Documente Academic

Documente Profesional

Documente Cultură

GEM Water-Based Drilling Fluid Combats Highly Reactive Shales Provides Near Gauge Wellbore

Încărcat de

Fauzan Rahman HaqDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

GEM Water-Based Drilling Fluid Combats Highly Reactive Shales Provides Near Gauge Wellbore

Încărcat de

Fauzan Rahman HaqDrepturi de autor:

Formate disponibile

Baroid

Case History Fluids Engineering

GEM Water-Based Drilling Fluid Combats Highly Reactive Shales, Provides Near Gauge Wellbore

Location: Ship Shoal, Gulf of Mexico

dilution rates and washout. Aer additional lab work, Baroid personnel recommended a custom formulation for the wells containing Baroids GEM water-based mud system as the base formulation. Key additives to the formulation included EZMUD shale stabilizer and BARO-TROL PLUS shale stabilizer to stabilize the wellbore and control ltration rates in the production section. ECONOMIC VALUE CREATED Both wells were successfully drilled without any gumbo attacks. Although dilution rates were still high with the GEM system, the wellbore remained almost gauge in both wells. A 9 7/8 hole was drilled on both wells, and the average hole size from caliper logs was 10.18 for the rst well and 10.22 for the second well. A very aggressive centralizer program was utilized to run the production casing on both wells, and the casing on both wells was successfully run to bottom. e rst well utilized a 7 5/8 casing string and the S-shaped well utilized a 7 production casing. ANKOR Energy was able to drill both wells with a waterbased system and successfully set casing at TD. Had the operator chosen an oil-based uid, the costs would have been on average an added $345,000 per well. e operator believes that gauge holes enhance the chance of a good cement job for production strings. Based on the cement bond logs run during completion operations, the operator classies the cement jobs on both wells as very good.

OPERATORS CHALLENGE ANKOR Energy was looking to switch from an oil-based drilling uid to a waterbased drilling uid; however, they realized that their typical choice of gypsum/KCL water-based mud was not going to provide the inhibition that they needed and that they had achieved with Baroids ACCOLADE oil-based mud system. ANKOR Energy wanted to try the water-based system on two wells in Ship Shoal 229 with measured depths of 8,321 and 7,553. e rst well was a build to 20.29 and the second well was an S-shaped well that built to 52.4 and then dropped back to vertical by well total depth (TD). HALLIBURTONS SOLUTION Baroid personnel conducted an extensive review of shale from the Ship Shoal area. Below are the x-ray diraction (XRD) and cation-exchange capacity (CEC) analyses of shales collected from Ship Shoal 229. Based on the review, it was determined that the area consisted of highly reactive shales. Further research showed that oset wells drilled with various water-based muds had experienced high

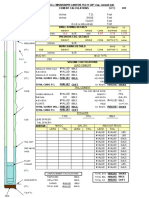

6504 ft (1-4-2010)

7485 ft (1-6-2010)

Barite, wt % Quartz, wt % Plagioclase Feldspar, wt % Calcite, wt % Dolomite, wt % Clay, wt % (smectite, illite, kaolin and chlorite)* CEC, meq/100g

8 27 tr 2 tr 63 22

15 24 tr 2 tr 59 21

2010 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the contract between Halliburton and the customer that is applicable to the sale. H07616 4/10 www.halliburton.com

S-ar putea să vă placă și

- Hse LeadershipDocument13 paginiHse LeadershipFauzan Rahman HaqÎncă nu există evaluări

- Affective Safety ManagementDocument13 paginiAffective Safety ManagementFauzan Rahman HaqÎncă nu există evaluări

- HSE LEADERSHIP Journey To HSE ExcellentDocument87 paginiHSE LEADERSHIP Journey To HSE ExcellentFauzan Rahman HaqÎncă nu există evaluări

- BOREMAX Fresh Water System Reduces Costs and Enables Drilling of Interval in One-Third Expected TimeDocument2 paginiBOREMAX Fresh Water System Reduces Costs and Enables Drilling of Interval in One-Third Expected TimeFauzan Rahman HaqÎncă nu există evaluări

- HYDRO-GUARD® Water-Based Drilling Fluid Delivering Stable Wellbore ThroughDocument1 paginăHYDRO-GUARD® Water-Based Drilling Fluid Delivering Stable Wellbore ThroughFauzan Rahman HaqÎncă nu există evaluări

- 06 BR1 108 - HPWBFDocument4 pagini06 BR1 108 - HPWBFCesar Kv RangelÎncă nu există evaluări

- Mettalurgy For The Non MettalurgistDocument317 paginiMettalurgy For The Non MettalurgistdianaagustaÎncă nu există evaluări

- Alternative Inhibiting Salt in WBM Helps Raise Environmental Acceptability in Rain Forest LocationsDocument1 paginăAlternative Inhibiting Salt in WBM Helps Raise Environmental Acceptability in Rain Forest LocationsFauzan Rahman HaqÎncă nu există evaluări

- Introduction To Coiled TubingDocument8 paginiIntroduction To Coiled TubingFauzan Rahman HaqÎncă nu există evaluări

- 03 CT WellControlEquip NEXTDocument19 pagini03 CT WellControlEquip NEXTFauzan Rahman HaqÎncă nu există evaluări

- BOREMAX Water-Based System Improves ROP in Intermediate IntervalsDocument1 paginăBOREMAX Water-Based System Improves ROP in Intermediate IntervalsFauzan Rahman HaqÎncă nu există evaluări

- 02 CT Equipment NEXTDocument31 pagini02 CT Equipment NEXTFauzan Rahman HaqÎncă nu există evaluări

- Introduction To Coiled Tubing: Module 00 - Day OneDocument7 paginiIntroduction To Coiled Tubing: Module 00 - Day OneFauzan Rahman HaqÎncă nu există evaluări

- Highly Inhibitive Water-Based Mud System Result in Zero Liquid Mud Haul Off and Saves $750000Document1 paginăHighly Inhibitive Water-Based Mud System Result in Zero Liquid Mud Haul Off and Saves $750000Fauzan Rahman HaqÎncă nu există evaluări

- 03 CT WellControlEquip NEXTDocument19 pagini03 CT WellControlEquip NEXTFauzan Rahman HaqÎncă nu există evaluări

- 10 - Drilling Fluids Design and Selection - HandoutDocument18 pagini10 - Drilling Fluids Design and Selection - HandoutFauzan Rahman HaqÎncă nu există evaluări

- 3 - Rheology and Hydraulics - PTM - HandoutDocument35 pagini3 - Rheology and Hydraulics - PTM - HandoutFauzan Rahman HaqÎncă nu există evaluări

- HandoutRoles of Drilling FluidDocument15 paginiHandoutRoles of Drilling FluidFauzan Rahman HaqÎncă nu există evaluări

- Prevent Stuck Pipe with Proper Drilling PracticesDocument24 paginiPrevent Stuck Pipe with Proper Drilling PracticesFauzan Rahman HaqÎncă nu există evaluări

- Prevent Stuck Pipe with Proper Drilling PracticesDocument24 paginiPrevent Stuck Pipe with Proper Drilling PracticesFauzan Rahman HaqÎncă nu există evaluări

- Completion Training NEXT Bali June 2010Document98 paginiCompletion Training NEXT Bali June 2010Fauzan Rahman HaqÎncă nu există evaluări

- Completion - Reservoir Drill in FluidsDocument45 paginiCompletion - Reservoir Drill in FluidsFauzan Rahman Haq100% (1)

- 5 - Naf PTM HandoutDocument14 pagini5 - Naf PTM HandoutFauzan Rahman HaqÎncă nu există evaluări

- 9 - Solid Control PTM - HandoutDocument60 pagini9 - Solid Control PTM - HandoutFauzan Rahman Haq100% (4)

- Lost Circulation Materials SelectionDocument22 paginiLost Circulation Materials SelectionFauzan Rahman HaqÎncă nu există evaluări

- 4 - Water Base Mud System - PTM - HandoutDocument32 pagini4 - Water Base Mud System - PTM - HandoutFauzan Rahman Haq100% (1)

- Basic Slickline 1Document60 paginiBasic Slickline 1Fauzan Rahman Haq100% (11)

- Perforating XDocument69 paginiPerforating XFauzan Rahman HaqÎncă nu există evaluări

- 2 - Clay Chemistry - PTM - HandoutDocument25 pagini2 - Clay Chemistry - PTM - HandoutFauzan Rahman HaqÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 2017 Rig Location Guide 30june2017Document50 pagini2017 Rig Location Guide 30june2017jinesh mjÎncă nu există evaluări

- Brochure Reflist Drilling Vessels Lowres B 210510Document3 paginiBrochure Reflist Drilling Vessels Lowres B 210510yogolainÎncă nu există evaluări

- Cementation Calculations SpreadsheetDocument8 paginiCementation Calculations SpreadsheetAnupam SinghÎncă nu există evaluări

- Casing Size Selection Is Determined From The Inside Outward and It Starts From The Bottom HoleDocument6 paginiCasing Size Selection Is Determined From The Inside Outward and It Starts From The Bottom HoleazizsarshoghÎncă nu există evaluări

- Guide to Well Completion, Maintenance, AbandonmentDocument73 paginiGuide to Well Completion, Maintenance, AbandonmentAnton De Beer100% (4)

- Well Control by HelbrtonDocument23 paginiWell Control by Helbrtonاحمد عبد الحسين جولانÎncă nu există evaluări

- Prevent Stuck PipeDocument65 paginiPrevent Stuck Pipeafreis29100% (2)

- Cement calculations for 20Document3 paginiCement calculations for 20stevebeardsleyÎncă nu există evaluări

- COSL Fleet BrochureDocument18 paginiCOSL Fleet BrochureAnonymous VNu3ODGavÎncă nu există evaluări

- WellSharp Formula Sheet 03 February 2017 PDFDocument5 paginiWellSharp Formula Sheet 03 February 2017 PDFAndi Priyo JatmikoÎncă nu există evaluări

- Workshop On Multilateral and Extended Reach WellsDocument49 paginiWorkshop On Multilateral and Extended Reach WellsbyedÎncă nu există evaluări

- Basic Understanding of Oil Well Casing and TubingDocument21 paginiBasic Understanding of Oil Well Casing and TubingmanibabuÎncă nu există evaluări

- Well Intervention Operation FlyerDocument21 paginiWell Intervention Operation Flyerfakhrurrozi arbianÎncă nu există evaluări

- PETE 628: Lesson 6Document54 paginiPETE 628: Lesson 6EdwinÎncă nu există evaluări

- PDF Well Control Question of The Day - CompressDocument10 paginiPDF Well Control Question of The Day - CompressNyak AlfarlakyÎncă nu există evaluări

- Typical Land Rig: National Oilwell VarcoDocument1 paginăTypical Land Rig: National Oilwell VarcoThomas DuÎncă nu există evaluări

- SPE 170980 - Subsea Well Intervention - Recent Developments and Recommendations To Increase Overall Project ReturnsDocument12 paginiSPE 170980 - Subsea Well Intervention - Recent Developments and Recommendations To Increase Overall Project ReturnsAdri Coca SuaznabarÎncă nu există evaluări

- IADC Dull Bit Grading Chart GuideDocument1 paginăIADC Dull Bit Grading Chart GuideanarkasisÎncă nu există evaluări

- MN38L - WESTSIDE - Drilling Fluids Program - V.1Document8 paginiMN38L - WESTSIDE - Drilling Fluids Program - V.1Gabriel PlazasÎncă nu există evaluări

- COMPLETION DESIGN OVERVIEWDocument22 paginiCOMPLETION DESIGN OVERVIEWAbiodun AkalaÎncă nu există evaluări

- The Deepwater Horizon Explosion - Non-Technical Skills Safety Culture and System ComplexityDocument21 paginiThe Deepwater Horizon Explosion - Non-Technical Skills Safety Culture and System Complexityapi-348448361Încă nu există evaluări

- Geomechanics & ERDDocument18 paginiGeomechanics & ERDRene Torres HinojosaÎncă nu există evaluări

- Preventing Shallow Gas BlowoutsDocument8 paginiPreventing Shallow Gas BlowoutsJohnSmithÎncă nu există evaluări

- Logging InnovationDocument8 paginiLogging InnovationAnkit ChourasiaÎncă nu există evaluări

- Oil and Gas Well Completion TaskDocument4 paginiOil and Gas Well Completion Taskapi-370721250% (2)

- Completions Packer CatalogDocument56 paginiCompletions Packer Catalogknn52unnÎncă nu există evaluări

- Charles Dunne (DM - Dsupt) CV 2012Document4 paginiCharles Dunne (DM - Dsupt) CV 2012Zhoudq DqÎncă nu există evaluări

- Squeeze Cementing JobDocument64 paginiSqueeze Cementing Jobkhushbu Hasan100% (1)

- Drilling FluidsDocument20 paginiDrilling Fluidsdekra abdo100% (1)

- Casing Design ManualDocument124 paginiCasing Design Manualfaraj0% (1)