Documente Academic

Documente Profesional

Documente Cultură

0 Hvac Checklist

Încărcat de

Assem ElhajjTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

0 Hvac Checklist

Încărcat de

Assem ElhajjDrepturi de autor:

Formate disponibile

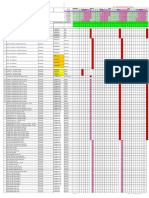

Preventive Maintenance Task Descriptions Quarterly Tasks HVAC - 25%

Sys tem s Pac kag eR efri g. Tow ers ans ls-F Coi Lev el Boi lers mp s

Hea t Pu

Coo ling

HQ1 *Auxiliary Equipment Function HQ2 *Burner Assembly & Control Condition HQ3 *Filter Condition HQ4 *Joint/Pipe Leaks

2 2 1 1

H1 30 20 15 H1 5 20 60 30 30 30 15 15

H2 30

H3 30 20 15 H3 30

H4

H5

H6 20

Hea t in g

Ski ll

ller s

Fan

Chi

H7

15 H2 20 5 30 30 30 15 15 15

20 15 H4 5

20 15 H5 5 H6 5 60

20 15 H7 5

Semi-Annual Tasks

HS1 *Blower Condition and Condensation Drain Operation HS2 Circulation and Water Spray Device Condition HS3 Combustion Chamber and Smoke Pipe Condition HS4 Condenser Condition and Function HS5 Condition of Interlock Functions & Limit and Shutdown Switches HS6 Condition of Motors, Pumps and/or Strainer Cleanliness HS7 *Distribution Pipe Condition HS8 Electrical Heating Coil Function HS9 Electrical Wiring Connection HS10 Entrapped Air HS11 Excessive Debris Build-up and Chips and Cracks on Blades HS12 Filter Cartridge Condition HS13 Filter Replacement HS14 Gearbox Condition HS15 General Lubrication and Lubrication of Flow Control Valves HS16 Noise, Vibration and Stability of Mounted Units HS17 Oil level HS18 Overall Condition, Cleanliness and Corrosion HS19 Pressure Gauges & Relief Valves HS20 Solution Tanks HS21 Temperature and Humidity Control HS22 Thermal Insulation and Vapor Barrier Condition HS23 Variable Frequency Drive Function HS24 Water Level and Flow Rate and Scale

1 2 2 2 2 2 2 2 2 2 1 3 1 1 1 1 1 2 2 2 2 1 2 1

30 30

5 30 30 30 15 15 15 15 30 5 30 5

5 30

15 15 15

15 15 15 30 30 15 15 30 30 15

15 15 15 30 15

15 15 15 30 30 15 15 30 30 15

15 30 15 15 30 30 30 15 30 H1 15 30 30

15 30 30 15 15 30 30 30 15 30 H2

45 15 30 15 15 30

15 30 15

15 30 H3 10

30 30 15

30 30 15

Annual Tasks

H4 10 H5 10 H6 H7 10

HA1 Back Feed Pumps Function HA2 *Belt Replacement HA3 Certification (per authority with jurisdiction) HA4 Condenser/Evaporator Tube Condition & Oil/Oil Filter Condition HA5 Evaporator Condition and Function HA6 Housing Stability HA7 Louver Condition HA8 Obstructions HA9 Piping Condition HA10 Pump Alignment HA11 Register and Duct Distribution

2 1 3 3 2 1 1 2 1 2 2

60 15 10 15 5 30 30 10 5 30 30

15

15

5 30 30

5 30 30

5 30 30 30

5 30 30

Preventive Maintenance Task Descriptions General Notes

1. Where noted: * - Recommended to perform monthly, but quarterly at a minimum. 2. Skill levels: Skill Level 1 Basic skill range with some formal training. Skill Level 2 Advanced skill range with formal training and certification. Skill Level 3 Advanced skill range with factory training and certification. 3. Times: Times are noted in minutes under the task item. Times are suggested averages and may vary.

Quarterly Task Descriptions

HQ1 *Auxiliary Equipment Function: Inspect support equipment, such as pumps, blowers, water sources, blowdown units and compressors, for proper operation. HQ2 Burner assemblies and Control Condition: Visually inspect for smooth ignition, proper flame color and positioning. Check operation of limit devices and/or flame sensors. Clean burners as needed. Test gas connections for leaks. HQ3 Filter Condition: Visually inspect filters for cleanliness and condition. Replace filters as recommended by unit manufacturer or sooner, if needed. HQ4 Joint / Pipe Leaks: Visually inspect piping for signs of leakage, deterioration, or weak points. Repair or replace as needed.

Semi-Annual Task Descriptions

HS1 Blower Condition and Condensate Drain Operation: Inspect blower for cleanliness, cracks and fin or blade stability. Verify correct rotation and listen for unusual sounds. Oil bearings as needed. Verify that equipment belt deflection is about 1". Test pulley alignment using a straight-edge laid along each pulley/belt/pulley combination to check for straight alignment from pulley to pulley. When servicing blower section remove any condensate drain restrictions. Pans should be free of debris, clean, and dry or draining. Fill and manually check condensate pumps to verify proper operation. HS2 Circulation and Water Spray Device Condition: Check and lubricate water recirculation pumps. Inspect for leaks, bearing noises, excess heat build-up on motors or bearings and motor coupling condition. Repair or re-adjust as required. Perform visual inspections to verify full and direct spray patterns of of water spray devices. Remove any scale buildup which can redirect spray patterns and allow scale buildup on coils. Combustion Chamber and Smoke Pipe Condition: Inspect combustion chamber to verify that an airtight condition exists from chamber to flu exit. Inspect heat exchangers for cracks, separations, excessive soot or discoloration. Visually inspect smoke/flu equipment for solid, airtight construction. Remove any blockage to insure the free flow of air and or gases. Condenser Condition and Function: Disassemble chiller condenser barrels at end caps/bells to allow for visual inspection. If needed, brush condenser tubes to remove debris which may inhibit efficient heat transfer and reduce tube/barrel life. Perform an electrical eddy test to determine tube wall thickness, as necessary. Condition of Interlock Functions, Limit and Shutdown Switches: Interlocks (safety devices/controls within control or safety circuits) insure proper sequencing for ignition or start/run cycles. Inspect switch condition and sequencing by simulating emergency conditions to insure correct operation. Check condition and operation of shutdown switches by manually operating switch. Test by simulating emergency conditions to verify correct operation. Condition of Motors, Pumps and Strainer Cleanliness: Clean excess oil or grease from motors and inspect bearings for excessive play or noise. Oil or grease and set amp draw per manufacturer recommendation. Use a diagnostic tool if applicable. Inspect pump equipment for proper operation and record amp draw readings to track performance and predict possible repairs or breakdowns. Inspect strainers and manually cleaned filters and clean per manufacturer instructions to promote clear flow and extend equipment life. Distribution Pipe Condition: (**with small repairs). Inspect distribution and return piping. Repair water leaks, torn or ripped insulation and missing supports.

HS3

HS4

HS5

HS6

HS7

Preventive Maintenance Task Descriptions Semi-Annual Task Descriptions (continued)

HS8 Electrical heating coil function: Check all strap/coil heating elements (crankcase, crankcase heaters, block heaters, condensate pan heaters, etc.) to insure that they are maintaining heat within the particular application range. Repair or adjust as required. Electrical Wiring Connections: Check electrical connections loose connections and wire connection conditions. Tighten any loose connections to eliminate over-heating at connection points.

HS9

HS10 Entrapped Air: Check all purge or prevention equipment for proper operation to eliminate entrapped air which can damage equipment. Repair any water leaks in these devices, because leaks generally indicate a problem. HS11 Excessive Debris Build-up and Chips and Cracks on Blades: Inspect leading edges of fan blades for debris build-up. Clean to insure proper operation. Inspect fan blades for chips or cracks which promote blade wobble, vibration and premature motor bearing wear. Replace blades if such conditions exist. HS12 Filter Cartridge Condition: Test the chiller filter cartridge for pressure drop or perform a visual inspection to evaluate filter element conditions. Replace filter elements as needed. HS13 Filter Replacement: Inspect and replace air filters as needed for proper unit operation. Dirty air filters cause higher electrical usage and shorten normal equipment life. HS14 Gearbox Condition: Inspect gearboxes for cleanliness, proper lubricant level, unusual noise, heat or vibration. Repair required. HS15 General Lubrication and Lubrication of Flow Control Valves: Oil motors and bearings per manufacturer recommendation to extend motor/bearing life. Inspect manually lubricated flow control valves for full operation range. Lubricate and exercise enclosed flow control valves to verify proper operation. HS16 Noise, Vibration and Stability of Mounted Units: Inspect for normal sound levels during equipment operation. Note unusual vibrations. Repair or adjust any metal-to-metal and out-ofbalance conditions. Inspect equipment hangers or attachment systems for stability by checking bolts and hardware for stress or weakness. Adjust or replace as required. HS17 Oil Level: Check the oil level at the sight glass on chiller equipment. Oil or lubricate per manufacturer recommendations. HS18 Overall Condition, Cleanliness and Corrosion: Visually inspect equipment for overall condition and cleanliness and to confirm that equipment and housings have no rust, fatigued metals or worn conditions. Repair the source of any oil stains which may indicate leaking seals or bearings. HS19 Pressure Gauges and Relief Valves: Visually inspect gauges and relief valves for leaks or loose fittings. Repair as required. Exercise per manufacturer instructions. HS20 Solution Tank Condition: Inspect solution tanks and associated tubing or piping for leaks and overall condition. Make repairs or adjustments as required HS21 Temperature and Humidity Control: Perform visual inspections to confirm performance and condition. Perform calibration if required. Test as necessary to maintain accuracy. HS22 Thermal Insulation, Vapor Barrier and/or Air Curtain Condition: Inspect insulation and vapor barrier condition. Repair and replace damaged or wet insulation or vapor barriers. Visually inspect air curtains. Perform service at intervals recommended by equipment manufacturer. HS23 Variable Frequency Drive Function: Inspect VFD motor controls for proper motor function. Cycle motors through a normal shutdown/turn-on sequence to verify VFD ability to ramp a motor to required speed. HS24 Water Levels, Flow Rate and Scale Conditions: Check water levels to insure proper equipment operation. Test flow rates per manufacturer instructions. Perform visual inspections for scale build-up. Remove scale to maximize equipment performance. Use commercial scale removers for extremely heavy buildups.

Preventive Maintenance Task Descriptions Annual Task Descriptions

HA1 Back Feed Pump Function: Reverse flow using valves as available to clean and clear any debris from pumps and screens. HA2 Belt Replacement: (*when servicing blower section of equipment). Remove and visually inspect drive belts for cracks, groves, or uneven appearance. Excessively high glossed appearance on working surfaces may indicate slippage. Replace as required. HA3 Certification (per authority with jurisdiction) Obtain required certifications by the appropriate and responsible jurisdictional party to testify that a piece of equipment or system performs in accordance to rules, regulations, laws and specifications. HA4 Condenser/Evaporator Tube Condition & Oil/Oil Filter Condition Disassemble chiller condenser barrels at end caps/bells to allow inspection. Brush evaporator tubes to remove debris that may inhibit efficient heat transfer and reduce life. Perform an electrical eddy test to determine tube wall thickness. Check evaporator coil for debris and blockage. Wash as needed. Service evaporator units as recommended by manufacturer, including refrigerant charge, fan motor/blade condition, oil and coil condition. Condensers should be clean with no signs of oil, oil stains or debris. Fins should be straight for proper air flow. Use a manufacturer approved cleaning product to wash finned coils as needed to remove excessive dirt and debris. Remove a chiller oil sample to check condition and acid content. Change or add oil as needed. Inspect or change oil filters at manufacturer recommended intervals or if acid or poor oil condition is noted when the sample is tested. HA5 Evaporator Condition and Function: Check the evaporator coil for debris and blockage. Wash dirty coils to enhance airflow. Evaporator units should be serviced for total operation, including refrigerant charge, fan motor/blade condition, oil and coil condition. HA6 Housing Stability: Inspect housings, support structures and metal connection points for signs of rust, deterioration or weak points. Repair or replace items as needed to extend system life. HA7 Louver Condition: Where applicable, check manual or pneumatic louver systems for free and easy movement, bent louvers, leaking lines or actuators. Repair or replace as needed. HA8 Obstructions: Inspect coils, fan blades, blower wheels and louvers. Remove debris or obstructions that prevent normal operation. HA9 Piping Condition: Inspect exposed piping for obvious leakage and insulation conditions. Repair or replace insulation covering pipes as needed. HA10 Pump Alignment: Check pump alignment using a straight edge device to aid in the verification and correction of alignment. Improper alignment destroys pump coupling devices and prematurely wears pump bearings. Adjust as required. HA11 Register and Duct Distribution: Visually inspect registers and ducts to insure unrestricted air flow and condition. Repair any separated ductwork or blocked. Wipe register faces clean as needed.

6/5/2003

Arizona School Facilities Board

Preventive Maintenance Checklist

School Name: Category: Equip. Type: Fiscal Year: HVAC H1 Boilers

Room (Optional) Check boxes using P (presently performing task) or N (new PM task being performed). Denotes item recommended to perform monthly, but quarterly at a minimum. Denotes item recommended to perform quarterly, but semi-annually at a minimum. Building (Optional)

> > > Note:

* **

1 2 3 4 Ref.

Quarterly Checks

1 2 3 4 Ref.

HQ1 *Auxiliary Equipment Function HQ2 *Burner Assembly & Control Condition HQ4 *Joint/Pipe Leaks Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign:

Semi-Annual

1 2 Ref.

HS1 *Blower Condition and Condensation Drain Operation

1 2 Ref.

HS15 General Lubrication and Lubrication of Flow Control Valves

HS2 Circulation & Water Spray Device Condition HS3 Combustion Chamber & Smoke pipe Condition HS5 HS6 Condition of Interlock Functions & Limit and Shutdown Switches Condition of Motors, Pumps and/or Strainer Cleanliness

HS16 Noise, Vibration and Stability of Mounted Units HS18 Overall Condition, Cleanliness and Corrosion HS19 Pressure Gauges & Relief Valves HS20 Solution Tanks HS21 Temperature and Humidity Control HS22 Thermal Insulation and Vapor Barrier Condition HS23 Variable Frequency Damper Function HS24 Water Level and Flow Rate and Scale

HS7 *Distribution Pipe Condition HS9 Electrical Wiring Connection HS10 Entrapped Air Tech. Date/Sign: Tech. Date/Sign:

Annual

1 Ref. HA1 Back Feed Pumps Function HA3 Certification (per authority with jurisdiction) HA4 Condenser/Evaporator Tube Condition & Oil/Oil Filter Condition 1 Ref.

HA8 Obstructions HA9 Piping Condition HA10 Pump Alignment

Tech. Date/Sign: Maintenance Director Signature/Date:

Number of possible checks on this checklist: List the number of checks actually performed:

52

6/5/2003

Arizona School Facilities Board

Preventive Maintenance Checklist

School Name: Category: Equip. Type: Fiscal Year: HVAC H2 Chillers

Room (Optional) Check boxes using P (presently performing task) or N (new PM task being performed). Denotes item recommended to perform monthly, but quarterly at a minimum. Denotes item recommended to perform quarterly, but semi-annually at a minimum. Building (Optional)

> > > Note:

* **

1 2 3 4 Ref.

Quarterly Checks

1 2 3 4 Ref.

HQ1 *Auxiliary Equipment Function HQ4 *Joint/Pipe Leaks Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign:

Semi-Annual

1 2 Ref.

HS2 Circulation and Water Spray Device Condition HS4 Condenser Condition and Function HS5 Condition of Interlock Functions & Limit and Shutdown Switches Condition of Motors, Pumps and/or

1 2 Ref.

HS17 Oil level HS18 Overall Condition, Cleanliness and Corrosion HS19 Pressure Gauges & Relief Valves HS20 Solution Tanks HS21 Temperature and Humidity Control HS22 Thermal Insulation and Vapor Barrier Condition HS23 Variable Frequency Damper Function HS24 Water Level and Flow Rate and Scale

HS6

Strainer Cleanliness HS7 *Distribution Pipe Condition HS9 Electrical Wiring Connection HS10 Entrapped Air HS12 Filter Cartridge Condition HS15 General Lubrication and Lubrication of Flow Control Valves HS16 Noise, Vibration and Stability of Mounted Units Tech. Date/Sign: Tech. Date/Sign:

Annual

1 Ref. Condenser/Evaporator Tube Condition & Oil/Oil HA4 Filter Condition HA5 Evaporator Condition and Function HA8 Obstructions HA9 Piping Condition HA10 Pump Alignment Tech. Date/Sign: Maintenance Director Signature/Date: 1 Ref.

Number of possible checks on this checklist: List the number of checks actually performed:

49

6/5/2003

Arizona School Facilities Board

Preventive Maintenance Checklist

School Name: Category: Equip. Type: Fiscal Year: HVAC H3 Cooling Towers

Room (Optional) Check boxes using P (presently performing task) or N (new PM task being performed). Denotes item recommended to perform monthly, but quarterly at a minimum. Denotes item recommended to perform quarterly, but semi-annually at a minimum. Building (Optional)

> > > Note:

* **

1 2 3 4 Ref.

Quarterly Checks

1 2 3 4 Ref.

HQ1 *Auxiliary Equipment Function HQ3 *Filter Condition HQ4 *Joint/Pipe Leaks Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign:

Semi-Annual

1 2 Ref.

HS2 Circulation and Water Spray Device Condition HS5 HS6 Condition of Interlock Functions & Limit and Shutdown Switches Condition of Motors, Pumps and/or

1 2 Ref.

HS16 Noise, Vibration and Stability of Mounted Units HS18 Overall Condition, Cleanliness and Corrosion HS19 Pressure Gauges & Relief Valves HS20 Solution Tanks HS23 Variable Frequency Damper Function HS24 Water Level and Flow Rate and Scale

Strainer Cleanliness HS9 Electrical Wiring Connection HS10 Entrapped Air HS11 Excessive Debris Build-up and Chips and Cracks on Blades General Lubrication and Lubrication of Flow Control Valves

HS14 Gearbox Condition HS15

Tech. Date/Sign: Tech. Date/Sign:

Annual

1 Ref. HA2 *Belt Replacement HA6 Housing Stability HA8 Obstructions HA9 Piping Condition HA11 Register and Duct Distribution 1 Ref.

Tech. Date/Sign:

Maintenance Director Signature/Date:

Number of possible checks on this checklist: List the number of checks actually performed:

45

6/5/2003

Preventive Maintenance Checklist

School Name: Category: Equip. Type: Fiscal Year: HVAC H4 Fan Coils-Fans

Room (Optional) Check boxes using P (presently performing task) or N (new PM task being performed). Denotes item recommended to perform monthly, but quarterly at a minimum. Denotes item recommended to perform quarterly, but semi-annually at a minimum. Building (Optional)

> > > Note:

* **

1 2 3 4

Ref.

Quarterly Checks

1 2 3 4 Ref.

HQ3 *Filter Condition HQ4 *Joint/Pipe Leaks Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign:

Semi-Annual

1 2 Ref.

HS1 HS6 *Blower Condition and Condensation Drain Operation Condition of Motors, Pumps and/or Strainer Cleanliness

1 2 Ref.

HS15 General Lubrication and Lubrication of Flow Control Valves

HS16 Noise, Vibration and Stability of Mounted Units HS18 Overall Condition, Cleanliness and Corrosion HS21 Temperature and Humidity Control HS22 Thermal Insulation and Vapor Barrier Condition HS23 Variable Frequency Drive Function

HS7 *Distribution Pipe Condition HS9 Electrical Wiring Connection HS10 Entrapped Air HS11 Excessive Debris Build-up and Chips and Cracks on Blades

HS13 Filter Replacement

Tech. Date/Sign: Tech. Date/Sign:

Annual

1 Ref. HA2 *Belt Replacement HA6 Housing Stability HA8 Obstructions HA9 Piping Condition HA11 Register and Duct Distribution 1 Ref.

Tech. Date/Sign:

Maintenance Director Signature/Date:

Number of possible checks on this checklist: List the number of checks actually performed:

39

6/5/2003

Arizona School Facilities Board

Preventive Maintenance Checklist

School Name: Category: Equip. Type: Fiscal Year: HVAC H5 Heat Pumps

Room (Optional) Check boxes using P (presently performing task) or N (new PM task being performed). Denotes item recommended to perform monthly, but quarterly at a minimum. Denotes item recommended to perform quarterly, but semi-annually at a minimum. Building (Optional)

> > > Note:

* **

1 2 3 4

Ref.

Quarterly Checks

1 2 3 4 Ref.

HQ3 *Filter Condition HQ4 *Joint/Pipe Leaks Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign:

Semi-Annual

1 2 Ref.

HS1 *Blower Condition and Condensation Drain Operation

1 2 Ref.

HS15 General Lubrication and Lubrication of Flow Control Valves HS16 Noise, Vibration and Stability of Mounted Units HS17 Oil level HS18 Overall Condition, Cleanliness and Corrosion HS19 Pressure Gauges & Relief Valves HS21 Temperature and Humidity Control HS22 Thermal Insulation and Vapor Barrier Condition HS23 Variable Frequency Drive Function

HS4 Condenser Condition and Function Condition of Interlock Functions & Limit and HS5 Shutdown Switches HS7 *Distribution Pipe Condition HS8 Electrical Heating Coil Function Excessive Debris Build-up and Chips and Cracks HS11 on Blades HS13 Filter Replacement

Tech. Date/Sign: Tech. Date/Sign:

Annual

1 Ref. HA2 *Belt Replacement HA5 Evaporator Condition and Function HA8 Obstructions HA9 Piping Condition HA11 Register and Duct Distribution 1 Ref.

Tech. Date/Sign:

Maintenance Director Signature/Date:

Number of possible checks on this checklist: List the number of checks actually performed:

43

6/5/2003

Arizona School Facilities Board

Preventive Maintenance Checklist

School Name: Category: Equip. Type: Fiscal Year: HVAC H6 Heating Systems

Room (Optional) Check boxes using P (presently performing task) or N (new PM task being performed). Denotes item recommended to perform monthly, but quarterly at a minimum. Denotes item recommended to perform quarterly, but semi-annually at a minimum. Building (Optional)

> > > Note:

* **

1 2 3 4 Ref.

Quarterly Checks

1 2 3 4 Ref.

HQ2 *Burner Assembly & Control Condition

Tech. Date/Sign: Tech. Date/Sign:

Tech. Date/Sign: Tech. Date/Sign:

Semi-Annual

1 2 Ref.

HS1 HS3 *Blower Condition and Condensation Drain Operation Combustion Chamber and Smoke pipe Condition

1 2 Ref.

HS21 Temperature and Humidity Control HS22 Thermal Insulation and Vapor Barrier Condition HS23 Variable Frequency Damper Function

HS7 *Distribution Pipe Condition HS8 Electrical Heating Coil Function HS11 Excessive Debris Build-up and Chips and Cracks on Blades HS13 Filter Replacement HS15 General Lubrication and Lubrication of Flow Control Valves HS16 Noise, Vibration and Stability of Mounted Units HS18 Overall Condition, Cleanliness and Corrosion

Tech. Date/Sign: Tech. Date/Sign:

Annual

1 Ref. HA11 Register and Duct Distribution 1 Ref.

Tech. Date/Sign:

Maintenance Director Signature/Date:

Number of possible checks on this checklist: List the number of checks actually performed:

29

6/5/2003

Arizona School Facilities Board

Preventive Maintenance Checklist

School Name: Category: Equip. Type: Fiscal Year: HVAC H7 Package Refrigeration

Room (Optional) Check boxes using P (presently performing task) or N (new PM task being performed). Denotes item recommended to perform monthly, but quarterly at a minimum. Denotes item recommended to perform quarterly, but semi-annually at a minimum. Building (Optional)

> > > Note:

* **

1 2 3 4

Ref.

Quarterly Checks

1 2 3 4 Ref.

HQ3 *Filter Condition HQ4 *Joint/Pipe Leaks Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign: Tech. Date/Sign:

Semi-Annual

1 2

Ref. HS1 HS4 HS5 HS8 HS11 *Blower Condition and Condensation Drain Operation Condenser Condition and Function Condition of Interlock Functions & Limit and Shutdown Switches Electrical Heating Coil Function Excessive Debris Build-up and Chips

1 2 Ref.

HS16 Noise, Vibration and Stability of Mounted Units HS17 Oil level HS18 Overall Condition, Cleanliness and Corrosion HS19 Pressure Gauges & Relief Valves HS21 Temperature and Humidity Control HS22 Thermal Insulation and Vapor Barrier Condition HS23 Variable Frequency Damper Function

and Cracks on Blades HS13 Filter Replacement HS15 General Lubrication and Lubrication of Flow Control Valves Tech. Date/Sign: Tech. Date/Sign:

Annual

1 Ref. HA2 *Belt Replacement HA5 Evaporator Condition and Function HA8 Obstructions HA9 Piping Condition HA11 Register and Duct Distribution 1 Ref.

Tech. Date/Sign:

Maintenance Director Signature/Date:

Number of possible checks on this checklist: List the number of checks actually performed:

41

######

Arizona School Facilities Board

Preventive Maintenance Annualized Cost Worksheet

Tra ve Ap l Tim + plic e abl Cos t (W e) hen

lR eq uir Av ed e ra ge Sa X lar Lev y for Sk el ill Tim X e to Co mp lete Tas Nu k mb X er of Tas k It em Fre s qu X enc y

HVAC

Quarterly Tasks

HQ1 HQ2 HQ3 HQ4 *Auxiliary Equipment Function *Burner Assembly & Control Condition *Filter Condition *Joint/Pipe Leaks

Semi-Annual Tasks

HS1 HS2 HS3 HS4 HS5 HS6 HS7 HS8 HS9 HS10 HS11 HS12 HS13 HS14 HS15 HS16 HS17 HS18 HS19 HS20 HS21 HS22 HS23 HS24 *Blower Condition and Condensation Drain Operation Circulation and Water Spray Device Condition Combustion Chamber and Smoke pipe Condition Condenser Condition and Function Condition-Interlock Functions&Limit/Shutdown Switches Condition of Motors, Pumps/Strainer Cleanliness *Distribution Pipe Condition Electrical Heating Coil Function Electrical Wiring Connection Entrapped Air Excessive Debris Build-up/Chips & Cracks on Blades Filter Cartridge Condition Filter Replacement Gearbox Condition General Lubrication/Lub. of Flow Control Valves Noise, Vibration and Stability of Mounted Units Oil level Overall Condition, Cleanliness and Corrosion Pressure Gauges & Relief Valves Solution Tanks Temperature and Humidity Control Thermal Insulation and Vapor Barrier Condition Variable Frequency Drive Function Water Level and Flow Rate and Scale

Pe rso nn e

Total Quarterly HVAC Tasks Annual Cost

Total Semi-Annual HVAC Tasks Annual Cost Subtotal Quarterly and Semi Annual Costs

Arizona School Facilities Board

Preventive Maintenance Checklist

Lev el

lR eq u

Sa lar

Co m

ple

HVAC

+ Ti m eC Ap o plic st (W abl hen e)

Tra vel

rS kill

ask te T

Tas k It em s X

ire d

y fo

age

Ti m e to

Pe rso n

ber

Annual Tasks

HA1 HA2 HA3 HA4 HA5 HA6 HA7 HA8 HA9 HA10 HA11 Back Feed Pumps Function *Belt Replacement Certification (per authority with jurisdiction) Condenser/Evaporator Tube Condition & Oil/Oil Filter Condition Evaporator Condition and Function Housing Stability Louver Condition Obstructions Piping Condition Pump Alignment Register and Duct Distribution

Total Annual HVAC Tasks Cost Total Estimated Annual Cost for HVAC Tasks

Fre qu

Av er

Nu m

enc y

ne

of

S-ar putea să vă placă și

- Preventative Maintenance GuideDocument6 paginiPreventative Maintenance GuideReza JafariÎncă nu există evaluări

- Chiller Maintenance ChecklistDocument2 paginiChiller Maintenance ChecklistAssem Elhajj100% (17)

- 1 Building Maintenance Checklist HVACDocument17 pagini1 Building Maintenance Checklist HVACamochieno100% (3)

- Hvac PM Service Checklist ContractorDocument1 paginăHvac PM Service Checklist Contractorudupiganesh3069100% (1)

- Hvac Long Form ChecklistDocument15 paginiHvac Long Form ChecklistPaul Garcia100% (4)

- Operations and Maintenance Preventive Maintenance ChecklistsDocument35 paginiOperations and Maintenance Preventive Maintenance Checklistssooriya_82100% (14)

- Chiller ChecklistDocument18 paginiChiller Checklistavinash rathod100% (1)

- Chiller ChecklistDocument3 paginiChiller ChecklistMohammed SayeeduddinÎncă nu există evaluări

- HVAC Maintenance FHDocument22 paginiHVAC Maintenance FHmhussainarabi@gmail.com100% (1)

- p2 - 221841 - MAINTENANCE ACMVDocument36 paginip2 - 221841 - MAINTENANCE ACMVVin BdsÎncă nu există evaluări

- Weekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekDocument8 paginiWeekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekfcfernandoÎncă nu există evaluări

- Package Units ChecklistDocument11 paginiPackage Units Checklistemanuel92Încă nu există evaluări

- Building Maintenance ChecklistDocument2 paginiBuilding Maintenance ChecklistDavid tangkelangiÎncă nu există evaluări

- Mannai Corporation: Mannai Trading Co. WLLDocument18 paginiMannai Corporation: Mannai Trading Co. WLLAyu Oktaviani100% (2)

- AHU FAHU - AnnuallyDocument3 paginiAHU FAHU - AnnuallyDreamliner100% (1)

- Preventive Maint Checklist PDFDocument1 paginăPreventive Maint Checklist PDFSoledayo Tom Osuntuyi100% (1)

- Approved 52 Week PPM Calendar 2011 - IBM Manyata C4Document161 paginiApproved 52 Week PPM Calendar 2011 - IBM Manyata C4shivakumarbaraguru88% (16)

- Air Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationDocument6 paginiAir Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationGopinath GopiÎncă nu există evaluări

- Building Maintenance ChecklistDocument5 paginiBuilding Maintenance Checklistchristheo54787100% (2)

- HVAC Maintenance ActivitiesDocument23 paginiHVAC Maintenance ActivitiesLungisaniÎncă nu există evaluări

- Operations and Maintenance Preventive Maintenance Checklists PDFDocument35 paginiOperations and Maintenance Preventive Maintenance Checklists PDFAdewale BamgbadeÎncă nu există evaluări

- Facility Preventive Maintenance Schedule Template Printable PDFDocument35 paginiFacility Preventive Maintenance Schedule Template Printable PDFEdmund Yoong100% (3)

- Maintenance ChecklistDocument2 paginiMaintenance ChecklistShreyasi Singh92% (13)

- New Age Facilities Management (November 2010)Document4 paginiNew Age Facilities Management (November 2010)Microcorp TechnologyÎncă nu există evaluări

- Mep Condition Survey Report2Document10 paginiMep Condition Survey Report2psn_kylmÎncă nu există evaluări

- Chiller Maintenance ChecklistDocument2 paginiChiller Maintenance ChecklistMd Rizwan Khan100% (3)

- Schedule Preventive Maintenance Esm2Document52 paginiSchedule Preventive Maintenance Esm2fitra100% (1)

- 52 Week PPM Planner Template-15 Jul 14Document26 pagini52 Week PPM Planner Template-15 Jul 14safetydellÎncă nu există evaluări

- SOP Operational and Preventive Maintenance ChecklistDocument2 paginiSOP Operational and Preventive Maintenance ChecklistMasomese Henry Kikile88% (8)

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDocument4 pagini2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanÎncă nu există evaluări

- Monthly Preventive Maintenance ChecklistDocument2 paginiMonthly Preventive Maintenance ChecklistAlia Marouf90% (10)

- Hvac Install ChecklistDocument4 paginiHvac Install Checklistadnyat0% (1)

- Raft TT FT FT FT FT AFT AF RAFDocument31 paginiRaft TT FT FT FT FT AFT AF RAFHugo Silva100% (1)

- Form Maintenance-Checklist DailyDocument15 paginiForm Maintenance-Checklist DailyRomly MechÎncă nu există evaluări

- Air-Cooled Chillers Maintenance & Inspection ChecklistDocument3 paginiAir-Cooled Chillers Maintenance & Inspection ChecklistdjukalÎncă nu există evaluări

- HVAC Commisioning ChecklistDocument65 paginiHVAC Commisioning ChecklistBalakumar100% (13)

- Present Chiller 2 Log Sheet.....Document1 paginăPresent Chiller 2 Log Sheet.....Madan Tiwari100% (1)

- Air Handling Unit QC Checklist: AHU InformationDocument5 paginiAir Handling Unit QC Checklist: AHU InformationRaheel AhmedÎncă nu există evaluări

- Chiller Maintenance Procedure PDFDocument4 paginiChiller Maintenance Procedure PDFMd. Yusuf100% (1)

- HVAC Duct Work Installation Method StatementDocument3 paginiHVAC Duct Work Installation Method StatementSudath Kularathna100% (1)

- Checklist For VRF InstallationDocument14 paginiChecklist For VRF InstallationblahblahÎncă nu există evaluări

- HVAC Procedures Forms ManualDocument279 paginiHVAC Procedures Forms Manualgeneroso67100% (12)

- Check ListDocument19 paginiCheck ListrihanÎncă nu există evaluări

- Facility Inspection ChecklistDocument50 paginiFacility Inspection ChecklistMurali Dharma Raja Praphu50% (2)

- VRF Execution Check ListDocument2 paginiVRF Execution Check ListSkill IndiaÎncă nu există evaluări

- Chiller Testing Procedure Rev 3 PDFDocument11 paginiChiller Testing Procedure Rev 3 PDFOanh NguyenÎncă nu există evaluări

- FCU ChecklistDocument11 paginiFCU ChecklistAnsari1918Încă nu există evaluări

- Major Works To Be DoneDocument6 paginiMajor Works To Be DoneAustin UdofiaÎncă nu există evaluări

- Cad 10005479Document4 paginiCad 10005479farman ali ahmedÎncă nu există evaluări

- Maintenance Check List of HydraulicDocument7 paginiMaintenance Check List of HydraulicShubham SinghÎncă nu există evaluări

- Maint IPENDocument13 paginiMaint IPENosmaidaÎncă nu există evaluări

- Generators Expected ServicesDocument3 paginiGenerators Expected Servicesmoaz zahidÎncă nu există evaluări

- Hvac Preventive Maintenance ChecklistDocument2 paginiHvac Preventive Maintenance ChecklistAlpesh Jain100% (1)

- Preventive Maintenance - Keeping Refrigeration Equipment in ShapeDocument5 paginiPreventive Maintenance - Keeping Refrigeration Equipment in ShapeSanjay RanaÎncă nu există evaluări

- Buiolding MantenanceDocument13 paginiBuiolding MantenanceSean ChanÎncă nu există evaluări

- High-Pressure Boiler Inspection Procedures: A Complete ChecklistDocument6 paginiHigh-Pressure Boiler Inspection Procedures: A Complete ChecklistROHITÎncă nu există evaluări

- Rohit Dave: Wednesday, February 17, 2010Document78 paginiRohit Dave: Wednesday, February 17, 2010Sérgio CruzÎncă nu există evaluări

- Method Statement of Chiller Preventive MaintenanceDocument5 paginiMethod Statement of Chiller Preventive MaintenanceBalajiÎncă nu există evaluări

- Hydraulic Power Pack 60 B29ADocument3 paginiHydraulic Power Pack 60 B29Agpcd1210Încă nu există evaluări

- Appendix F Sample Graving Dock Maintenance Tasks: Pumpwell Biennial PMDocument4 paginiAppendix F Sample Graving Dock Maintenance Tasks: Pumpwell Biennial PMwaleedyehiaÎncă nu există evaluări

- Calculation For Pressure DropDocument2 paginiCalculation For Pressure Droplutfi awn100% (1)

- Standard Org Chart & Role DescriptionsDocument15 paginiStandard Org Chart & Role DescriptionsAssem ElhajjÎncă nu există evaluări

- Communications Plan ExcelDocument12 paginiCommunications Plan ExcelPedro BentoÎncă nu există evaluări

- Excel Gantt v4Document14 paginiExcel Gantt v4PMPÎncă nu există evaluări

- COST Model Template V04Document457 paginiCOST Model Template V04Assem Elhajj100% (1)

- Anchor BoltDocument15 paginiAnchor BoltRyan Wiratama67% (3)

- 01 Build DeliverablesDocument7 pagini01 Build DeliverablesAssem ElhajjÎncă nu există evaluări

- MFC Hierarchy Chart3of3Document1 paginăMFC Hierarchy Chart3of3Assem ElhajjÎncă nu există evaluări

- RET Org ChartDocument2 paginiRET Org ChartAssem ElhajjÎncă nu există evaluări

- Area CalculationsDocument11 paginiArea Calculationsash1968Încă nu există evaluări

- Electrical EstimateDocument55 paginiElectrical EstimateAssem ElhajjÎncă nu există evaluări

- Box PlotsDocument2 paginiBox PlotsAssem ElhajjÎncă nu există evaluări

- Site Inspection Check List2Document38 paginiSite Inspection Check List2Assem Elhajj100% (2)

- S.NO. Item No. Description Unit QTY Rate AMOUNT RemarksDocument1 paginăS.NO. Item No. Description Unit QTY Rate AMOUNT RemarksAssem Elhajj100% (1)

- Kaizen Structure Rev0Document86 paginiKaizen Structure Rev0hiattolaÎncă nu există evaluări

- Organization Charts UNDP AODocument2 paginiOrganization Charts UNDP AOAssem ElhajjÎncă nu există evaluări

- 0030 Budget EstimateDocument56 pagini0030 Budget EstimateAssem ElhajjÎncă nu există evaluări

- 0-Air Distribution System CHECKLISTDocument2 pagini0-Air Distribution System CHECKLISTAssem ElhajjÎncă nu există evaluări

- Gantt Chart TemplateDocument2 paginiGantt Chart TemplateAssem ElhajjÎncă nu există evaluări

- Activities: Gantt Chart - Priority Area - AgencyDocument2 paginiActivities: Gantt Chart - Priority Area - AgencyAssem ElhajjÎncă nu există evaluări

- Material Takeoff SheetDocument14 paginiMaterial Takeoff SheetAssem ElhajjÎncă nu există evaluări

- Task Start Date Duration in Days End Date: Proposed Programme of WorksDocument2 paginiTask Start Date Duration in Days End Date: Proposed Programme of WorksAssem ElhajjÎncă nu există evaluări

- SixSigma QFD MatrixDocument6 paginiSixSigma QFD MatrixAssem ElhajjÎncă nu există evaluări

- ScheduleDocument1 paginăScheduleAssem ElhajjÎncă nu există evaluări

- Task Start Date Duration in Days End Date: Proposed Programme of WorksDocument2 paginiTask Start Date Duration in Days End Date: Proposed Programme of WorksAssem ElhajjÎncă nu există evaluări

- Bar Chart: Headquarters LocationDocument2 paginiBar Chart: Headquarters LocationAssem ElhajjÎncă nu există evaluări

- Task Start Date Duration End DateDocument2 paginiTask Start Date Duration End DateAssem ElhajjÎncă nu există evaluări

- Task Start Date Duration End DateDocument2 paginiTask Start Date Duration End DateAssem ElhajjÎncă nu există evaluări

- Client: Project: Location: Scope: Dated:: Project Schedule Project ScheduleDocument1 paginăClient: Project: Location: Scope: Dated:: Project Schedule Project ScheduleAssem ElhajjÎncă nu există evaluări

- 4201-232-V4-8900-08018 - 001 - Code 2Document82 pagini4201-232-V4-8900-08018 - 001 - Code 2Shoaib KhanÎncă nu există evaluări

- LePage Epoxy Steel, 25-mL Canadian TireDocument5 paginiLePage Epoxy Steel, 25-mL Canadian Tireming_zhu10Încă nu există evaluări

- Lecture - 3 - Doors and WindowDocument45 paginiLecture - 3 - Doors and WindowGanesh.Rajan100% (2)

- Group: Two Stage Evaporative Air-CoolingDocument4 paginiGroup: Two Stage Evaporative Air-CoolingHaseeb ChaudhryÎncă nu există evaluări

- 04 Full-Scale Testing of Two Corrugated Steel Box Culverts With Different Crown StiffnessDocument10 pagini04 Full-Scale Testing of Two Corrugated Steel Box Culverts With Different Crown StiffnessSafwat El RoubyÎncă nu există evaluări

- Alucobest Aluminum Composite Panel For Sign, Display and Digital PrintingDocument12 paginiAlucobest Aluminum Composite Panel For Sign, Display and Digital PrintingAli ZhangÎncă nu există evaluări

- ITP - Public Address InstallationDocument9 paginiITP - Public Address InstallationGultom Juliana LiliesÎncă nu există evaluări

- Milano Mixers PDFDocument8 paginiMilano Mixers PDFKhader Abu-daggaÎncă nu există evaluări

- Piping - Canada Culvert CSP ManualDocument12 paginiPiping - Canada Culvert CSP ManualRotax_KidÎncă nu există evaluări

- Structural Calculations and Analysis: Proposed 2-Storey Residential HouseDocument39 paginiStructural Calculations and Analysis: Proposed 2-Storey Residential HouseGrace LagnayoÎncă nu există evaluări

- Bulk Density of BricksDocument1 paginăBulk Density of BrickssuryakantameÎncă nu există evaluări

- Creating A Timber Frame House v1Document77 paginiCreating A Timber Frame House v1Gregor100% (2)

- Relief and Flare Sytem Design (Autosaved)Document51 paginiRelief and Flare Sytem Design (Autosaved)Qayyum KhanÎncă nu există evaluări

- A Guideline For The Design and Construction of Asphalt Parking Lots in ColoradoDocument18 paginiA Guideline For The Design and Construction of Asphalt Parking Lots in ColoradothescubataterÎncă nu există evaluări

- Grouping of Conductors or Cables: Nature of Soil k3Document4 paginiGrouping of Conductors or Cables: Nature of Soil k3HistoMadeÎncă nu există evaluări

- Report On Junkers CalorimeterDocument5 paginiReport On Junkers CalorimeterSandip PatelÎncă nu există evaluări

- Outdoor Voltage Transformer: Type VOG-24Document4 paginiOutdoor Voltage Transformer: Type VOG-24dfsgsdf df3tegdfgÎncă nu există evaluări

- Polyacrylic or Acrylic Resin (Pmma)Document1 paginăPolyacrylic or Acrylic Resin (Pmma)Dl Al-azizÎncă nu există evaluări

- Plate 2 Lecture 2Document4 paginiPlate 2 Lecture 2Hunter BravoÎncă nu există evaluări

- Session 4 - Structural Systems in Tall BuildingsDocument36 paginiSession 4 - Structural Systems in Tall BuildingsAlec PÎncă nu există evaluări

- Scope of ThermodynamicsDocument14 paginiScope of Thermodynamicsbabar.muet33% (3)

- Assignment 05Document3 paginiAssignment 05Arapat SyamsuddinÎncă nu există evaluări

- CHI Article Absorption Chiller AdvancesDocument5 paginiCHI Article Absorption Chiller AdvancesUmar MajeedÎncă nu există evaluări

- Brochure - Aerial SCPT 12 24 CoreDocument3 paginiBrochure - Aerial SCPT 12 24 Coretomi mulkiÎncă nu există evaluări

- BS 476-21-1987Document22 paginiBS 476-21-1987Hadi Iz'aanÎncă nu există evaluări

- SB Part Bill - 3 (GR Floor) of Protik Fine Ceramics Factory BuildingDocument10 paginiSB Part Bill - 3 (GR Floor) of Protik Fine Ceramics Factory BuildingShafiul AlamÎncă nu există evaluări

- Alfa Laval Helpman TYRDocument26 paginiAlfa Laval Helpman TYRNhiem phamÎncă nu există evaluări

- 【Discontinued Model】APV・SPV Series (0.1MB)Document3 pagini【Discontinued Model】APV・SPV Series (0.1MB)Wei-Feng FangÎncă nu există evaluări

- Broen Butterfly Valves v9Document13 paginiBroen Butterfly Valves v9bojanmileticÎncă nu există evaluări

- Comparison Fibre Glass VS XLPEDocument1 paginăComparison Fibre Glass VS XLPEsooriya_82100% (1)