Documente Academic

Documente Profesional

Documente Cultură

LM101A/LH2101A: General Purpose Operational Amplifier

Încărcat de

Alexandre S. CorrêaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LM101A/LH2101A: General Purpose Operational Amplifier

Încărcat de

Alexandre S. CorrêaDrepturi de autor:

Formate disponibile

www.fairchildsemi.

com

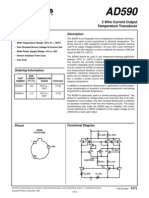

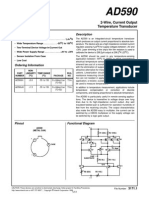

LM101A/LH2101A

General Purpose Operational Amplier

Features

Input offset voltage 0.7 mV Input bias current 30 nA Input offset current 1.5 nA Full frequency compensation 30pF Supply voltage 5.0V to 20V

Description

The LM101A/LH2101A is a general purpose high performance operational amplier fabricated monolithically on a silicon chip by an advanced epitaxial process. The LH2101A consists of two LM101A ICs in one 16-lead DIP. The units may be fully compensated with the addition of a 30 pF capacitor stabilizing the circuit for all feedback congurations including capacitive loads. The device may be operated as a comparator with a differential input as high as 30V. Used as a comparator the output can be clamped at any desired level to make it compatible with logic circuits. The LM101A and LH2101A operate over the full military temperature range from -55C to +125C.

Rev 1.0.1

LM101A/LH2101A

PRODUCT SPECIFICATION

Pin Assignments

8-Lead Metal Can (Top View)

Comp Comp/VOS Trim -Input +Input 2 3 4 -VS 5 VOS Trim -VS 4

65-101A-01

8-Lead DIP (Top View)

Comp/VOS Trim 1 -Input 2 8 7 6 5 Comp +VS Output VOS Trim

8 1 7

+VS

Output +Input 3

16-Lead DIP (Top View)

+VS (A) 1 Comp (A) 2 Comp/VOS Trim (A) 3 -Input (A) 4 +Input (A) 5 -VS 6 VOS Trim (B) 7 Ouput (B) 8

65-101A-02

16 Output (A) 15 NC A 14 VOS Trim (A) 13 +Input (B) 12 -Input (B) B 11 Comp/VOS Trim (B) 10 Comp (B) 9 +VS (B)

Absolute Maximum Ratings

Parameter Supply Voltage Differential Input Voltage Input Voltage

1

Min.

Max. 22 30 15 Indefinite

Units V V V C C C

Output Short-Circuit Duration2 Storage Temperature Range Operating Temperature Range Lead Soldering Temperature (60 sec) -65 -55

+150 +125 +300

Notes: 1. For supply voltages less than 15V, the absolute maximum input voltage is equal to the supply voltage. 2. Observe package thermal characteristics.

PRODUCT SPECIFICATION

LM101A/LH2101A

Thermal Characteristics

8-Lead Ceramic DIP +175C 833 mW 45C/W 150C/W 8.33 mW/C 8-Lead TO-99 Metal Can +175C 658 mW 50C/W 190C/W 5.26 mW/C 16-Lead Ceramic DIP +175C 1042 mW 60C/W 120C/W 8.33 mW/C

Parameter Maximum Junction Temperature Maximum PD TA <50C Thermal Resistance, qJC Thermal Resistance, qJA For TA > 50C Derate at

Electrical Characteristics

C = 30pF; 5.0V VS 20V; -55C TA +125C unless otherwise specied LM101A/LH2101 A Parameters Input Offset Voltage Input Offset Current Input Bias Current Input Resistance Supply Current Large Signal Voltage Gain Input Offset Voltage Average Input Offset Voltage Drift Input Offset Current Average Input Offset Current Drift Input Bias Current Supply Current Large Signal Voltage Gain Output Voltage Swing Input Voltage Range Common Mode Rejection Ratio Power Supply Rejection Ratio TA = +125C, VS = 20V VS = 15V VOUT = 10V, RL 2 KW VS = 15V, VS = 20V RS 50 KW RS 50 KW RL = 10 KW RL = 2 KW 25 12 10 15 80 80 96 96 14 13 V dB dB 1.2 +25C TA +125C -55C TA +25C 0.01 0.02 Test Conditions TA = +25C, RS 50 kW TA = +25C TA = +25C TA = +25C TA = +25C VS = 20V TA = +25C, VS = 15V VOUT = 10V, RL 2 KW RS 50 KW RS 50 KW 3.0 50 1.5 Mln. Typ. 0.7 1.5 30 4.0 1.8 160 3.0 15 20 0.1 0.2 100 2.5 nA mA V/mV V 3.0 Max. 2.0 10 75 Units mV nA nA MW mA V/mV mV mV/C nA nA/C

LM101A/LH2101A

PRODUCT SPECIFICATION

Typical Performance Characteristics

2.5 2.0 ISY (mA) 1.5 1.0 0.5 0 5 10 VS (V) Figure 1. Supply Current vs. Supply Voltage 15

T A = -55 C

120

110

T A = +25 C T A = +125 C

65-101A-03

T A = -55 C T A = +25 C

AV (dB)

100

20

80 5

10 VS (V)

15

20

Figure 2. Voltage Gain vs. Supply Voltage

400

T A = -55 C

15

Vs = 15V

300 IB (nA)

VOUT (V)

10

TA = +25 C TA = +125 C

65-101A-06

200

T A = -55 C

65-101A-05

100

T A = -55 C

10 VS (V)

15

20

10

15 IOUT (mA)

20

25

30

Figure 3. Input Bias Current vs. Supply Voltage

Figure 4. Current Limiting Output Voltage vs. Output Current

400

VS = 15V

600 500 Pd (mW) 400 300 200

IOS

65-101A-07

300 IB, IOS (nA)

IB

Metal Can

200

DIP

100 0 +25 +45 +65 +85 +105

0 -75

-50

-25

+25 +50 +75 +100 +125 TA (C)

+125

TA (C) Figure 6. Maximum Power Dissipation vs. Temperature

Figure 5. Input Bias, Offset Current vs. Temperature

65-101A-08

100

65-101A-04

90

T A = +125 C

PRODUCT SPECIFICATION

LM101A/LH2101A

Typical Performance Characteristics (continued)

120 100 80 AVOL (dB) 60 40

65-101A-09

16

VS = 15V T A = +25 C

14 12 VOUT (V) 10 8 6

V S = 15V T A = +25 C

C1 = 3 pF

C1 = 3 pF

0 -20 1 10 100 1K 10K 100K F (Hz) Figure 7. Open Loop Gain vs. Frequency 1M

2 0 1K

C1 = 30 pF

10M

10K

100K F (Hz)

1M

10M

Figure 8. Output Voltage Swing vs. Frequency

10 8 6 4 2 0 -2 -4 -6 -8 -10

VS = 15V TA = +25 C Input Output

VOUT (V)

10 20 30 40 50 60 70 80 Time (S)

Figure 9. Follower Large Signal Pulse Response Output Voltage vs. Time

65-101A-11

65-101A-10

20

C1 = 30 pF

LM101A/LH2101A

PRODUCT SPECIFICATION

Typical Applications

R1 Input 2 R EQ* LM101A 3 1 8 C1 30 pF 6 5 Output R2

R5 5.1M -VS Inputs

2 3 LM101A 8 D1 LM103 36

65-101A-13

Output

R4 10M

R3 50K

*May be zero or equal to parallel combination of R1 and R2 for minimum offset.

65-101A-12

Figure 10. Inverting Amplifier with Balancing Circuit

Figure 11. Voltage Comparator for Driving DTL or TTL ICs

Output R2 150K 2 -VS Input LM101A 3 8 1 6 R1 91K Sample Q2

Q1 2N3456

+VS

Output 2 Inputs 3 LM101A 8 D1 FD777

65-101A-14

C2* 0.01m F

R1 60W

Q1 2N2222

C1 30 pF

D2 FD777

65-101A-15

*Polycarbonate dielectric capacitor Figure 12. Low Drift Sample and Hold

Figure 13. Voltage Comparator for Driving RTL Logic or High Current Driver

PRODUCT SPECIFICATION

LM101A/LH2101A

Notes:

LM101A/LH2101A

PRODUCT SPECIFICATION

Notes:

PRODUCT SPECIFICATION

LM101A/LH2101A

Mechanical Dimensions

8-Lead TO-99 Metal Can

D Symbol D1 A b b1 D D1 D2 e e1 F k k1 L L1 L2 Q a Notes: e1 1. (All leads) b applies between L1 & L2. b1 applies between L2 & .500 (12.70mm) from the reference plane. Diameter is uncontrolled in L1 & beyond .500 (12.70mm) from the reference plane. 2. Measured from the maximum diameter of the product. 3. Leads having a maximum diameter .019 (.48mm) measured in gauging plane, .054 (1.37mm) +.001 (.03mm) .000 (.00mm) below the reference plane of the product shall be within .007 (.18mm) of their true position relative to a maximum width tab. a 4. The product may be measured by direct methods or by gauge. 5. All leads increase maximum limit by .003 (.08mm) when lead finish is applied. k k1 Inches Min. Max. Millimeters Min. Max. 1, 5 1, 5

Notes

L1

L2 L

b BASE and SEATING PLANE b1

REFERENCE PLANE

.165 .185 .016 .019 .016 .021 .335 .375 .305 .335 .110 .160 .200 BSC .100 BSC .040 .027 .034 .027 .045 .500 .750 .050 .250 .010 .045 45 BSC

4.19 4.70 .41 .48 .41 .53 8.51 9.52 7.75 8.51 2.79 4.06 5.08 BSC 2.54 BSC 1.02 .69 .86 .69 1.14 12.70 19.05 1.27 6.35 .25 1.14 45 BSC

2 1 1 1

D2

LM101A/LH2101A

PRODUCT SPECIFICATION

Mechanical Dimensions (continued)

8-Lead Ceramic DIP

Inches Min. A b1 b2 c1 D E e eA L Q s1 a Max. Millimeters Min. Max. 8 2, 8 8 4 4 5, 9 7 3 6 Notes: Notes 1. Index area: a notch or a pin one identification mark shall be located adjacent to pin one. The manufacturer's identification shall not be used as pin one identification mark. 2. The minimum limit for dimension "b2" may be .023 (.58mm) for leads number 1, 4, 5 and 8 only. 3. Dimension "Q" shall be measured from the seating plane to the base plane. 4. This dimension allows for off-center lid, meniscus and glass overrun. 5. The basic pin spacing is .100 (2.54mm) between centerlines. Each pin centerline shall be located within .010 (.25mm) of its exact longitudinal position relative to pins 1 and 8. 6. Applies to all four corners (leads number 1, 4, 5, and 8). 7. "eA" shall be measured at the center of the lead bends or at the centerline of the leads when "a" is 90. 8. All leads Increase maximum limit by .003 (.08mm) measured at the center of the flat, when lead finish applied. 9. Six spaces. D 4 1 Note 1 E

Symbol

.200 .014 .023 .045 .065 .008 .015 .405 .220 .310 .100 BSC .300 BSC .125 .200 .015 .060 .005 90 105

5.08 .36 .58 1.14 1.65 .20 .38 10.29 5.59 7.87 2.54 BSC 7.62 BSC 3.18 5.08 .38 1.52 .13 90 105

5 s1

eA

A Q L b2 b1 a c1

10

PRODUCT SPECIFICATION

LM101A/LH2101A

Mechanical Dimensions (continued)

16-Lead Ceramic DIP

Inches Min. A b1 b2 c1 D E e eA L Q s1 a Max. Millimeters Min. Max. 8 2 8 4 4 5, 9 7 3 6 Notes: Notes 1. Index area: a notch or a pin one identification mark shall be located adjacent to pin one. The manufacturer's identification shall not be used as pin one identification mark. 2. The minimum limit for dimension "b2" may be .023 (.58mm) for leads number 1, 8, 9 and 16 only. 3. Dimension "Q" shall be measured from the seating plane to the base plane. 4. This dimension allows for off-center lid, meniscus and glass overrun. 5. The basic pin spacing is .100 (2.54mm) between centerlines. Each pin centerline shall be located within .010 (.25mm) of its exact longitudinal position relative to pins 1 and 16. 6. Applies to all four corners (leads number 1, 8, 9, and 16). 7. "eA" shall be measured at the center of the lead bends or at the centerline of the leads when "a" is 90. 8. All leads Increase maximum limit by .003 (.08mm) measured at the center of the flat, when lead finish applied. 9. Fourteen spaces. D

8 1

Symbol

.200 .014 .023 .050 .065 .008 .015 .745 .840 .220 .310 .100 BSC .300 BSC .115 .160 .015 .060 .005 90 105

5.08 .36 .58 1.27 1.65 .20 .38 18.92 21.33 5.59 7.87 2.54 BSC 7.62 BSC 2.92 4.06 .38 1.52 .13 90 105

NOTE 1

16

s1 eA

A Q L b1 a c1

11

PRODUCT SPECIFICATION

LM101A/LH2101A

Ordering Information

Operating Temperature Range -55C to +125C -55C to +125C -55C to +125C -55C to +125C -55C to +1 25C -55C to +125C

Part Number LM101AD LM101AD/883B LM101AT LM101AT/883B LH2101AD LH2101AD/883B

Package 8-Lead Ceramic DIP 8-Lead Ceramic DIP 8-Lead Metal Can 8-Lead Metal Can 16-Lead Ceramic DIP 16-Lead Ceramic DIP

Notes: 1. /883B suffix denotes Mil-Std-883. Level B processing. 2. Contact a Fairchild Semiconductor sales office or representative for ordering information on special package/ temperature range combinations.

LIFE SUPPORT POLICY FAIRCHILDS PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION. As used herein: 1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) support or sustain life, and (c) whose failure to perform when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in a significant injury of the user.

www.fairchildsemi.com 5/20/98 0.0m 001 Stock#DS3000101A 1998 Fairchild Semiconductor Corporation

2. A critical component in any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life support device or system, or to affect its safety or effectiveness.

S-ar putea să vă placă și

- AD590Document0 paginiAD590Alvaro Mompi RuizÎncă nu există evaluări

- ICL8069 - Low Voltage Reference - Intersil CorporationDocument6 paginiICL8069 - Low Voltage Reference - Intersil Corporationwlen2012Încă nu există evaluări

- ACPL312TDocument18 paginiACPL312Tcms_saÎncă nu există evaluări

- Emotron m20 Data Sheet 01-4134-01 enDocument8 paginiEmotron m20 Data Sheet 01-4134-01 enAungÎncă nu există evaluări

- 3141E Hall Sensor SwitchDocument9 pagini3141E Hall Sensor SwitchbarbosiÎncă nu există evaluări

- OpAmp - LM308AN - MotorolaDocument9 paginiOpAmp - LM308AN - MotorolaLudwig SchmidtÎncă nu există evaluări

- CA3086 - General Purpose NPN Transistor Array - IntersilDocument7 paginiCA3086 - General Purpose NPN Transistor Array - IntersilglamorousoneÎncă nu există evaluări

- Tle2426 High Precision Virtual GroundDocument29 paginiTle2426 High Precision Virtual GroundgofuckingdieÎncă nu există evaluări

- Dac 0800Document16 paginiDac 0800Ali A-cÎncă nu există evaluări

- Chip Ca3098eDocument12 paginiChip Ca3098etopogigio240Încă nu există evaluări

- Ucc2800 PDFDocument22 paginiUcc2800 PDFgarrycÎncă nu există evaluări

- ECM100UT32Document4 paginiECM100UT32TERASAT SAÎncă nu există evaluări

- Datasheet 741Document5 paginiDatasheet 741Lucas Ernesto Caetano ErnestoÎncă nu există evaluări

- MCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsDocument7 paginiMCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsErnestoGarciaMontanoÎncă nu există evaluări

- LT1019 Datasheet (1019fd)Document12 paginiLT1019 Datasheet (1019fd)gblackweÎncă nu există evaluări

- Bu 941Document9 paginiBu 941Uriel HernandezÎncă nu există evaluări

- DVP06SN11R DatasheetDocument2 paginiDVP06SN11R DatasheetBustamante PerroneÎncă nu există evaluări

- Hall-Effect Latches: FeaturesDocument8 paginiHall-Effect Latches: Featuresjdaudpoto100% (1)

- ST2009DHI: High Voltage Fast-Switching NPN Power TransistorDocument7 paginiST2009DHI: High Voltage Fast-Switching NPN Power TransistorMiloud ChouguiÎncă nu există evaluări

- 2N6027Document9 pagini2N6027mariogizziÎncă nu există evaluări

- General Purpose NPN Transistor Array Applications: FN483.6 Data Sheet December 15, 2011Document7 paginiGeneral Purpose NPN Transistor Array Applications: FN483.6 Data Sheet December 15, 2011Leidy Ferro100% (1)

- Ap 34063Document10 paginiAp 34063Hoang LeÎncă nu există evaluări

- MC1458 OnDocument8 paginiMC1458 OnDanteLupuÎncă nu există evaluări

- Apc 2000alw PDFDocument5 paginiApc 2000alw PDFvan_dall_2Încă nu există evaluări

- Lm301 Alta PerformanceDocument8 paginiLm301 Alta PerformanceJohn PachecoÎncă nu există evaluări

- Ca3260, Ca3260A: 4Mhz, Bimos Operational Amplifier With Mosfet Input/Cmos Output FeaturesDocument4 paginiCa3260, Ca3260A: 4Mhz, Bimos Operational Amplifier With Mosfet Input/Cmos Output FeaturesPaulo Cesar SimonettiÎncă nu există evaluări

- La 42102Document8 paginiLa 42102buyadiÎncă nu există evaluări

- LC0406FC3.3C LC0406FC36C: ApplicationsDocument6 paginiLC0406FC3.3C LC0406FC36C: ApplicationsselocaÎncă nu există evaluări

- CA3059, CA3079: Description FeaturesDocument12 paginiCA3059, CA3079: Description FeaturesMiltongrimi GrimilÎncă nu există evaluări

- ST2001HI: High Voltage Fast-Switching NPN Power TransistorDocument7 paginiST2001HI: High Voltage Fast-Switching NPN Power Transistorsharck82Încă nu există evaluări

- HCPL-0302 DatasheetDocument15 paginiHCPL-0302 DatasheetJeziel Vazquez NavaÎncă nu există evaluări

- TsaDocument4 paginiTsaAlexandra GrigoreÎncă nu există evaluări

- Imprimir Datasheet 1Document14 paginiImprimir Datasheet 1Randy Siancas VelezÎncă nu există evaluări

- AD590Document11 paginiAD590Timmy Neil SixxÎncă nu există evaluări

- ST 232Document11 paginiST 232Negru P. PlantatieÎncă nu există evaluări

- DVP-Slim Digitai IO Module Instruction SheetDocument2 paginiDVP-Slim Digitai IO Module Instruction SheetAgnimuthuÎncă nu există evaluări

- Micropower, Single-Supply, Cmos: Ina321 Ina2321Document23 paginiMicropower, Single-Supply, Cmos: Ina321 Ina2321James LivingstonÎncă nu există evaluări

- Difet: Features ApplicationsDocument9 paginiDifet: Features ApplicationsodipasÎncă nu există evaluări

- AV02-2483EN DS ACNV4506 31aug2011Document14 paginiAV02-2483EN DS ACNV4506 31aug2011moabdolyÎncă nu există evaluări

- lm35 PDFDocument15 paginilm35 PDFRogers Ferreras BenitezÎncă nu există evaluări

- MC1458 MC1558: High Performance Dual Operational AmplifiersDocument7 paginiMC1458 MC1558: High Performance Dual Operational AmplifiersAlejandro Borrego DominguezÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- 110 Waveform Generator Projects for the Home ConstructorDe la Everand110 Waveform Generator Projects for the Home ConstructorEvaluare: 4 din 5 stele4/5 (1)

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1De la EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Evaluare: 4.5 din 5 stele4.5/5 (3)

- 110 Integrated Circuit Projects for the Home ConstructorDe la Everand110 Integrated Circuit Projects for the Home ConstructorEvaluare: 4.5 din 5 stele4.5/5 (2)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsDe la EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Operational Amplifier Circuits: Analysis and DesignDe la EverandOperational Amplifier Circuits: Analysis and DesignEvaluare: 4.5 din 5 stele4.5/5 (2)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe la EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsEvaluare: 3.5 din 5 stele3.5/5 (6)

- The UltralightDocument20 paginiThe UltralightAlexandre S. Corrêa100% (2)

- Manual 2016 Nitro g5Document2 paginiManual 2016 Nitro g5Alexandre S. CorrêaÎncă nu există evaluări

- F e A T U R e SDocument2 paginiF e A T U R e SAlexandre S. CorrêaÎncă nu există evaluări

- Manual Transistor PDFDocument4 paginiManual Transistor PDFAlexandre S. CorrêaÎncă nu există evaluări

- Modular CNC Router 2009v1 FREE PLANSDocument10 paginiModular CNC Router 2009v1 FREE PLANSModularCNC57% (7)

- Optical Comp Exp - Edu SilvaDocument6 paginiOptical Comp Exp - Edu SilvaAlexandre S. CorrêaÎncă nu există evaluări

- Sansung CL21A551MLDocument9 paginiSansung CL21A551MLleno2Încă nu există evaluări

- 1947 Trailer For TwoDocument7 pagini1947 Trailer For TwoAlexandre S. CorrêaÎncă nu există evaluări

- Vistabule 2014 Feb Brochure LRDocument10 paginiVistabule 2014 Feb Brochure LRAlexandre S. CorrêaÎncă nu există evaluări

- Schematic Diagrams: Special NoteDocument12 paginiSchematic Diagrams: Special NoteAlexandre S. Corrêa100% (1)

- 4HD D0049.0611 - 06FDocument104 pagini4HD D0049.0611 - 06FCarlosLimaÎncă nu există evaluări

- TDA2002 10wDocument21 paginiTDA2002 10wAlexandre S. CorrêaÎncă nu există evaluări

- Build "Wild Goose": A Sturdy Overnight TrailerDocument7 paginiBuild "Wild Goose": A Sturdy Overnight TrailerAlexandre S. CorrêaÎncă nu există evaluări

- CCE TV HPS-2071B Diagrama EsquematicoDocument1 paginăCCE TV HPS-2071B Diagrama EsquematicoDaniel AvecillaÎncă nu există evaluări

- Datasheet 7400Document9 paginiDatasheet 7400gab50Încă nu există evaluări

- Yamaha Receiver Rxv-595 SchematicDocument7 paginiYamaha Receiver Rxv-595 SchematicMauricio Bumba100% (1)

- Schematic Diagram DVD-P370Document8 paginiSchematic Diagram DVD-P370Alexandre S. Corrêa0% (1)

- 74574Document6 pagini74574Alexandre S. CorrêaÎncă nu există evaluări

- 74573Document4 pagini74573jamesrychurdÎncă nu există evaluări

- Cold Cold HOT HOT: QFP80 QFP80Document1 paginăCold Cold HOT HOT: QFP80 QFP80Jone Ferreira Dos SantosÎncă nu există evaluări

- Tip41-2 20wDocument3 paginiTip41-2 20wAlexandre S. CorrêaÎncă nu există evaluări

- TL 074Document10 paginiTL 074Alexandre S. CorrêaÎncă nu există evaluări

- Build Your Own VAWT by David MussellDocument17 paginiBuild Your Own VAWT by David MussellMr Void100% (9)

- XR-A550 XR-A330: Stereo CD Cassette Deck ReceiverDocument82 paginiXR-A550 XR-A330: Stereo CD Cassette Deck ReceiverAlexandre S. CorrêaÎncă nu există evaluări

- 74688Document4 pagini74688Alexandre S. CorrêaÎncă nu există evaluări

- ICL7106 and ICL7107 VoltmeterDocument16 paginiICL7106 and ICL7107 VoltmeterAntonino ScordatoÎncă nu există evaluări

- Ta 8403 KDocument5 paginiTa 8403 KFlorenz RemasteredÎncă nu există evaluări

- 74VHCU04Document6 pagini74VHCU04Alexandre S. CorrêaÎncă nu există evaluări

- DC Da90Document24 paginiDC Da90Alexandre S. CorrêaÎncă nu există evaluări

- 802Document4 pagini802BooksÎncă nu există evaluări

- Hardware Lecture 10Document8 paginiHardware Lecture 10charles0% (1)

- EC 2205 Electronic Circuits I Nov-Dec 2013 Question PaperDocument2 paginiEC 2205 Electronic Circuits I Nov-Dec 2013 Question Papervishnu.kvlv0% (1)

- Horn AntennaDocument18 paginiHorn AntennaMuhammad HashimÎncă nu există evaluări

- Timing AnalysysDocument15 paginiTiming AnalysysrrramananÎncă nu există evaluări

- White Paper PRACH Preamble Detection and Timing Advance Estimation For ...Document30 paginiWhite Paper PRACH Preamble Detection and Timing Advance Estimation For ...Vivek KesharwaniÎncă nu există evaluări

- Warning BIOSDocument2 paginiWarning BIOSAnton RayaÎncă nu există evaluări

- University of Çukurova Institute of Natural and Applied ScienceDocument227 paginiUniversity of Çukurova Institute of Natural and Applied ScienceSharmiladevy Prasanna100% (1)

- HDTV Antenna Big BerthaDocument22 paginiHDTV Antenna Big BerthaCarrancoMikeÎncă nu există evaluări

- Programa SPI MestreDocument5 paginiPrograma SPI MestreAlan Robson100% (1)

- Operational Specification: Q7T3 (CPT Panel) LCD Monitor Service Guide Engineering SpecificationDocument19 paginiOperational Specification: Q7T3 (CPT Panel) LCD Monitor Service Guide Engineering SpecificationChirita ElenaÎncă nu există evaluări

- LG Manual 42LB671V PDFDocument356 paginiLG Manual 42LB671V PDFmanueltoimilÎncă nu există evaluări

- LCD Monitor: Owner'S ManualDocument31 paginiLCD Monitor: Owner'S Manualqwerty69sÎncă nu există evaluări

- PH CONTROL IN A BIOREACTOR PDFDocument45 paginiPH CONTROL IN A BIOREACTOR PDFrijilpoothadiÎncă nu există evaluări

- F2833x Analogue Digital Converter: V V V D VDocument28 paginiF2833x Analogue Digital Converter: V V V D VSaiÎncă nu există evaluări

- Detailed Z80 Instruction SetDocument11 paginiDetailed Z80 Instruction SetDang KhueÎncă nu există evaluări

- Chapter 8Document7 paginiChapter 8Salvador FayssalÎncă nu există evaluări

- Service Tool: Manual 26250 L-Series Integrated Speed ControlDocument2 paginiService Tool: Manual 26250 L-Series Integrated Speed ControlAnonymous V9fdC6Încă nu există evaluări

- Lexmark MX711dtheDocument2 paginiLexmark MX711dthePedro SingleÎncă nu există evaluări

- Budgetary Broadcast Camera StudioDocument3 paginiBudgetary Broadcast Camera StudioTirtanto SetiawanÎncă nu există evaluări

- EEE 102 - Expt 6 - Max PowerDocument3 paginiEEE 102 - Expt 6 - Max Powernushrat.khlÎncă nu există evaluări

- Verilog Code For 4 Bit Ring Counter With TestbenchDocument3 paginiVerilog Code For 4 Bit Ring Counter With Testbenchsoumya100% (1)

- DBXNH 6565a R2MDocument4 paginiDBXNH 6565a R2MBobby CarrÎncă nu există evaluări

- Premier Magnetics IncDocument2 paginiPremier Magnetics IncMile ĐorđevićÎncă nu există evaluări

- 7.5" Touch Screen Operator Interface: DatasheetDocument3 pagini7.5" Touch Screen Operator Interface: DatasheetHammad AshrafÎncă nu există evaluări

- Unit - I Difference Between Microprocessor and MicrocontrollerDocument30 paginiUnit - I Difference Between Microprocessor and MicrocontrollerGopinathan MÎncă nu există evaluări

- 8 VSB Generation and DetectionDocument15 pagini8 VSB Generation and DetectionMohamed shabanaÎncă nu există evaluări

- Peripheral Series: Frequency Measurement CardDocument2 paginiPeripheral Series: Frequency Measurement CardSohail AÎncă nu există evaluări

- E700 WiringDocument3 paginiE700 WiringTrần HoàngÎncă nu există evaluări

- 50lb45rq Service Manual PDFDocument50 pagini50lb45rq Service Manual PDFAnibalÎncă nu există evaluări

- Lecture 3 - Design FlowDocument18 paginiLecture 3 - Design Flowkumarkankipati19100% (1)