Documente Academic

Documente Profesional

Documente Cultură

Journal Alberta

Încărcat de

Erick Antonio Niño AguilarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Journal Alberta

Încărcat de

Erick Antonio Niño AguilarDrepturi de autor:

Formate disponibile

1075

Carpentry workers issues and efficiencies related to construction productivity in commercial construction projects in Alberta

Kasun N. Hewage and Janaka Y. Ruwanpura

Abstract: For decades, many researchers have reported the decline in construction productivity, but it is impossible to generalize the productivity problems due to issues such as geographical differences, weather changes, skill level differences in the labour force, and workload demand. There are currently approximately 160 000 construction workers in Alberta, and the value of ongoing and future projects in the oil and gas sector alone is over Can$200 billion. Because of the high demand and necessity for a comprehensive research study for Alberta to improve construction productivity, a 2 year study commenced with the collaboration of four eminent contractors to investigate human, management, and external issues. Under human issues, 101 construction workers in the carpentry trade were observed, interviewed, and surveyed by questionnaire. This paper discusses the research method, results, and recommendations of the productivity research specific to the human issues. These recommendations were communicated to the contractors for improving the human issues by developing and analyzing a new expectancy model considering construction workers effort and performance and the tool times observed to mitigate the reasons for non-tool time. Key words: construction productivity, worker motivation, expectancy theory, tool time, construction workers. Rsum : Les chercheurs ont fait tat, depuis plusieurs dcennies, de la baisse de productivit en construction. Cependant, les problmes de productivit ne peuvent pas tre gnraliss en raison des questions telles que les diffrences gographiques, les changements de temprature, les diffrences dans les niveaux de comptence de la main-duvre, les charges de travail, etc. LAlberta compte environ 160 000 travailleurs de la construction et des projets en dveloppement pour une valeur de 200 milliards de dollars. En raison de la forte demande et de la ncessit davoir une tude de recherche complte pour que lAlberta puisse amliorer la productivit en construction, il a t recommand dentreprendre, avec la collaboration de quatre grands entrepreneurs, une tude de deux ans afin dexaminer les questions humaines, externes et de gestion. Pour ce qui est des questions humaines, 101 charpentiers ont t observs, interviews et ont eu rpondre un sondage. Cet article aborde la mthode de recherche, les rsultats et les recommandations de la recherche sur la productivit spcifiques aux questions humaines. Ces recommandations ont t communiques aux entrepreneurs afin damliorer les aspects humains en dveloppant et en analysant un nouveau modle dattentes qui tient compte de leffort et du rendement des travailleurs de la construction, ainsi que des temps rels de travail observs afin dattnuer les raisons des temps non consacrs au travail. Mots cls : productivit en construction, motivation des travailleurs, thorie des attentes, temps de travail, travailleurs de la construction. [Traduit par la Rdaction] Hewage and Ruwanpura 1089

Introduction

Productivity improvement is one of the key focus areas in the present construction industry in Alberta, as well as in North America. The decline in construction productivity across North America since the mid-1970s has been reported

Received 11 October 2005. Revision accepted 6 March 2006. Published on the NRC Research Press Web site at http://cjce.nrc.ca/ on 23 October 2006. K.N. Hewage and J.Y. Ruwanpura.1 Department of Civil Engineering, Schulich School of Engineering, University of Calgary, 2500 University Drive NW, Calgary, AB T2N 1N4, Canada. Written discussion of this article is welcomed and will be received by the Editor until 31 December 2006.

1

Corresponding author (e-mail: janaka@ucalgary.ca).

by many researchers, however, including Heale (1993). The construction industry represents a substantial portion of the Canadian economy, and thus research and development in this area have an important impact on the national economy. The latest statistics for major projects in Alberta show a value of over Can$200 billion for ongoing and future projects in the oil and gas sector alone (Alberta Economic Development 2004). In Alberta only, there are approximately 160 000 construction workers in construction projects at present (Canadian Construction Association 2004). Generally, construction labour itself represents about 25% of the total project cost (The Business Roundtable 1989). Therefore, it is very important to find solutions for declining construction productivity in terms of labour issues to save billions of dollars and make construction a professional and attractive business. Productivity has many definitions, including performance factors, production rate, and unit person hour rate. Generally

2006 NRC Canada

Can. J. Civ. Eng. 33: 10751089 (2006)

doi:10.1139/L06-050

1076

Can. J. Civ. Eng. Vol. 33, 2006

in construction, however, productivity is stated as an inplace value divided by inputs, such as work hours (Oglesby et al. 1989). High productivity is the intensive and (or) efficient use of scarce resources converting input into output, which results in greater profit (Arditi 1985). Some argue that productivity can be achievedincreased by working harder, faster, or longer. In the real world, however, productivity cannot be achieved by speed and harder work only without adopting better work practices (Banik 1999). Some previous Canadian researchers, such as McTague and Jergeas (2003) and Dozzi and AbouRizk (1993), stated that the present rate of actual working time (tool time) of a construction worker is about 56%, which means that 44% of the workers time is spent on nonproductive activities. Dozzi and AbouRizk have given many reasons for low productivity, including the following: unavailability of the right materials, tools, or equipment; poor relations between workers and management; poorly organized projects; breakdown in communication; unfair work assignments; incomplete designengineering work; lack of cooperation among different crafts; poor supervision; rework; no worker participation in the decision-making process; and restrictive and burdensome procedures. Almost all the previous researchers on construction productivity in Canada refer to other published documents, however, which are not Canadian and are outdated, to analyze and make conclusions about productivity issues. Further, no root-level investigation has been conducted by many of the Canadian researchers to determine actual worker concerns and issues. Most of the researchers seem comfortable using the views of construction managers to find solutions and totally neglect the views of construction workers and supervisors at lower operational levels. Previous research studies also showed that there is a wide discrepancy between what employees consider as important in their jobs and what their supervisors think is important to employees. Liberda et al. (2003) conducted a pilot survey with Alberta-based construction companies and stated that the views of workers in construction productivity are quite different from those of the managers. Hence, identifying the most critical factors that impact construction productivity is a key issue. Although several studies have been conducted in the past, there was no direct relation to construction contractors or projects in Alberta and Canada. The paper focuses on the research study conducted on human issues related to improving construction productivity. Under the human issues research, individual worker performance and motivational factors were identified through observations, interviews, and questionnaire surveys. Observations were conducted with 101 workers to understand construction work practices and work time distributions.

(1982), motivation is intangible: a hypothetical construct that is used to explain human behaviour. Further, they state that motivation has a direct impact on work performance and can be positively influenced or managed by external factors, such as incentives and rewards. Pioneering and extensive research regarding motivation was conducted, especially during the 1970s (see, for example, Borcherding 1976; Schrader 1972). Maloney and McFillen (1987) conducted a comprehensive research study in which they investigated the motivational patterns of construction labourers, focusing on the importance attached to various job-related factors and their satisfaction with each factor. Motivational programs in the construction industry can be grouped into five main categories according to The Business Roundtable (1989): (i) goal setting, (ii) incentives, (iii) positive reinforcement (i.e., recognition for a job), (iv) work participation, and (v) work facilitation. The findings of Laufer and Borcherding (1981) indicate that financial incentive programs for the construction labour force not only are feasible, but also could materially raise productivity, lower production costs, shorten construction time, improve the quality of management, and increase the earnings of the workers. Further, Borcherding and Oglesby (1974) previously concluded that the satisfaction of construction workers is inherent in the work itself. Their research concluded that the most important set of factors included those relating to the intrinsic nature of the work, such as working like a craftsman and performing challenging work. Overall satisfaction with the job was measured, and a multiple regression analysis revealed that satisfaction with intrinsic factors makes the greatest contribution to general job satisfaction. These studies were conducted in some time ago, however, and were limited mainly to Maslows need theory (Maslow 1959) and Herzbergs two-factor theory (Herzberg et al. 1959). Although the approaches of Maslow and Herzberg have a surface logic, are easy to understand, and can be readily translated into practice, the research evidence shows definite limitations. There is very little research support for the theoretical basis and predictability of either model. Jenkins et al. (1982) recommend, instead, using the more accepted expectancy theory of work motivation from which new guidelines for managing labour motivation can be derived. Teamwork is also an important aspect of construction productivity. Team dynamics refers to what makes a team work and how individuals influence the team as a whole. Understanding and accepting individual differences in worker preferences can significantly improve the project performance (Gordon and Smith 2001).

Research objectives

The first phase of the productivity study was conducted by a construction productivity research team with 53 professionals in Alberta-based construction companies. The team identified 51 factors that affect productivity, of which 35 are management-related factors. The 53 industry professionals using a questionnaire survey identified the most critical productivity factors from the 51 factors. The top five factors included changes in drawings and specifications, worker

2006 NRC Canada

Background

For the last 70 years, researchers and academics have looked at various research works related to humans and teamwork, but significantly less research has been done with construction workers. Human potential is boundless, but it requires motivation to excel (Schrader 1972). The term motivation has several definitions. According to Jenkins et al.

Hewage and Ruwanpura

1077

experience and skills, worker motivation, worker attitude and morale, and inadequate communication. By considering the results of the first phase, the research steering committee, which consists of senior construction managers and university researchers, decided to perform extensive research in specific areas of human, external, and management issues that affect construction productivity. The focus of the human issues was limited to motivation and effective communication, as they were identified as priority areas through the first phase of the research. Therefore, the overall objective of the research project under human issues is to understand and investigate the human issues to develop the best practices and tools for the construction industry to improve productivity. The following are the defined sub-objectives: (i) identify the most critical factors that affect construction productivity by surveying a large sample from each of the collaborating companies; (ii) identify the most relevant motives and motivational patterns of construction workers; (iii) determine the present worker efficiency in Alberta construction projects in terms of tool time; (iv) understand the opinions of workers in terms of motivation, work satisfaction, and teamwork to improve construction productivity; (v) investigate the background and the factors that contribute to worker skills and team spirit; and (vi) recommend practices, guidelines, and tools to improve motivation and communication at construction sites. The focus of this paper is to discuss worker motivation and productivity, which are under human issues. The researchers overcame the challenge of quantification of motivation by using the motivational expectancy theory of Vroom (1964) with other construction applicable theories such as equity theory, Herzbergs hygiene theory, and reinforcement theory. Construction carpenters, carpentry helpers, and foremen were selected as the research sample. More than 100 workers participated in this research, and all participants were observed, interviewed, and surveyed by questionnaire to collect the required data. The research activities spanned the period from January 2004 to May 2005.

Research methodology and focus

Four construction job sites were used as the primary data collection source. The research focused on the construction activities of carpenters, carpentry foremen, and carpentry helpers. The construction activities included formwork, false work (the supporting structure for formwork such as jacks and props), and columns. Both unionized and open-shop labourers were included as research subjects, although it is not possible to disclose the differentiation because of the ethical restrictions imposed on the research project. The required data were collected using interviews, questionnaires, and observations during the winter season from January 2004 to May 2005. All the observations (101) were conducted in the open-site environment. The range in number of workers from all the companies is 2328, and 73% are open-shop workers. This part of the research focused on understanding the efficiency and qualities of construction workers, such as team spirit and motivation. Construction worker efficiency was determined through observation by measuring direct work-

ing time (tool time) and non-working time and by identifying the reasons for not working. Interviews, questionnaire surveys, and direct observations were used to collect data for the productivity research. Interviews focused on worker motivation, team spirit, and background information related to worker skills and experience. Further, workers were allowed to discuss concerns they had related to the job site during the interview time. Questionnaire surveys were conducted to identify construction workers motives and measure each workers level of motivation associated with each motive. Observations were conducted mainly to understand the working patterns, time distributions for each activity, and efficiencies of construction workers. There are many work sampling and measurement techniques to serve different purposes. For example, multi-minute measurement, which observed worker movements every 5 10 min, is suitable for repetitive and time-consuming operations. The time study, which observes a worker continuously for a relatively short period of time, is suitable for observing complex work operations with several activities (Failing et al. 1988). Because of the complex nature of carpentry work, researchers selected continuous time study and conducted a pilot study of 1 month to determine time duration: 15, 30, 45, and 60 min time durations were tested, and 30 min was selected because of the practical difficulties caused by the movement of carpenters from one work area to another. The following summarizes how the interviews, questionnaire surveys, and observations were conducted: Interviews Candidates (research subjects) were selected on a random and voluntary basis. Supervisor advice and permission were also factors in the selection process. Each interview lasted for about 20 min and was conducted in a closed room to protect the privacy of the worker. One hundred and one workers were interviewed in four participating companies. An average of 25% of the total carpentry workforce in each company participated in the research. The demographic information of individual companies is not included in the paper, however, because of the ethical and confidentiality agreements. Questionnaire surveys Each research subject was issued a questionnaire after the interview and was allowed to take it home for completion and return it later. All 101 research subjects were given the questionnaire, and the response rate was about 45%. Observations Each of the 101 workers was continuously observed twice: 30 min in a morning shift and 30 min in an afternoon shift to measure working time and other time spent on different activities such as looking for materials and tools, instructions, and moving. The data triangulation method, which measures the same variable with different techniques to verify its accuracy, was used to improve the validity of the results. For example, worker motivation was measured and evaluated through interviews and questionnaire surveys.

Theoretical framework

As stated earlier, the theoretical framework of this research was mainly based on the motivational expectancy theory. Expectancy theory can be defined as follows: workers

2006 NRC Canada

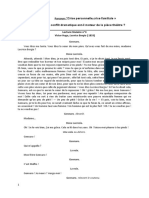

1078 Fig. 1. Expectancy theory model for measuring construction worker motivation.

Can. J. Civ. Eng. Vol. 33, 2006

Table 1. Selection of factors (motives) used in the questionnaire and the most applicable theories for each selected factor. Question Bonus or rewards Amount of salary Friendliness and helpfulness of the coworkers Amount of freedom in your work Chance for getting a promotion Chances to learn new things Respect received from the coworkers and supervisors Opportunity for challenging work Tools and equipment Chances to accomplish something worthwhile Chances to do the things which you do best and like most Type of physical surroundings (washrooms, lunch rooms, etc.) Teamwork with Supervisors understanding of the quality of technical details Supervisors direction and support Safety procedures at the site Chances to take part in decision making Opportunities to develop skills and abilities Job security Opportunity to work entire period of site before moving to a new one Seeing the ultimate results of work Supervisors positive feedback after successfully completing a task Holidays and free time (lunch and coffee breaks) during work Applicable theorya ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, ET, HT, RT EQT, RT HT, MT, AT MT, AT RT, HT HT MT, AT EQT, HT EQT MT, RT, HT, AT RT, HT EQT, HT MT, EQT, AT EQT, HT EQT, HT MT, EQT, HT, AT MT, HT, AT HT MT, EQT, HT, AT EQT, RT MT, HT, AT MT, RT, HT, AT RT, HT, EQT

a AT, Alderfers theory; EQT, equity theory; ET, expectancy theory; HT, Herzbergs theory; MT, Maslows theory; RT, reinforcement theory.

motivation to produce could be predicted from the way they perceive their performance as a path to attainment of their goals (Vroom 1964). In expectancy theory, motivation is defined as a function of expectancy, instrumentality, and valence: [1] motivation = f (E P) (P O) V

where E P is the effort to performance expectancy (EP expectancy), P O is the performance to outcome expectancy (instrumentality or PO expectancy), and V is the valence. Expectancy is the subjective probability that a persons action will be followed by an outcome. Effort to performance expectancy (EP) is the belief that effort leads to a de 2006 NRC Canada

Hewage and Ruwanpura Table 2. Clusters of motivational factors. Cluster Incentives Working team (work participation) Factors

1079

Working conditions (work facilitation)

Management and supervision (positive reinforcement)

Intrinsic motives (goal setting)

Bonus and rewards Amount of salary Friendliness and helpfulness of coworkers Respect received from the coworkers and supervisors Team you work with Amount of freedom in work Chances to learn new things Opportunity for challenging work Tools and equipment Type of physical surroundings Safety procedures at site Chances for getting a promotion Supervisors understanding of quality of technical details Supervisors direction and support Job security Opportunities to work entire period at site before moving to a new one Supervisors positive feedback after successfully completing a job Holidays and free time Chances to accomplish something worthwhile Chances to do things which you like most and do best Chances to take part in decision making Opportunities to develop skills and abilities Seeing the ultimate results of work

Table 3. Demographic information of research subjects. Job category Foremen Journeyman carpenters Apprentice carpenters Carpentry labourers General labourers Surveyors No. of subjects 13 58 15 7 5 3 Avg. no of years of experience 22.8 16.5 3.2 6.7 10.3 6.0 Range (years) 9.040.0 5.031.0 0.85.0 0.133.0 0.137.0 5.08.0

sired performance level. In other words, workers tend to perform more if they believe in and feel confident about their efforts. Performance to outcome expectancy (PO) is the belief that performance will be followed by the desired outcome. Valence is the preference or appreciation of the outcomes or end results. There are two types of outcomes, namely extrinsic and intrinsic. Extrinsic outcomes refers to the outcomes that are received from someone else by appreciating performance (pay increase, promotion, quality awards). Intrinsic outcomes are peoples own feelings about their performance (self-actualization, satisfaction, more individual control). This research used only the expectancy theory for motivation quantification purposes and used other theories to explain construction worker behaviour more realistically. Vrooms (1964) expectancy theory examines motivation from the perspective of why people choose to follow a particular course of action. This theory would seem most applicable to construction work in which how motivated employees are depends on whether they want the reward on offer for doing a good job and whether they believe more effort will lead to that reward. Expectancy theory itself is not

sufficient to completely understand the motivational patterns of construction workers, however. Thus, the model presented in Fig. 1 was developed by combining expectancy theory, needs theory (Maslow 1954), equity theory (Adam 1963), and reinforcement theory (Skinner 1969). People have several needs to be satisfied, and they are not motivated by the same factors once these needs are achieved. The boxes to the left and right in Fig. 1 show Maslows need hierarchy, which discusses the steps of human needs. Maslows hierarchy of needs states that people must satisfy each need in turn, starting with the first, which deals with the most obvious needs for survival itself. Only when the lower order needs of physical and emotional well-being are satisfied will people then be concerned with the higher order needs of influence and personal development. Conversely, if the things that satisfy lower order needs are swept away, people are no longer concerned about the maintenance of their higher order needs. There is an interesting extension of Maslows theory called Alderfers ERG theory (Alderfer 1969). Similar to Maslows five levels, ERG theory consists of three levels, namely existence needs (E), relatedness needs (R), and growth needs (G). Unlike Maslows theory,

2006 NRC Canada

1080 Table 4. Definitions and values of working and non-working times. Category Work (tool) time Looking for materials Definition Direct effective working time Time spent on searching, waiting, or moving materials from another place away from individuals working area Time spent on searching, waiting, or moving tools from another place away from individuals working area Socializing or chatting time on top of the assigned breaks Moving around the site without performing anything related to the given work Time spent on receiving or giving instructions Time spent at construction site without performing anything related to the assigned job Moving away from the working observational area, staying near heaters, or something not mentioned in all previous categories Avg. (%) 50.7 14.6 Overall range (%) 49.552.1 12.520.4 Foremens range (%) 53.360.7 12.019.1

Can. J. Civ. Eng. Vol. 33, 2006

Carpenters range (%) 41.451.8 11.120.9

Carpentry helpers range (%) 43.155.2 12.223.7

Looking for tools

1.5

1.12.4

0.41.0

0.62.4

1.95.1

Socializing Moving

8.6 7.8

6.910.1 4.810.1

3.410.2 4.813.8

8.510.9 4.39.9

6.77.9 3.08.1

Instructions

2.8

2.64.5

Idle

9.3

8.310.6

Added to tool time (2.918.6) 0.58.4

2.03.9

1.05.5

8.611.6

6.6.10.5

Other

4.7

4.06.5

0.99.6

2.65.4

2.810.8

Fig. 2. Overall working time distribution.

ERG theory recognizes that the order of importance of needs varies for each individual. ERG theory also emphasizes that the multiple levels of needs can be satisfied simultaneously. Further, ERG theory acknowledges that if higher level needs remain unfulfilled, the person may regress to lower level needs that appear easier to satisfy. As mentioned, Maslows and Alderfers theories have not been used in this research to quantify motivation because of the lack of empirical support. Adams equity theory (Adam 1963) explains the balance between what people put into a job and what they get out of it. Adam calls these inputs and outputs. People form perceptions of inputs and outputs by comparing their own

situations with other reference points or examples in the marketplace. They are also influenced by colleagues, friends, and partners in establishing these benchmarks. Reinforcement theory (Skinner 1969) discusses the reinforces for better performance. For example, hard work leads to a valued reward such as a paycheck, bonus, or promotion; if these rewards satisfy a need, the employee will be motivated to continue with the hard work. In this case, reward is the reinforcer (Society for Industrial and Organizational Psychology, Inc. 2006). The questionnaire given to workers also considered Herzbergs theory (Herzberg et al. 1959). In his theory, Herzberg suggested that job satisfaction and job dissatisfac 2006 NRC Canada

Hewage and Ruwanpura Fig. 3. Cumulative density function of tool time of four construction companies (AD).

1081

Table 5. Description of the Likert scale. Likert No. 1 2 3 4 5 6 7 Description Strongly disagree very low Disagreelow Somewhat disagree somewhat low Neutral average Somewhat agree somewhat high Agreehigh Strongly agree very high

tion are caused by different and independent sets of factors. He found that when people are satisfied, they attribute their satisfaction to the work itself, while when people are dissatisfied with their jobs, they are concerned about the environment in which they work. This means that job satisfaction is caused by a set of factors related to the work itself, such as the nature of the job, achievement in the work, possibilities of personal growth and recognition, and promotion opportunities. Hertzberg calls these factors motivators. In contrast, job dissatisfaction is a result of conditions that surround the doing of the job, such as (physical) working conditions, salary, company policies, job security, quality of supervision, and relations with others. Herzberg called these factors hygiene (or maintenance) factors. These are not an intrinsic part of a job: they refer to the environment and have the function of preventing job dissatisfaction. The hygiene factors must be continually maintained by management because they are never completely satisfied (Mannisera et al. 2005). Porter and Lawler (1968) developed a model based on expectancy theory for motivation. Porter and Lawler did not include Maslows theory or reinforcement theory in their model, but it is similar in other parts such as equity of rewards and value of rewards to the proposed model explained in the paper. Figure 1 was developed by combining several theories and explains the construction workers process of motivation in a more realistic and construction applicable manner; accordingly, the data analysis in this research was based on the said model. The developed model

can be used as a motivation measurement tool for the construction workers. Table 1 shows the selection of factors (motives) in a questionnaire based on Maslows theory (MT), Alderfers theory (AT), expectancy theory (ET), reinforcement theory (RT), equity theory (EQT), and Herzbergs theory (HT). All the questions were related to expectancy theory by asking about the belief in effort to performance, performance to outcome, and appreciation of outcomes, which are shown in Table 1. Table 1 also shows the most applicable theories for each selected factor because it is possible to relate any theory to most of the questions in Table 1. The factors presented in Table 1 were selected through literature reviews and informal interviews with construction workers. The factors stated in Table 1 can be further classified into clusters as shown in Table 2. More weight had been given to management and supervision and working conditions based on the recommendations of a productivity survey conducted by Liberda et al. (2003) and the construction productivity research group at the University of Calgary in 2003.

Results: construction worker efficiencies and working time distributions

As mentioned earlier, 101 construction workers were interviewed, surveyed by questionnaire, and observed under the human issues of productivity research. Table 3 shows the demographic information of the research participants. The central limit theorem in statistics indicates that obtaining large samples (generally sample size > 30) from any population, the sample mean will follow an approximate normal distribution (Kvanli et al. 2000). Further, according to the sample size calculations in Johnson and Bhattacharyya (1996), for a sample size of 101 with a 90% certainty in the error of estimation and 15% standard deviation in working time (found in the pilot study and reconfirmed by overall results), it is possible to achieve 2.45% error margin in working time distributions. Hence, 101 samples are statistically valid to draw conclusions in this instance. Individual worker observations were conducted in the morning and afternoon shifts to identify working time distri 2006 NRC Canada

1082 Table 6. Results of the interviews for EP, PO, and valence. Factor EP Time frame availability Past experience in similar type of work Working conditions Group feelings PO Past experience in similar type of work Salary as compared to level of effort Rewards allocation fairness EP expectancy Working conditions Group feelings Valence Other sources of income Need to earn more at the moment Future benefits from rewards Fairness of salary and rewards Mean 5.69 4.37 5.53 5.12 4.37 4.68 3.90 5.68 5.53 5.12 1.82 4.71 3.74 4.76 SD 0.91 2.16 0.82 0.98 2.16 1.41 1.76 0.87 0.82 0.98 1.45 1.81 1.81 1.56 Mode 6 7 6 6 7 6 2 6 6 6 1 6 2 6

Can. J. Civ. Eng. Vol. 33, 2006

Mode % 72 23 60 41 23 36 22 73 60 41 64 42 27 45

Median 6 5 6 5 5 5 4 6 6 5 1 6 4 5

Note: Means in bold indicate that the factor is rated as important.

butions and efficiencies. Workers time spent for construction activities was divided into two main categories, namely working and non-working time. The non-working time was further divided into seven subcategories (Table 4). Table 4 also shows the range and overall average working time distribution of participating companies. The working time distribution of different job categories is also presented in Table 4. The overall tool time is mainly governed by carpenters, since carpenters make up 73% of the sample. It is well observed that the working efficiency of foremen is significantly higher than that of other carpenters and workers. Further, Fig. 2 was developed by considering the working time distribution of all participating companies. Overall effective working time (tool time) of all companies is around 51%, which means 49% of the time is nontool time; however, 49% of the non-tool time consists of other supporting activities such as material handling and instructions. It was observed at the majority of construction sites that working time in the afternoon shifts is slightly (about 3%5%) less than that in the morning shifts. Although 27% of the workforce is unionized, a significant difference was not observed between the tool time of unionized workers and that of open-shop workers where the difference is less than 1%. Non-tool time of unionized and open-shop workers was very similar except in two categories. The looking for material category was higher in open-shop workers, and socializing was higher in unionized workers, with a difference of between 2% and 3%. The largest portion of non-tool time in Fig. 2 is looking for materials (see the definition in Table 4). If the companies could add at least 5% of the looking for materials or searching time to effective work, it would make a significant difference in the output. The times when workers were looking for materials led to other interruptions, such as stopping at several other places, chatting, and smoking. On many occasions, it was observed that workers and foremen did not

plan for material requirements based on work progress or the work targets of the day; as a result, workers had to deal with the immediate demands of issues related to materials. Construction workers spent about 9% of their working time socializing (Fig. 2). Idling was the third largest portion of non-working time. It is a common understanding that workers are unable to work continuously without a break; however, it was observed that senior workers tended to spend more time idling than younger workers. Temperature also affected idling time. For example, when the temperature was below 10 C, workers spent less time idling and more time moving out from the working area. The cumulative density function (CDF) graph in Fig. 3 represents the tool time of each company as a cumulative distribution. For an example, 80% of the Y axis of company A represents 39 on the X axis in the CDF. This means 80% of the time (80th percentile) the tool time is 39 min or less for a 1 h period for that particular company. Further, a leftskewed curve shows that all the workers are in the range of relatively less tool time, and vice versa. The lower and upper bands of CDF curves of four companies have significant variation compared with the middle portion because of the working pattern and style differences in different construction companies.

Results: worker motivation

Worker motivational issues were investigated through interviews and questionnaire surveys. Interviews focused on identifying variables that affect EP, PO, and valance, and questionnaire surveys identified the motives of construction workers in prioritized order. Further, questionnaire surveys identified EP, PO, and valence for each and every motive. All the questions in both interviews and questionnaire surveys were rated on a Likert scale of 17. Table 5 shows the descriptions and ratings of the Likert scale used.

2006 NRC Canada

Hewage and Ruwanpura Table 7. Motivational levels and valence by questionnaire surveys. Motivational level (cubic root) Cluster Incentives Working team (work participation) Factors Bonus and rewards Amount of salary Friendliness and helpfulness of coworkers Respect receive from the coworkers and supervisors Team you work with Amount of freedom in work Chances to learn new things Opportunity for challenging work Tools and equipment Type of physical surroundings Safety procedures at site Chances for getting a promotion Supervisors understanding of quality of technical details Supervisors direction and support Job security Opportunities to work entire period at site before moving to a new one Supervisors positive feedback after successfully completing a job Holidays and free time Chances to accomplish something worthwhile Chances to do things which you like most and do best Chances to take part in decision making Opportunities to develop skills and abilities Seeing the ultimate results of work Mean 4.59 5.28 5.19 5.71 5.13 5.16 5.78 5.13 5.69 4.44 5.12 5.23 5.56 5.27 5.46 4.75 SD 1.25 1.02 1.23 0.83 0.91 0.96 0.84 0.87 0.86 0.94 1.09 1.08 0.83 0.89 1.09 1.25 Mode 4.16 5.31 5.65 7.00 5.81 4.93 5.65 5.24 5.31 4.93 5.81 4.93 5.65 5.81 5.65 4.93 Median 4.63 5.48 5.52 5.67 5.46 5.31 5.67 5.24 5.94 4.48 5.24 5.31 5.65 5.48 5.65 4.93 Valence Mean 4.56 5.72 5.64 5.85 5.95 5.15 6.00 5.82 6.10 5.33 6.26 5.05 5.85 5.92 5.56 4.69 SD 1.82 1.39 1.16 1.16 0.86 1.25 1.05 1.02 0.94 1.22 0.91 1.64 0.99 1.09 1.35 1.58 Mode 6 7 6 6 6 6 7 6 7 5 7 7 6 7 7 5

1083

Median 5 6 6 6 6 5 6 6 6 5 7 5 6 6 6 5

Working conditions (work facilitation)

Management and supervision (positive reinforcement)

5.27

0.96

5.31

5.31

5.51

1.30

Intrinsic motives (goal setting)

4.25 5.31 5.32 5.07 5.60 5.55

0.99 0.99 0.83 1.05 0.86 0.94

4.79 5.65 6.32 4.58 6.00 6.32

4.38 5.59 5.31 5.31 5.65 5.65

5.26 5.74 5.51 5.26 5.74 5.67

1.27 0.99 1.32 1.16 1.07 0.98

5 5 6 6 6 6

5 6 6 6 6 6

Note: Means of the most important motives identified by the workers at all construction sites are given in bold.

EP expectancy by interviews EP expectancy reflects the workers belief that effort leads to performance. Time frame availability, past experience in a similar type of work, working conditions, and group feelings were identified as the variables that affect EP expectancy. Table 6 summarizes the EP beliefs of the researched construction sites. The following are the specific comments for each variable. Time frame availability was not a concern for most of the interviewed workers. They were content with the managerial decisions of targets. A few carpentry workers complained about continuous work loads, however, and moving all around the site for the work. Moreover, senior workers

were interested in getting involved in the decision-making planning process to define targets for work tasks. This factor was rated 6 out of 7 by 72% of the workers. Average years of experience (related as past experience in similar type of work) of an interviewed worker was about 15 years. During the observations, it was often noted that most of the workers could perform their work with minimum supervision. Only one work-related argumentissue was observed during the observation period, and this disagreement was with a foreman. Almost all the workers appreciated the working conditions in observed construction sites. Working conditions included the overall outside environment at the job site, such

2006 NRC Canada

1084 Table 8. Recommendations to improve on-site communication. Motivational category Activity Looking for materials and tools Incentives Work participation Provide opportunities to workers to express their views and innovative methods about construction methods and processes Promote an on-site newsletter or brochure to discuss issues related to teamwork, non-tool time, inventions, appreciations, etc.

Can. J. Civ. Eng. Vol. 33, 2006

Work facilitation It is possible to update an online database about the materialstools availabilities and locations and provide access to site level Employ more lower level managers to work with workers at site level

Socializing, idle, and moving

Instructions

It is possible to conduct a discussion time within the working team, at least once in 2 weeks, to listen to each others views of effective teamwork and communication

Employ more lower level managers to work with workers at site level

as weather, company management, safety at work, and the physical facilities (e.g.,washrooms, lunchrooms). This factor was rated 6 out of 7 by 60% of the workers. Group feelings refers to the communication from other workers about the working conditions. As shown in Table 6, most of the workers were well informed by the other coworkers about good working conditions. By considering ratings for all the factors that affect EP (refer to the values in bold in Table 6), all the aforementioned factors except past experience in similar type of work are rated as important on a benchmark of 5 on the scale of 1 to 7 in Table 3. PO expectancy by interviews PO expectancy is the belief that better performance leads to more outcome or output. Past experience in similar type of work, salary as compared to level of effort, rewards allocation fairness, EP expectancy, working conditions, and group feelings are the factors that were identified under PO expectancy. The variables and their responses that affect PO expectancy of four companies are given in Table 6. As mentioned earlier, Alberta has a highly experienced workforce and the past experience may have reinforced the belief that better performance leads to a better outcome. About 50% of the workers believed that they would receive more salary for their work, especially the senior workers. Some young carpenters complained that they were getting salaries similar to those of labourers. As a result, the workers were not highly motivated. In general, there was no performance-based rewards scheme at the sites and thus workers were not motivated to perform extra tasks or more efficiently. The only rewards they received were a few safety rewards. A fair and justifiable performance-based

rewards scheme would be a key factor for improving construction productivity. EP expectancy itself has an impact on PO expectancy, that is, the workers belief that more effort leads to better performance. Even though they believed in EP expectancy, they did not have a reason to put more effort into their work because they were not getting a salary based on performance or work targets. As mentioned under EP expectancy, workers were well informed by the other coworkers about good working conditions. By considering ratings for all the factors that affect PO (refer to the values in bold in Table 6), EP expectancy, working conditions, and group feelings are rated as important on a benchmark of 5 on the scale of 1 to 7 in Table 3. Valence by interviews Valence indicates how much the workers value or appreciate the outcomes or outputs of their performance and depends on other sources of income, need to earn more, belief in future benefits from rewards, and belief in fairness of salary and rewards. The variables and responses that affect valence of the four companies are given in Table 6. Most of the construction workers did not have other sources of income (64% of the workers interviewed had no other income). Their only income was through the company and construction work. This factor was a positive one for worker motivation on the site level, however. In this particular case, a lower rating is more beneficial for the company from the motivation point of view. More than 70% of the workers in all observed sites wanted to earn more (need to earn more at the moment). Others were satisfied with their current income. The younger workers especially wanted to earn more, whereas senior workers were satisfied with their current income.

2006 NRC Canada

Hewage and Ruwanpura

1085

Positive reinforcement Top managers such as project managers, field engineers, and project coordinators should be more approachable for on-site workers Training programs for managers and foremen about communication may improve the present status; it is possible to allow managers to pursue technical communication and work site communication courses in educational and technical institutions from time to time Implementing listening environment at the site could also improve communication substantially Weekly meetings with all the workers and explain at least weekly targets of project; these meetings can also be used as conflict and dispute resolution medium for both managers and workers; furthermore, all important notices, safety instructions, new policies, common problems, etc. can be discussed in these meetings; this approach will build close relationships and trust between management and workers Top managers such as project managers, field engineers, and project coordinators should be more approachable for on-site lead workers

Goal setting Similar to theme in safety first zero accidents, companies should convey a message to workers to achieve a systematic standard in materials and tools placing Workers should be continuously updated about working targets and deadlines; work targets and achievements can be displayed on notice boards; these boards can be located in lunch rooms, site offices, and other gathering areas

Use of three-dimensional models and drawings in the display areas of site is a great communication method; most interviewees mentioned that they were not aware of the end product of the project and would like to see the details of construction at regular intervals

Allow workers to access more blueprints, specifications, and other construction-related information when required

Workers were also questioned about their belief of getting future benefits from rewards if they performed more at present. Interestingly, about 75% of the workers did not believe that they would receive any future rewards or benefits. This lack of belief was mainly the result of there being no performance-based rewards scheme. Workers did not see any reason to perform or work more productively. Most of the workers believed, however, that they were getting a fair salary from the company based on the present industry norms (fairness of salary and rewards). According to Table 6 (refer to the values in bold), the only factor that is beneficial from the point of view of the companies is the lower other sources of income of construction workers.

Prioritization of motivational level and valence by questionnaire surveys

As mentioned previously, a questionnaire was issued to every worker after the interview. Each worker was allowed to take the questionnaire home for completion and return it later. The main focus of the questionnaire was to understand the motives and motivational levels for each motive. Further, the workers were allowed to identify and rank any motives other than those identified in the questionnaire. The overall response rate for the questionnaires was about 45%. The individual motivational levels for each factor were calculated using the expectancy theory model shown in Fig. 1. Each question was rated on a Likert scale of 17. The motivational level (ML) is in the range of 1343 (7 7 7, where EP, PO, and valence were rated on a Likert scale of 17; for expectancy theory, ML = EP PO valence). For example, if a worker rates all EP, PO, and valence as 6, then the motivational level is 216; if all are 7, then the motiva-

tional level is 343; if all are 5, then the motivational level is 125; etc. For comparison purposes, however, the cubic root of the motivational levels was taken where the values were in the 7 point scale. Table 7 shows the motivational levels at the construction sites considering the present site conditions. Valence represents the workers appreciationlikeliness for each motive, irrespective of the existing conditions at the present job site, that is, how much they preferred a motive as a motivator, as shown in Table 7. There are many common factors identified as the most important by the workers at the four different construction sites. Almost all the workers considered the respect they receive from coworkers as more important than the average level (which is 4 on a Likert scale of 17). Workers always prefer to be respected by their supervisors, managers, and coworkers. In addition, workers identified chances to learn new things as another important motivational factor. Even the most experienced workers commented on the chances to learn new things. Workers did not believe their performance might improve the type of physical surroundings, holidays and free time, and bonus and rewards, however. The levels for the most important motives identified by the workers at all construction sites are given in bold in Table 7. Safety procedures at site is one of the highly appreciated factors by construction workers, and most workers preferred to learn new things in construction. Further, they appreciated the factors that have a direct relationship with on-site work, such as tools and equipment and supervisors direction and support. Workers preferred to have better direction and support from foremen and supervisors. Most of the managers assume that the financial incentives are the main motives for construction workers, but only one out of four sites rated salary as one of the priorities. That

2006 NRC Canada

1086 Table 9. Recommendations for working conditions, supervision, and equipment and tools management. Motivational category Activity Looking for materials and tools Incentives

Can. J. Civ. Eng. Vol. 33, 2006

Work participation It is possible to identify material requirements for individual teams at least for a weekly schedule

Companies can employ some general labourers to stock materials for a nearby area in a proper order; at the moment, workers move materials for the instant demands

Socializing, idle, and moving

Implementation of effective reward scheme may motivate workers considerably; at present, all workers get fixed wages regardless of their performance and productivity level; usually, workers get motivated due to rewards like company stickers, tool kits, company jackets, and safety equipment; the company should recognize the long-term benefits due to these rewards

Workers tend to use working time as a socializing time because of the lack of social activities at construction sites; companies may have regular gettogethers, and it may help to develop more team spirit

Instructions

Foremen and supervisors should be strictly careful about the language they use for instructions; many workers complained about disrespectful behaviour of supervisors

particular site employed a relatively young workforce in which 65% had less than 10 years of experience. Interestingly, most of the workers rated Bonus and rewards as less important. However, they complained during the interviews about the lack of performance-based reward schemes. It seems workers do not think they will ever get rewards and bonuses in construction because of the present conditions in construction. The workers rating of opportunities to work entire period on site before moving to a new one is relatively low compared with that of other motives. By considering the views of all workers who participated in the productivity research study, it is possible to summarize the following as the most important motives for

Albertan construction workers: (i) safety procedures at the site, (ii) tools and equipment, (iii) chances to learn new things, (iv) team you work with, (v) supervisors direction and support, (vi) respect received from the coworkers and supervisors, (vii) supervisors understanding of quality of technical details, and (viii) opportunity for challenging work. Further, workers believed their performance level has an impact on the following factors based on the present settings at construction sites: (i) chances to learn new things, (ii) respect received from the coworkers and supervisors, (iii) better tools and equipment to work with, (iv) opportunities to develop skills and abilities, (v) supervisors understanding of quality of technical details (having a qualified

2006 NRC Canada

Hewage and Ruwanpura

1087

Work facilitation Use of proper materials and tools inventory system might minimize confusion; at present, most site workers do not know the availability and location of tools and materials; site staff can use a simple computer program to update material and tools availabilities on a daily basis; each foreman should have access to this information Paretos 80/20 rule can be used to store or stack materials and equipments; the rule says 80% of the time workers need 20% of the tools or materials, and 20% of the time they need 80% of the tools or materials; in general, the idea is to identify priorities and requirements of tools and equipment Most of the interviewed workers complained about routine work styles; it is better to rotate worker teams from time to time to different activities; this process will improve the skills of workers and reduce the chances of feeling bored; for example, occasionally a column crew can be switched with a carpentry crew working on slabs; however, this requires justification through research-based site observations to make sure that productivity is not affected due to learning curve

Positive reinforcement Employ more low-level managers such as foremen and field coordinators in construction sites; it will solve many problems in communication, materials, tools, and safety; utilization of foremen is not a considerable extra cost for the companies; these personnel are also working like ordinary workers but with additional responsibilities

Goal setting Full work package can be divided into manageable components where handling and tracking is manageable to the managers of company; development of weekly work packages and planning for required materials and tools is another suggestion The observed sites had many delays due to problems in utilizing tower cranes; major equipment requirements such as tower cranes could be scheduled in weekly work plans and also in monthly plans Delegating responsibilities to the lower level managers may reduce much confusion and delays; at the moment, all the observed companies tend to have control over all the site activities

It is advisable to have more events to celebrate their successful accomplishments, as workers believe that teamwork is success for better achievements

Companies should advice lower level managers such as foremen not to compromise safety for tight work schedules

It is advisable to provide managerial training courses for site-level managers such as foremen Positive feedback is very important in any type of construction activity; usually, managers and supervisors play a watch-dog role and identify only the defects in construction; this approach demotivates workers to be more productive and also prevents innovation of new methods and techniques

More worker involvement in defining work targets and deadlines is a necessity

It is possible to delegate some of foremen responsibilities to lead workers, since most of the sites have well-experienced construction workers

supervisor), (vi) job security, (vii) chances to do things which you like most and do best, and (viii) chances to accomplish something worthwhile. It was frequently noticed in the data analysis that workers rated all the motives above 4 on the Likert scale of 17 in the questionnaire surveys. This finding gives strong support for the validity of the 23 motives identified for construction workers through the literature review.

Recommendations to improve productivity

Many recommendations were suggested to the participating companies based on the data analysis in the construction

productivity research study. Interestingly, some of the recommendations had already been implemented at the observed sites, and companies were planning to implement many more in their future construction projects. Under the recommendations of this paper, only the common recommendations that are applicable to all the companies are stated, although each company was given specific recommendations. Recommendations presented in this paper cover the following influential areas based on the research results: (i) onsite communication; and (ii) working environment, supervision, and equipment and tools management. The recommendations in this paper are stated in matrix form to combine

2006 NRC Canada

1088

Can. J. Civ. Eng. Vol. 33, 2006

and focus both observations and questionnaire surveys. These matrices include clusters in the questionnaire surveys (Table 2) and non-tool time categories in the observations (Fig. 2). On-site communication More than 40% of the interviewees from all construction sites complained about the lack of communication. Some said they did not even know the type of work they were to perform for their next work shift. They all depended on instructions from the foremen, and so sometimes ineffective communication caused extensive delays and idle time. Workers were willing to know the entire work plan for the site activities and project. The interviewer had to spend a reasonable amount of time listening to the workers concerns about communication. When the question What could be improved in your team? was asked, the answer workers gave most often was lack of communication. Construction managers have a great responsibility for improving the ineffective communication at construction sites. One of the previous researchers said that many managers were brought up in the old school or through the trades, where authoritarian leadership was usually the rule (Oglesby et al. 1989). The present workforce, however, does not accept directions from the manager without knowing the basis or reason behind the decision. Workers blamed management for faulty communication and believed that they themselves were not responsible for ineffective communication that led to poor productivity and shorter tool time. The recommendations to improve on-site communication are given in Table 8. Working environment, supervision, and equipment and tools management Ineffective management has been cited as the primary cause of poor productivity rather than an unmotivated and unskilled workforce (Sanvido 1988). Lack of supervision was observed on many occasions at all construction sites. Most of the workers inefficiencies were observed to be the result of poor supervision and decision-making. Further, most of the motivational factors related to management and supervision are comparatively high in Table 7, which emphasizes the need to have better supervision. Moreover, most of the workers mentioned the lack of a performance-based reward system in the company. They argued that there is no reason to perform more if higher performance is not recognized or rewarded. One of the main factors contributing to high productivity is proper equipment and materials utilization. The utilization will be low if the equipment is not available, the wrong size, at the wrong place, not working, not suitable for the job, not operating properly, and so on. More front-end planning should be done to overcome these problems. The workers are not responsible for the low productivity caused by unavailability of materials and tools. The following recommendations are suggested to improve materials, equipment, and tool management. (The working time distribution pie chart in Fig. 2 shows that the workers spend about 15% of their total working time looking for materials and tools.) Further, as shown in Table 7, almost all the workers at the participating construction sites rated tools and equipment as a highly appreciated motive. The recommendations

for working environment, supervision, and equipment and tools management are given in Table 9.

Conclusions

The research study presented in this paper allowed an analysis that was based on monitoring construction work and interviewing 101 construction workers from four major construction contractors work sites. Tool time was measured through observation, and the same workers were interviewed to understand their concerns about work efficiency and motivation. According to the observed data for the 101 workers, the direct tool time of the same construction workers was about 51%. Workers spent a considerable amount of time involved in material movements, idling, and socializing. This study found a new expectancy motivational model for construction workers. The model identified the factors leading to three areas: effort to performance, performance to outcome, and valence. The most highlighted factors in this new model for productivity improvement are time frame availability, group feelings, working conditions, effort to performance expectancy, and non-existence of other sources of income. The main finding from the interviews was the inadequacy of communication. More than 40% of the interviewed workers at all the construction sites mentioned communication issues and named the site managers as responsible. Workers were not satisfied with the available performance-based reward schemes at the construction sites. They questioned why they should be motivated to perform better if all are getting the same rewards irrespective of their outputs. Chances to learn new things and tools and equipment were prioritized in all construction sites as important motives. It is interesting to observe that a workforce with an average of 15 years experience is still motivated by learning new things. The topmost rated motive for the construction workers is safety procedures at construction sites, but the workers do not believe their level of performance has much impact on improvements in safety procedures. Generally, the safety standards were excellent at the majority of the observed sites. Safety officers were performing their duties strictly, and most of the workers appreciated their efforts. The only reward scheme mentioned by the workers was safety rewards. Recommendations to solve the identified problem areas given here are under the areas of communication, working environment, supervision, and equipment and tools. The recommendations include implementation of a performancebased rewards scheme, use of three-dimensional models and drawings in display areas, communication-focused training programs for managers, employing more lower level managers such as foremen, implementation of a material tracking system, and so on. This study provides a landmark for construction productivity improvement research in Canada. The findings of the research in terms of efficiency, tool time, and what the related human issues are will truly benefit not only the four construction companies but also the Canadian construction industry and its benchmarking. Construction industry personnel and the companies who participated in the study received the opportunity to learn from this research done

2006 NRC Canada

Hewage and Ruwanpura

1089 Canadian Construction Association. 2004. Canadian construction industry forecast, 20052009 [online]. Available from http://www.cca-acc.com/factsheet/factsheet.html [accessed 19 September 2005]. Dozzi, S.P., and AbouRizk, S.M. 1993. Productivity in construction. Institute for Research in Construction, Ottawa, Ont. Failing, R.G., Janzen, J.L., and Blevins, L.D. 1988. Work measurement techniques. Journal of Accountancy, 165(4): 104. Gordon, C., and Smith, A. 2001. Understanding psychological type to improve project team performance. Journal of Management in Engineering, 17: 2433. Heale, D.G. 1993. Qualitative and quantitative analysis of the factors affecting productivity in Canadian construction projects. M.Eng. thesis, Memorial University of Newfoundland, St. Johns, N.L. Herzberg, F., Mausner, B., and Snyderman, B.B. 1959. The motivation to work. 2nd ed. John Wiley & Sons, Inc., New York. Jenkins, J.R., Douglas, G., and Laufer, A. 1982. Improving construction productivity: the case for motivation. AACE Transactions, AACE International, Morgantown, W.Va. Johnson, R.A., and Bhattacharyya, G.K. 1996. Statistics: principles and methods. 3rd ed. John Wiley & Sons, Inc., New York. Kvanli, A.H., Pavur, R.J., and Guyness, C.S. 2000. Introduction to business statistics: a computer integrated data analysis approach. 5th ed. South-Western College Publishing, Mason, Ohio. Laufer, A., and Borcherding, J.D. 1981. Financial incentives to raise productivity. ASCE Journal of the Construction Division, 107(4): 745756. Liberda, M., Ruwanpura, J.Y., and Jergeas, G. 2003. Construction productivity improvement: a study of human, managerial and external factors. In Winds of Change: Integration and Innovation in Construction: Proceedings of the Construction Research Congress, Honolulu, Hawaii, 1921 March 2003. Edited by K.R. Molenaar and P.S. Chinowsky. ASCE, Reston, Va. CD-ROM. Maloney, W.F., and McFillen, J.M. 1987. Motivational impact on work crews. ASCE Journal of Construction Engineering and Management, 113: 208221. Mannisera, M., Dusseldorp, E., and Anita, J. 2005. Component structure of job satisfaction based on Herzbergs theory. Department of Quantitative Methods, University of Brescia, Brescia, Italy. Maslow, A. 1954. Motivation and personality. Harper & Row, New York. McTague, B., and Jergeas, G. 2003. Productivity improvement on Alberta major construction projects [online]. Alberta Economic Development Board, Calgary, Alta. Available from http://www.alberta-canada.com [accessed 7 February 2005]. Oglesby, C.H., Parker, H.W., and Howel, G.A. 1989. Productivity improvement in construction, McGraw Hill, New York. Porter, L.W., and Lawler, E.E. 1968. Managerial attitudes and performance. Dorsey Press, Homewood, Ill. Sanvido, V.E. 1988. Conceptual construction process model. ASCE Journal of Construction Engineering and Management, 114: 294311. Schrader, C.R. 1972. Motivation of construction craftsmen. ASCE Journal of the Construction Division, 98: 257273. Skinner, B.F. 1969. Contingencies of reinforcement: a theoretical analysis. Prentice-Hall Inc., Englewood Cliffs, N.J. Society for Industrial and Organizational Psychology, Inc. 2006. Society for Industrial and Organizational Psychology, Inc. (SIOP), Bowling Green, Ohio. Available from http://siop. org/Instruct/Motivate/sld004.htm [accessed 2 August 2005]. The Business Roundtable. 1989. Construction labour motivation. Report A-2, The Business Roundtable, Washington, D.C. Vroom, V.H. 1964. Work and motivation. Wiley, New York.

2006 NRC Canada

independently in the university environment. Companies had the opportunity to understand their work efficiency and human and productivity issues so that they can improve their work practices. Each company was provided with a comparison of the same data from the other companies without naming those companies. This comparison also allowed the companies to compare their performance with that of the other contractors who participated in the study. It is hoped that these new findings will truly affect how the construction companies plan and manage future projects to improve their competitive advantage in the construction industry. The following are limitations of this study: (1) The study allowed an analysis that was based on monitoring construction work and interviewing industry personnel over a limited period and only for a specific construction trade. The results of the study cannot be generalized to other trades because of the complex nature of the construction business and operations. (2) Although tool time was measured accurately by monitoring 101 workers, it was not possible to measure the output for many reasons. The workers scopes of work were not consistent for measuring the output. Workers did several work tasks of which it was not possible to measure the output, such as sawing, constructing formwork edges, holding and moving form boards, and nailing on formwork. (3) Vroom (1964) expectancy theory was used in this research by focusing on construction on-site settings.

Acknowledgements

The authors wish to acknowledge the support and funding for this research project by Ellis Don, Graham, PCL, and Ledcor companies, the Construction Research Institute of Canada, the Canadian Construction Research Board, Calgary Construction Association, and the Natural Sciences and Engineering Research Council of Canada under Collaborative Research and Development Grant CRDPJ 299392-03.

References

Adam, J.S. 1963. Toward an understanding of inequity. Journal of Abnormal and Social Psychology, 67: 422436. Alberta Economic Development. 2004. Alberta Canada web page [online]. Available from http://www.alberta-canada.com [accessed 20 January 2005]. Alderfer, C.P. 1969. An empirical test of a new theory of human needs. Organizational Behavior and Human Performance, 4: 142175. Arditi, D. 1985. Construction productivity improvement. ASCE Journal of Construction Engineering and Management, 111: 114. Banik, G.C. 1999. Construction productivity improvement. In Proceedings of the Associated Schools of Construction (ASC) 35th Annual Conference, San Luis Obispo, Calif., 710 April 1999. Edited by C. Berryman. Associated Schools of Construction (ASC), Colorado State University, Fort Collins, Colo. pp. 165178. Borcherding, J.D. 1976. Improving productivity in industrial construction. ASCE Journal of the Construction Division, 102(4): 599614. Borcherding, J.D., and Oglesby, C.H. 1974. Construction productivity and job satisfaction. ASCE Journal of the Construction Division, 100(3): 413431.

S-ar putea să vă placă și

- Formulaire-Candidature-Recrutement-titre 2022Document8 paginiFormulaire-Candidature-Recrutement-titre 2022oui nonÎncă nu există evaluări

- S5 LING ArabeDocument2 paginiS5 LING ArabeMohamed El-FassiÎncă nu există evaluări

- SC TempleDeLaDeesseRougeDocument10 paginiSC TempleDeLaDeesseRougeMORIN100% (1)

- These UniqueDocument318 paginiThese UniqueAhmed Abdenasser AhmedÎncă nu există evaluări

- Maintien de L Ordre 116p Rapport OfficielDocument116 paginiMaintien de L Ordre 116p Rapport OfficieldomÎncă nu există evaluări

- Cas Loue Joue V2019Document13 paginiCas Loue Joue V2019Hedfi Ahmed KhalilÎncă nu există evaluări

- Amérique Du Nord - Mythes Et Rites AmérindiensDocument48 paginiAmérique Du Nord - Mythes Et Rites AmérindiensAricieÎncă nu există evaluări

- Exemple de Liste Principale SAP BPMLDocument125 paginiExemple de Liste Principale SAP BPMLScribdTranslationsÎncă nu există evaluări

- Swot ReferencesDocument59 paginiSwot ReferencesMed MomoÎncă nu există evaluări

- Audit Precautions Standard - Guide PDFDocument18 paginiAudit Precautions Standard - Guide PDFismailÎncă nu există evaluări

- BP Pizzeria FinDocument28 paginiBP Pizzeria FinfrankelouattÎncă nu există evaluări

- Offre D'emploi - Moniteurs MultisectorielsDocument5 paginiOffre D'emploi - Moniteurs MultisectorielsConstiÎncă nu există evaluări

- Ben Laden - Recherche GoogleDocument1 paginăBen Laden - Recherche GoogleAthiran PaheerathanÎncă nu există evaluări

- Victor Hugo - Lucrèce Borgia, TXT CopieDocument3 paginiVictor Hugo - Lucrèce Borgia, TXT Copiebouhaddou fatimaÎncă nu există evaluări

- 5 C Hamza Esprit Saint en IslamDocument7 pagini5 C Hamza Esprit Saint en IslamOuattÎncă nu există evaluări

- Rencontre SALVO VALENTI 1er Au 9octobre 2022 V6Document2 paginiRencontre SALVO VALENTI 1er Au 9octobre 2022 V6stefÎncă nu există evaluări

- La Bourse en 110 ExercicesDocument170 paginiLa Bourse en 110 Exerciceshervediby3756Încă nu există evaluări

- td2 CorrectionDocument11 paginitd2 Correctionhajar elouadihÎncă nu există evaluări

- Polycopié PDFDocument19 paginiPolycopié PDFabdettawabeÎncă nu există evaluări

- Maitre Gims-Bella - TexteDocument2 paginiMaitre Gims-Bella - TexteAndreiposteÎncă nu există evaluări

- C'est Quoi La Comptabilité ?Document6 paginiC'est Quoi La Comptabilité ?Anaïs cappeÎncă nu există evaluări

- Mini Projet IpamDocument23 paginiMini Projet IpamHind ElqasimyÎncă nu există evaluări

- La Ferme Fortifiée 04Document1 paginăLa Ferme Fortifiée 04Paul PitronÎncă nu există evaluări

- RC - 060 La CordeDocument16 paginiRC - 060 La CordePatrick AlbrechtÎncă nu există evaluări

- Audit Social Et Bien Être Au TravailDocument714 paginiAudit Social Et Bien Être Au TravailbounahikawtharÎncă nu există evaluări

- L'évaluation Des Entreprises Et Des Titres Des SociétésDocument114 paginiL'évaluation Des Entreprises Et Des Titres Des Sociétésblsless100% (2)