Documente Academic

Documente Profesional

Documente Cultură

Automated Line Following

Încărcat de

Manoj KumarDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Automated Line Following

Încărcat de

Manoj KumarDrepturi de autor:

Formate disponibile

ICFYCC ROBOT FOR INDUSTRIAL SAFETY (I CAN FOLLOW YOU CAN CONTROL ROBOT) TEAM MEMBERS: MANOJKUMAR.R, ARAVINTH.M.

Email-id: manojkumarr161@gmail.com. COLLEGE: PANIMALAR ENGINEERING COLLEGE (EIE DEPARTMENT), ANNA UNIVERSITY, CHENNAI. ABSTRACT: ICFYCC is a dual purpose robot which can be a line follower and also a RF remote controlled robot. Since the robot can be a line follower, it can be used for providing the tools to some of the hazardous manufacturing areas where manual intervention is difficult in industries. At the same time the robot can also be a remote controlled (RF) so we can save the costlier tools from damaging when industries undergo any accidents and it can be extend to its application for various purposes such as surveillance. For robot model a AT89C51 micro controller for line follower purpose and HD12D, HD12E for RF controlling is used. Assembly language is used for programming the microcontroller. . LINE FOLLOWER OPERATION: Line-following robots are commonly used in manufacturing plants where the manual intervention and error is under serious consideration. These move on a specified path to pick the components from specified locations and take them to desired locations. Basically, a line-following robot is a self-operating robot that detects and follows a line drawn on the floor. The path to be taken is indicated by a black line on a white surface. The control system used must sense the line and man oeuvre the robot to stay on course while constantly correcting the wrong moves using feedback mechanism, thus forming a simple yet effective closed-loop system

BLOCK DIAGRAM: The block diagram of the ICFYCC is shown below. It consists of three pairs of infrared sensors, three voltage comparators, micro controller and a motor driver. The robot is built using microcontroller AT89C51 (used as the decision-making device), motor driver L293D, operational amplifier LM324 (comparator), infrared sensor and a few discrete components.

In the circuit, the sensors (infrared sensors) are used to detect the black strip on a white background. The sensor output is fed to the microcontroller, which takes the decision and gives appropriate command to motor driver L293D so as to move the motor accordingly. Sensor. The sensor senses the light reflected from the surface and feeds the output to the comparator. When the sensor is above the black background the light falling on it from the source reflects to the sensor, and when the sensor is above the black background the light from the source doesnt reflect to it. The sensor senses the reflected light to give an output, which is fed to the comparator. Comparator. The comparator compares the analogue inputs from sensors with a fixed

reference voltage. If this voltage is greaterthan the reference voltage the comparator outputs a low voltage, and if it is smaller the comparator generates a high voltage that acts as input for the decision-making device (microcontroller). Motor driver. The current supplied by the microcontroller to drive the motor is small. Therefore a motor-driver IC is used. It provides sufficient current to drive the motor. Microcontroller. The microcontroller is programmed to make the robot move forward, turn right or turn left based on the input coming from the comparator. The outputs of the microcontroller are fed to the motor driver.

WORKING: At the start, when the robot is at point A, sensors T1 and T2 are above the black surface and port pins P3.0 and P3.1 of the microcontroller receive logic 0. As a result, the robot moves forward in straight direction. At point B, a left turn is encountered,

and the left sensor comes above the black surface, whereas the right sensor remains above the black surface. Port pin P3.0 of the microcontroller receives logic 1 from the left sensor and port pin P3.1 receives logic 0 from the right sensor. As a result, the left motor stops and the right motor rotates, to

make the robot turn left. This process continues until the left sensor comes above the black background. Similarly, at point C, where a right turn is encountered, the same procedure for right

turn is executed. When both the sensors are at the black surface, the robot should stop. The output of the microcontroller (IC2) depends on the inputs received at its port pins P3.0 and P3.1 as shown in table.

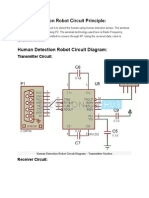

RF REMOTE CONTROLLED OPERATION: The easiest solution would be to take a cheap wireless toy car take out its receiver module along with its remote and use them in our robot. The other way round is this to make your own RF remote . We will be using ASK (Amplitude Shift Keying) based Tx/Rx (transmitter/receiver) pair operating at 433 MHz. The transmitter module accepts serial data at a maximum of XX baud rate. It can be directly interfaced with a microcontroller or can be used in remote control applications with the help of encoder/decoder ICs. Now in order to control say a dc motor, we require 2 bits of information (switching it on/off) while we need 4 bits of information to control 2 motors. HT12E and HT12D are 4 channelencoder/decoder ICs directly compatible with the specified RF module. The schematic is as shown below.

In order to drive motors, we would need to connect a suitable motor driver at the output of the decoder IC. The motor driver circuit can consist of a relay, transistorized H-Bridge ormotor driver ICs like the L293D, L298 etc. The example above shows the receiver section using the HT-12D decoder IC for a 4-bit RF remote control system. Similarly the transmitter and receiver module can also use the Holtek 8-bit HT640/HT-648L remote control

encoder/decoder combination for an 8bit RF remote control system.

4 CHANNEL ENCODER HT12E:

Features Operating voltage 2.4V~5V for the HT12A 2.4V~12V for the HT12E Low power and high noise immunity CMOS technology Low standby current: 0.1_A (typ.) at VDD=5V HT12A with a 38kHz carrier for infrared transmission medium Minimum transmission word Four words for the HT12E One word for the HT12A Built-in oscillator needs only 5% resistor

Data code has positive polarity Minimal external components HT12A/E: 18-pin DIP/20-pin SOP package General Description The 212 encoders are a series of CMOS LSIs for remote control system applications. They are capable of encoding information which consists of N address bits and 12N data bits. Each address/data input can be set to one of the two logic states. The programmed addresses/data are transmitted together with the header bits via an RF or an infrared transmission medium

upon receipt of a trigger signal. The capability to select a TE trigger on the HT12E or a DATA trigger on the HT12A further enhances the application flexibility of the 212 series of encoders. The HT12A additionally provides a 38kHz carrierfor infrared systems.

4 CHANNEL DECODER HT12D:

Features Operating voltage: 2.4V~12V Low power and high noise immunity CMOStechnology Low standby current Capable of decoding 12 bits of information Binary address setting Received codes are checked 3 times

Address/Data number combination HT12D: 8 address bits and 4 data bits HT12F: 12 address bits only Built-in oscillator needs only 5% resistor Valid transmission indicator Easy interface with an RF or an infrared transmissionmedium

Minimal external components Pair Holtek

with s

212 series of encoders 18-pin DIP, 20-pin SOP package General Description The 212 decoders are a series of CMOS LSIs for remote control system applications. They are paired with Holtek s 212 series of encoders. For proper operation, a pair of encoder/decoder with the same number of addresses and data format should be chosen. The decoders

receive serial addresses and data from a programmed 212 series of encoders that are transmitted by a carrier using an RF or an IR transmission medium. They compare the serial input data three times continuously with their local addresses. If no error or unmatched codes are found, the input data codes are decoded and then transferred to the output pins. The VT pin also goes high to indicate a valid transmission. The 212 series of decoders are capable of decoding informations that consist of N bits of address and 12_Nbits of data. Of this series, the HT12D is arranged to provide 8 address bits and 4 data bits, and HT12F is used to decode 12 bits of address information.

S-ar putea să vă placă și

- LGEC002 Door Lock System Using RFDocument8 paginiLGEC002 Door Lock System Using RFShivani MehrotraÎncă nu există evaluări

- PC Controll Wireless Robot Using RF ModuleDocument53 paginiPC Controll Wireless Robot Using RF ModuleanilÎncă nu există evaluări

- WarField Land Rover That Alerts On Sensing Panted Land MinesDocument32 paginiWarField Land Rover That Alerts On Sensing Panted Land MinesPavan KPÎncă nu există evaluări

- Alcohol Detector Mini 1Document29 paginiAlcohol Detector Mini 1Vishal KukrejaÎncă nu există evaluări

- File 1406270302Document25 paginiFile 1406270302rupeshÎncă nu există evaluări

- Vehicle Speed Control System Using RF CommunicationDocument20 paginiVehicle Speed Control System Using RF CommunicationRaina John100% (2)

- RF Based Robot SynopsisDocument6 paginiRF Based Robot SynopsisManpreet Singh100% (1)

- War Field Spying Robot With Night Vision Wireless Camera: Submitted byDocument26 paginiWar Field Spying Robot With Night Vision Wireless Camera: Submitted byankita dhengaleÎncă nu există evaluări

- Wireless Operated Fire Extinguisher Vehicles With Water Jet SprayDocument25 paginiWireless Operated Fire Extinguisher Vehicles With Water Jet SprayRaushanVijaySinghÎncă nu există evaluări

- Wireless Robot Control Through RFDocument9 paginiWireless Robot Control Through RFarun1cmÎncă nu există evaluări

- Heart Beat MoniteringDocument5 paginiHeart Beat MoniteringmadhavMIETÎncă nu există evaluări

- Human Detection Robot Circuit PrincipleDocument4 paginiHuman Detection Robot Circuit PrincipleAli KhanÎncă nu există evaluări

- Intelligent Train Engine: PROJECT WORK 2009-2010Document41 paginiIntelligent Train Engine: PROJECT WORK 2009-2010Naresh9535714401Încă nu există evaluări

- Minor Project ReportDocument26 paginiMinor Project ReportSaurabh ShuklaÎncă nu există evaluări

- Prototype Metro Train by Using MicrocontrollerDocument18 paginiPrototype Metro Train by Using Microcontrollernksingh786Încă nu există evaluări

- Circuit Diagram Wireless TransmitterDocument17 paginiCircuit Diagram Wireless Transmitterumaiya1990100% (2)

- Working Principle: 1) System CheckDocument8 paginiWorking Principle: 1) System CheckHans IngoleÎncă nu există evaluări

- RF Id Attendence MemoryDocument128 paginiRF Id Attendence Memoryakhilesh thapliyalÎncă nu există evaluări

- RF Based Automatic Speed Limiter For VehiclesDocument35 paginiRF Based Automatic Speed Limiter For Vehiclesv3rajasekarÎncă nu există evaluări

- Line Follower RobotDocument22 paginiLine Follower Robotkawish4uÎncă nu există evaluări

- Android Application Controlled Remote Robot Operation: Under The Guidance ofDocument36 paginiAndroid Application Controlled Remote Robot Operation: Under The Guidance ofAndrew ValentineÎncă nu există evaluări

- Hand Gesture Control Robot PDFDocument3 paginiHand Gesture Control Robot PDFMd IrfanÎncă nu există evaluări

- RF and GSM Based Wireless Power Theft MonitoringDocument27 paginiRF and GSM Based Wireless Power Theft MonitoringDebashishParida50% (2)

- Remote Accident Report System For Highways Using RFDocument17 paginiRemote Accident Report System For Highways Using RFPradeep CheekatlaÎncă nu există evaluări

- Line Follower Robot With IntelligenceDocument11 paginiLine Follower Robot With IntelligenceSabhakant Tripathi0% (1)

- Speed Control of Induction Motor by Using IR11Document16 paginiSpeed Control of Induction Motor by Using IR11Anuj TripathiÎncă nu există evaluări

- File 1389426553Document25 paginiFile 1389426553Er Amarsinh RÎncă nu există evaluări

- Literature Survey On Automatic Campus CabDocument5 paginiLiterature Survey On Automatic Campus CabGowtham S ShettyÎncă nu există evaluări

- Block Diagram:: Device Control Using Mobile PhoneDocument12 paginiBlock Diagram:: Device Control Using Mobile PhoneNirosh KumarÎncă nu există evaluări

- Cell Phone Operated LandroverDocument31 paginiCell Phone Operated Landrover8bitrebellionÎncă nu există evaluări

- Remote Control Operated Spy Robot Circuit - Block DiagramDocument7 paginiRemote Control Operated Spy Robot Circuit - Block Diagramanon_802118071Încă nu există evaluări

- Final Report On Line Follower RobotDocument44 paginiFinal Report On Line Follower RobotAjay Verma50% (4)

- Institute of Engineering and Technology, Alwar, Rajasthan: Wireless Keypad Controlled RobotDocument44 paginiInstitute of Engineering and Technology, Alwar, Rajasthan: Wireless Keypad Controlled RobotTwinkle SinghÎncă nu există evaluări

- Report (1) (2) Anti Loss DeviceDocument18 paginiReport (1) (2) Anti Loss DeviceakshayÎncă nu există evaluări

- Metal Detector Robotic Vehicle: Submitted byDocument25 paginiMetal Detector Robotic Vehicle: Submitted byDarshan ParmarÎncă nu există evaluări

- Chap 1Document92 paginiChap 1Arth PatelÎncă nu există evaluări

- Research Report - CEPDocument3 paginiResearch Report - CEPFahad AliÎncă nu există evaluări

- Gesture Control Car Using Arduino LilypadDocument17 paginiGesture Control Car Using Arduino LilypadMohammed KhaleelullahÎncă nu există evaluări

- Project Report On Mobile Controlled Robot Using DTMF TechnologyDocument11 paginiProject Report On Mobile Controlled Robot Using DTMF TechnologyKusum VermaÎncă nu există evaluări

- Thermal SensorDocument22 paginiThermal SensorJesmine GandhiÎncă nu există evaluări

- Automatic Room Light Controller With Visitor Counter: DescriptionDocument10 paginiAutomatic Room Light Controller With Visitor Counter: DescriptionDanny PinheiroÎncă nu există evaluări

- Fully Automated Toll Tax Collection Using RF Technology. No Need To Stop Car On Toll GateDocument13 paginiFully Automated Toll Tax Collection Using RF Technology. No Need To Stop Car On Toll GateHimanshu SharmaÎncă nu există evaluări

- RFID-Based Automatic Vehicle Parking System Using MicrocontrollerDocument4 paginiRFID-Based Automatic Vehicle Parking System Using MicrocontrollerSeun AlhassanÎncă nu există evaluări

- Ir Remote Based Stepper Motor Control PDFDocument70 paginiIr Remote Based Stepper Motor Control PDFsanoopmk100% (1)

- Cip 8Document4 paginiCip 8hthusithÎncă nu există evaluări

- GSM Based Fire Fighting RobotDocument35 paginiGSM Based Fire Fighting RobotRaushanVijaySingh100% (1)

- Metro TrainDocument24 paginiMetro Trainguddu9Încă nu există evaluări

- Hand Gesture Controlled RobotDocument59 paginiHand Gesture Controlled RobotNiharikaÎncă nu există evaluări

- Speed Control System With Rfid Equipped VehicleDocument27 paginiSpeed Control System With Rfid Equipped VehicleAnonymous L9fB0XUÎncă nu există evaluări

- RF Based Dual Mode RobotDocument17 paginiRF Based Dual Mode Robotshuhaibasharaf100% (2)

- DC Motor Speed ControlDocument23 paginiDC Motor Speed ControlVibhu BansalÎncă nu există evaluări

- Mobile Phone Operated Land Rover: AbstractDocument34 paginiMobile Phone Operated Land Rover: AbstractVishal JainÎncă nu există evaluări

- CKT DSRPTNDocument10 paginiCKT DSRPTNMadhusudan MunegalÎncă nu există evaluări

- Automatic Gate Opening System For Vehicles With Rfid or Password-194Document7 paginiAutomatic Gate Opening System For Vehicles With Rfid or Password-194rajatpreetÎncă nu există evaluări

- Communication Antenna Switching System Based On Micro ControllerDocument4 paginiCommunication Antenna Switching System Based On Micro ControllerAjay Kumar YadavÎncă nu există evaluări

- Exploring Arduino: Tools and Techniques for Engineering WizardryDe la EverandExploring Arduino: Tools and Techniques for Engineering WizardryEvaluare: 4.5 din 5 stele4.5/5 (5)

- Placa PC Chip M909Document64 paginiPlaca PC Chip M909michigato100% (1)

- Transformer - Construction, Working, Types & ApplicationDocument11 paginiTransformer - Construction, Working, Types & ApplicationDeepakDeepÎncă nu există evaluări

- TDS-11SA Rig Up ChecklistDocument2 paginiTDS-11SA Rig Up Checklistluis lopezÎncă nu există evaluări

- Motor Test FormDocument1 paginăMotor Test FormArie Yantoe100% (1)

- 1 Perform Diesel Engine Tune Up 1Document29 pagini1 Perform Diesel Engine Tune Up 1Jheng Delos Reyes Pantoja100% (2)

- W-4600CPR - Rev03Document156 paginiW-4600CPR - Rev03william.carvalhoÎncă nu există evaluări

- Service Instructions "P-1Nn/F" Single Pressure Compensator With Load Sense, Series F1U ControlDocument20 paginiService Instructions "P-1Nn/F" Single Pressure Compensator With Load Sense, Series F1U ControlAndre RuestaÎncă nu există evaluări

- Instruction Manual: Omron Ultrasonic NebuliserDocument12 paginiInstruction Manual: Omron Ultrasonic Nebuliserblaise honore TchimogneÎncă nu există evaluări

- Avm 30 3306Document6 paginiAvm 30 3306PanochonÎncă nu există evaluări

- UK - How To Install LED StripsDocument12 paginiUK - How To Install LED StripsAntonio BrasíliaÎncă nu există evaluări

- 2018 DAIKIN Product Line-UpDocument25 pagini2018 DAIKIN Product Line-UpLhexter Mhervin CoÎncă nu există evaluări

- Medium Voltage Switchgear Room DesignDocument3 paginiMedium Voltage Switchgear Room DesignSunil ParikhÎncă nu există evaluări

- QuotationDocument2 paginiQuotationsittichai saelimÎncă nu există evaluări

- Trolley Weight EstimationDocument7 paginiTrolley Weight EstimationRaj KumarÎncă nu există evaluări

- Ac 1Document2 paginiAc 1Alfredo jose Medina revattaÎncă nu există evaluări

- GHH Fahrzeuge MK-A20LP EN V1-16 2016-03-30 NeuDocument4 paginiGHH Fahrzeuge MK-A20LP EN V1-16 2016-03-30 Neujyothi prakashÎncă nu există evaluări

- HydraulicPowerUnit PowerTransmissionDocument4 paginiHydraulicPowerUnit PowerTransmissionCesar Ruben SosaÎncă nu există evaluări

- Instruction Manual: Raytech Usa, IncDocument57 paginiInstruction Manual: Raytech Usa, IncRuben Dario Gutierrez MontenegroÎncă nu există evaluări

- GEA Bock Open Type Compressors FDocument64 paginiGEA Bock Open Type Compressors FElif UsluÎncă nu există evaluări

- Vertiv Chilled Water CCU IOM ManualDocument193 paginiVertiv Chilled Water CCU IOM Manualabeon augustineÎncă nu există evaluări

- BinMaster SensorsDocument10 paginiBinMaster SensorsdarkpilotÎncă nu există evaluări

- Product Bulletin Fisher Vee Ball v150 v200 v300 Rotary Control Valves en 122994Document28 paginiProduct Bulletin Fisher Vee Ball v150 v200 v300 Rotary Control Valves en 122994Swastik MahapatraÎncă nu există evaluări

- KCCEC List of EquipmentDocument45 paginiKCCEC List of Equipmentahmedsaber2007Încă nu există evaluări

- On The Simulation of Three Phase Induction Machine PDFDocument3 paginiOn The Simulation of Three Phase Induction Machine PDFJOHN MINKHANTÎncă nu există evaluări

- TSS721Document14 paginiTSS721api-3744762100% (1)

- TruTrak Evolution Type II FINAL - Cleared 08aug12Document2 paginiTruTrak Evolution Type II FINAL - Cleared 08aug12smouhabÎncă nu există evaluări

- Volvo TWD1643GE - 613 KW PDFDocument2 paginiVolvo TWD1643GE - 613 KW PDFvictoros27Încă nu există evaluări

- Ilp P.gudangDocument8 paginiIlp P.gudangmsanusiÎncă nu există evaluări

- Timing Belt Installation PDFDocument7 paginiTiming Belt Installation PDFHadeka PainoÎncă nu există evaluări

- Ichroma II User GuideDocument60 paginiIchroma II User Guidejasmine AdlerÎncă nu există evaluări