Documente Academic

Documente Profesional

Documente Cultură

Spherilastik

Încărcat de

dandolea75Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Spherilastik

Încărcat de

dandolea75Drepturi de autor:

Formate disponibile

Metalastik type Spherilastik Bearings

Features/Applications A heavy duty flexible bearing which combines highload carrying capacity with the ability to accommodate torsional and angular movements in all planes without lubrication and metal-to-metal wear. Spherilastik bearings with through holes or solid centre members are available in a range of sizes as detailed in this leaflet.

Typical uses include traction and braking reaction rods for rail, road and off-road vehicles, hydraulic damper fixings and other applications where a high duty bearing of compact size is required.

Metalastik type Spherilastik Bearings

Centre Bore

Pz

z

z

The diagram shows overall and fitting dimensions only. It is recommended that a drawing of the product is obtained before ordering.

Part No. Pz kN Kz MN/m

13/1316

13/1962 34 70 8 0.9 6 0.9 25 66 48 54 0.83

13/2201 34 70 8 0.9 6 0.9 25.4 66.7 47.6 54 0.41

13/2047 35 32 10 3.2 8 2.9 38.1 104.8 76.2 82.6 3.2

13/2108 53 83 8 2.6 6 2.6 41.3 90.5 101.6 65 1.5

13/1295 53.5 83 8 2.6 6 2.6 41.3 90.5 70 73.2 2.2

13/2106 58 100 8 2.8 6 2.8 28.6 90 70 76.2 1.8

34 70 o 8 Kxx kNm/rad 0,9 6 Kyy kNm/rad 0,9 A mm 25,4 B mm 66,7 C mm 47,6 D mm 54 Mass weight, kg 0,84

General guidance notes for selection:

1. 2. 3. 4. Properties quoted for the components in this leaflet relate to continuous steady loading or deformation conditions. For continuous dynamic cyclic loading or deformation, the maximum values should be reduced to approximately 30% of the figures quoted, depending on frequency. For medium and low incidence loading and deformation, the tabled values may be increased up to 2 to 3 times. Combined stressing in the different modes and the effects of stress reversals may require a more critical assessment.

Trelleborg Industrial AVS operates a policy of continuous improvement and development. We reserve the right to change design and specification of our products without prior notification or alteration of literature. We will not be held responsible for any danger or damage incurred through improper use or installation.

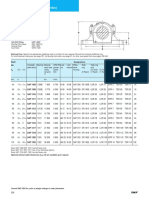

Metalastik type Spherilastik Bearings

Centre Bore

Pz

z

z

The diagram shows overall and fitting dimensions only. It is recommended that a drawing of the product is obtained before ordering.

Part No. Pz kN Kz MN/m

13/1006

13/1285 78 90 8 4.5 7 3.8 38.1 104.8 76.2 82.6 3.4

13/1180 110 100 10 7 6 6 44.5 127 101.6 104.8 6.6

13/0894 180 100 9 30 8 20 76.2 200 152.4 139.7 21.9

13/1680 220 260 6 15 5 13 50.1 127 101.6 104.8 6.3

13/1339 400 350 7 26 6 20 114.3 200 152.4 114.3 19.4

13/1990 425 470 7 21 6 18 60 150 120 134 11.5

58 93 o 8 Kxx kNm/rad 2.8 6 Kyy kNm/rad 2.8 A mm 28.6 B mm 90.5 C mm 70 D mm 76.5 Mass weight, kg 2.5

General guidance notes for selection:

1. 2. 3. 4. Properties quoted for the components in this leaflet relate to continuous steady loading or deformation conditions. For continuous dynamic cyclic loading or deformation, the maximum values should be reduced to approximately 30% of the figures quoted, depending on frequency. For medium and low incidence loading and deformation, the tabled values may be increased up to 2 to 3 times. Combined stressing in the different modes and the effects of stress reversals may require a more critical assessment.

Trelleborg Industrial AVS operates a policy of continuous improvement and development. We reserve the right to change design and specification of our products without prior notification or alteration of literature. We will not be held responsible for any danger or damage incurred through improper use or installation.

Metalastik type Spherilastik Bearings

Trunnion Type

Pz C z G

y B

x A

z E

The diagram shows overall and fitting dimensions only. It is recommended that a drawing of the product is obtained before ordering.

F crs D

Part No. Pz kN Kz MN/m

13/2092

13/2202 34 70 8 0.7 6 0.9 35 66.7 47.6 120 20 90 13 1.14

13/2203 34 70 8 0.7 6 0.9 35 66.7 47.6 126 20 96 17 1.02

13/2181 58 90 10 2,8 6 2.8 48 90.6 70 190 30 140 20.5 2.8

13/2192 58 90 8 2.8 6 2.8 48 90.6 70 170 30 130 20.5 3

13/2033 75 150 8 2.8 6 2.8 40 84 65 155 20 120 16.5 2.8

13/2223 80 100 8 4.5 7 3.8 50.5 104.8 76.2 170 30 130 19 5.8

12 34 o 8 Kxx kNm/rad 0.17 6 Kyy kNm/rad 0.2 A mm 30 B mm 45 C mm 35 D mm 105 E mm 12 F mm 75 Gmm 13 Mass weight, kg 0.47

General guidance notes for selection:

1. 2. 3. 4. Properties quoted for the components in this leaflet relate to continuous steady loading or deformation conditions. For continuous dynamic cyclic loading or deformation, the maximum values should be reduced to approximately 30% of the figures quoted, depending on frequency. For medium and low incidence loading and deformation, the tabled values may be increased up to 2 to 3 times. Combined stressing in the different modes and the effects of stress reversals may require a more critical assessment.

Trelleborg Industrial AVS operates a policy of continuous improvement and development. We reserve the right to change design and specification of our products without prior notification or alteration of literature. We will not be held responsible for any danger or damage incurred through improper use or installation.

Metalastik type Spherilastik Bearings

Control links

A crs 1.5

Features/Applications A range of Control Links incorporating Spherilastik Bearings is available and typical sizes are listed below. Further details are available on request.

Part No. Spherilastik Part No. Type A1mm 13/2233 13/2235 13/2154 13/2280 13/2369 13/2192 13/2107 1371006 13/1006 13/2192 2 2 1 1 2 490 644 673 720 1315

Nominal P. max kN 58 58 58 58 58

Mass weight Degrees Degrees kg 6 6 6 6 6 8 8 8 8 8 12 14 15 16 27

Properties quoted are for 60H rubber compound

General guidance notes for selection:

1. 2. 3. 4. Properties quoted for the components in this leaflet relate to continuous steady loading or deformation conditions. For continuous dynamic cyclic loading or deformation, the maximum values should be reduced to approximately 30% of the figures quoted, depending on frequency. For medium and low incidence loading and deformation, the tabled values may be increased up to 2 to 3 times. Combined stressing in the different modes and the effects of stress reversals may require a more critical assessment.

Trelleborg Industrial AVS operates a policy of continuous improvement and development. We reserve the right to change design and specification of our products without prior notification or alteration of literature. We will not be held responsible for any danger or damage incurred through improper use or installation.

Metalastik type Spherilastik Bearings

Trelleborg Industrial AVS, 1 Hoods Close, Leicester LE4 2BN, UK. Tel: +44 116 267 0300. Fax: +44 116 267 0301. www.metalastik.com

Reg. no. 21-00079-01 08 03

S-ar putea să vă placă și

- GM 6t70 UpdatesDocument45 paginiGM 6t70 UpdatesThePokeOne100% (9)

- Nissan QR VQ Shop ManualDocument270 paginiNissan QR VQ Shop ManualMauricio Delgado100% (1)

- Hydraulic Cylinder Tie Rod Design: Replaces: 02.13Document68 paginiHydraulic Cylinder Tie Rod Design: Replaces: 02.13Juan Diego Garcia EsquenÎncă nu există evaluări

- ZF 6wg310Document192 paginiZF 6wg310Tomasz BedrunkaÎncă nu există evaluări

- Pathfinder Motor HandbookDocument83 paginiPathfinder Motor Handbookchristianyankel100% (3)

- Lifting Analysis GuideDocument3 paginiLifting Analysis GuideNwosu Augustine100% (1)

- To 17Document50 paginiTo 17dandolea75100% (1)

- Aba Aeg 2 0Document25 paginiAba Aeg 2 0Diego NunesÎncă nu există evaluări

- 17740958-Mccormick CX Series Cx50 Cx60 Cx70 Cx80 Cx90 Cx100 Tractors Dealer Shop Service Repair Manual - DownloadDocument921 pagini17740958-Mccormick CX Series Cx50 Cx60 Cx70 Cx80 Cx90 Cx100 Tractors Dealer Shop Service Repair Manual - DownloadLengyel RichardÎncă nu există evaluări

- Re 15224Document12 paginiRe 15224Ahmed Abd ElhakeemÎncă nu există evaluări

- TensionersDocument20 paginiTensionersSuresh KumarÎncă nu există evaluări

- Snatch Pulley Charlet ED - 19pgDocument19 paginiSnatch Pulley Charlet ED - 19pgtvmehta01Încă nu există evaluări

- Kampfflieger Blohm Voss P.179 1x48Document5 paginiKampfflieger Blohm Voss P.179 1x48dandolea75Încă nu există evaluări

- Hydraulic UTMDocument14 paginiHydraulic UTMEduardo CruzÎncă nu există evaluări

- Curved Jaw CouplingDocument22 paginiCurved Jaw CouplingchikoopandaÎncă nu există evaluări

- 16 V 4000Document4 pagini16 V 4000aup0% (1)

- Kampfflieger Blohm Voss BV P.170 1x48Document10 paginiKampfflieger Blohm Voss BV P.170 1x48dandolea75100% (1)

- Blueprint Feb 2011Document108 paginiBlueprint Feb 2011dandolea75Încă nu există evaluări

- TIL 1132 2R1 - VIGV Inspection, Thrust WasherDocument5 paginiTIL 1132 2R1 - VIGV Inspection, Thrust WasherHernan Giraut100% (2)

- ThesisDocument41 paginiThesisdandolea75Încă nu există evaluări

- JC Series Jaw Crusher PDFDocument8 paginiJC Series Jaw Crusher PDFgarrybieber100% (1)

- 25 Kkatas de ShotokanDocument88 pagini25 Kkatas de ShotokanKrloz Bakz100% (4)

- TTM Post TensioningDocument103 paginiTTM Post Tensioninghorea67100% (2)

- SMC MPC Multi Position Cylinder RodDocument14 paginiSMC MPC Multi Position Cylinder RodNut KhaopatumthipÎncă nu există evaluări

- WT7554 Schwingmetall Catalog enDocument108 paginiWT7554 Schwingmetall Catalog enmarkomasÎncă nu există evaluări

- 8 Stressing PDFDocument14 pagini8 Stressing PDFKaushal K SharmaÎncă nu există evaluări

- Series: Dual Rod CylinderDocument22 paginiSeries: Dual Rod CylinderAnonymous A55PY1bÎncă nu există evaluări

- DC卷筒联轴器 coupling-20141022104458Document15 paginiDC卷筒联轴器 coupling-20141022104458Ashley DeanÎncă nu există evaluări

- Series 88S Specification SheetDocument2 paginiSeries 88S Specification SheetWattsÎncă nu există evaluări

- Acoplamientos TSK PDFDocument4 paginiAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesÎncă nu există evaluări

- Architectural Products Group: C-APG08Document16 paginiArchitectural Products Group: C-APG08lesgiuÎncă nu există evaluări

- Catálogo de Acoplamientos Lovejoy - JISDocument8 paginiCatálogo de Acoplamientos Lovejoy - JISJavier Salas ZavaletaÎncă nu există evaluări

- Brochure - 14.458 DC Spring Apllied BrakesDocument2 paginiBrochure - 14.458 DC Spring Apllied Brakeskpr_02161371Încă nu există evaluări

- Jost CatalogueDocument227 paginiJost CatalogueLechien LeÎncă nu există evaluări

- Sicop Bimetal OL Relay Type 3UA5-6 3UC5-6Document14 paginiSicop Bimetal OL Relay Type 3UA5-6 3UC5-6erkamlakar2234Încă nu există evaluări

- Catalogo MavDocument36 paginiCatalogo MavAllison JonesÎncă nu există evaluări

- Behavior and Design of Selected Elastomeric Bearing Pads: Leonard TulinDocument20 paginiBehavior and Design of Selected Elastomeric Bearing Pads: Leonard TulinpetricoqÎncă nu există evaluări

- SEBF8149 - Specifications For Connecting Rods Used in 3500 Family of EnginesDocument24 paginiSEBF8149 - Specifications For Connecting Rods Used in 3500 Family of Enginesyahmanmahira4Încă nu există evaluări

- Grundfos White PaperDocument8 paginiGrundfos White PapermishraenggÎncă nu există evaluări

- Installation and Operation: General MountingDocument9 paginiInstallation and Operation: General MountingLarry JorgensonÎncă nu există evaluări

- SEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series EnginesDocument19 paginiSEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series Enginesyahmanmahira4Încă nu există evaluări

- Bidim Tech Aus 6-5-09Document2 paginiBidim Tech Aus 6-5-09dafo407Încă nu există evaluări

- Fatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresDocument9 paginiFatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresAndreyÎncă nu există evaluări

- E 08Document16 paginiE 08João PauloÎncă nu există evaluări

- Lovejoy Tipo CJDocument22 paginiLovejoy Tipo CJyerandasÎncă nu există evaluări

- TSKDocument4 paginiTSKar174_569868987Încă nu există evaluări

- Pulleys TechDocument8 paginiPulleys TechashkansoheylÎncă nu există evaluări

- M68 Dimensions of Propulsion Shafts and Their Permissible Torsional Vibration Stresses M68Document8 paginiM68 Dimensions of Propulsion Shafts and Their Permissible Torsional Vibration Stresses M68uniroshaÎncă nu există evaluări

- SAI - GM Tech CatalogDocument54 paginiSAI - GM Tech CatalogBoban SimicÎncă nu există evaluări

- Shimpo Able VRS BrochureDocument4 paginiShimpo Able VRS BrochureElectromateÎncă nu există evaluări

- 000 669e 11.15 5.0Document6 pagini000 669e 11.15 5.0Karmen CevilleÎncă nu există evaluări

- MSZ Selection CalculationDocument20 paginiMSZ Selection Calculationlojzemulec5966Încă nu există evaluări

- John Crane Met A StreamDocument4 paginiJohn Crane Met A StreamGÎncă nu există evaluări

- Yalecglc70vx Lifttruck Service Repair ManualDocument60 paginiYalecglc70vx Lifttruck Service Repair Manualestelios aretosÎncă nu există evaluări

- Thomson Super Metric Ball Bushing Bearings SpecsheetDocument11 paginiThomson Super Metric Ball Bushing Bearings SpecsheetElectromateÎncă nu există evaluări

- H-3860 Los Angeles Abrasion MachineDocument8 paginiH-3860 Los Angeles Abrasion MachineAris Co AbergosÎncă nu există evaluări

- Mud Agitator ManualDocument7 paginiMud Agitator ManualCatalin RadÎncă nu există evaluări

- 003 Bowex enDocument34 pagini003 Bowex encarlosÎncă nu există evaluări

- Tyre Coupling CatalogDocument9 paginiTyre Coupling CatalogKariem R NoweerÎncă nu există evaluări

- H1000e K FJDocument8 paginiH1000e K FJSyarif HidayatullahÎncă nu există evaluări

- Collar EyeBolt To BS4278 Table 1Document9 paginiCollar EyeBolt To BS4278 Table 1Rajesh N Priya GopinathanÎncă nu există evaluări

- Hydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Document6 paginiHydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Stoianovici CristianÎncă nu există evaluări

- Testeo TransmisionDocument31 paginiTesteo TransmisionmockshaÎncă nu există evaluări

- Siemens Flender 05 BipexDocument8 paginiSiemens Flender 05 BipexDhanielÎncă nu există evaluări

- N-Eupex y N-Eupex Ds - CatalogoDocument25 paginiN-Eupex y N-Eupex Ds - CatalogoJohn Salazar0% (1)

- AF-650 GP General Purpose Drive: Brake Resistor Design GuideDocument30 paginiAF-650 GP General Purpose Drive: Brake Resistor Design GuideonafetsÎncă nu există evaluări

- Er 26Document2 paginiEr 26michaelxiaoÎncă nu există evaluări

- Pump DatasheetDocument15 paginiPump DatasheetHedi Ben MohamedÎncă nu există evaluări

- Hydraulic Modeling of Torque ConvertersDocument8 paginiHydraulic Modeling of Torque Convertersserf007100% (1)

- Effect of Geometrical Imperfections of Gears in Large Offshore Wind Turbine Gear Trains Case StudiesDocument10 paginiEffect of Geometrical Imperfections of Gears in Large Offshore Wind Turbine Gear Trains Case StudiesFatho JamylÎncă nu există evaluări

- FLENDER Standard CouplingsDocument278 paginiFLENDER Standard Couplingsalfredo_fredo_1Încă nu există evaluări

- Aro Electrodes enDocument19 paginiAro Electrodes endandolea75Încă nu există evaluări

- Durco Mark 3 In-Line: Asme (Ansi) B73.2 Vertical In-Line Chemical Process PumpsDocument8 paginiDurco Mark 3 In-Line: Asme (Ansi) B73.2 Vertical In-Line Chemical Process Pumpslgarci12_1984Încă nu există evaluări

- Dr.-Ing. E.H. Richard Van Basshuysen, VDIDocument21 paginiDr.-Ing. E.H. Richard Van Basshuysen, VDIfildi95Încă nu există evaluări

- Rosta - TechnologyDocument7 paginiRosta - TechnologyseanfsmythÎncă nu există evaluări

- Service & Maintenance Manual High Speed Separator: Product No. 881039-12-01/1 Book No. 568854-02 Rev. 2Document133 paginiService & Maintenance Manual High Speed Separator: Product No. 881039-12-01/1 Book No. 568854-02 Rev. 2امير الموسوي100% (1)

- Project Report NEIDocument36 paginiProject Report NEISamar Jeet50% (2)

- MPB-VG: Walkie Low Lift PalletDocument16 paginiMPB-VG: Walkie Low Lift PalletJuan LemusÎncă nu există evaluări

- 2013 DB Introduction V1Document67 pagini2013 DB Introduction V1Amro Metwally El HendawyÎncă nu există evaluări

- Riddhi Polymers: Date: 06-12-2016 ToDocument3 paginiRiddhi Polymers: Date: 06-12-2016 ToVasoya ManojÎncă nu există evaluări

- Seminar Report Practice WorkDocument46 paginiSeminar Report Practice WorkMuhd Shabeeb AÎncă nu există evaluări

- Book: Automotive Mechanics by S. Srinivasan: Engine Performs WorkDocument8 paginiBook: Automotive Mechanics by S. Srinivasan: Engine Performs WorkNurul AmirahÎncă nu există evaluări

- Wire Rope Selection Criteria For Dam Gate OperationDocument65 paginiWire Rope Selection Criteria For Dam Gate OperationTimbo6808Încă nu există evaluări

- Installation and Operating InstructionsDocument18 paginiInstallation and Operating InstructionsMarco LatosaÎncă nu există evaluări

- Bearing MaterialsDocument1 paginăBearing MaterialsShameekaÎncă nu există evaluări

- Breaking Loads For TVN Carriage Bearing HousingsDocument4 paginiBreaking Loads For TVN Carriage Bearing HousingsJasinthaja AsankaÎncă nu există evaluări

- 8.3 Dodge Washdown Ball BearingsDocument16 pagini8.3 Dodge Washdown Ball Bearingsrrobles011Încă nu există evaluări

- Construction Details of CNCDocument80 paginiConstruction Details of CNCSenthil KumarÎncă nu există evaluări

- Induction MotorsDocument28 paginiInduction MotorsMarvin MarcaidaÎncă nu există evaluări

- Vdma 442 T. Klenk Et Al. Conductive SimmerringsDocument7 paginiVdma 442 T. Klenk Et Al. Conductive SimmerringsChandrasekar KrishnamurthyÎncă nu există evaluări

- 9.4.6 Goulds 320L Spec Sheet7313Document7 pagini9.4.6 Goulds 320L Spec Sheet7313LeonelleÎncă nu există evaluări

- 2013 ESP Workshop Summary of PresentationsDocument28 pagini2013 ESP Workshop Summary of PresentationsScott YoungÎncă nu există evaluări

- Super: Tracked PaverDocument16 paginiSuper: Tracked PaverDebrajÎncă nu există evaluări

- Product Design SpecificationDocument2 paginiProduct Design SpecificationCharlie100% (1)

- PG 358-440Document83 paginiPG 358-440Anonymous PIqdeNp8Încă nu există evaluări