6 KV, 3 phase, 50 Hz : 9.76 tonnes : 28 tonnes/hr : 64-68 A : 67 ton/hr for 110 MW : 0.58 kg : 200 mesh

Ball Mill: Mill capacity Mill current Coal consumption Coal consumption in KW/hr Coal fineness Classifiers:

30

Type No. of per boilers Type of drive Method of control Range & efficiency

: Raymond type 330, Raymond type 880 :3 : electric motor, 7.5 KW (variable) : Vane control : Adjustable

TURBINE MAINTENANCE DEPARTMENT (TMD)

The main works of this department are maintenance of turbine and look after all the things related with turbine. The steam turbine has been used predominantly as mover in all thermal power stations. It is not likely to be replaced in the future. Turbines are mainly divided into three groups: Impulsive turbines Reaction turbines Impulsive-reaction turbines In both types of turbine, first the heat energy of the steam at high pressure is converted into kinetic energy passing through the nozzles. The turbines are classified as impulsive in impulsive turbinate steam coming at a very high velocity through the fixed nozzle impinges on the blade fixed on the periphery of the rotor. In the reaction turbine the high pressure steam boiler is passed through the nozzle. When the steam comes out through these nozzles, the velocity of steam increases relative to rotation and this resulting force of steam on the nozzles give the rotating motion to the disc and shaft.

31

The shaft rotates in opposite direction of steam jet. In an impulsive reaction turbine the steam expands both in fixed and in moving blades continuously as it passes over them. Therefore, the pressure drop occurs gradually and continuously over both moving and fixed blades. For e.g. Parsons turbine. COMPOUNDING OF THE STEAM TURBINES If the entire pressure drop from boiler pressure to condenser pressure is carried out in a single stage nozzle, then the velocity of the steam entering into the turbine could be very high of the order of 1500 m/s. The turbine rotor velocity (blade velocity) will be very high of the order of 3000 rpm as it is directly proportional to the steam entering velocity. Such high rpm of turbine is not useful for practical purpose and a reduction gear is necessary between the turbine and external equipment (generator driven by the turbine). There is also a danger of structure failure of the blade due to excessive centrifugal stresses. Therefore the velocity of the blades is limited to 400 m/s. The velocity of the steam at the exit of the turbine is sufficiently high when single stage blades are used. This gives a considerable loss of kinetic energy (about 10-20 %). The compounding can solve the above mentioned difficulties associated with the single stage turbine. The combinations of the stages are known as compounding. There are three types of compounding which are generally done. a. Velocity compounding: In this type of compounding there is only one set of nozzles and two or more rows of moving blades. There is also a row of fixed blades in between the moving blades. The function of the fixed blades is only to direct the steam coming out from first moving row to the next moving row without altering pressure and velocity of the steam. The heat energy drop takes place only in the nozzle at the first stage and it converts into kinetic energy. The kinetic energy of the steam gained in the nozzles is successively used by rows of moving blades and finally exhausted from the last row of the blades on the turbine rotor. A turbine working on this principle is known as velocity compounded impulse turbine. For e.g. Curtis turbine. b. Pressure compounding: A number of simple impulse turbine sets arranged in series is known as pressure compounding. In this arrangement, the turbine is provided

32

with one row of the fixed blades at the entry of each row of the fixed blades, which work as nozzle. For e.g. Rateau turbine. GOVERNING SYSTEM OF TURBINE 1. Speed range is 2850 rpm to 3360 rpm corresponding to primary oil pressure of 2.17 to 2.99 atmosphere at oil temperature of 50o C (3000 rpm corresponds to 2.38 atm primary oil pressure.) 2. The non uniform changer (NUC) enables the exchanging of non uniformity continuously in the range of 3.5 to 5 %. 3. Before start of increase of secondary oil pressure, safe oil pressure can be achieved by limiter only when the main relay is in engaged position. 4. During the starting of machine upto 2730 rpm, safe oil pressure is regulated by limiter. 5. When the turbine has taken over the regulation function, the limiter works as by-pass valve on the secondary oil system.

TURBINE PROTECTION TESTING The following protection parameters of turbine have to checked & recovered in log book: 1. Primary oil pressure should be 3.05 kg/cm 2 2. Control gear pressure should be 7.00 kg/cm 2 (regulation oil pressure) TURBINE OIL PRESSURE REGULATING SYSTEM 1. Reset the supply turbine. 2. Reduce the turbine oil from turbine local panel as described in T.G. set manual. 3. Further reduce the turbine oil pressure by procedure given above and watch so that E.O.P. (A.C.) starts at 0.8 kg/cm2. Now further reduce the pressure & water so that E.O.P. (D.C.) gets started automatically at 0.7 kg/cm 2. 4. Mechanical shift tripping.

33

5. Low vacuum tripping.

SPECIFICATIONS OF 105 MW TURBINE

Rated output at generator terminals Rated speed Rated steam pressure just before stop valve Maximum steam pressure just before stop valve Rated temperature just before stop valve Reheated steam pressure Maximum steam pressure before MP casing : 110 MW : 3000 rpm : 130 kg/sq. cm : 146 kg/sq. cm : 540 : 27.4 kg/sq. cm : 36 kg/sq. cm

IMPORTANT FEATURES OF TURBINE

No. of regulated extractions No. of wheels in HP rotors No. of wheels in MP rotors No. of wheels in LP rotors No. of high pressure control valves No. of interceptor valves Range of critical speed Weight of HP rotor Weight of MP rotor Weight of LP rotor Direction of rotation Material construction HP MP outer casing HP MP Inner casing molybdenum carbon steel :8 : 2 row Curtis, 8 HP (impulse) : 12 impulse : 4 impulse of double flow design :4 :2 : 1200 to 2500 : 5.5 Tonnes : 11 Tonnes : 24 Tonnes : Clockwise from front bearing stand : special cast steel : Casting of chromium vanadium steel : Casting of chromium vanadium

ELECTRONIC INSTRUMENTS USEFUL FOR THE PLANT

34

The following instruments are found to be very useful for the power plant: 1. PR6422 2. PR6423 3. PR6424 4. CON 010 5. Conductivity Indicator Controller 6. pH-Redox Transmitter PP9041 7. Linear Displacement Transducers, PR9350 Series (LD 5000) PR6422, PR6423, PR6424 Operation and construction: The transducers belonging to the PR6422, PR6423, PR6424 series based on the eddy currents measuring principle form together with the signal converter CON 010 an oscillator circuit, whose amplitude of oscillation is damped by the proximity of the metallic object w.r.t. face of the transducer. The damping is proportional to the distance between the transducer coil and the object. The transducers are available for different static and dynamic measuring ranges and with different dimensions. The transducers PR6422 and PR6423 are fitted with a 1m long cable. Transducer PR6424 is fitted with a 4m long cable. The zero point and gradient of the measuring s/n can be adjusted by means of components located under a gas tight cover. The units are delivered fully adjusted so that no onside calibration is required. The transducer is connected via a self locking, water proof, plug connection. The power supply and s/n o/p connections are via screw terminals. Intrinsically safe operation is possible when zener barriers are used. The units correspond to the relevant VDI, API and ISO standards.

Application: These units are designed for use in many branches of industries and in laboratories for measurement and supervision of small displacements and vibration on ferromagnetic objects. Such various applications are:

35

Monitoring distances between rotor parts Monitoring vibration of mechanical elements Monitoring deformation or bending of mechanical parts Contact-less measurement of shaft eccentricity, vibration and small displacements Transducers operate on the eddy current principle for static and dynamic measurements Transducers easy to mount and adjust Compact design This contact-less measuring principle as well as the small size, robust construction and the resistance of the transducer to aggressive chemical influences, make this system ideal for continuous supervision of all types of rational machinery. Measuring chains made up of displacements transducers, signal converter and the additional electronic equipment belonging to the RMS700 system moderately priced and maintenance free supervision of small shaft displacements with respect to the shaft bearing or housing in two different modes: 1. Radial, static displacement of the shaft and relative shaft vibration. 2. Axial, shaft displacement and relative expansion. The following static and dynamic relative measurements are necessary for supervision of the important mechanical parameters governing turbomachinery breakdown prevention. a. Axial position of the shaft with respect to the housing. b. Radial position of the shaft with respect to the housing. c. Shaft vibration. CON 010 (SIGNAL CONVERTER) The signal converters contain the electronics necessary for energisation and signal conversion, which is generally identical for all types. The signal converter must be energized with 24 DC with +5 or -5%. The normal deviation of the output voltage for the measuring range of connected transducer is 4-20V. The converter is delivered together with the transducer for which it was calibrated. Therefore, care must be taken that transducer and system converter remain together.

36

The converter CON 010 is accommodated in a robust housing, the electronics is encapsulated. The converter is delivered as a T6 version: transducer connection is by means of a LEMO socket. CONDUCTIVITY INDICATOR CONTROLLER Specification: 1. Auto fluid temperature compensation 25-100o C in split ranges of 2550o C, 40-70o C and 60-100o C. 2. Temperature sensor: Resistance thermometer R=100 ohms at 0 o C DIN 4370. Stem length 3/2, three wire connection. 3. Maximum RT length: All the three load lengths should be the same and less than 5 ohm. 4. RT mounting: Linear arrangement with BSPT connection. 5. Accuracy of compensation: Within 4% of the normal slope of 2.5% per degree centigrade. 6. Maximum lead length of the conductivity cell : 60 meters Installation: The resistance bulb holder is to be connected in line before the conductivity cell. For this BSPT connections are provided. RT bulb to be inserted in the holder and the clamping not to be tightened checking that at of the tip is dipped in the liquid. The RT bulb wires to be connected to the terminal block provided at the rear panel of the instrument. The resistive arm of RT to be connected between the terminal marked A and B and the compensating cable to the terminal marked C. Operation: (a) Location of controls: An auto/ manual switch is provided on the front panel. It has got three auto positions in the ranges 25-50o C, 40-70o C and 60-100o C besides the manual position. Under auto mode, temperature compensation is provided automatically for the different fluid temperature. (b) Normal Operating instructions: For auto temperature compensation set the auto switch to the approximate temperature range of the fluid. The instrument then reads

37

the equivalent conductivity of the fluid at the reference temperature of 25o C for different temperature of the fluid. pH-REDOX TRANSMITTER PP9041 The Philips PP9041 is a pH-redox transmitter with a spam of 10 pH and with zero settings at pH 0, pH 2 & pH 4. This allows the following measuring ranges to be selected: a. pH 0pH 10 b. pH 2pH 12 c. pH 4pH 14 Furthermore, eight mV ranges can be selected with a spam of 1000 mV, output current ranges of 0-20 mV of 4-20 mV can be selected to use the transmitter for the either electronic or pneumatic control to avoid earthing and/or interfacing problems, both electrode inputs are highly ohmic. This allows the use of any electrode as a reference. The features of the instrument make it very suitable for water treatment and pressure control application.

TRAINING IN EMD

Panki Thermal power station has four units for generation. Each unit has a separate transformer. Transformer rating depends on the generating capacity of each unit. Units 3 and 4 generate power at 11 KV. Units 1 and 2 are closed. Rating of Transformers of Unit 3 and Unit 4 KVA No Load Volts Winding Temperature Amperes H.V. L.V. H.V. L.V. H.V. L.V. 87500/12500 87500/12500 242000 11000 30 degree c 298 656

38

Phase

3 3 Types of cooling ON/OFF Frequency 50 Hz Impedance Volts 12.15% Vector group symbol Yd11 Core winding weight 104000 kg Weight of oil 34700 kg Total weight 187000 kg Oil 38550 litres Oil circulation 2 x 1800 litres/min Air circulation 24 x 50 m3/min Type of circuit breaker O.F. (Oil Filter/ A.B.) The ratings of major electrical equipments such as all transformers, for 110 MW units are as follows: Power rating of generating transformer Power rating of unit auxiliary transformer (UAT) Voltage transformation ratio of generating transformer Voltage transformation ratio of UAT Voltage transformation ratio of reserve transformer : 125 MVA : 16 MVA : 11/242 KV : 11/6.6 KV : 132/6.6 KV

H.V. L.V.

In PTPS, the generation of electrical power is done at 11 KV. The generated power at this voltage goes to the bus bar through transformer which step-up the voltage. Then power is ready for transmission and is fed into transmission network. After the generating transformer, the current transformer and the potential transformer are located. After the CT and PT, two circuit breakers are connected. One of the circuit breakers is manual while the other is automatic. The automatic circuit breaker is air blast circuit breaker (ABCB). When excessive current or over voltage or sudden dip in voltage occurs then the circuit breaker disconnects the line.

CURRENT TRANSFORMER (C.T.) At this substation a number of current transformers are used. These current transformers are used with low ammeters to measure high current in high

39

voltage A.C. circuit where it is not practical to connect instruments or ammeters directly from high voltage lines. In addition to insulate the instrument from high voltage it steps down the current in known ratio. The current transformer has a primary coil of very few turns of thick wire connected in series with the line whose current is to be measured. The secondary consists of a large number of turns of thin wire and it is connected across the ammeter terminals. At required voltage the current transformer is of step-up type. But it is sure that the current will be step down. Thus if the current transformer has primary to secondary ratio of 100:5, then it step-ups the voltage 20 times whereas it step-downs the current to 1/20 times of it. POTENTIAL TRANSFORMER (P.T.) The potential transformers are used to operate as voltmeters. The potential coil of wattmeter and relays form high lines. The primary winding of the potential transformer is connected across the line carrying the voltage to be measured and the voltage circuit is connected across the secondary winding; the design of a potential transformer is quite similar to that of a proper transformer but the loading of a P.T. is always small. The potential transformers are used to measure the high voltage. The potential transformer is also used for operating the relays in control circuit. For safety the secondary winding it is completely insulated from the high voltage of primary side and grounded for boundary protection of the operators. Three types of cooling techniques are employed for the transformers. These techniques are as follows: a. Oil Natural Air Force b. Oil Natural Air Natural c. Oil Force Air Force GENERATOR AND EXCITER The electric generator is most important part of the power station. The principal of electromagnetic induction is used to generate electric power

40

with the help of synchronous generator. All modern type of AC generators essentially consists of fixed starter and revolution rotor. An alternating e.m.f. is induced when the shaft of the rotor is revolved with the help of a prime mover. The rotor provides the magnetic flux to the machine. The winding of three generators may be connected either in delta or star arrangement. With star arrangement two voltages can be obtained as the line voltage or as the phase voltage. The neutral is connected to the earth and this helps in designing a protective system in order to keep the temperature rise of various parts from exceeding the respective maximum permissible values. Every generator requires continuous cooling during its operation. The system cooling adopted for the cooling purpose consists of a fan that circulates the air through the alternator and the warm air is cooled by the water coolers before being circulated again. This system gives good protection against fire in alternator due to restricted air supply. Carbon dioxide can also be easily injected to extinguish the fire. The exciter provides the direct current mended to excite the rotor field magnets. The present on excitation must be absolutely reliable since their failures will shutdown the alternators. The higher the total load and more the lagging power factor, the greater excitation is required.

INTRODUCTION TO SWITCH GEARS, CIRCUIT BREAKERS AND RELAYS

41

Switch gear in a broad sense covers a wide range of equipments connected with switching and protection. A circuit breaker is a switching (current interrupting or making) device in switch gear. The basic requirements of switching in power system practice are two fold: 1. To permit apparatus and circuits to be conveniently put into or taken out of service. 2. To permit appropriate and safe isolation of apparatus and circuits automatically, in a pre-determined time period when they develop faults. DEVICES USED FOR CIRCUIT BREAKING (OR MAKING) 1. Fuse and Iron Clad Switches Fuse is an over-current switch in the sense that when the current exceeds a pre-assigned value in a circuit or device, it melts and causes current interruption. The supply is restored only when a healthy one replaces the damaged (melted) fuse in the line. To permit this without any danger of shock to the operator, fuses are connected on the load side of an iron clad switch.

42

2. Isolators An isolator is a switch connected after a circuit breaker. When a circuit or a busbar is taken out of service by tripping the circuit breaker, the isolator is then open circuited and the isolated line is earthed through earth switch so that the trapped line charges are safely conducted to ground. These devices are used to break or isolate the circuit. They are however, slower than circuit breakers in operation. They are used to locate and rectify faults in circuit elements and therefore they relieve the CB which may also be used for these operations. (However it is not advisable to turn CB in off position for a long duration as this may damage its springs.) In general, two isolators are put in circuit, one each on both sides of CB, in order to facilitate repair of CB as well as circuit isolation and repair. Air pressure for isolators at Panki thermal power station is 16 kg/cm 2. 3. Circuit Breakers Make or break both normal and abnormal currents. Appropriately manage the high-energy arc associated with current interruption. The problem has become more acute due to interconnection of power stations resulting in very high fault levels. Current interruption occurs only when it is called upon to do so by the relay circuits. In fact they are required to trip for a minimum of the internal fault current and remain inoperative for a maximum of through fault current. Rapid and successive automatic breaking and making to aid stable system operation. 3-pole and single pole auto-reclosing arrangement. In addition to these breaking and making capabilities, a circuit breaker is required to do so under the following typical conditions: Short-circuit interruption Interruption of small inductive currents Capacitor switching

43

Interruption of short-line fault Asynchronous switching

Principles of circuit breaking a. DC circuit breaking: effect of decreasing current and increasing arc length. b. AC circuit breaking: It is performed by several techniques which are current-zero period, distortion of AC current wave by arc voltage recovery and restriking voltages, single frequency and double frequency transients, rate of rise of recovery voltage (RRRV), control of RRRV, Resistance switching. Current chopping-interruption of low magnetizing currents-Opening resistors-capacitive current breaking-Switching of capacitor banks and unloaded lines-Interrupting terminal faults and short-line faults. Ratings of Circuit Breakers Rated Voltage Rated insulation Rated Frequency Rated normal current Rated short circuit breaking current Rated short circuit making current Rated opening sequence for auto-reclose CBs Rated transient recovery voltage for terminal faults (Representation of TRV by 4-parameters and 2-parameters) CB interrupting time-its components in relation to fault clearing time Single-pole auto-reclosing and its effects on system performance Classification of Circuit Breakers The circuit breakers are mainly classified as follows: 1. Air-break circuit breaker or miniature circuit breaker 2. Oil circuit breaker 3. Minimum oil circuit breaker 4. Air blast circuit breaker

44

5. SF6 circuit breaker 6. Vacuum circuit breaker A CB is used to make or break a circuit either manually or automatically under faulty conditions. The following types of CBs are used at Panki Thermal Power Station: 1. Air circuit breaker 2. Air blast circuit breaker (ABCB) 3. Oil circuit breaker (OCB) 4. SF6 CB a. Air Circuit Breaker (ACB): Upto a certain medium range of voltage, ACB are widely used for the low voltage circuits as well as the highest transmission voltage. Simple ACB which do not corporate any air, control devices used for voltages below 1 KV. These CB usually have two pair of contacts per phase. The main pair of contact handles the current under normal operating conditions and is made of copper. The additional pair actually becomes the arcing electrode as the CB is opened and is made of carbon because of the vaporizing of surface material of the contacts. The main contacts separate while the arcing pair is still in contact and the arc is initiated only when the arcing pair separates. b. Air Blast circuit breaker: These breakers employ a high pressure blast as an arc quenching medium. The contacts are opened in a flow of air blast established by the opening of the blast valve. The air blast cools off the arc and sweeps away the arcing products to the atmosphere. This rapidly increases the dielectric strength of the medium contacts and therefore prevents the arc from re-establishing. Consequently, the arc is extinguished and flow of current is interrupted. It has a major advantage that no fire risks are involved as opposed to OCB. At Panki thermal power station, air pressure limit for ABCB are 33 kg/cm 2 to 40 kg/cm 2.

45

c. Oil Circuit Breaker: In such CB, insulating oil is used as an arc quenching medium. The contacts are opened under oil and arc is struck between them. The heat of the arc evaporates the surrounding oil and dissociates its substantial volume of gaseous hydrogen at high pressure. It has the advantage of better and efficient arc quenching medium but on the negative side it involves risk of fire. d. SF6 CB: In such circuit breakers SF6 gas is used as the arc quenching medium. The SF6 is an electronegative gas and has a strong tendency to absorb free electron. The contacts of the breakers are opened in a high pressure medium of SF6 gas and arc is struck between them. The conducting free electrons in the arc are rapidly captured by the gas to form relatively large, immobile negative ions. This loss of conducting electrons in the arc quickly builds up enough insulation strength to extinguish the arc. The SF6 CB has been found to be very effective for high power and high voltage service. The advantages of SF6 CBs are as follows: 1. Very short arcing time. 2. Can interrupt much larger current. 3. Noiseless operation. 4. No moisture problem. 5. No risk of fire. 6. Low maintenance cost. The only disadvantage of SF6 CB is that SF6 is costly thereby increasing the cost of CB. Types of indoor switchgears: a. Stationary Cubicle type b. Draw-out or Truck type c. SF6 filled switchgear d. Fuse-switch units e. Flame proof or Explosion proof switchgear f. Cellular type g. Corridor switchboard h. Mimic diagram board i. Metal-clad switchgear

46

j. Isolator and earthing switch-Vertical break isolator-Double break isolator THERMAL RELAYS A thermal relay consists of a bimetallic strip which is heated by the means of a heating coil that is supplied through a current transformer. An insulated arm carrying contact is pivoted and is held in contact with the strip with the help of a spring. The tension of spring can be varied by rotating the sector shaped plate. Under normal working conditions, the strip remains straight, but when the strip is heated it bends and the tension of the spring is released thus the relay contacts are closed which energises the trip circuit. The setting of relay can be achieved by varying the tension of the spring. The construction of bimetallic element consists of two nickel-alloyed strips and steel strips welded together. These strips have high heat resistivity and are free from thermal secondary effects and aging. Each of theses strips is subjected to an artificial aging process and they are individually calibrated under currents. These relays assume a temperature higher than the surrounding parts and must have a short circuit capacity corresponding to the breaking capacity of circuit breaker itself. This is achieved by using the heat resisting bimetal material of suitable dimensions having large thermal time constant. These over current tripping relays are used mostly for motor controls and their heating elements are designed to withstand short time overload upto seven times the full load current. Only the smaller size of the indirect current heated bimetallic elements from 4A to 6.5A are used while 30A motor protective circuit breaker will call for the additional fuses for the protection of winding along with relays. The smallest thermal relays of 400A circuit breakers are short circuit proof upto 200 times their top current rating, i.e. upto 8 KA which is adequate. Ratings of thermal relay are as follows: With winding-temperature indication type R.B. form- H2AW74 Contact capacity for (a) Cooker control 5A & 230V (b) For all arms 0.2A & 125V (D.C.) (c) For trip 0.2A & 125V (D.C.)

47

Power supply Bushing A6 B6 C6 N N Sec. Thermal AS1 + AS2 BS1 + BS2 CS1 + CS2 N1S1 - N1S2 N2S1 - N2S2

230V (A.C.) Current Ratio -400/1 -400/1 -VA -60 -60 -Accuracy -5P20 -5P20 --

GRID SUBSTATION The Panki grid substation has five buses at different voltage levels namely: 1. 220 KV bus 2. 132 KV bus 3. 33 KV bus 4. 25 KV bus 5. 25 KV bus Some of the power supplied by Panki thermal power station to the grid substation is fed back for the purpose of operation of auxiliary components.

WAVE TRAP This is used for communication by means of which, two grid substations may communicate and receive messages. SWITCHYARD The air at high pressure required for ABCB is produced by the compressor. There are two compressors for this purpose at PTPS. Both the compressors are run by the diesel engines. This is to ensure that interruption of power supply does not effect the operation of CB. The compressor maintains the pressure of air in main air tank. The compressor starts automatically when pressure of air in main tank falls below 33 kg/cm 2 and stops automatically when pressure in main tank has reached 40 kg/cm 2. Each ABCB is provided with its own subsidiary air tank. This tank contains air at pressure of 23 kg/cm 2 which is the operating pressure of the ABCB.

48

The subsidiary tank ensures that sufficient air is available for ABCB operation while its operation does not affect the main tank pressure. Similarly, subsidiary tank of isolation contain air at pressure of 16 kg/cm 2. Two sets of contact are provided for each phase of ABCB so that one of these may operate if the other fails.

TRACKS FOR TRANSFORMER Transformers are placed on the tracks (similar to railway tracks). This is done to aid the transportation, loading, unloading and installation of transformer. Using these tracks, transformer may be taken to the cranes which then lift and place the transformer on the vehicle. Similarly, cranes download these transformers which are then transported through the tracks to the site of installation.

CONTROL & INSTRUMENTATION DIVISION

This is the backbone of a thermal power plant. Various parameters in various auxiliaries are controlled from here. The equipments are very sensitive and can even pick up minute disturbances. Automatic control compares the actual value of the plant output with the desired value, determined the deviation and produces control signal which will reduce the deviation to zero or a small value. The industrial automatic controllers that are employed in the control and instrumentation section are as follows: 1. Two position or on-off controllers 2. Proportional controllers 3. integral controllers 4. Proportionally-integral controllers (PI) 5. Derivative controllers 6. Proportionally-integral-derivative controllers (PID) Various instruments of the C&I department 1. Boiler Drum: There are numerous red and green lights in the control room. The light continuously indicates the boiler drum steam and water level. When the level goes in the danger region, on alarm is activated.

49

2. Feeding Desk: On this panel the knobs are available for the operations. Steam dust collectors are measured in these stages. The boiler pressure is indicated by corresponding dial. When the boiler steam reaches the super-heated and attains a temperature of 485 o C. This steam is released to turbines. A temperature higher than the allowed value is indicated by an alarm. A control panel also indicates pressure in the boiler tube. There is also a coal burner control. For initial firing we require coal temperature of 800-1000 o C. The primary air fan controls the pressure of air. 3. Pulverised coal feeding desk: When vapor is fully open, the pulverized coal feeder will start otherwise pipe line will be heated. 4. Furnace draft control desk: by this vacuum and air quantity is maintained quick closing valve are opened. TURBO SUPERVISORY EQUIPMENTS The turbo equipments observe the following parameters: a) Vibration b) Sensitivity c) M.P. expansion d) Overall expansion e) Bearing temperature and oil pressure at bottling of axial shaft. Vibration Vibratory picks up are to pick up the vibrations and then amplified scientific pick ups are used to pick up displacement of even or few micrometers. M.P. Expansion Differential expansion of stator frame is observed at turbo supervisory equipment because if the more than, they break up. Maximum and minimum allowable expansions in different sections are shown below: High-pressure Medium-pressure Low-pressure Eccentricity Minimum 1.5 mm 1.5 mm 2.0 mm Maximum 3.5 mm 3.5 mm 4.0 mm

50

Since the rotor moves at a very high speed of about 2900 rpm to 3000 rpm, due to impinging of steam at high temperature, the expansion of rotor takes place. This is called eccentricity. Bearing Temperature Bearings are made of those metals, which melt at 100o C. Therefore allowable temperature is 7.5o C. Platinum resistance thermometers are used. The oil pressure is maintained at 35 kg/cm 2 at the header and a pressure of 15.8 kg/cm 2 at ball bearing. WATER POLLUTION CONTROL Main source of pollution in PTPS is polluted water that comes out. It is not made to flow as such into nearby river. Rather it is first purified by effluent treatment plant. Waste in the water us called sludge is collected in sludge, dyeing beds. From there it is taken away by trolleys once in a year. The general working of plant is as followsStep-1 Polluted water comes for treatment through gate A of inlet drain. It is first through screen. Before being collected in grease trap which is * feet deep, big particles, polythene, rappers etc. have already been screened before collection of water into oil and gases trap. Some dust and heavy parts and oil, grease come in the upper parts which is sucked by oil and grease pump. Oil is collected into drum from time to time this oil is sent to boiler for use. Step-2 Water from oil and grease trap goes to a 17A deep chamber, here water remains stand still for some time, heavy sludge, particles and impurities that do not dissolve in water settles down. Water from here goes to aeration tank through feed pumps. Step-3 Aeration tanks are deep tank where oil is mined in water. There are 3 aerators for this purpose. An aerator is basically a tabulator that is like a fan and rotates in water. In this way oxygen is mixed in water. This is necessary for the life of small bacteria that clear the water and makes it natural; 35 kg lime and 15 kg urea are mined in water. They are used as water purifiers.

51

Step-4 From aeration tank water comes to air fan tank. Motor is the center of purifier which rotates at the speed of two rotations per hour. It amplifies due to centripetal force created by the rotating sludge and by the particles which move toward the centre of the tank.

Step-5 Pure water is discharged from the center i=of the air fan tank. Sludge pumps from the center of air tank fan pit and send it into sludge drying beds. Water vaporizes from this sludge beds and sludge remarks that are thrown away by turn from time to time. AIR POLLUTION CONTROL Air pollution occurs due to ash present in the exhaust gas released from the chimney of the power plant. Therefore, fly ash can almost effectively be prevented from entering into atmosphere by employing electrostatic precipitation technique.

52

CONCLUSION

It was worth an educational experience to see the working of various mechanical devices in practical, which I had just read about in books. The process of knowing about the various stages of thermal power generation (from coal) including the boiler & its auxiliaries, the steam generating units & auxiliaries and the compounding, governing, protection testing & regulation of turbines was a great experience. Observing the practical implementation of the various mechanical devices like boilers, turbines, pumps, compressors, fans and the electrical equipments like current transformers, potential transformers, generators, exciters, switch gears, circuit breakers etc. added a lot to my knowledge. To know about the various stages in a water treatment plant was a new experience. And lastly, I would like to mention about the team work, co-ordination and time management which exists among the various departments of the unit. This has really helped me to learn about the job skills.

S-ar putea să vă placă și

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- NTPC Mechanical ReportDocument52 paginiNTPC Mechanical Reportraushan kumarÎncă nu există evaluări

- Overview of NTPC PDFDocument40 paginiOverview of NTPC PDFRahul KediaÎncă nu există evaluări

- Training Report TOYEB PDFDocument39 paginiTraining Report TOYEB PDFDevesh Pratap YadavÎncă nu există evaluări

- " Suratgarh Super Thermal Power Station": Submitted ToDocument58 pagini" Suratgarh Super Thermal Power Station": Submitted ToSahuManishÎncă nu există evaluări

- Report ShiviDocument54 paginiReport ShivigargshiviÎncă nu există evaluări

- Report On Thermal Power PlantDocument39 paginiReport On Thermal Power PlantRajatÎncă nu există evaluări

- Project Report: (1 JUNE, 19 To 30 JUNE, 19)Document34 paginiProject Report: (1 JUNE, 19 To 30 JUNE, 19)AnkurÎncă nu există evaluări

- Overview of Power Plant and Transformer ProtectionDocument45 paginiOverview of Power Plant and Transformer ProtectionGaurav KumarÎncă nu există evaluări

- Project ReportDocument67 paginiProject ReportDivyanshu DkÎncă nu există evaluări

- Project Report: Vocational Training atDocument32 paginiProject Report: Vocational Training atShrinivas PrabhuÎncă nu există evaluări

- Thermal Report AnkitDocument42 paginiThermal Report Ankitankursharma1490Încă nu există evaluări

- Sagar Pandey AtpDocument44 paginiSagar Pandey AtpIshankÎncă nu există evaluări

- Technical Report PDFDocument57 paginiTechnical Report PDFKaushik ArnavÎncă nu există evaluări

- Training Report KTPS - NGDocument24 paginiTraining Report KTPS - NGHarsh DungarwalÎncă nu există evaluări

- Fully Automated Burner Management System Using PLCDocument80 paginiFully Automated Burner Management System Using PLCGanesh Seetharaman100% (1)

- Summer Training Report NTPC BadarpurDocument68 paginiSummer Training Report NTPC BadarpurKavish Kumar50% (2)

- Training ReportDocument23 paginiTraining ReportSumit GuptaÎncă nu există evaluări

- Thermal Plant Report MechatronicsDocument50 paginiThermal Plant Report Mechatronicsहिमाँशु पालÎncă nu există evaluări

- BTPS Summer Training ReportDocument60 paginiBTPS Summer Training ReportAnkur YadavÎncă nu există evaluări

- NTPCDocument35 paginiNTPCArun KumarÎncă nu există evaluări

- KTPS o and M of TurbinesDocument41 paginiKTPS o and M of TurbinesKrishna Kishor100% (1)

- TTPS Divisions GuideDocument34 paginiTTPS Divisions GuideRamanand bharadwajÎncă nu există evaluări

- intership reportDocument35 paginiintership reportShashank ShrivastavaÎncă nu există evaluări

- TPS SikkaDocument53 paginiTPS SikkaAnkleshwariya SidhÎncă nu există evaluări

- Training Report ON Familiarisation of Thermal Power Plant: Aakash Ranjan GhoshDocument25 paginiTraining Report ON Familiarisation of Thermal Power Plant: Aakash Ranjan GhoshAR GÎncă nu există evaluări

- Report @NTPCDocument34 paginiReport @NTPCme11727100% (1)

- Thermal ReportDocument15 paginiThermal ReportMahesh YogiÎncă nu există evaluări

- Presentation ON: Submitted By: Submitted ToDocument34 paginiPresentation ON: Submitted By: Submitted ToTushar AnandÎncă nu există evaluări

- Summer Training Report On NTPCDocument31 paginiSummer Training Report On NTPCAmit SinghÎncă nu există evaluări

- Thermal Plant Control Instrumentation IDocument41 paginiThermal Plant Control Instrumentation IVishal KhachaneÎncă nu există evaluări

- Shivam TrainingDocument25 paginiShivam TrainingAR GÎncă nu există evaluări

- NTPC Barh Summer Training Report (Electrical)Document44 paginiNTPC Barh Summer Training Report (Electrical)Mithilesh91% (35)

- CESC Budge Budge VT ReportDocument51 paginiCESC Budge Budge VT ReportMainak Dutta100% (8)

- NTPC - Industrial Training ReportDocument84 paginiNTPC - Industrial Training ReportMd Khalid Akhtar100% (1)

- Power Plant Engineering - 2 Marks - All 5 UnitsDocument25 paginiPower Plant Engineering - 2 Marks - All 5 UnitsMohan Prasad.M89% (9)

- Final ProjectDocument45 paginiFinal Projectrahulshandilya2k100% (1)

- Summer Training Report NTPC Badarpur 1Document35 paginiSummer Training Report NTPC Badarpur 1Vaishak NairÎncă nu există evaluări

- Suratgarh ThermalDocument45 paginiSuratgarh ThermalSahuManishÎncă nu există evaluări

- Industrial Training Report-IPGCL& PPCLDocument49 paginiIndustrial Training Report-IPGCL& PPCLBrajesh YadavÎncă nu există evaluări

- Rishu NewDocument37 paginiRishu NewAbhay AswalÎncă nu există evaluări

- Badarpur Thermal Power StationDocument54 paginiBadarpur Thermal Power StationNarendra TrivediÎncă nu există evaluări

- Inplant Training ReportDocument74 paginiInplant Training ReportKushal GangarÎncă nu există evaluări

- Kota Training ReportDocument37 paginiKota Training Reportanshulh35Încă nu există evaluări

- Tata Power 2Document39 paginiTata Power 2Sourav Kumar100% (1)

- Summer Training Report: Amit Kumar Verma ECE (6th Sem)Document26 paginiSummer Training Report: Amit Kumar Verma ECE (6th Sem)Sukriti JainÎncă nu există evaluări

- The Durgapur PR-WPS OfficeDocument33 paginiThe Durgapur PR-WPS OfficeSuraj SharmaÎncă nu există evaluări

- Vocational Training Report On Thermal Power PlantDocument51 paginiVocational Training Report On Thermal Power PlantShubham Agrawal100% (4)

- Sahil Sharma (01625511115) 3rd Yr (NTPC PPT)Document23 paginiSahil Sharma (01625511115) 3rd Yr (NTPC PPT)smriti sharmaÎncă nu există evaluări

- Industrial Training Report-IPGCL& PPCLDocument92 paginiIndustrial Training Report-IPGCL& PPCLSaurav Kumar100% (2)

- Training Report (NTPC)Document80 paginiTraining Report (NTPC)Rupak KumarÎncă nu există evaluări

- Training ReportDocument33 paginiTraining ReportMayank KamnaniÎncă nu există evaluări

- Longwall Mining at Shallow Depth of Cover in IndiaDe la EverandLongwall Mining at Shallow Depth of Cover in IndiaÎncă nu există evaluări

- Marine Electrical Practice: Marine Engineering SeriesDe la EverandMarine Electrical Practice: Marine Engineering SeriesEvaluare: 4 din 5 stele4/5 (8)

- A Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationDe la EverandA Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationÎncă nu există evaluări

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerDe la Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerÎncă nu există evaluări

- Database SystemDocument24 paginiDatabase SystemnsutharÎncă nu există evaluări

- G SyllabusDocument10 paginiG SyllabusAjit JainÎncă nu există evaluări

- Faculty MembersDocument1 paginăFaculty MembersDheeraj KumarÎncă nu există evaluări

- 2 Entity Relationship ModelDocument36 pagini2 Entity Relationship ModelSushil KumarÎncă nu există evaluări

- Unit 3Document13 paginiUnit 3Ajit JainÎncă nu există evaluări

- Application For Student Discipline CommitteeDocument2 paginiApplication For Student Discipline CommitteeAjit JainÎncă nu există evaluări

- SynopsisDocument5 paginiSynopsisAjit JainÎncă nu există evaluări

- Et14 AdvtDocument4 paginiEt14 Advtsrikanth2828Încă nu există evaluări

- Upse AnsDocument40 paginiUpse AnsAjit JainÎncă nu există evaluări

- Power Electronics EEE602Document3 paginiPower Electronics EEE602Ajit JainÎncă nu există evaluări

- Power Electronics EEE602Document3 paginiPower Electronics EEE602Ajit JainÎncă nu există evaluări

- Unit 1loklkldvljfjfjfckjkxkc, M,, CLKCLCLCLCL LCLCCLCLCNDocument69 paginiUnit 1loklkldvljfjfjfckjkxkc, M,, CLKCLCLCLCL LCLCCLCLCNAjit JainÎncă nu există evaluări

- UPPCL 220kV Substation ReportDocument37 paginiUPPCL 220kV Substation ReportAjit JainÎncă nu există evaluări

- Wise NocDocument1 paginăWise NocKabir Sai Prasanna SuryavanshÎncă nu există evaluări

- Kruti Dev 010 (TrueType)Document1 paginăKruti Dev 010 (TrueType)Ajit JainÎncă nu există evaluări

- Don't Send ItDocument3 paginiDon't Send ItAjit JainÎncă nu există evaluări

- Introduction To NC and CNC Machines CNC Controls and RS274 ProgrammingDocument32 paginiIntroduction To NC and CNC Machines CNC Controls and RS274 ProgrammingRamanujam O SÎncă nu există evaluări

- Unit 3Document13 paginiUnit 3Ajit JainÎncă nu există evaluări

- Manufacturing Process of 500 MW Turbo Generator Stator Winding BarDocument21 paginiManufacturing Process of 500 MW Turbo Generator Stator Winding BarHimanshu SharmaÎncă nu există evaluări

- Mock Test Notice For WednenmbsdayDocument7 paginiMock Test Notice For WednenmbsdayAjit JainÎncă nu există evaluări

- G SyllabusDocument10 paginiG SyllabusAjit JainÎncă nu există evaluări

- To, The Director Ajay Kumar Garg Engg. College Ghaziabad SUB: Permission For Local Promotion For SCROLLS'13Document1 paginăTo, The Director Ajay Kumar Garg Engg. College Ghaziabad SUB: Permission For Local Promotion For SCROLLS'13Ajit JainÎncă nu există evaluări

- Ajay Kumar Garg Engineering College GhaziabadDocument2 paginiAjay Kumar Garg Engineering College GhaziabadAjit JainÎncă nu există evaluări

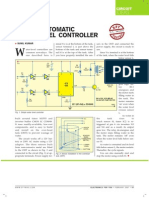

- Simple Water IndicatormnlDocument1 paginăSimple Water IndicatormnlAjit JainÎncă nu există evaluări

- Automatic Water Level Controller Circuit Is A Simple Engineering ProdsjectDocument5 paginiAutomatic Water Level Controller Circuit Is A Simple Engineering ProdsjectAjit JainÎncă nu există evaluări

- Subject: Application For Asking Permission To Stay Back in Hostel For Baskeball Practice and To Represent Our College in Jamia Islamia TournmentDocument1 paginăSubject: Application For Asking Permission To Stay Back in Hostel For Baskeball Practice and To Represent Our College in Jamia Islamia TournmentAjit JainÎncă nu există evaluări

- JJDocument18 paginiJJAjit JainÎncă nu există evaluări

- UPSC Allahabad Medical Officer Selection ListDocument58 paginiUPSC Allahabad Medical Officer Selection ListAjit JainÎncă nu există evaluări

- Anti Ragging AffidavitDocument4 paginiAnti Ragging AffidavitsambitpgdbaÎncă nu există evaluări

- PDS Project Profile 500-kV Hassayampa SwitchyardDocument1 paginăPDS Project Profile 500-kV Hassayampa SwitchyardKCGeraghtyÎncă nu există evaluări

- ValleyLab Force 2 - Service ManualDocument68 paginiValleyLab Force 2 - Service ManualRuben Dario Vazquez Vera100% (8)

- High Voltage FuseseDocument28 paginiHigh Voltage Fusesezbyszko201234Încă nu există evaluări