Documente Academic

Documente Profesional

Documente Cultură

Me2402 Cim

Încărcat de

Karthik SubramaniDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Me2402 Cim

Încărcat de

Karthik SubramaniDrepturi de autor:

Formate disponibile

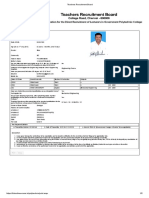

PSNA COLLEGE OF ENGINEERING & TECHNOLOGY, DINDIGUL LESSON PLAN

Faculty Name Subject Name Year Degree & Branch

Objective:

: : : :

K.SURESH KUMAR COMPUTER INTEGRATED MANUFACTURING IV B.E. Mechanical Engineering Code Semester : : ME2402 VII

To gain knowledge on how computers are integrated at various levels of planning and manufacturing understand computer aided planning and control and computer monitoring. TEXT BOOKS: 1. Mikell. P. Groover Automation, Production Systems and Computer Integrated Manufacturing, Pearson Education 2001. REFERENCES: 1. Mikell. P. Groover and Emory Zimmers Jr.,CAD/CAM, Prentice hall of India Pvt. Ltd., 1998. 2. Yorem Koren, Computer Integrated Manufacturing, McGraw Hill, 2005. 3. P N Rao, CAD/CAM Principles and Applications, TMH Publications, 2007.

Sl. No.

Proposed Date

Actual date

Hours reqd

Hours taken

Unit

Topic(s)

Book No.

UNIT I - COMPUTER AIDED DESIGN

1 2 3 4 5 2 2 2 2 2 I I I I I

9 Concept of CAD facility, desirable features of CAD package Drawing features in CAD Scaling, rotation, translation, Editing, dimensioning, labeling,

T1,R3 T1,R3 T1,R3 T1,R3 T1,R3

Zoom, pan, redraw and regenerate Typical CAD command structure, wire frame modeling Surface modeling and solid modeling in relation to popular CAD packages. CIM as a concept and a technology CASA/Sme model of CIM, CIM II, benefits of CIM Communication matrix in CIM,

UNIT II - COMPONENTS OF CIM

6 7 8 1 1 2 II II II

9

T1,R2 T1,R2 T1,R2

fundamentals communication in CIM CIM data transmission methods serial, parallel, asynchronous, modulation, synchronous,

II

T1,R2

10

II

demodulation, simplex and duplex. Types of communication in CIM point to point, star and multiplexing. Computer networking in CIM the seven layer OSI model, LAN model, MAP model network topologies star, ring and bus, advantages of networks in CIM History Of Group Technology role of G.T in CAD/CAM Integration Part families classification DCLASS and MCLASS and OPTIZ codings Facility design using G.T benefits of G.T cellular manufacturing. Process planning - role of process planning in CAD/CAM Integration Computer aided process planning variant approach and generative approaches CAPP and CMPP

T1,R2

11

II

T1,R2

12

II

T1,R2

UNIT III - GROUP TECHNOLOGY AND COMPUTER AIDED PROCESS PLANNING

13 14 15 16 2 2 2 2 III III III III

9

T1,R1 T1,R1 T1,R1 T1,R1

17

III

T1,R1

UNIT IV - SHOP FLOOR CONTROL AND INTRODUCTION TO FMS

Sl. No. 18

Proposed Date

Actual date

Hours reqd 2 2

Hours taken

Unit IV

Topic(s)

Book No. T1,R1

Shop floor control phases factory data collection system Automatic identification methods Bar code technology automated data collection system. FMS components of FMS types FMS workstation Material handling and storage system FMS layout Computer control systems

19

IV

T1,R1

20 21 22

2 2 2

IV IV IV

T1,R1 T1,R1 T1,R1

applications and benefits Production planning and control cost planning and control Inventory management material requirements planning Shop floor control. Lean and Agile Manufacturing. Types of production monitoring

UNIT V - COMPUTER AIDED PLANNING AND CONTROL AND COMPUTER MONITORING

23 24 25 26 27 2 2 2 2 V V V V V

9

T1,R2 T1,R2 T1,R2 T1,R2 T1,R2

systems Structure model of manufacturing process control and strategies

L = 50,

TOTAL: 50 PERIODS

T - Text Book / R - Reference Books

Signature of the Staff In-Charge

HOD / Mechanical

S-ar putea să vă placă și

- Mf5102 Computer Integrated Manufacturing Systems: For Syllabus, Question Papers, Notes & Many MoreDocument2 paginiMf5102 Computer Integrated Manufacturing Systems: For Syllabus, Question Papers, Notes & Many MoreNandha Gopal SenthilnathanÎncă nu există evaluări

- CIM Course OverviewDocument2 paginiCIM Course OverviewbalakaleesÎncă nu există evaluări

- Me2402 - CimDocument1 paginăMe2402 - CimhariccetÎncă nu există evaluări

- 13.804 Compter Integrated Manufacturing (MU)Document2 pagini13.804 Compter Integrated Manufacturing (MU)Manjunath NadarajanÎncă nu există evaluări

- Computer Integrated Manufacturing CourseDocument3 paginiComputer Integrated Manufacturing CoursesatheeshÎncă nu există evaluări

- Me8691-Computer Aided Design and ManufacturingDocument2 paginiMe8691-Computer Aided Design and ManufacturingGeorge Oliver100% (3)

- CIM Systems for Manufacturing Design, Planning & ControlDocument1 paginăCIM Systems for Manufacturing Design, Planning & ControlJeganÎncă nu există evaluări

- ME8691 Syllabus Edubuzz360Document2 paginiME8691 Syllabus Edubuzz360Johnson PaulÎncă nu există evaluări

- CAM Lesson PlanDocument7 paginiCAM Lesson PlanVijay ShakarÎncă nu există evaluări

- Course ObjectivesDocument4 paginiCourse Objectivesmkumar_234155Încă nu există evaluări

- CIM SYSTEMS DESIGN MACHINE ELEMENTSDocument6 paginiCIM SYSTEMS DESIGN MACHINE ELEMENTSBala NarayanasamyÎncă nu există evaluări

- Master of Computer Applications Curriculum and SyllabiDocument73 paginiMaster of Computer Applications Curriculum and SyllabiStanly JonesÎncă nu există evaluări

- CIM Subject Guide for Mechanical Engineering StudentsDocument7 paginiCIM Subject Guide for Mechanical Engineering StudentsKeerthe VaasanÎncă nu există evaluări

- Fundamentals of Cad CamDocument1 paginăFundamentals of Cad CamKrista JacksonÎncă nu există evaluări

- Me8691 Computer Aided Design and Manufacturing SyllabusDocument2 paginiMe8691 Computer Aided Design and Manufacturing SyllabusGanapathy TÎncă nu există evaluări

- ME6703 SCAD MSM by WWW - Learnengineering.inDocument88 paginiME6703 SCAD MSM by WWW - Learnengineering.inAnonymous VC2zZcPCivÎncă nu există evaluări

- CAD CAM SyllabusDocument2 paginiCAD CAM SyllabusDeepak AwasthiÎncă nu există evaluări

- Cim SyllabusDocument2 paginiCim SyllabusHarish HÎncă nu există evaluări

- Computer Integrated ManufacturingDocument2 paginiComputer Integrated ManufacturingNarendra Dvv0% (1)

- Computer Integrated ManufacturingDocument108 paginiComputer Integrated ManufacturingMuthuselvi SÎncă nu există evaluări

- Advanced Manufacturing SystemsDocument23 paginiAdvanced Manufacturing SystemsDhanish KumarÎncă nu există evaluări

- M.Tech Specialization in CAD/CAM Course Structure and SyllabusDocument15 paginiM.Tech Specialization in CAD/CAM Course Structure and Syllabusram00345Încă nu există evaluări

- References:: Sl. No. Author Title PublisherDocument1 paginăReferences:: Sl. No. Author Title PublisherGayathri BolugodduÎncă nu există evaluări

- Computer Integrated Manufacturing: Course ObjectivesDocument3 paginiComputer Integrated Manufacturing: Course ObjectivesPrashanth JÎncă nu există evaluări

- Course Outline CIM 14Document3 paginiCourse Outline CIM 14Bizuayehu TadesseÎncă nu există evaluări

- Prist University B.Tech Part Time Mechanical Engineering Question Bank for Computer Integrated ManufacturingDocument5 paginiPrist University B.Tech Part Time Mechanical Engineering Question Bank for Computer Integrated ManufacturingMahalingam NanjappanÎncă nu există evaluări

- 7 ThsemsyllabusDocument8 pagini7 ThsemsyllabusDhakshina KÎncă nu există evaluări

- New Cad&m Mtech SyllabusDocument3 paginiNew Cad&m Mtech SyllabusupenderÎncă nu există evaluări

- Cim (English)Document320 paginiCim (English)DaRkSouLÎncă nu există evaluări

- 1.cim Text BookDocument18 pagini1.cim Text BookVinayakÎncă nu există evaluări

- CADCAMDocument50 paginiCADCAMPrem Chander100% (5)

- CADCAM-minDocument91 paginiCADCAM-minBandi KumarreddyÎncă nu există evaluări

- Cam 25062016 030053amDocument4 paginiCam 25062016 030053amRemi KwetchaÎncă nu există evaluări

- Computer Applications in Mining SyllabusDocument2 paginiComputer Applications in Mining SyllabusMartin JanuaryÎncă nu există evaluări

- Embedded SystemsDocument1 paginăEmbedded SystemsSasikumar UmaÎncă nu există evaluări

- Syll, QB - SEM 5Document130 paginiSyll, QB - SEM 5dce_geethaÎncă nu există evaluări

- CD5291 Computer Aided Tools for Manufacturing Detailed SyllabusDocument2 paginiCD5291 Computer Aided Tools for Manufacturing Detailed SyllabusKamalakkannan RadhakrishnanÎncă nu există evaluări

- M.E.embedded System TechnologiesDocument32 paginiM.E.embedded System TechnologiesSri RamÎncă nu există evaluări

- MCA ChennaiDocument50 paginiMCA ChennaicsisajurajÎncă nu există evaluări

- 4Document17 pagini4oktavija18Încă nu există evaluări

- CAD CAM II SemDocument13 paginiCAD CAM II SemSayyadh Rahamath BabaÎncă nu există evaluări

- Me1403 - Computer Integrated Manufacturing: IV Year Mechanical Engg. Notes On Lesson Unit - I: IntroductionDocument17 paginiMe1403 - Computer Integrated Manufacturing: IV Year Mechanical Engg. Notes On Lesson Unit - I: Introductionmohan_killerÎncă nu există evaluări

- Embedded Systems SyllabusDocument4 paginiEmbedded Systems Syllabusjohnwesley0% (1)

- Mf3404 Flexible Manufactuirng SystemsDocument1 paginăMf3404 Flexible Manufactuirng Systemsnkchandru100% (1)

- Mechanical - VI. Sem Syllabus GtuDocument115 paginiMechanical - VI. Sem Syllabus GtukishormechÎncă nu există evaluări

- EmbeddedDocument9 paginiEmbeddedNanc Joy100% (1)

- Components of CIM & Data CommunicationDocument3 paginiComponents of CIM & Data Communicationkannanviknesh086319Încă nu există evaluări

- ERTOS Course OutcomesDocument2 paginiERTOS Course OutcomesSyed AshmadÎncă nu există evaluări

- 161ME51 Cad/Cam/Cae: L-T-P C 3-0-0 3 Programme: Sem: 5 Category: PC Aim: Course OutcomesDocument2 pagini161ME51 Cad/Cam/Cae: L-T-P C 3-0-0 3 Programme: Sem: 5 Category: PC Aim: Course OutcomeskganesanÎncă nu există evaluări

- Intelligent Manufacturing Systems Web ReferencesDocument2 paginiIntelligent Manufacturing Systems Web ReferencesGopinath GangadhariÎncă nu există evaluări

- Computer Applcations SyllabusDocument1 paginăComputer Applcations SyllabustresspasseeÎncă nu există evaluări

- Bcomccss2009computer ApplicationDocument8 paginiBcomccss2009computer Applicationyadug723Încă nu există evaluări

- Calicut University BTech Mechanical Engineering Scheme and CurriculumDocument4 paginiCalicut University BTech Mechanical Engineering Scheme and CurriculumAnish SukumarÎncă nu există evaluări

- Gujarat Technological University: Page 1 of 3Document3 paginiGujarat Technological University: Page 1 of 3ashish patelÎncă nu există evaluări

- Manufact Engg FDocument31 paginiManufact Engg FtskcbeÎncă nu există evaluări

- Design Automation of Cyber-Physical SystemsDe la EverandDesign Automation of Cyber-Physical SystemsMohammad Abdullah Al FaruqueÎncă nu există evaluări

- Modeling and Problem Solving Techniques for EngineersDe la EverandModeling and Problem Solving Techniques for EngineersÎncă nu există evaluări

- Hydraulics and Pneumatics: Varun Pratap SinghDocument38 paginiHydraulics and Pneumatics: Varun Pratap SinghKarthik SubramaniÎncă nu există evaluări

- Dislocation & Strengthening MechanismsDocument40 paginiDislocation & Strengthening MechanismsKarthik SubramaniÎncă nu există evaluări

- Design of Hydraulic and Pneumatic Systems - QPDocument11 paginiDesign of Hydraulic and Pneumatic Systems - QPKarthik SubramaniÎncă nu există evaluări

- Practice - Geometric ConstructionDocument13 paginiPractice - Geometric ConstructionKarthik SubramaniÎncă nu există evaluări

- Crane CompressedDocument69 paginiCrane CompressedJhonRider100% (1)

- CS8591 Computer Networks L T P C 3 0 0 3 ObjectivesDocument5 paginiCS8591 Computer Networks L T P C 3 0 0 3 Objectivesjayaprasanna1230% (1)

- Me6012 Me Mech Viist Au Unit IVDocument21 paginiMe6012 Me Mech Viist Au Unit IVKarthik SubramaniÎncă nu există evaluări

- Fracture Mechanics Solution Manual Chapter 1 Stresses StrainsDocument120 paginiFracture Mechanics Solution Manual Chapter 1 Stresses StrainsMahesh Raja50% (2)

- PDFDocument108 paginiPDFKarthik SubramaniÎncă nu există evaluări

- 2013 RegulationDocument2 pagini2013 RegulationKarthik SubramaniÎncă nu există evaluări

- Me6012 Me Mech Viist Au Unit III PDFDocument20 paginiMe6012 Me Mech Viist Au Unit III PDFKarthik SubramaniÎncă nu există evaluări

- Dislocation Stress Fields: Theory of DislocationsDocument17 paginiDislocation Stress Fields: Theory of DislocationsAbdulRehmanÎncă nu există evaluări

- Me6012 Me Mech Viist Au Unit III PDFDocument20 paginiMe6012 Me Mech Viist Au Unit III PDFKarthik SubramaniÎncă nu există evaluări

- Journallist 1 PDFDocument400 paginiJournallist 1 PDFRajasekar PichaimuthuÎncă nu există evaluări

- SafteyDocument5 paginiSafteyKarthik SubramaniÎncă nu există evaluări

- VEC Mechanical Engineering PLM Question Bank for III Semester M.E CAD/CAMDocument8 paginiVEC Mechanical Engineering PLM Question Bank for III Semester M.E CAD/CAMKarthik Subramani67% (3)

- Maintenance Engineering - VijayaragavanDocument6 paginiMaintenance Engineering - VijayaragavanKarthik SubramaniÎncă nu există evaluări

- 16 Hoisting and Conveying EquipmentDocument71 pagini16 Hoisting and Conveying EquipmentVenkata DineshÎncă nu există evaluări

- HMT University Solved ProblemsDocument69 paginiHMT University Solved ProblemsKendra Kaiser60% (5)

- B.e.cseDocument107 paginiB.e.cseSangeetha ShankaranÎncă nu există evaluări

- Mechanical Properties of Hybrid Polymer Composite PlatesDocument8 paginiMechanical Properties of Hybrid Polymer Composite PlatesKarthik SubramaniÎncă nu există evaluări

- Jaw Aid 2013Document6 paginiJaw Aid 2013Karthik SubramaniÎncă nu există evaluări

- Me6012 Me Mech Viist Au Unit IVDocument21 paginiMe6012 Me Mech Viist Au Unit IVKarthik SubramaniÎncă nu există evaluări

- Maintenance Engineering - Vijayaragavan1Document6 paginiMaintenance Engineering - Vijayaragavan1Karthik SubramaniÎncă nu există evaluări

- Maintenance Engineering - VijayaragavanDocument6 paginiMaintenance Engineering - VijayaragavanKarthik SubramaniÎncă nu există evaluări

- Maintenance Engineering - Vijayaragavan1Document7 paginiMaintenance Engineering - Vijayaragavan1Karthik SubramaniÎncă nu există evaluări

- Cs8383 Oops Lab ManualDocument81 paginiCs8383 Oops Lab ManualKarthik Subramani83% (12)

- Ch3 AxisymmDocument2 paginiCh3 AxisymmKarthik SubramaniÎncă nu există evaluări

- Approx Method Draw Involute ToothDocument10 paginiApprox Method Draw Involute ToothAustin BruceÎncă nu există evaluări

- Best Maintenance Repair PracticesDocument4 paginiBest Maintenance Repair Practicessantosh_jslÎncă nu există evaluări

- Annals of Medicine and Surgery: Bliss J. ChangDocument2 paginiAnnals of Medicine and Surgery: Bliss J. ChangroromutiaraÎncă nu există evaluări

- Is It Worth Dropping One More Year For GATE - QuoraDocument6 paginiIs It Worth Dropping One More Year For GATE - QuoraRaJu SinGhÎncă nu există evaluări

- FMEADocument10 paginiFMEAlibyanleopardÎncă nu există evaluări

- Activities For Teens and AdultsDocument130 paginiActivities For Teens and AdultsDonata Marletta100% (12)

- CH 02Document20 paginiCH 02Pauline Nguyen100% (1)

- ClinicalKey - Supporting Healthcare ProfessionalsDocument51 paginiClinicalKey - Supporting Healthcare ProfessionalsrsbhyÎncă nu există evaluări

- Alzheimers and DementiaDocument4 paginiAlzheimers and DementiaNidhi ManojÎncă nu există evaluări

- The History of AstronomyDocument3 paginiThe History of AstronomyAguilon Layto WendyÎncă nu există evaluări

- E2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsDocument3 paginiE2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsSatya kaliprasad vangaraÎncă nu există evaluări

- Anti AgingDocument5 paginiAnti AgingsaturninojonesÎncă nu există evaluări

- DLL CSS Week 5Document3 paginiDLL CSS Week 5Juanits BugayÎncă nu există evaluări

- Naval Gathering ReportDocument15 paginiNaval Gathering ReportRafee RevaldiÎncă nu există evaluări

- Building Trust and Constructive Conflict Management in OrganizationsDocument243 paginiBuilding Trust and Constructive Conflict Management in OrganizationsJose Luis100% (1)

- FormworksDocument94 paginiFormworksLouie Zavalla LeyvaÎncă nu există evaluări

- Wiki SpeedDocument5 paginiWiki Speedprashanthfeb90100% (1)

- Form 4 Student Subject AllocationDocument5 paginiForm 4 Student Subject Allocationapi-484150872Încă nu există evaluări

- Total Productive MaintenanceDocument41 paginiTotal Productive Maintenancejeff090288Încă nu există evaluări

- L o N G e V I T y NotesDocument24 paginiL o N G e V I T y NotesRajeswara Rao NidasanametlaÎncă nu există evaluări

- FGD on Preparing Learning Materials at Old Cabalan Integrated SchoolDocument3 paginiFGD on Preparing Learning Materials at Old Cabalan Integrated SchoolRAQUEL TORRESÎncă nu există evaluări

- VirginDocument14 paginiVirginGururaj Prakash75% (4)

- Model 9200-2123: 1 RS-422 Input/3 RS-422 Output ModuleDocument2 paginiModel 9200-2123: 1 RS-422 Input/3 RS-422 Output ModuleNisar AhmedÎncă nu există evaluări

- 9-Nietzsche and Super LaughterDocument18 pagini9-Nietzsche and Super Laughtergannoa02Încă nu există evaluări

- Design and Fabrication of Electric BikeDocument47 paginiDesign and Fabrication of Electric BikeHarish Dangeti100% (1)

- Wilkes PDFDocument2 paginiWilkes PDFReyes Lopez EstebanÎncă nu există evaluări

- Tools of Data CollectionDocument36 paginiTools of Data CollectionJmarie Calumba100% (1)

- Daftar Pustaka: Poltekkes Kemenkes YogyakartaDocument6 paginiDaftar Pustaka: Poltekkes Kemenkes YogyakartaNurhadi KebluksÎncă nu există evaluări

- 1st Bay Area Mathematical Olympiad February 23, 1999Document2 pagini1st Bay Area Mathematical Olympiad February 23, 1999Karn KumarÎncă nu există evaluări

- Trends in Linguistics - Studies and MonographsDocument550 paginiTrends in Linguistics - Studies and MonographsNelly PaniaguaÎncă nu există evaluări

- BCGDocument36 paginiBCGdadaisgreat100% (1)