Documente Academic

Documente Profesional

Documente Cultură

Flare Header Purge Rate Data

Încărcat de

ppsutorDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Flare Header Purge Rate Data

Încărcat de

ppsutorDrepturi de autor:

Formate disponibile

VELOCITY PURGE REDUCER Notes and Purge Rates

What is Purge Gas?

Purge gas (or "purge flow") is required to prevent air impingement in the process header when there is little or no process flow going to the flare (as in the case of a dedicated intermittent or ESD flare). Should air enter the flare stack, a release of process gas could result in a combustible mixture present within the flare in a restricted zone. The ignition of this air/gas mixture can result in an explosion and cause severe equipment damage.

What is a Velocity Purge Reducer?

Velocity or fluidic seals (Purge Reducers) are used to limit the required fuel gas, "sweep flow" or "purge flow" rate. The Velocity Seal is intended to manipulate the flow path at the top of the flare so as to inhibit air infiltration by buoyant decanting and thus, reduce the amount of continuous purge gas needed to protect the stack against atmospheric air infiltration. Velocity seals have no factor of safety for cases of loss of purge and the correct rate of purge must be maintained at all times. The velocity seal is much lower in cost than other seal methods (molecular or liquid) and is located in the base of the flare tip, it reduces the purge or sweep rate by 92%. Because seal remains out of the flame zone it can be constructed of either carbon steel or stainless steel. The seal can also be equipped with drain holes to prevent rain or condensation from collecting, and damaging the flare tip wall. Integral velocity seals are known by numerous other vendor specific names, such as Airrestor, Reactive, Orifice, Integral or Baffle Type seals.

How does a Velocity Purge Reducer work?

The action of such a seal is three-fold: 1) It presents a smaller cross section area to the upward moving gases thereby reducing the volume of gas needed in order to maintain a fixed purge velocity or momentum; 2) It allows flows in the correct (up-flow) direction to suffer lesser flowing friction losses than incoming (downward) air flows; 3) It acts to reduce the amount of purge because it simulates a length of stack somewhat greater than its true length by presenting an impedance to air flows down into the stack. Typically, a seal of this type may simulate 2 to 20 stack diameters, depending on its design configuration and minimum diameter As per API 521, This seal works under the premise that infiltrating air enters through the flare tip and hugs the inner wall of the flare tip. The velocity is a cone shaped obstruction with single or multiple baffles, which forces the air away from the wall where it encounters the focused purge gas flow and is swept out of the tip. This seal normally reduces the purge gas velocity through the tip to between 0.02 feet per second and 0.04 feet per second, which keeps the oxygen concentrations below the seal to 4 percent to 8 recent (approximately 50 percent of the limiting oxygen concentration required to create a flammable mixture).

Application Notes

Purge Reducers are not effective in preventing oxygen entry into the flare under conditions of internal suction (negative pressure) caused by thermal contractions of the process gases. Such matters must be considered separately. Purge Reducers do add pressure drop to the overall system and the sizing and selection of the equipment becomes an integral part of system sizing as well as a purge consideration. Purge Reducers are not flame arrestors and should not be thought of as equivalents, even though the underlying issue in the use of a gas seal is the prevention of flash-back. A flame arrestor works passively whereas a "seal" must be properly purged to have any effect. Additionally, a true flame arrestor or detonation arrestor must be employed in situations where oxygen rich gas mixtures originate within the plant, whereas Purge Reducers have no beneficial effect on this condition. In the undesirable event of an actual flash back, and a subsequent explosion or detonation because of the pressure piling effect in the pipe, the use of a gas seal may not be beneficial and some seals can be detrimental at arresting the detonation. As Purge Reducers incur a significant flowing pressure loss when compared with the length of plain pipe they replace, any flame passing (backward) through the seal can experience a dramatic change of pressure condition and turbulence. In many cases the total equivalent distance traveled by the flame passing (backward) through the seal can approach or exceed the run-up distance limit to an explosive condition. The basis for selection, location and sizing of the Purge Reducers and its associated purge conditions must be such that the oxygen concentration on the input side is maintained to be less than the Upper Explosive Limit (UEL) and will not support further passage of a flame.

TORNADO Technologies Inc. 1-888-882-3882

Velocity Purge Reducer Notes and Purge Rates Page 2 of 3

TORNADO Velocity Purge Reducer PURGE RATES

Min. Purge c/w Purge Reducer [SCFH]

3 7 13 30 50 80 118 143 190 241 298 380 435 685 990 1353 1772 2247 2760

See Note (1)

Model

2-inch Velocity Purge Reducer 3-inch Velocity Purge Reducer 4-inch Velocity Purge Reducer 6-inch Velocity Purge Reducer 8-inch Velocity Purge Reducer 10-inch Velocity Purge Reducer 12-inch Velocity Purge Reducer 14-inch Velocity Purge Reducer 16-inch Velocity Purge Reducer 18-inch Velocity Purge Reducer 20-inch Velocity Purge Reducer 22-inch Velocity Purge Reducer 24-inch Velocity Purge Reducer 30-inch Velocity Purge Reducer 36-inch Velocity Purge Reducer 42-inch Velocity Purge Reducer 48-inch Velocity Purge Reducer 54-inch Velocity Purge Reducer 60-inch Velocity Purge Reducer

Min. Purge w/o Purge Reducer [SCFH]

40 90 157 353 628 982 1414 1724 2283 2921 3638 5307 8400 12200 15125 16705 21920 27746 34255

See Note (2)

Note (1): Tornado Velocity Purge Reducer uses a 0.04 ft/s Purge Velocity (Reference API RP521 4.4.3.4.2 b) Velocity Seal pp.48 Note (2): Purge Velocity when No Purge Reducer is supplied is based on 0.5 ft/s velocity, as per Imperial and Home Oil Studies

TORNADO Technologies Inc. 1-888-882-3882

Velocity Purge Reducer Notes and Purge Rates Page 3 of 3

S-ar putea să vă placă și

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDe la EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentÎncă nu există evaluări

- Flare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out FlaDocument10 paginiFlare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out FlaJR RomanÎncă nu există evaluări

- Statistics for Process Control Engineers: A Practical ApproachDe la EverandStatistics for Process Control Engineers: A Practical ApproachÎncă nu există evaluări

- Air Eliminators and Combination Air Eliminators Strainers: Descrip OnDocument10 paginiAir Eliminators and Combination Air Eliminators Strainers: Descrip OnvendsrbÎncă nu există evaluări

- Hydrate Formation in ValvesDocument6 paginiHydrate Formation in ValvesChem.EnggÎncă nu există evaluări

- Liquid Thermal Sizing SheetDocument1 paginăLiquid Thermal Sizing SheetapgoslingÎncă nu există evaluări

- Offsites and UtilitiesDocument70 paginiOffsites and Utilitiesankitalalwani100% (1)

- Design Alternatives For Sweetening LPG's and Liquid Hydrocarbons With Amines PDFDocument7 paginiDesign Alternatives For Sweetening LPG's and Liquid Hydrocarbons With Amines PDFmohamedÎncă nu există evaluări

- Location of Reboiler Return Inlet Nozzle in ColumnDocument10 paginiLocation of Reboiler Return Inlet Nozzle in Columnxaaabbb_550464353Încă nu există evaluări

- Restriction Orifice RO Flow Control Instrument PDFDocument8 paginiRestriction Orifice RO Flow Control Instrument PDFRaphael212219Încă nu există evaluări

- Estimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnsDocument10 paginiEstimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnssdddÎncă nu există evaluări

- 2 Phase Seperator PDFDocument66 pagini2 Phase Seperator PDFKanthan DevanÎncă nu există evaluări

- FlareDocument39 paginiFlareMuhammad Tahir RazaÎncă nu există evaluări

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocument7 paginiMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHIÎncă nu există evaluări

- Calculate Saturated-Gas Loads For Vacuum SystemsDocument3 paginiCalculate Saturated-Gas Loads For Vacuum SystemsFred FaberÎncă nu există evaluări

- Flarenet Best PracticesDocument2 paginiFlarenet Best Practiceskelvery chewÎncă nu există evaluări

- NGL SeparationDocument6 paginiNGL SeparationhoustonmathÎncă nu există evaluări

- Thermosiphon ReboilersDocument3 paginiThermosiphon ReboilersMuhammadÎncă nu există evaluări

- Ejector technology for efficient and cost effective flare gas recoveryDocument10 paginiEjector technology for efficient and cost effective flare gas recoverySdadÎncă nu există evaluări

- GoyalDocument3 paginiGoyalVan LeÎncă nu există evaluări

- White Paper - Calculating Safe NPSH (A)Document3 paginiWhite Paper - Calculating Safe NPSH (A)Stephen BeasleyÎncă nu există evaluări

- Safe Operation of Reboilers Condensers in Air Separation UnitsDocument31 paginiSafe Operation of Reboilers Condensers in Air Separation UnitsTusenkrishÎncă nu există evaluări

- E1.0 - Crude Stab - Foaming PDFDocument32 paginiE1.0 - Crude Stab - Foaming PDFRégis Ongollo100% (2)

- Avoid Pressure-Relief System PitfallsDocument8 paginiAvoid Pressure-Relief System PitfallschublackÎncă nu există evaluări

- Aminas - Iran IDocument4 paginiAminas - Iran IJesus BcÎncă nu există evaluări

- PSV For Distillation GuidelinesDocument3 paginiPSV For Distillation GuidelinesMubarik AliÎncă nu există evaluări

- Finger Type Slug CatcherDocument41 paginiFinger Type Slug CatcherIrfaan Taufiiqul Rayadi100% (1)

- Reboiler Case StudyDocument6 paginiReboiler Case StudyamlhrdsÎncă nu există evaluări

- Guidelines For The Safe and Optimum Design ofDocument9 paginiGuidelines For The Safe and Optimum Design ofMoca PhoenixÎncă nu există evaluări

- Relief System PipingDocument7 paginiRelief System PipingbalajikrishnanÎncă nu există evaluări

- PETROFED workshop discusses Oxy Enrich process for increasing sulfur recovery capacityDocument22 paginiPETROFED workshop discusses Oxy Enrich process for increasing sulfur recovery capacitysara25dec689288Încă nu există evaluări

- HP New Analysis For FlaresDocument0 paginiHP New Analysis For Flareskataria200784Încă nu există evaluări

- Optimization of Propane Refrigeration System For Hydrocarbon Dew by Mahmood Moshfeghian On 21 Jul 08.PpDocument22 paginiOptimization of Propane Refrigeration System For Hydrocarbon Dew by Mahmood Moshfeghian On 21 Jul 08.PpRama Krishnan100% (1)

- Using Installed Gain To Improve Valve Selection and Valves & Specialty Metal Materials - CE - October 2010 PDFDocument8 paginiUsing Installed Gain To Improve Valve Selection and Valves & Specialty Metal Materials - CE - October 2010 PDFonizuka-t2263Încă nu există evaluări

- What Are The Types of HRSGDocument2 paginiWhat Are The Types of HRSGThiruvengadamÎncă nu există evaluări

- For Exchanger Tube Rupture PDFDocument3 paginiFor Exchanger Tube Rupture PDFNikhil DivateÎncă nu există evaluări

- Gas/Liquid Separators: Quantifying Separation Performance - Part 1Document10 paginiGas/Liquid Separators: Quantifying Separation Performance - Part 1sara25dec689288Încă nu există evaluări

- Safety Moment 15 Common Process Safety Hazards Part 3Document4 paginiSafety Moment 15 Common Process Safety Hazards Part 3fciausiÎncă nu există evaluări

- CHE Facts 1211Document1 paginăCHE Facts 1211kumar_chemicalÎncă nu există evaluări

- Heat exchanger tube rupture case study: Addressing metal embrittlement risksDocument6 paginiHeat exchanger tube rupture case study: Addressing metal embrittlement risksaegean227100% (1)

- Structured PackingDocument8 paginiStructured PackingUsama IqbalÎncă nu există evaluări

- Flare System Design For A Refinery Mega ComplexDocument4 paginiFlare System Design For A Refinery Mega Complexroberdani12100% (1)

- PSV Load Calculation For Gas Expantion Fire Case PDFDocument2 paginiPSV Load Calculation For Gas Expantion Fire Case PDFAnonymous V5UYBUMaÎncă nu există evaluări

- Horizontal - THREE (Revisar, Petroleum and Gas Field ProcessingDocument4 paginiHorizontal - THREE (Revisar, Petroleum and Gas Field Processingrene123456789eduardoÎncă nu există evaluări

- Article PSV Specific HeatDocument6 paginiArticle PSV Specific Heatprq123Încă nu există evaluări

- Com - Nargan at Liravinia - BDocument22 paginiCom - Nargan at Liravinia - BMorteza DianatfarÎncă nu există evaluări

- Tray Column DesignDocument17 paginiTray Column DesignLaras Wuri D.100% (3)

- Optimize Flare System DesignDocument8 paginiOptimize Flare System DesignVinothrajaÎncă nu există evaluări

- Smokelesss Flare - Air AssistsedDocument19 paginiSmokelesss Flare - Air AssistsedvasuÎncă nu există evaluări

- How to Size Liquid Ring Vacuum PumpsDocument3 paginiHow to Size Liquid Ring Vacuum PumpsdayrogÎncă nu există evaluări

- 14 Hot Oil Systems v3Document14 pagini14 Hot Oil Systems v3sssss100% (1)

- The Weby's: PSV Selection For BeginnerDocument15 paginiThe Weby's: PSV Selection For BeginnerShanmuga MuthukumarÎncă nu există evaluări

- Design and Control of Condensate and Vapor Throttling ReboilersDocument12 paginiDesign and Control of Condensate and Vapor Throttling ReboilerscymyÎncă nu există evaluări

- Page 1 of 5 Compressor Blocked Discharge - Chemical EngineersDocument5 paginiPage 1 of 5 Compressor Blocked Discharge - Chemical EngineersKarthikeyan SivaÎncă nu există evaluări

- Tornado Technologies - Velocity Purge Reducer Notes and Purge RatesDocument3 paginiTornado Technologies - Velocity Purge Reducer Notes and Purge RatesIan MannÎncă nu există evaluări

- DryGasSealCentrifugCompressors PDFDocument15 paginiDryGasSealCentrifugCompressors PDFDeepak GoyalÎncă nu există evaluări

- Dry Gas SealDocument15 paginiDry Gas Seal5skyÎncă nu există evaluări

- Mud Gas Separator Poor Boy DegasserDocument3 paginiMud Gas Separator Poor Boy DegasserZain Ul AbdeenÎncă nu există evaluări

- (Paul E. Minton) Handbook of Evaporation Technology - 170-182Document13 pagini(Paul E. Minton) Handbook of Evaporation Technology - 170-182Ahmad Asfahani100% (1)

- MAINTENANCE & RELIABILITY | Sealing SystemsDocument5 paginiMAINTENANCE & RELIABILITY | Sealing Systemsasimozma100% (1)

- Masoneilan - 21000Document24 paginiMasoneilan - 21000ppsutorÎncă nu există evaluări

- Masoneilan - Tables 2Document23 paginiMasoneilan - Tables 2ppsutorÎncă nu există evaluări

- Latin America PDFDocument6 paginiLatin America PDFppsutorÎncă nu există evaluări

- Gulfpub Wo 201805Document81 paginiGulfpub Wo 201805Patricia.PÎncă nu există evaluări

- Therminol 59 Oil PropertiesDocument8 paginiTherminol 59 Oil PropertiesppsutorÎncă nu există evaluări

- CMHC Canadian Wood-Frame House Construction 2014Document378 paginiCMHC Canadian Wood-Frame House Construction 2014purple_onionÎncă nu există evaluări

- T5H Pump InfoDocument1 paginăT5H Pump InfoppsutorÎncă nu există evaluări

- AGA 11 Flow Computer CalculationsDocument2 paginiAGA 11 Flow Computer Calculationsppsutor100% (1)

- BuTech - Milton RoyDocument234 paginiBuTech - Milton RoyppsutorÎncă nu există evaluări

- Valves CHE Facts 0808Document1 paginăValves CHE Facts 0808isosicaÎncă nu există evaluări

- Assessment Details:: Scenario (Relevant To Ass.1, Ass.2 & Ass.3)Document2 paginiAssessment Details:: Scenario (Relevant To Ass.1, Ass.2 & Ass.3)Farzana AlamÎncă nu există evaluări

- Strategic ManagmentDocument15 paginiStrategic ManagmentOzunitos ComunicaÎncă nu există evaluări

- 943-Article Text-943-1-10-20160308Document8 pagini943-Article Text-943-1-10-20160308sosoÎncă nu există evaluări

- Gas Turbine Trip System 2.2.5.3 Trip MatrixDocument1 paginăGas Turbine Trip System 2.2.5.3 Trip MatrixMohammad Jahangir AlamÎncă nu există evaluări

- Reservoir Structure Planning and Construction MethodsDocument9 paginiReservoir Structure Planning and Construction MethodssinggihÎncă nu există evaluări

- Product Recommendation Hyster Forklift Trucks, Diesel H2.5FT Yanmar 4TNE92 (2005 and After)Document1 paginăProduct Recommendation Hyster Forklift Trucks, Diesel H2.5FT Yanmar 4TNE92 (2005 and After)Nelson ConselhoÎncă nu există evaluări

- Safe Transportation System: A Project Submitted byDocument29 paginiSafe Transportation System: A Project Submitted byshahinÎncă nu există evaluări

- Techniques and Tools For Software Analysis: Freescale SemiconductorDocument7 paginiTechniques and Tools For Software Analysis: Freescale SemiconductorjohnÎncă nu există evaluări

- Tugas Resume Strategi Pembelajaran Di SDDocument8 paginiTugas Resume Strategi Pembelajaran Di SDDega YogaswaraÎncă nu există evaluări

- CISSP NotesDocument95 paginiCISSP Notespranjay1487Încă nu există evaluări

- POLYCAB - MV Power Cable IEC 60502 2Document32 paginiPOLYCAB - MV Power Cable IEC 60502 2AmitabhaÎncă nu există evaluări

- Homework Assignment #3: EE122: Introduction To Communication Networks (Fall 2007)Document4 paginiHomework Assignment #3: EE122: Introduction To Communication Networks (Fall 2007)Jack Chen Su-LeeÎncă nu există evaluări

- Tamilnadu Food Ind PDFDocument150 paginiTamilnadu Food Ind PDFdeva nesan100% (4)

- Test of Mathematics For University Admission: Paper 1 2018 Worked AnswersDocument25 paginiTest of Mathematics For University Admission: Paper 1 2018 Worked AnswersNguyễn Hoàng AnÎncă nu există evaluări

- How to update a crack using pattern search and hex editingDocument17 paginiHow to update a crack using pattern search and hex editingpeterÎncă nu există evaluări

- Band III VHF Antennas 174 240 MHZDocument14 paginiBand III VHF Antennas 174 240 MHZragiÎncă nu există evaluări

- Wrap-Up Quiz 8 - Session 9 - Human Resource Management-T123WSB-3Document12 paginiWrap-Up Quiz 8 - Session 9 - Human Resource Management-T123WSB-3Le Hong Ngoc DoanÎncă nu există evaluări

- BCP EjorDocument25 paginiBCP EjorSitraka Fitia Rosanna RaharizoÎncă nu există evaluări

- Manual Apex Thermal SightsDocument56 paginiManual Apex Thermal SightsGuido Catello0% (1)

- BS 46-1-1958Document36 paginiBS 46-1-1958Hans SchwabÎncă nu există evaluări

- Account Management FormDocument1 paginăAccount Management FormJhannel TupanÎncă nu există evaluări

- VLSI Lab Manual - Digital Cirucit Design Using VHDLDocument82 paginiVLSI Lab Manual - Digital Cirucit Design Using VHDLSakthikumar Balasundaram100% (3)

- About SiWIMDocument29 paginiAbout SiWIMFrancesco GinesiÎncă nu există evaluări

- Chapter 2 Research - Shiela MaeDocument6 paginiChapter 2 Research - Shiela MaeKate Alyzza TubatoÎncă nu există evaluări

- Carbon DLS™ 3D Printing Process Engineering Handbook: Updated 06.24.2022Document56 paginiCarbon DLS™ 3D Printing Process Engineering Handbook: Updated 06.24.2022JordiÎncă nu există evaluări

- Holiday Homework for Class 10 Cbse 2015Document7 paginiHoliday Homework for Class 10 Cbse 2015afmtcbjca100% (1)

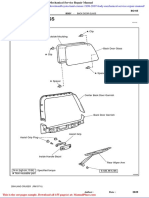

- Toyota Land Cruiser 1998 2007 Body Mechanical Service Repair ManualDocument10 paginiToyota Land Cruiser 1998 2007 Body Mechanical Service Repair Manualhector100% (47)

- Iron Inspection Manual BAKER - Sept 25 2013 PDFDocument434 paginiIron Inspection Manual BAKER - Sept 25 2013 PDFRonni100% (2)

- Commerce ProjectDocument20 paginiCommerce ProjectParam DesaiÎncă nu există evaluări

- A Theorem On Hurwitz SeriesDocument3 paginiA Theorem On Hurwitz Seriesykw kcckcÎncă nu există evaluări

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherDe la EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherÎncă nu există evaluări

- The Inimitable Jeeves [Classic Tales Edition]De la EverandThe Inimitable Jeeves [Classic Tales Edition]Evaluare: 5 din 5 stele5/5 (3)

- The Importance of Being Earnest: Classic Tales EditionDe la EverandThe Importance of Being Earnest: Classic Tales EditionEvaluare: 4.5 din 5 stele4.5/5 (43)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedDe la EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedEvaluare: 4.5 din 5 stele4.5/5 (5)

- Other People's Dirt: A Housecleaner's Curious AdventuresDe la EverandOther People's Dirt: A Housecleaner's Curious AdventuresEvaluare: 3.5 din 5 stele3.5/5 (104)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDe la EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseEvaluare: 4.5 din 5 stele4.5/5 (50)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtDe la EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtEvaluare: 4 din 5 stele4/5 (60)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticDe la EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticEvaluare: 3.5 din 5 stele3.5/5 (10)

- The Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverDe la EverandThe Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverEvaluare: 3.5 din 5 stele3.5/5 (4)

- Lessons from Tara: Life Advice from the World's Most Brilliant DogDe la EverandLessons from Tara: Life Advice from the World's Most Brilliant DogEvaluare: 4.5 din 5 stele4.5/5 (42)

- Sexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesDe la EverandSexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesEvaluare: 3.5 din 5 stele3.5/5 (7)

- 100 Bible Verses Everyone Should Know by HeartDe la Everand100 Bible Verses Everyone Should Know by HeartEvaluare: 4.5 din 5 stele4.5/5 (20)

- Humorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreDe la EverandHumorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreÎncă nu există evaluări

- The Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolDe la EverandThe Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolEvaluare: 4 din 5 stele4/5 (14)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)