Documente Academic

Documente Profesional

Documente Cultură

Iso Manual

Încărcat de

Sanjay MalhotraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Iso Manual

Încărcat de

Sanjay MalhotraDrepturi de autor:

Formate disponibile

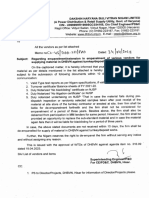

REVISION RECORD SHEET

TITLE : PROCEDURE FOR

REV.NO 00 CONTROLLING NONCONFORMING PRODUCT. DESC. OF AMENDMENT DATE OF AMENDMENT PROCEDURE RE-STATED. 16.03.1997

PR.NO : QP-13-01 PAGE NO : 1 OF 5 ISSUE NO : 01 REV NO : B DATE : 04.07.1997 REASON FOR AMENDMENT QS 9000 ; 1995 UPDATION

DISTRIBUTED TO :

SL.NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 PREPARED BY: DESIGNATION NAME & SIGNATURE OF THE RECEIVER

APPROVED & REVIEWED AND RELEASE CONTROLLED BY: .

QUALITY ASSURANCE PROCEDURE

TITLE : Procedure for Controlling Non-Conforming

Product. PURPOSE : Scope :

PR.NO : QP-13-01 PAGE NO : 2 OF 5 ISSUE NO : 01 REV NO : B DATE : 04.07.1997

To define the procedure for control and disposition of Non Conforming Products (N. C. P.) All N. C. P. identified during incoming, inprocess and final inspection in the organisation including customer returns. AGM - QA for LS & Dy. Mgr - QA for STB 01.The discovery of NCP can occur during the following stages: Incoming Inspection Inprocess , Final Inspection, Customer Returns 02. The control system for handling NCP shall be as described as further The system is common for all the stages identified above and whenever specific for a particular stage, the same shall be indicated). The overview of the system are as follows : Discovery Identification Segregation Review for disposition Approval Documentation Disposal Close out Tracking

Responsibility : Procedure :

The details of each are as follows : A) DISCOVERY A NCP shall be discovered by : At Receipt Inspection QA Engr. / Lab incharge At Inprocess & Final Inspection - Operator / QA Inspector Customer returns shall be brought to the notice of respective QA Incharge by Mktg. Heads. A REJECTED/ REWORK/ HOLD Tag / Sticker shall be put on such NCPs. Such NCP shall be shifted to respective Quarantines from shift to shift. The NC shall be logged in the respective NC register : RG-13-01 For Incoming Inspection RG-13-02/A For Inprocess & Final Inspection where Arepresents L for Leaf spring and S for stabilizer bar. RG-13-03/L For Assy. Inspection RG-13-04/L & RG-13-03/S For Customer returns.

QUALITY ASSURANCE PROCEDURE

TITLE : Procedure for Controlling Non-Conforming

Product. The incoming NC register shall have the following information: Sl.no Date Vendor with MRN no. Section / Diameter Specifications Process drawing with revision status Disposition - (a) Reject (b) Use as it is Total Qty. Corrective Action Inspected by & remarks comments, if any

PR.NO : QP-13-01 PAGE NO : 3 OF 5 ISSUE NO : 01 REV NO : B DATE : 04.07.1997

The inprocess NC register shall have the following information: Sl.no Date & shift Process drawing no. with revision status Opn no. & Desc Part no & Desc Nature of defect No. of NCP Total Batch Qty. Disposition - (a) Reject / Scrap (b) Rework Salvaging Corrective Action Remarks Approved by.

(c) Use as it is

(d) Regrade (e)

B) IDENTIFICATION : Upon the discovery of the NCP, all such material shall be identified by putting a tag / stickerREJECTED/ REWORK/ HOLD TAG by respective Inspector/operator. In the incoming inspection the tag shall have information about the vendor, MRN no., the inspectors sign on the tag & the Qnty. In the inprocess & final inspection, the tag shall have information about the operation no., date, shift, disposition operator and qnty & the operators/inspectors sign on the tag along with cross reference to product route card.

QUALITY ASSURANCE PROCEDURE

TITLE : Procedure for Controlling Non-Conforming

Product. C) SEGREGATION

PR.NO : QP-13-01 PAGE NO : 4 OF 5 ISSUE NO : 01 REV NO : B DATE : 04.07.1997

Having clearly identified NCP, the respective Inspectors/ operators shall segregate / quarantine to the area identified at the respective work stations until the decision has been reached on disposition. This shall be under the strict super vision of the Inspectors. D) REVIEW FOR DISPOSITION

+

The Material Review Board (MRB) / comprising of Managers of QA & Production, shall review the NCP every day for all the three stages. In the absence of MRB for any reason, the respective shift engineer/inspector shall put a HOLD tag on the non conforming product, stored at the identified area till the MRB meets and reviews for disposition. The review shall be carried out in the following methodology : Stage I: Assess the source documents that whether the specifications are clearly / adequately defined and that the NCP is actually a non conformance or defective or both. Stage II : Assess the criticality of the NCP based on two aspects: The maximum deviation from specification The qnty or rate of items non conforming E) APPROVAL The NC Register shall be completed to indicate disposition, liability and actions required, which affected parties sign to signify their approval. The responsibility for obtaining & overall control of the process shall be that of MRB. Whenever MRB is not in a position to decide on disposition, the same shall be referred to GM(O)/AGM-STB and decided accordingly. F) DOCUMENTATION INVOLVED Based on the disposition decided, the following documents as appropriate shall be raised. When the decision taken are: USE AS IT IS - a deviation note, which is a written authorization prior to use or release of a qnty of items produced which do not conform to the specified requirements. REWORK INSTRUCTION/PLAN- to indicate the nature the type of rework to be carried out. SCRAP NOTE - Authorisation to dispose the material which cannot be reworked, repaired or used for any other purpose.

QUALITY ASSURANCE PROCEDURE

TITLE : Procedure for Controlling Non-Conforming

Product.

PR.NO : QP-13-01 PAGE NO : 5 OF 5 ISSUE NO : 01 REV NO : B DATE : 04.07.1997

RETURN NOTE - Notification to a vendor of the reason for returning material This document sometimes incorporates the corrective action request document. SALVAGING - Authorisation to salvage the material which cannot be reworked, repaired or used for any other purpose. CORRECTIVE ACTION - Any immediate corrective action shall be recorded in the respective NC register and shall be informed to the operators concerned. G) DISPOSAL After approval & disposition identified QA Inspectors shall get the disposition done as documented. H) CLOSEOUT AGM - QA for LS & Dy. Mgr.(QA) for STB shall ensure that follow up actions , approved on NC Register, for correction or prevention are implemented. For rework or repair this shall require reinspection of the items. I) TRACKING Records of NCP shall be maintained by AGM - QA for LS & Dy. Mgr.(QA) for STB to determine whether actions taken are effective in reducing the no. of Ncs. AGM - QA for LS & Dy. Mgr.(QA) shall ensure that a weekly summary of NCPs is made and analysed for corrective & preventive action as per Proc. No. QP-14-01. The summary is discussed & analysed jointly with respective Production & Engg. incharges. The overall effectiveness is determined by plotting the quantity of NCPs discovered monthly. Engineering Approved Product Authorisation : The situation when changes are to be incorporated in any of the parameters of process set up prevailing at the time of sample approval, prior approval from the customer shall be obtained if the product is different from the currently approved one. Refer PPAP requirements as detailed in procedure QP-21-01. Similar control of products shall apply on products purchased from sub-contractors . This situations of change in product nature if approved by customer for a specific period or quantity, Marketing / Engg. Incharge shall communicate the details to Q. A. Incharge who in turn shall maintain record of quantities supplied with customer authorization. After expiration of this concession / authorisation he shall ensure meeting with original quality requirements. The material shipped under authorisation shall be marked or identified separately.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- New Technology in Solar CellDocument5 paginiNew Technology in Solar CellSanjay MalhotraÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Pipeline Basics 2. 3. 4. 5. 6. Repairing FracturesDocument36 paginiPipeline Basics 2. 3. 4. 5. 6. Repairing FracturesSanjay MalhotraÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- List Manufacturers Empanelled VendorsDocument14 paginiList Manufacturers Empanelled VendorsSanjay MalhotraÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- 1) Salary and Wages (Per Month) : (Incld. Stores, Power and Maintenance)Document1 pagină1) Salary and Wages (Per Month) : (Incld. Stores, Power and Maintenance)Sanjay MalhotraÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- LIST Engineering ArchitectDocument5 paginiLIST Engineering ArchitectSanjay MalhotraÎncă nu există evaluări

- Profitibility of The Project: (All Values in Lacs of Rupees)Document1 paginăProfitibility of The Project: (All Values in Lacs of Rupees)Sanjay MalhotraÎncă nu există evaluări

- HamburgDocument2 paginiHamburgSanjay MalhotraÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Result With Held Dean PUDocument2 paginiResult With Held Dean PUSanjay MalhotraÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Promoters Profile: Mr. ABC Having - Years of Experience in Finance, AccountsDocument1 paginăPromoters Profile: Mr. ABC Having - Years of Experience in Finance, AccountsSanjay MalhotraÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Project at Glance: Project: Material Handling, Automation and Special Purpose Machines. Promoters: MRDocument2 paginiProject at Glance: Project: Material Handling, Automation and Special Purpose Machines. Promoters: MRSanjay MalhotraÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Production Facilities and Machinery: ExportsDocument1 paginăProduction Facilities and Machinery: ExportsSanjay MalhotraÎncă nu există evaluări

- Project 8Document1 paginăProject 8Sanjay MalhotraÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- To Whom So Ever It May Concern FormatDocument1 paginăTo Whom So Ever It May Concern FormatSanjay MalhotraÎncă nu există evaluări

- Bank Statement LetterDocument2 paginiBank Statement LetterSanjay MalhotraÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Bible 2Document2 paginiBible 2Sanjay MalhotraÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Products To Be Manufactured: Marketing DemandDocument1 paginăProducts To Be Manufactured: Marketing DemandSanjay MalhotraÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Check ListDocument14 paginiCheck ListSanjay MalhotraÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Legal MaximsDocument7 paginiLegal MaximsSanjay MalhotraÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- PU Chinese Fees DepositDocument1 paginăPU Chinese Fees DepositSanjay MalhotraÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Visiting CardDocument1 paginăVisiting CardSanjay MalhotraÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- NOVA Invoice ToasterDocument1 paginăNOVA Invoice ToasterSanjay MalhotraÎncă nu există evaluări

- Advance Salary ApplicationDocument1 paginăAdvance Salary ApplicationSanjay Malhotra100% (1)

- Terms and Conditions AuctionDocument13 paginiTerms and Conditions AuctionSanjay MalhotraÎncă nu există evaluări

- List Chemical PU 2015Document3 paginiList Chemical PU 2015Sanjay MalhotraÎncă nu există evaluări

- List Uiet 2015Document3 paginiList Uiet 2015Sanjay MalhotraÎncă nu există evaluări

- Eric Young v. Jodi Blatt, 4th Cir. (2014)Document2 paginiEric Young v. Jodi Blatt, 4th Cir. (2014)Scribd Government DocsÎncă nu există evaluări

- 2018 - 11 - 07 GR 190800Document4 pagini2018 - 11 - 07 GR 190800SabÎncă nu există evaluări

- Cor AdDocument12 paginiCor AdCarl Izan Clapero III0% (1)

- Role of Lokpal and Lokyukta in India Redressal of PublicDocument14 paginiRole of Lokpal and Lokyukta in India Redressal of Publictayyaba redaÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Jimenez Vs SoronganDocument2 paginiJimenez Vs SoronganEAÎncă nu există evaluări

- Succession CodalDocument4 paginiSuccession CodalJo-Al Gealon50% (2)

- Coronado vs. CADocument5 paginiCoronado vs. CAashaxleÎncă nu există evaluări

- (HC) Najera v. Scrivner - Document No. 3Document2 pagini(HC) Najera v. Scrivner - Document No. 3Justia.comÎncă nu există evaluări

- General Conditions of Contract For Services (GCC) FINAL GCC MARCH 2018Document102 paginiGeneral Conditions of Contract For Services (GCC) FINAL GCC MARCH 2018Abhi Nav83% (6)

- Ople V Torres Due ProcessDocument2 paginiOple V Torres Due ProcessLester Nazarene OpleÎncă nu există evaluări

- Karanvir Singh and Ors Vs State of Punjab and Ors On 30 September, 2016Document9 paginiKaranvir Singh and Ors Vs State of Punjab and Ors On 30 September, 2016Kunal VermaÎncă nu există evaluări

- Department of Education: Republic of The PhilippinesDocument5 paginiDepartment of Education: Republic of The PhilippinesThering Doc-BotardoÎncă nu există evaluări

- Introduction To Air LawDocument22 paginiIntroduction To Air LawJaycee Quiambao0% (1)

- Article 21Document17 paginiArticle 21shanikaÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Legal Aptitude: Contracts - 1Document6 paginiLegal Aptitude: Contracts - 1Vishal JainÎncă nu există evaluări

- Competition Entry Form: (Please Note That ONE Form Should Be Filled in For EACH Competition You Wish To Enter.)Document2 paginiCompetition Entry Form: (Please Note That ONE Form Should Be Filled in For EACH Competition You Wish To Enter.)Juan Pablo Honorato BrugereÎncă nu există evaluări

- Definitions - No Definition in The Code For: G. Capital Gains & LossesDocument5 paginiDefinitions - No Definition in The Code For: G. Capital Gains & LossesJen MoloÎncă nu există evaluări

- ALTI Minutes of The Meeting 04Document3 paginiALTI Minutes of The Meeting 04Dave Jasm MatusalemÎncă nu există evaluări

- Emergence of BangladeshDocument11 paginiEmergence of BangladeshNerdBoy 619Încă nu există evaluări

- Sagrada Orden v. Nacoco DigestDocument1 paginăSagrada Orden v. Nacoco DigestLaya100% (1)

- Write A File MEMO On Any One of The Topics Belowdocx 2408Document2 paginiWrite A File MEMO On Any One of The Topics Belowdocx 2408ashibhallau0% (1)

- Cervantes V Aquino Digest PDFDocument2 paginiCervantes V Aquino Digest PDFmpbhcostalesÎncă nu există evaluări

- CSIS Injury AssessmentDocument8 paginiCSIS Injury Assessmentthe fifth estateÎncă nu există evaluări

- Calalang V WilliamsDocument1 paginăCalalang V WilliamsErca Gecel BuquingÎncă nu există evaluări

- Insight IAS Test - 8 SolutionsDocument34 paginiInsight IAS Test - 8 SolutionsSrutishree BiswalÎncă nu există evaluări

- Civil Law Reviewer QuestionsDocument230 paginiCivil Law Reviewer QuestionsStrawber Ry100% (2)

- Rajasthan Housing Board, Circle - Ii, JaipurDocument2 paginiRajasthan Housing Board, Circle - Ii, JaipurSandeep SoniÎncă nu există evaluări

- Article 1-Curiously Worded Labour Legislation-Industrial Peace in Sri LankaDocument5 paginiArticle 1-Curiously Worded Labour Legislation-Industrial Peace in Sri LankathusharagoÎncă nu există evaluări

- Rate The Lobbysists SurveyDocument1 paginăRate The Lobbysists SurveySarah MirkÎncă nu există evaluări

- Cromwell V CirDocument1 paginăCromwell V CirVenus KeizylÎncă nu există evaluări