Documente Academic

Documente Profesional

Documente Cultură

Iacs Ur - Ui Jan-Jun 2013 - e

Încărcat de

nikoskarandinosTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Iacs Ur - Ui Jan-Jun 2013 - e

Încărcat de

nikoskarandinosDrepturi de autor:

Formate disponibile

External Affairs Division

Vol.5 (1 August 2013)

IACS Technical Resolutions adopted from January to June 2013

ClassNK is delighted to inform you of the recent information related to the International Association of Classification Societies (IACS). ClassNK has been regularly providing preliminary reports of outcomes of the International Maritime Organization (IMO)s meetings and the latest development at IACS. For this issue, we would like to introduce the Unified Requirements (URs) and Unified Interpretations (UIs) adopted from January 2013 to June 2013 with their summaries. URs and UIs are technical resolutions, which are set, revised and withdrawn by IACS. URs are classification rules established for the uniform implementation among IACS member societies. URs shall be incorporated in the rules of each member society within one year of adoption unless otherwise specified. UIs are developed for uniform interpretations of the requirements of Convention which are left to the satisfaction of the Administration or vaguely worded while Administrations have not set clear instructions. Hereunder, URs and UIs are shown in Table 1 (URs) and Table 2 (UIs) with their summaries respectively. Texts of these resolutions and their Technical Backgrounds have been published in IACS website. These resolutions are/will be incorporated into ClassNKs Rules and Guidance for the survey and construction of steel ships after review by ClassNKs relevant Technical Committee. In addition, the underlined versions (revised parts are clearly shown) of URs and UIs have been published in ClassNKs website.

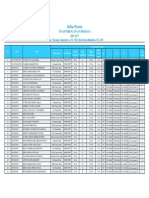

Table 1 List of new/amendments to URs (Unified Requirements) adopted from January 2013 to June 2013

UR UR S27 UR Z18 UR L2 UR S6 UR W30 UR W31 Revision Rev.6 Rev.3 Rev.2 Rev.7 New New Adoption Jun. 2013 Apr.2013 Apr. 2013 Apr. 2013 Feb. 2013 Jan. 2013 Title Strength Requirements for Fore Deck Fittings and Equipment Periodical survey of Machinery Intact stability matter of class Use of Steel Grades for Various Hull Members Ships of 90 m in Length and Above Normal and higher strength corrosion resistant steels for cargo oil tanks Application of YP47 Steel Plates Implementation 1 Jul. 2014 1 Jan. 2014 1 Jul. 2014 1 Jul. 2014 1 Jan. 2014 1 Jan. 2014

1/5

UR S33 UR G3 UR W24 UR P2.12

New Rev.5 Corr.1 Corr.1

Jan. 2013 Jan. 2013 Jan.2013 Jan. 2013

Requirements for Use of Extremely Thick Steel Plates Liquefied gas cargo and process piping Cast Copper Alloy Propellers Flexible Hoses

1 Jan. 2014 1 Jan. 2014 -

Table 2 List of new/amendments to UIs (Unified Interpretations) adopted from January 2013 to June 2013

UI UI SC262 UI SC235 UI SC261 UI SC257 UI HSC9 UI LL78 UI MPC104 UI SC260 Revision New Corr.2 New Corr.1 New New New New Adoption Jun. 2013 Jun. 2013 May 2013 Apr. 2013 Mar. 2013 Mar. 2013 Mar. 2013 Mar. 2013 Title Fixed Foam Fire Extinguishing Systems, Foam-generating Capacity (FSS Code / CHAPTER 6 / 3.2.1.2 and 3.3.1.2 as amended by MSC.327(90)) Navigation bridge visibility to ships side Interpretation of Performance Standards for voyage data recorders (VDRs) (resolution MSC.333(90)) Pilot Transfer Arrangements (SOLAS V/23 as amended by Resolution MSC.308(88)) Keel Laying Date for Fibre-Reinforced Plastic (FRP) Craft Keel Laying Date for Fibre-Reinforced Plastic (FRP) Craft Keel Laying Date for Fibre-Reinforced Plastic (FRP) Craft Sample Extraction Smoke Detection System (FSS Code / Chapter 10 / 2.4.1.2 as amended by MSC.292 (87)) For Application of SOLAS Regulation II-1/3-11 Performance Standard for Protective Coatings for Cargo Oil Tanks of Crude Oil Tankers (PSPC-COT), adopted by Resolution MSC.288(87) For Application of Regulation 3-11, Part A-1, Chapter II-1 of the SOLAS Convention (Corrosion Protection of Cargo Oil Tanks of Crude Oil Tankers), adopted by Resolution MSC.289 (87) The Performance Standard for Alternative Means of Corrosion Protection for Cargo Oil Tanks of Crude Oil Tankers Testing and approval of pipe penetrations and cable transits for use in A class divisions (IMO FTP Code 2010 Part 3) Interpretation to COLREG 1972 Annex 1, Section 9(b) Implementation of SOLAS II-1, Regulation 3-5 and MSC.1/Circ.1379 Identical Replacement Regulation 13) Engines (MARPOL Annex VI Implementation 1 Jan. 2014 1 Jul. 2014 1 Jan. 2014 1 Jan. 2014 1 Jan. 2014 1 Jan. 2014

UI SC259

New

Feb. 2013

1 Jan. 2014

UI SC258

New

Jan. 2013

1 Jan. 2013

UI FTP6 UI COLREG1 UI SC249 UI MPC103

New Corr.1 Rev.1 New

Feb. 2013 Feb.2013 Feb. 2013 Jan. 2013

1 Jan. 2014 1 Jul. 2013 1 Jan. 2014

UI SC191

Rev.5

May 2013

IACS Unified Interpretations (UI) SC 191 for the application of amended SOLAS regulation II-1/3-6 (resolution MSC.151(78)) and revised Technical provisions for means of access for inspections (resolution MSC.158(78))

24 Jun. 2013

*Corr.(Corrigenda) means the correction that basically does not include the contents of resolution but literal error. 2/5

Outlines of IACS Technical Resolutions listed in the above Tables are mentioned below. (1) UR S27 UR S27 provides strength requirements to resist green sea forces for items such as air pipes, ventilator pipes and their closing devices, the securing of windlasses etc. located within the forward quarter length of the ship. According to Rev.5 of the UR the velocity V of water over the fore deck (used in the calculation of design pressure in section 4.1.1) is 13.5 m/s for exposed items located less than 22m or 0.1L (whichever is the lesser) above the summer load waterline. The objective of Rev.6 (June 2013) is to adjust the velocity V taking the actual height of the item into account, removing unreasonable requirements to the devises such as hold ventilator on the upper deck on large car carrier, almost 22 m above the summer load waterline. (2) UR Z18 UR Z18 details the general requirements of special, annual and continuous surveys of the machinery, survey of steam boilers, propulsion steam turbines and machinery verification runs. In Rev.3 (Apr 2013), the reference to drydocking section 4.1 was removed because of the fact that the request of dock trial should be not directly related to the fact that the ship was docked. It should be more pertinent to relate dock trial as an operation to be carried out in order to complete a periodical (renewal) or an occasional machinery survey, as appropriate. (3) UR L2 UR L2 stipulates that all new ships with a length of 24 m and above will be assigned class only after it has been demonstrated that their intact stability is adequate for the service intended. This UR was revised (Rev.2 Apr 2013) to further clarify that this is applicable only to ships of length 24 m and above and make the resolution in line with IMO resolution MSC.267(85). For vessels of smaller size flag state requirements or individual class requirements may apply.

(4) UR S6 UR S6 details the use of steel grades for various hull members of ships of 90 m in length and above, other than CSR Bulk Carriers and Tankers. This UR was revised (Rev.7 Apr 2013) to clarify the scope of application with regard to LNG carriers and to identify minimum steel grades for selected structures on membrane type liquefied gas carriers. The revision of the UR makes it in line with current industry practice. (5) UR W30 The Performance Standard for Alternative Means of Corrosion Protection for Cargo Oil Tanks of Crude Oil Tankers (IMO Resolution MSC.289 (87)) allows for the use of "Corrosion Resistant Steel". This steel is modified ship steel with micro additions of certain chemical elements that have been found to have a beneficial effect by retarding the corrosion rate in the environments found in cargo tanks of crude oil carriers. In response to the request of steel Industry, IACS has developed UR W30 on these corrosion resistant steels. UR W30 stipulates IACS unified approach to the approval, manufacture, certification and shipyard application of these steels. Also in addition to the UR W30, a Unified Interpretation (UI SC 258) was also developed to clarify various provisions given in Resolution MSC.289 (87). (6) UR W31 UR W31 gives the basic concepts for application of YP47 steel plates to longitudinal structural members in the upper deck region of Container Carriers (such as hatch side coaming, hatch coaming top and the attached longitudinals) incorporating extremely thick steel plates (over 50mm and not greater than 100mm ). UR covers HT factor and material selection, material specification, manufacturing process approval, welding consumables, welding procedure qualification test etc. (7) UR S33 UR S33 specifies the measures for identification and prevention of brittle fractures of Container Carriers to which extremely thick steel plates (over 50mm and not greater than 100mm) are applied for 3/5

longitudinal structural members. The UR covers the requirements of Non-Destructive Testing (NDT) during construction, periodic NDT after delivery and brittle crack arrest design. (8) UR G3 UR G3 specifies the requirements applicable to liquefied gas cargo and process piping including cargo gas piping and exhaust lines of safety valves. In Rev.5 (Jan 2013), the requirements regarding prototype and production tests of safety valves were revised. The revision was based on the comments and proposals submitted by a safety valve manufacturing company. (9) UI SC262 UI SC262 intent to clarify criteria to be adopted when determining the size of the largest protected space as referred to in the International Code for Fire Safety Systems (FSS Code) Ch. 6 (as amended by MSC Res. 327(90)). The UI applies to a machinery space of category A protected by a fixed high-expansion foam fire-extinguishing system complying with the provisions of the FSS Code. (10) UI SC261 UI SC261 was developed to clarify the application of Resolution MSC.333(90), the phrase installed on or after 1 July 2014. For ships for which the building contract is placed on or after 1 July 2014, or in the absence of the contract, constructed on or after 1 July 2014, "installed on or after 1 July 2014" means any installation on the ship; and for other ships "installed on or after 1 July 2014" means a contractual delivery date for the equipment or, in the absence of a contractual delivery date, the actual delivery of the equipment to the ship on or after 1 July 2014. The source of the interpretation of install is similar to that in MSC.1/ Circ.1375/ Rev.1. (11) UI HSC9, LL78 & MPC104 With the introduction of the NOx Tier I/II/III requirements and other emerging statutory legislation, it has become necessary for IACS to agree to a consistent interpretation for the term the keels of which are laid or which are at a similar stage of construction for Fibre-Reinforced Plastic (FRP) 4/5

Craft. UI HSC9, LL78 and MPC104 stipulates that for the purposes of the application of the IMO Conventions and Codes (Performance Standards, Technical Standards, Resolutions and Circulars) for FRP Craft, the term the keels of which are laid or which are at a similar stage of construction should be interpreted as the date that the first structural reinforcement of the complete thickness of the approved laminate schedule is laid either in or on the mould. (12) UI SC260 UI SC260 is intended to clarify the definition of Fire control station for the purpose of the application of FSS Code 10.2.4.1.2 amended by MSC.292(87). Since CO2 room with CO2 control equipment complying with the provision of the FSS Code Chapter 5 is considered to be a fire control station, control panel of Sample Extraction Smoke Detection System could be located in CO2 room when applying the requirement of the regulation of FSS Code 10.2.4.1.2. (13) UI SC259 UI SC259 specifies interpretation for PSPC-COT of Resolution MSC.288(87) in the same manner of UI SC223 for PSPC-WBT of Resolution MSC.215(82). The UI covers definitions, general principles, coating standard, coating system approval, coating inspection and verification requirements, and alternative systems. (14) UI SC258 The Performance Standard for Alternative Means of Corrosion Protection for Cargo Oil Tanks of Crude Oil Tankers (IMO Resolution MSC.289 (87)) allows for the use of "Corrosion Resistant Steel". In response to the request of Japanese steel Industry , IACS has developed UI SC 258 to clarify various provisions given in Resolution MSC.289 (87). The UI details of general principles, technical file to be prepared by the shipbuilder for administration, scope of application, inspection, verification and approval requirements, and test procedures for qualification of corrosion resistant steel for cargo tanks in crude oil tankers.

(15) UI FTP6 UI FTP6 clarifies and harmonizes additional design and test requirements for pipe penetrations and cable transits that do not incorporate the traditional welded structural steel sleeve with non-removable filling. A-class pipe penetrations and cable transits that are constructed without structural sleeves of minimum 3 mm thickness and minimum 60 mm length welded or bolted to the division; and/or constructed with removable, soft or intumescent filling material are to be subject to additional testing and/or design criteria stipulated in the UI. (16) UI SC249 UI SC249 provides a common basis for certifying that new installations on ships are asbestos-free based on declarations and supporting documentation. Rev.1 (Feb 2013) of the UI, which was prepared in light of approved text of MSC/1/Circ.1426, adds to the UI that the verification process to comply with SOLAS Chapter II-1, Regulation 3-5 shall be done taking into account appendix 8 of the 2011 Guidelines for the development of the inventory of hazardous materials (resolution MEPC.197(62)).

(17) UI MPC103 UI MPC103 provides a common basis by which to assess whether or not a replacement engine is identical to the engine being replaced. In this instance identical relates specifically to the NOx emission characteristic of the engine. The UI stipulates that an identical engine is, as compared to the engine being replaced, an engine which is of the same design and model, rated power, rated speed, use, number of cylinders and fuel system type as well as additional criteria depending on the possession of EIAPP certificate. (18) UI SC191 Based on the outcome of the IMO DE 57 and MSC92, UI SC191(Rev.5 May,2013) has been revised to make it in line with MSC circular on Unified Interpretations (MSC.1/Circ.1464 dated 24 June 2013). Text related to the extension of the relaxation of vertical and horizontal access holes was deleted from the interpretation of Technical Provision, resolution MSC.158(78), paragraph 3.10 and 3.11.

A proceeding to revise NKs Rules will be commenced to incorporate the above URs and UIs appropriately. ClassNK External Affairs Division is pleased to provide international trends promptly.

For any questions about the above, please contact: NIPPON KAIJI KYOKAI (ClassNK) External Affairs Division, Administration Center, Head Office Address: 4-7 Kioi-cho, Chiyoda-ku, Tokyo 102-8567, Japan Tel.: +81-3-5226-2038 Fax: +81-3-5226-2024 E-mail: xad@classnk.or.jp

1. Disclaimer ClassNK does not provide any warranty or assurance in respect of this document. ClassNK assumes no responsibility and shall not be liable for any person for any loss, damage or expense caused by reliance on the information in this document. 2. Copyright Unless otherwise stated, the copyright and all other intellectual property rights of the contents in this document are vested in and shall remain vested in ClassNK.

5/5

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- LR Guidance For Cryogenic SpillDocument22 paginiLR Guidance For Cryogenic SpillnikoskarandinosÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Molliere Diagram PropaneDocument1 paginăMolliere Diagram PropanenikoskarandinosÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Admiralty and Maritime Law PDFDocument28 paginiAdmiralty and Maritime Law PDFnikoskarandinosÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- ExxonmobilDocument61 paginiExxonmobilnikoskarandinosÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Chevrontexaco Charter Party Clause Rev Apr 2004Document21 paginiChevrontexaco Charter Party Clause Rev Apr 2004nikoskarandinosÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- SG More Than 1025Document1 paginăSG More Than 1025nikoskarandinosÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Lavera Hbis Berth Reducer Gaz InterceptorDocument1 paginăLavera Hbis Berth Reducer Gaz InterceptornikoskarandinosÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- 7 9DI Questionnaire 2011Document11 pagini7 9DI Questionnaire 2011nikoskarandinosÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Astm TablesDocument253 paginiAstm Tablesnikoskarandinos100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Tables Astm 58Document3 paginiTables Astm 58nikoskarandinosÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Super ASTMDocument2 paginiSuper ASTMnikoskarandinos0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Voyage EstimationDocument1 paginăVoyage Estimationnikoskarandinos0% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Deviation StatementDocument2 paginiDeviation StatementnikoskarandinosÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Actions To Protect and Safeguard All Persons On Board in EmergenciesDocument29 paginiActions To Protect and Safeguard All Persons On Board in EmergenciesnikoskarandinosÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- CoolingDocument51 paginiCoolingnikoskarandinosÎncă nu există evaluări

- Bow Mariner Report 72653a1Document56 paginiBow Mariner Report 72653a1nikoskarandinosÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Hip Ion (B Rmuda Limited: The MutualDocument26 paginiHip Ion (B Rmuda Limited: The Mutualnikoskarandinos100% (3)

- A Master's Guide To Using Fuel Oil On Board ShipsDocument74 paginiA Master's Guide To Using Fuel Oil On Board Shipsnikoskarandinos100% (1)

- Hip Ion (B Rmuda Limited: The MutualDocument26 paginiHip Ion (B Rmuda Limited: The Mutualnikoskarandinos100% (3)

- Ship Safe ManagementDocument26 paginiShip Safe ManagementnikoskarandinosÎncă nu există evaluări

- Industry Passage Plan Pilot BoardingDocument24 paginiIndustry Passage Plan Pilot Boardingnikoskarandinos100% (3)

- Timber Deck CargoesDocument70 paginiTimber Deck CargoesPratap Singh Rathore KinsariyaÎncă nu există evaluări

- A Master's Guide To Using Fuel Oil On Board ShipsDocument74 paginiA Master's Guide To Using Fuel Oil On Board Shipsnikoskarandinos100% (1)

- Shipboard Cargo Handling Safety GuideDocument55 paginiShipboard Cargo Handling Safety GuidenikoskarandinosÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Cargo Handling and StowageDocument24 paginiCargo Handling and StowageDudy Achmad Abdul Gafar100% (1)

- Propulsion System LR-1Document4 paginiPropulsion System LR-1thisbchÎncă nu există evaluări

- Mepc 245 66 PDFDocument33 paginiMepc 245 66 PDFSatish DabralÎncă nu există evaluări

- Standards in Shipping: Looking ForwardDocument62 paginiStandards in Shipping: Looking ForwardAjithkumar SukumarnÎncă nu există evaluări

- A Guide To Shaft AlignmentDocument12 paginiA Guide To Shaft AlignmentpropulziÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Fsru BaliDocument56 paginiFsru Balimahera wijaksaraÎncă nu există evaluări

- Categories of Cargo and Types of ShipsDocument14 paginiCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- WUHUMAX LNG Carrier: Main Dimensions Machinery & PropulsionDocument2 paginiWUHUMAX LNG Carrier: Main Dimensions Machinery & Propulsionrevan 101Încă nu există evaluări

- Offshore LNG Regasification Design Memorandum: ProjectDocument8 paginiOffshore LNG Regasification Design Memorandum: Projectsyamsudin2006Încă nu există evaluări

- Gastech-Conf-Brochure FINAL JAN 2011Document20 paginiGastech-Conf-Brochure FINAL JAN 2011KIRANJOSHIÎncă nu există evaluări

- Chapter 1. General InformationDocument33 paginiChapter 1. General InformationaliÎncă nu există evaluări

- 20 Ammonia Ebook Draft 5Document28 pagini20 Ammonia Ebook Draft 5Dũng LêÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Ship Dimensions: 22.1. GeneralDocument32 paginiShip Dimensions: 22.1. GeneralHoàng TâmÎncă nu există evaluări

- LNG FSRU BOG SystemDocument4 paginiLNG FSRU BOG Systemdmscott10Încă nu există evaluări

- PIlot Operated Safety ValveDocument6 paginiPIlot Operated Safety ValveTrisha SalinasÎncă nu există evaluări

- Guideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling FacilityDocument117 paginiGuideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling Facilityshahjada100% (1)

- DNV RFC Ships P0CH01 User Information, Amendments and IndexesDocument68 paginiDNV RFC Ships P0CH01 User Information, Amendments and Indexeslearsipi061Încă nu există evaluări

- Completing The LNG Value ChainDocument8 paginiCompleting The LNG Value ChainManoj Gupta100% (1)

- Petronet LNG LTD., India: Investment in LNG Terminals & Future For The Downstream IndustriesDocument26 paginiPetronet LNG LTD., India: Investment in LNG Terminals & Future For The Downstream Industriesjan.pa87534Încă nu există evaluări

- LNGC RAAHI - IMO 9253703 - Cargo Operating ManualDocument281 paginiLNGC RAAHI - IMO 9253703 - Cargo Operating Manualseawolf50Încă nu există evaluări

- Innovation of LNGCDocument63 paginiInnovation of LNGCpadangiringÎncă nu există evaluări

- INSG Nandgi Jan23Document10 paginiINSG Nandgi Jan23candymaluÎncă nu există evaluări

- NO96 Max LNG Tanks (GTT)Document2 paginiNO96 Max LNG Tanks (GTT)EdutamÎncă nu există evaluări

- Data Tugas Rekayasa Dermaga Kelas PDocument1 paginăData Tugas Rekayasa Dermaga Kelas PdianaÎncă nu există evaluări

- Comparison of Spherical and Membrane Large LNG2 PDFDocument27 paginiComparison of Spherical and Membrane Large LNG2 PDFlaurent delacroixÎncă nu există evaluări

- Wartsila FSRU LNG Regasification ModulesDocument8 paginiWartsila FSRU LNG Regasification Moduleshermit44535100% (3)

- 02 ME-GI ConceptDocument44 pagini02 ME-GI ConceptValera MarahovskiyÎncă nu există evaluări

- Types of Ship and Port Material Handling Equipment & TechnologyDocument36 paginiTypes of Ship and Port Material Handling Equipment & TechnologyKaren Shui100% (20)

- MEPC 78 7 16 Comments On The Report of The Correspondence Group On Carbon Intensity Reduction TOR 3 ICS and INTERTANKODocument7 paginiMEPC 78 7 16 Comments On The Report of The Correspondence Group On Carbon Intensity Reduction TOR 3 ICS and INTERTANKOsalman rifkanÎncă nu există evaluări

- Class Notice No.15-New Revision of URZ, URS & UI (2015)Document4 paginiClass Notice No.15-New Revision of URZ, URS & UI (2015)Arunkumar MuthukrishnanÎncă nu există evaluări

- Oisd STD 194Document59 paginiOisd STD 194HSE SABSÎncă nu există evaluări