Documente Academic

Documente Profesional

Documente Cultură

Tangential Air Separators Asme: Pressure Drop Performance Curves

Încărcat de

Shafqat AfridiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tangential Air Separators Asme: Pressure Drop Performance Curves

Încărcat de

Shafqat AfridiDrepturi de autor:

Formate disponibile

TANGENTIAL AIR SEPARATORS ASME

Pressure Drop Performance Curves

The AMTROL air separator flow chart indicates pressure drop in feet (meters) of water versus flow in gallons per minute (L/sec) with strainer. This is the recommended method for properly computing pressure drop in AMTROL Air Separators.

Models AS and AS-L

AMTROL Air Separator without Strainer Flow Chart

Designing the Ideal System Flow Rate

AMTROL Sizing Theorem The closer you can design your system flow rate to six feet/second (1.83 m/s), the greater the percentage of air elimination on each pass through the air separator.

Maximum Flow Rate Based On Design Velocity

Model No. 1 AS-L 2 AS-L 2 1/2 AS-L 3 AS-L 4 AS-L 5 AS-L 6 AS-L 8 AS-L 10 AS-L 12 AS-L 14 AS-L 16 AS-L 19 AS-L 20 AS-L 24 AS-L

Vel. 4 ft./sec. Vel. 1.2 m/sec.Vel. 6 ft./sec. Vel. 1.8 m/sec. Vel. 8 ft./sec. Vel. 2.4 m/sec.Vel.10 ft./sec. Vel.3 m/sec. gpm L/sec. gpm L/sec. gpm L/sec. gpm L/sec.

10.00

AMTROL Air Separator with Strainer Flow Chart

3

10 42 60 93 160 250 360 630 990 1400 1680 2200 3300 4500 5500

.631 2.65 3.78 6 10 16 23 40 62 88 106 139 208 284 347

15 63 90 140 240 375 540 940 1500 2100 2500 2800 4200 5600 7000

1 4 6 9 15 24 34 59 95 133 158 177 265 353 442

20 84 120 185 320 500 720 1250 1980 2800 3350 3500 5200 7000 8800

1.26 5 7.5 12 20 32 45 79 125 177 211 221 328 442 555

25 105 150 230 400 630 900 1580 2470 3500 4200 5000 7500 10000 12500

1.57 7 15 25 40 57 100 156 221 265 316 473 631 789

0.10 10 100 1,000 Flow Rate (GPM) .631 6.31 63.1 Flow Rate L/Sec 631 6310 10,000 100,000 .05 Pressure Drop (Feet of Head)

9.5

1.00

.3

Typical Specifications

Furnish and install, as shown on plans, a centrifugal type air separator. The unit shall have ____ (NPT/flanged/grooved) inlet and outlet connections tangential to the vessel shell. An NPT vent connection shall be fitted to the top of the vessel to enable installation of piping. Air separators shall have all steel body construction. The unit shall have a removable stainless steel system strainer with 3/16 (4.8mm) diameter holes (perforations). A blowdown connection shall be provided to facilitate routine cleaning of the strainer. (Disregard this paragraph if system strainer is not specified). Manufacturer to furnish data sheet specifying air collection efficiency and pressure drop at rated flow.

Data confirmed by independent 3rd party testing.

The air separator must be designed, constructed, and stamped for 125 psig (8.8 bar), 150 psig (10.5 bar) @ 350 F (177C) in accordance with Section VIII, Division 1 of the ASME Boiler and Pressure Vessel Code, and registered with the National Board of Boiler and Pressure Vessel Inspectors. The air separator(s ) shall be painted with one shop coat of red oxide primer. A manufacturers Data Report for Pressure Vessels, Form U-1 as required by the provisions of the ASME Boiler and Pressure Vessel Code shall be furnished for each air separator upon request. Each air separator shall be AMTROL Model __ - AS L (without system strainer) or __ - AS (with system strainer) air separator for _____GPM (L/Sec).

*Refer to installation manual for warranty information or visit our website at www.amtrol.com

Corporate Headquarters 1400 Division Road, West Warwick, RI USA 02893 Telephone: 401-884-6300 Fax: 401-884-5276 AMTROL Canada, Ltd. 275 Shoemaker Street, Kitchener, Ontario N2E 3B3 Telephone: 519-478-1138 Fax: 519-748-4231

w w w . a m t r o l . c o m

AMTROL Asia Pacific Ltd. 89 Owen Road, Singapore 218902 Telephone: 65-6294 4611 Fax: 65-6294 3231

The AMTROL logo and EXTROL are registered trademarks of AMTROL Inc. In the interest of continuous development, AMTROL Inc. and its subsidiaries reserve the right to alter designs and specifications without prior notice.

P/N: 9017-107 MC# 2336 (08/07)

2007 AMTROL Inc. Printed in USA

Pressure Drop (MH2O)

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Toriconical Head Ver 1.1Document4 paginiToriconical Head Ver 1.1Iqbal AhmadsÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- API 650 Tank Design 1Document5 paginiAPI 650 Tank Design 1robertantoreni100% (9)

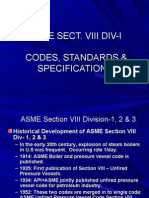

- ASME SECTION VIII DIVISION-1 CODES, STANDARDS & SPECIFICATIONSDocument73 paginiASME SECTION VIII DIVISION-1 CODES, STANDARDS & SPECIFICATIONSShafqat Afridi100% (5)

- API 650 Tank Design 1Document5 paginiAPI 650 Tank Design 1robertantoreni100% (9)

- Tranter Platecoil InformationDocument28 paginiTranter Platecoil InformationShafqat AfridiÎncă nu există evaluări

- Tranter Platecoil ApplicationsDocument12 paginiTranter Platecoil ApplicationsShafqat AfridiÎncă nu există evaluări

- Sizing The Extrol: Diaphragm-Type Hydro-Pneumatic TankDocument8 paginiSizing The Extrol: Diaphragm-Type Hydro-Pneumatic TankShafqat AfridiÎncă nu există evaluări

- Boiler Exam Study Guide 1Document7 paginiBoiler Exam Study Guide 1Shafqat AfridiÎncă nu există evaluări

- Boiler SafetyDocument16 paginiBoiler SafetyTGUlabreaÎncă nu există evaluări

- Model 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyDocument56 paginiModel 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyShafqat AfridiÎncă nu există evaluări

- Boiler Selection PDFDocument25 paginiBoiler Selection PDFShafqat AfridiÎncă nu există evaluări

- Boilers 1Document29 paginiBoilers 1Thakur Kamal Prasad50% (2)

- Boiler Efficiency Guide PDFDocument24 paginiBoiler Efficiency Guide PDFShafqat Afridi100% (1)

- Tank FoundationsDocument83 paginiTank Foundationsdroates100% (17)

- Hot Forming Brochure from J Bown & CoDocument9 paginiHot Forming Brochure from J Bown & CoClayton Kok100% (3)

- Can You SwimDocument1 paginăCan You SwimSiriwadee BuadangÎncă nu există evaluări

- Model 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyDocument56 paginiModel 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyShafqat AfridiÎncă nu există evaluări

- Model 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyDocument56 paginiModel 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyShafqat AfridiÎncă nu există evaluări

- 046 Angle Iron DataDocument6 pagini046 Angle Iron DataShafqat AfridiÎncă nu există evaluări

- Can Your Idea BikeDocument2 paginiCan Your Idea BikeCristina PuigdollersÎncă nu există evaluări

- Bell & Gossett: Not For Potable Water SystemsDocument2 paginiBell & Gossett: Not For Potable Water SystemsShafqat Afridi0% (1)

- Weight CalculatorDocument12 paginiWeight CalculatorShafqat AfridiÎncă nu există evaluări

- The Battles of The Prophet Muhammad (PBUH)Document221 paginiThe Battles of The Prophet Muhammad (PBUH)Shafqat AfridiÎncă nu există evaluări

- Pig Trap Data SheetDocument1 paginăPig Trap Data SheetShafqat Afridi100% (3)

- Dictionary of Islamic Philoophical TermsDocument158 paginiDictionary of Islamic Philoophical TermsSory WebÎncă nu există evaluări

- Pipe Hanger Design-05Document82 paginiPipe Hanger Design-05kjsvonb100% (4)

- BS EN - 13445-1.general.2002Document16 paginiBS EN - 13445-1.general.2002Jose Luis Frias ColoradoÎncă nu există evaluări

- Steel ExamplesDocument3 paginiSteel Examplesrasiq7Încă nu există evaluări

- Cement HydrationDocument15 paginiCement HydrationRADADÎncă nu există evaluări

- NORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameDocument69 paginiNORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameMEHDI FARROKHIÎncă nu există evaluări

- Ar002 PDFDocument104 paginiAr002 PDFwaheed2286Încă nu există evaluări

- Acoustic Plaster and Spray BrochureDocument12 paginiAcoustic Plaster and Spray BrochureStil_AcousticsÎncă nu există evaluări

- 13 Concrete Repairs 4CDocument17 pagini13 Concrete Repairs 4CMina SaflorÎncă nu există evaluări

- Durco Mark 3: ASME (ANSI) Chemical Process PumpsDocument36 paginiDurco Mark 3: ASME (ANSI) Chemical Process PumpsMohd Danial HÎncă nu există evaluări

- Tripole University: Glass-Ceramic "MME660"Document3 paginiTripole University: Glass-Ceramic "MME660"amnajamÎncă nu există evaluări

- Site Feasibility 4 - Site Conditions Surveyed - Building Survey - Site Measuring 2019Document48 paginiSite Feasibility 4 - Site Conditions Surveyed - Building Survey - Site Measuring 2019Tiep Mai ThanhÎncă nu există evaluări

- Lecture 1Document24 paginiLecture 1SaurabhÎncă nu există evaluări

- History of PiezopolymersDocument14 paginiHistory of PiezopolymersrachmajuwitaÎncă nu există evaluări

- ACI 350 CalculationDocument3 paginiACI 350 CalculationBoris GalindoÎncă nu există evaluări

- Bernt - EC3 1 5Document44 paginiBernt - EC3 1 5Rosario BlancaÎncă nu există evaluări

- Copper Pipe and Insulation 2009 Thailand or ChinaDocument18 paginiCopper Pipe and Insulation 2009 Thailand or ChinaLe Manh HieuÎncă nu există evaluări

- Nonlinear Material Properties of StructuralDocument9 paginiNonlinear Material Properties of Structuralkhawaja AliÎncă nu există evaluări

- Housekeeping ScheduleDocument2 paginiHousekeeping ScheduleZeyya Nikka Cordova Pingad100% (1)

- DESIGN OF SHALLOW FOUNDATIONS FOR BUILDINGSDocument19 paginiDESIGN OF SHALLOW FOUNDATIONS FOR BUILDINGSJule LobresÎncă nu există evaluări

- Detailed Plan: Scale 1: 50 @A3 (Foyer Ground Block C)Document1 paginăDetailed Plan: Scale 1: 50 @A3 (Foyer Ground Block C)Richard LeongÎncă nu există evaluări

- Flexural Toughness and Strength of Fiber ConcreteDocument8 paginiFlexural Toughness and Strength of Fiber ConcreteGabriel Cachi Cerna100% (2)

- Chloorrubber HB Coating (EN)Document2 paginiChloorrubber HB Coating (EN)Tomislav BrezicÎncă nu există evaluări

- Practice problems-STEELDocument14 paginiPractice problems-STEELreanÎncă nu există evaluări

- Acson Catalogue Air Handling Unit 1201 PDFDocument12 paginiAcson Catalogue Air Handling Unit 1201 PDFfaiz budiÎncă nu există evaluări

- 2 Parking Garage - Shotcrete - 1002Document1 pagină2 Parking Garage - Shotcrete - 1002VJ QatarÎncă nu există evaluări

- Dry EtchingDocument12 paginiDry EtchingMosaddekÎncă nu există evaluări

- Guide To The Layout Requirements For A Commercial Laundry Room PDFDocument11 paginiGuide To The Layout Requirements For A Commercial Laundry Room PDFTueÎncă nu există evaluări

- Stalargo Stainless Steel I-Beams: For Demanding ApplicationsDocument4 paginiStalargo Stainless Steel I-Beams: For Demanding ApplicationsTushar PatilÎncă nu există evaluări

- Sans 10292Document31 paginiSans 10292leandroÎncă nu există evaluări

- Sports-Cote Pro PUDocument2 paginiSports-Cote Pro PURahul KalathingalÎncă nu există evaluări

- 26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureDocument25 pagini26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureAsril Sang Lentera Senja100% (1)

- Proper Maintenance of InstrumentsDocument92 paginiProper Maintenance of InstrumentsDimi DimoÎncă nu există evaluări

- Flux Skimming PDFDocument6 paginiFlux Skimming PDFpbp2956Încă nu există evaluări