Documente Academic

Documente Profesional

Documente Cultură

Crane Hoist

Încărcat de

JackSparrow86Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Crane Hoist

Încărcat de

JackSparrow86Drepturi de autor:

Formate disponibile

Clause No.

TECHNICAL REQUIREMENTS

Crane Hoist & Service Elevators

1.00.00 GENERAL The EOT cranes shall be used during erection and also for maintenance of various power plant equipments located within the Turbine hall, C.W. pump house, air compressor area, central work shop area. Semi EOT cranes and monorail hoists shall be provided as per Part-A. The equipments to be handled by the E.O.T cranes are the main turbine, generator rotor and generator auxiliaries, turbine driven boiler feed pump, motor driven boiler feed pump, condensate extraction pump, turbine oil coolers and auxiliary equipment, high pressure and low pressure heaters, and similar handling activities in different areas of installations. 1.01.00 1.02.00 The cranes will run on rails which will be fixed to the steel gantry girder. During the period of erection of the power station the EOT cranes will be frequently used. The duty cycle during this period shall conform to class 2 duty as per IS:3177. During the period of erection of the power station the semi EOT cranes and monorail Hoist (manual / electric) of class 2 duty to IS : 3832 and accessories as well will be used. The design, manufacture inspection and testing of the crane shall comply with the requirement of latest version of IS:3177 and other standards specified. The stipulations of all statutory codes like Indian Electricity Act, Indian Electricity Rules, Factory Acts, Local Municipality Act etc. shall however prevail over the specification requirements, incase any conflict arises between this specification and the statutory codes. Monorail hoist (manual / electric) shall be suitable for operation from floor level. Hand chain shall be provided for long travel of trolley. For electric hoist, Hoisting shall be electric. Design Criteria/Type/Rating for EOT cranes i) Creep speed for main hook as well as Auxiliary hook Creep speed for bridge and trolley drive Control location 10% of full load speed

1.03.00

1.04.00

1.05.00

1.06.00

1.07.00

ii) iii)

10% of rated speed Operators cabin or floor operated pendent. According to IS :1893-77

SUB-SECTION-IIIA-11 Crane Hoist & Service Elevators

iv)

Design seismic Co-efficient

Bid Doc. No.: CS-9451-108-2

KODARMA (2X500MW)

MAIN PLANT TURNKEY PACKAGE

TECHNICAL SPECIFICATIONS SECTION-VI, PART B

Page 1 of 6

Clause No.

TECHNICAL REQUIREMENTS (Zone III) v) The hook approaches for either sides shall be as per owners requirements/code/standard. Approximate max. full load speed After discussion with owner.

vi)

Note: The above parameters are tentative. Owner reserves the right to change the parameters of crane during finalization of design.

2.00.00 2.01.00 2.01.01

SERVICE ELEVATORS DESIGN CRITERA AND OPERATIONAL SPECIFICATION Design Elevator shall be of panorama type with fire glass panels on rear for Service Building and conventional enclosure type for ESP Control Rooms & TG buildings. The elevator shall meet the quality of international standard. The quality of glass panel on rear should be of highest grade from safety point of view and should meet the best standard.

2.01.02

No. of floors to be served shall be as required. The final landing elevations for all buildings shall be subject to approval by the Employer after award. Bidders shall quote for variation in price for addition/deletion of one landing level in the relevant schedule of Forms and Procedures. Elevators shall confirm to the following: Operating Speed (m/second) Size of platform Operation of Elevator : 01 meters/second : IS 14665 : a) Selective duplex collective automotive operation with or without attendant. Provision for locking control in auto or attendant position.

2.01.03

b)

2.01.04

Elevators shall be designed based on following criteria : i) Design/construction/installation codes. : a) Latest edition of IS: 14665 all parts

Page 2 of 6

KODARMA (2X500MW)

MAIN PLANT TURNKEY PACKAGE

Bid Doc. No.: CS-9451-108-2

TECHNICAL SPECIFICATIONS SECTION-VI, PART B

SUB-SECTION-IIIA-11 Crane Hoist & Service Elevators

Clause No.

TECHNICAL REQUIREMENTS b) Panorama conventional subject Employers approval. type/ type, to

ii)

Load carrying capacity

: a) 1088 kgs. (equivalent to 16 persons) : 1.0 m/sec. : As per design/installation code at 2.01.03 above. : As per Electrical Specifications. : As per Specification. Electrical

iii) iv)

Rated speed Entrance & Platform size

v)

Drive/motor

vi)

Method of control

vii)

Position of machine room

: Directly above the lift shaft.

viii) Elevator landings (subject to Employers : As required. approval after award) ix) Machine room : Air-conditioned Machine Room as per the requirements of lift manufacturer. : As detailed in Electrical Specification.

x)

Power supply

2.01.05

Landing doors of the elevators shall have fire resistance as per IS:14665 (Latest edition). These doors shall also be smoke tight as far as possible. Providing metallic wire mesh/screen for counter weight guard in the elevator pit. CONSTRUCTION Construction of the elevators shall specifically meet all requirements of the codes indicated and shall have following additional features: i) Flooring of Cabin : Vitrified ceramic tile of matt finish. : Stainless Steel (SS:304)

TECHNICAL SPECIFICATIONS SECTION-VI, PART B

SUB-SECTION-IIIA-11 Crane Hoist & Service Elevators

2.01.06 3.00.00 3.01.00

ii)

Design, Construction

Bid Doc. No.: CS-9451-108-2

KODARMA (2X500MW)

MAIN PLANT TURNKEY PACKAGE

Page 3 of 6

Clause No.

TECHNICAL REQUIREMENTS

iii) iv) v)

Car entrance and landing doors Car Door construction Signals

: As per IS 14665 (latest edition) : Stainless Steel (SS:304) : Car position indication in Car both visual and audio, hall position indicator at all floors, tell lights at all floors, battery operated alarm bell and emergency light and fan & telephone without handset with suitable battery, charger & controls. : Standard indicators or alternatively luminous button in car operating panel and digital hall position indicator on all floors. (All fixtures in stainless steel face plates). : In case of Emergency hold-ups in between the floors, automatic flashers should indicate its location of hold-up both audio & visually as well.

vi)

Type of Indicators

Vii)

Emergency indicator

1.

AUTOMATIC RESCUE DEVICE (ARD)-(BATTERY DRIVE): Bidder to provide a modern Advanced electronic drive system of RESTUING Passenger Trapped in a ELEVATOR.

2.

EMERGENCY SAFETY DEVICES: The lift shall be provided with safety Device attached to the lift car frame and placed beneath the car. The safety device shall be capable of stopping and sustaining the lift car up at Governor Tripping speed with full rated load in car. The application of safety device shall not cause the lift platform to become out of level in excess of 3 cm/m measured in any direction.

3.

ACWVF CONTROL: The drive system for the Elevator should be variable voltage variable Frequency Drive system. The Level accuracy will be + - 8 mm. with dynamic braking system.

KODARMA (2X500MW)

MAIN PLANT TURNKEY PACKAGE

Bid Doc. No.: CS-9451-108-2

TECHNICAL SPECIFICATIONS SECTION-VI, PART B

SUB-SECTION-IIIA-11 Crane Hoist & Service Elevators

Page 4 of 6

Clause No.

TECHNICAL REQUIREMENTS

3.02.00 3.03.00

Provide sound reducing material below machines in machine room. Provide special corrosion resistant treatment on all elevator components. The protective treatment shall be subject to Employers approval. Required doors complete with door frames, hangers, tracks etc. shall be designed so as not to exceed a maximum live load of 500 Kg/M2 on the landings as specified. Guide rails complete with supporting brackets for the car and counter weights. Elevator drive machines complete with electric motor, reduction gear units, suspension ropes, buffers for the cars and the counter weights and other drive and control mechanism. All foundation anchor bolts, sleeves, anchoring steel and any item required to complete the job satisfactorily shall be provided by the bidder. The bidder shall also provide for the grouting of anchor bolts, sleeves, anchoring steel, etc. and other anchorages. Any other steel works as well as all other accessories/components not specified in the specification but necessary for making the Elevator complete. Complete erection, testing and commissioning including all testing and commissioning materials, consumables and other tools and tackles required for erection. All minor building work including the supply of steel items, associated with installation of equipment in the machine room hoist way, hoist way door, frames and Elevator pit, shall form part of bidders scope of service, owner will provide the Elevator-well complete with foundation and brick walls around the lit-well together with overhead machine room. The machine room will be provided with R.C.C. floor slab with necessary pockets for anchor bolts and slots. OPERATION Elevator shall have provisions to meet following operational requirements : a) Selective Duplex collective, automatic operation with or without operation through illuminated push button station located inside the lift car. Power operated with automatic opening/closing car and landing doors. Two push buttons, one for upward movement and the other for downward movement at each intermediate landing and one push button at each terminal landing shall be provided in order to call the car. Push buttons shall be fixed in the car for holding the doors open for any length of the time required.

Bid Doc. No.: CS-9451-108-2

3.04.00

3.05.00 3.06.00

3.07.00

3.08.00

3.09.00

4.00.00 4.01.00

b) c)

d)

KODARMA (2X500MW)

MAIN PLANT TURNKEY PACKAGE

TECHNICAL SPECIFICATIONS SECTION-VI, PART B

SUB-SECTION-IIIA-11 Crane Hoist & Service Elevators

Page 5 of 6

Clause No. e)

TECHNICAL REQUIREMENTS All other safety/protection/operation interlocks as required by IS:4666 (latest edition). Indication for : 1) 2) Position and call indication inside the car. Up/down travel direction in car and at each landing.

f)

KODARMA (2X500MW)

MAIN PLANT TURNKEY PACKAGE

Bid Doc. No.: CS-9451-108-2

TECHNICAL SPECIFICATIONS SECTION-VI, PART B

SUB-SECTION-IIIA-11 Crane Hoist & Service Elevators

Page 6 of 6

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- 1 212 AirPreheater Ljungstrom-DetailsDocument14 pagini1 212 AirPreheater Ljungstrom-DetailsAmit Prajapati100% (2)

- BFP TDDocument22 paginiBFP TDJackSparrow8650% (2)

- BFP BHEL Manual For 500MWDocument675 paginiBFP BHEL Manual For 500MWtanumay.gemini83% (12)

- Operation Procedures For MDBFPDocument7 paginiOperation Procedures For MDBFPJackSparrow86100% (1)

- Air Pre HeatingDocument85 paginiAir Pre Heatingmn_sundaraamÎncă nu există evaluări

- Difficulties FacedDocument6 paginiDifficulties FacedJackSparrow86Încă nu există evaluări

- Operation Procedures For MDBFPDocument7 paginiOperation Procedures For MDBFPJackSparrow86100% (1)

- BFP BHEL Manual For 500MWDocument675 paginiBFP BHEL Manual For 500MWtanumay.gemini83% (12)

- TDBFP ManulDocument266 paginiTDBFP ManulJackSparrow8678% (9)

- Difficulties FacedDocument6 paginiDifficulties FacedJackSparrow86Încă nu există evaluări

- Power Cycle PipingDocument7 paginiPower Cycle PipingJackSparrow86Încă nu există evaluări

- LP Bypass SystemDocument7 paginiLP Bypass SystemJackSparrow86Încă nu există evaluări

- Interlocks & Protections-NTPCDocument87 paginiInterlocks & Protections-NTPCJackSparrow86100% (2)

- Procedure For Bearing and Jack Oil Intial CirculationDocument11 paginiProcedure For Bearing and Jack Oil Intial CirculationLakshmi NarayanÎncă nu există evaluări

- Procedure For Condenser Flood Test and Vacuum Tightness TestDocument13 paginiProcedure For Condenser Flood Test and Vacuum Tightness TestJackSparrow86Încă nu există evaluări

- BFP TDDocument22 paginiBFP TDJackSparrow8650% (2)

- Protection and Interlock-NTPCDocument89 paginiProtection and Interlock-NTPCJackSparrow8657% (7)

- Alstom's Flexible Supercritical PowerDocument34 paginiAlstom's Flexible Supercritical PowerelrajilÎncă nu există evaluări

- Procedure For Commissioning of Central Lube Oil Storage & Purification SystemDocument12 paginiProcedure For Commissioning of Central Lube Oil Storage & Purification SystemLakshmi NarayanÎncă nu există evaluări

- Procedure For Commissioning of Auxiliary Prds SystemDocument14 paginiProcedure For Commissioning of Auxiliary Prds SystemJackSparrow86100% (1)

- Procedure For Condenser Flood Test and Vacuum Tightness TestDocument13 paginiProcedure For Condenser Flood Test and Vacuum Tightness TestJackSparrow86Încă nu există evaluări

- Testing Schedule For Commissioning of Condensate Extraction PumpsDocument13 paginiTesting Schedule For Commissioning of Condensate Extraction PumpsJackSparrow86100% (1)

- Exp 7 Centrifugal Pump CharacteristicsDocument10 paginiExp 7 Centrifugal Pump CharacteristicsJackSparrow86Încă nu există evaluări

- Exp 7 Centrifugal Pump CharacteristicsDocument10 paginiExp 7 Centrifugal Pump CharacteristicsJackSparrow86Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Specification For Electric Chain Hoists (First Revision of IS 6547)Document24 paginiSpecification For Electric Chain Hoists (First Revision of IS 6547)Dheeraj ThakurÎncă nu există evaluări

- CBIP Publication No 295Document422 paginiCBIP Publication No 295Pravin Narkhede100% (7)

- The Railway Age (Train History)Document70 paginiThe Railway Age (Train History)Titea Razvan100% (5)

- BBS For CW BuildingDocument32 paginiBBS For CW BuildingSaraswati ChandraÎncă nu există evaluări

- Ranger XL Single CabDocument2 paginiRanger XL Single CabMohd ZamirÎncă nu există evaluări

- Multi - Modal Passenger Terminal Project Final Bus and Rail CompleteDocument175 paginiMulti - Modal Passenger Terminal Project Final Bus and Rail CompleteAnonymous HiQx2gFÎncă nu există evaluări

- Publicity Steam AustraliaDocument135 paginiPublicity Steam AustraliarodeimeÎncă nu există evaluări

- HAL Placement QuestionDocument10 paginiHAL Placement Questionmathan kumarÎncă nu există evaluări

- Draftsman Grade II Town Planning Surveyor GR IIDocument13 paginiDraftsman Grade II Town Planning Surveyor GR IIBasil Baby-PisharathuÎncă nu există evaluări

- Electrical Vendor Directory Jan 2020 To Jun 2020Document231 paginiElectrical Vendor Directory Jan 2020 To Jun 2020sumitshyamal0% (1)

- Part 1 - Report of Lokayukta Santosh Hegde On Karnataka MiningDocument284 paginiPart 1 - Report of Lokayukta Santosh Hegde On Karnataka MiningavulapavanÎncă nu există evaluări

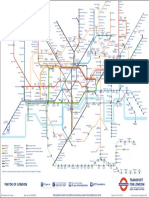

- London Tube MapDocument1 paginăLondon Tube MaprxvvvÎncă nu există evaluări

- Indian Locomotive Class WAP-7Document5 paginiIndian Locomotive Class WAP-7Vijay SinghÎncă nu există evaluări

- Pamphlet On Lubrication of Rail JointDocument4 paginiPamphlet On Lubrication of Rail JointANIRBAN BHOWMIKÎncă nu există evaluări

- Bi-Metallic Overload Relays Selection Guide - Rockwell Automation PDFDocument14 paginiBi-Metallic Overload Relays Selection Guide - Rockwell Automation PDFRaghavendra SarafÎncă nu există evaluări

- Learn To Drive Smart: Your Guide To Driving SafelyDocument184 paginiLearn To Drive Smart: Your Guide To Driving SafelypoppyzhaoooÎncă nu există evaluări

- Star InterviewDocument1 paginăStar InterviewAzrul AzliÎncă nu există evaluări

- Kakatiya TPP I - Wet Ash Handling System, Rev 3 (09.10.2012)Document259 paginiKakatiya TPP I - Wet Ash Handling System, Rev 3 (09.10.2012)rukmagoudÎncă nu există evaluări

- A Ust TunnelDocument3 paginiA Ust TunnelTunnel BhauÎncă nu există evaluări

- Agenda Package 2Document6 paginiAgenda Package 2Prince KumarÎncă nu există evaluări

- PipDocument15 paginiPipmaryannxx100% (1)

- Dubai Tramway - Case Study - EnglishDocument2 paginiDubai Tramway - Case Study - EnglishLuca Marius CristianÎncă nu există evaluări

- BS 5974 1990 Temporary ScaffoldDocument53 paginiBS 5974 1990 Temporary ScaffoldRizqi Nasution100% (2)

- As 1418.19-2007 - Cranes Hoists & Winches - Telescopic HandlersDocument65 paginiAs 1418.19-2007 - Cranes Hoists & Winches - Telescopic HandlersMarcus van Riet100% (1)

- ATEGO - SpecificationsDocument18 paginiATEGO - SpecificationsKovács Áron100% (3)

- 1 - Family Fortunes - Present Perfect and Past SimpleDocument1 pagină1 - Family Fortunes - Present Perfect and Past SimplePedro d'AlteÎncă nu există evaluări

- Railway Traning Report-1Document56 paginiRailway Traning Report-1ShubhamJain100% (1)

- Bulletin 35Document27 paginiBulletin 35Vikash SinghiÎncă nu există evaluări