Documente Academic

Documente Profesional

Documente Cultură

Soil Compaction Basics

Încărcat de

Anu VishnuTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Soil Compaction Basics

Încărcat de

Anu VishnuDrepturi de autor:

Formate disponibile

ction is defined as the method of mechanically increasing fion soil.

nc ons tra u ion , th is is a ignc ific tap tn o the building ao ct is Ide fi ned sctthe me thod ofsme haa nn ic lla yri cfre asing pe rf fo rmed mp rt ope , se emen tign of t heaso ld o ccu yo so il. In ic ons rucr tl iy on , ttt hli14.330 s is a s ific ntil pc aou rMechanics to ft he br uilding Soil n unne cessa ry roperly, settlement of the soil could occur pe rformed imp SOIL DENSITY cie osts o ncunne cr essary . Al SOIL DENSITY nil cu er ce os ts mos or t all il ing ites and ad ilu re.sAl mos t all n ojec ses uta ili ze u ilp dr ing st it nd comp a c tt is on on proj e c utilize

Soil Compaction

SOIL COMPACTION BASICS

l compaction s.

Loose Soil (poor load support)

Figure Loose 1 Soil (poor load support)

Compacted Soil (improved load support)

ed in place or deposited by various forces such ap sl g ae cio er rs , wind lak es aa nd rive med in alc depos it,ed b yv rious fr os r ces r o r g a n ic a ll y . F o ll ow i ng a r e i mpo r ta n t such as glaciers, wind, lakes and rivers so ilrc all ct i.on :llowing are important o ro gomp anica y Fo

il? oil?

Figure 1 Compacted Soil (improved load support) Figure courtesy of Soil Compaction: A Basic Handbook by MultiQuip.

Soil Compaction: vtia b rce y. is simply the deadweight of the machine, S tr iat csoil fo or Densification of by n a pp l y i ng downw a forde ce a on the so su rfam cea ,c ch om -, e soil compaction: Static force is simp lr ydthe dwe igh t il of the ine p ess ing the soil p a ticl heton yw yrtfo ce h sture content ar pp ly ing downw a rr d foes rc. eT on he lso il a su ac ,a cnge ompe the removal of air. t he e ff e c t i ve c omp a c t i on f o r c e i s b y a dd i ng o r pressing the soil particles. The only way to change ct ion rtten req o is tureff co on t uired

These different types of effort are found in the two p incipd le types f comp cff tio on e : static nd Tr hese iff erento types ofae rt f ao rr ecf ound inat he two v i b r at o r y . principle types of compaction force: static and

action effort required

ve princi ple re2/2012 asons to compact soil: Revised ive rin ci le rea es lop ad b ep ar ing csons apacitto y compact soil:

ac t? p ac t?

s so ilase tt emen a nd frtos es lo dble aringtc a paci y t damage

su bte ra c tc ing the wei gh of fto he m ac .S tatic the ff e tive comp a ctit on rce is bh yine add ing orcomp ac on con fined to t uppe r so il la ye rs atat ndic iscli mi-ted su bttir actiis ng the weigh of the m ac h ine .S om tp oaa app ron ecifi aned ble dep th. Kr ne ail d i p ressu re re Courtesy of http://www.extension.umn.edu cny tion is c to uppe so lng ayea rnd sa nd is lim ita ed Slide 1 of 37 ttwo exa mp les tat ic c aca tid on . and pressure are o any a ppr ecio af bs le dep tomp h. Kne ing two xr a mp esuses of stat comp ction . ally engineV ibrae to y forlce a ic me chana ism , usu

14.330 Soil Mechanics Soil Compaction

RESULTS O F POOR COMPACTION

WHY COMPACT SOILS?

Figure courtesy of Soil Compaction: A Basic Handbook by MultiQuip.

Revised 2/2012

Figure 2

Slide 2 of 37

These illustrations show the results of improper compaction and how proper compaction can ensure a longer structural life, eliminating future foundation problems.

14.330 Soil Mechanics Soil Compaction

MOIST UNIT WEIGHT () vs. MOISTURE CONTENT (w)

Conceptual (Figure 4.1. Das FGE (2005))

=

Revised 2/2012

Weight (W) Volume (V)

Silty Clay (LL=37, PI =14) Example (from Johnson and Sllberg 1960, taken from TRB State of the Art Report 8, 1990)

Slide 3 of 37

14.330 Soil Mechanics Soil Compaction

LABORATORY COMPACTION TESTS (i.e. Proctors)

Standard Hammer Ejector

6 inch Mold

Soil Plug Scale

Modified Hammer Soil Plug

4 inch Mold

Typical Proctor Test Equipment

(Figure courtesy of test-llc.com)

Revised 2/2012 Slide 4 of 37

14.330 Soil Mechanics Soil Compaction

LABORATORY COMPACTION TEST SUMMARY

Test Standard (SCDOT) Modified ASTM/ AASHTO D698 T-99 D1557 T-180 Hammer Compaction Hammer Drop Effort Weight (lb) (in) (kip-ft/ft3) 5.5 12 12.4

10

18

56

Revised 2/2012

Slide 5 of 37

14.330 Soil Mechanics Soil Compaction

LABORATORY COMPACTION TEST SUMMARY

Test Method STANDARD ASTM D698/AASHTO T-99 A

20% Retained by #4 Sieve

MODIFIED ASTM D1557/AASHTO T-180 A

20% Retained by #4 Sieve

B

>20% Retained on #4 20% Retained by 3/8 in Sieve

C

>20% Retained on 3/8 in < 30% Retained by 3/4 in Sieve

B

>20% Retained on #4 20% Retained by 3/8 in Sieve

C

>20% Retained on 3/8 in < 30% Retained by 3/4 in Sieve

Material

Use Soil Passing Sieve Mold Dia. (in) No. of Layers No. Blows/Layer

Revised 2/2012

#4 4 3 25

3/8 in 4 3 25

in 6 3 56

#4 4 5 25

3/8 in 4 5 25

in 6 5 56

Slide 6 of 37

14.330 Soil Mechanics Soil Compaction

LABORATORY COMPACTION TEST SUMMARY PROCTOR TEST

Figure 10

Revised 2/2012

Figure courtesy of Soil Compaction: A Basic Handbook by MultiQuip.

FIELD DENSITY TESTING METHODS

Sand Cone Balloon Densometer Shelby Tube

Slide 7 of 37

Nuclear Gauge

14.330 Soil Mechanics Soil Compaction

LABORATORY COMPACTION TESTS (i.e. Proctors)

Automated Proctor Equipment

(Figure courtesy of Humboldt)

Revised 2/2012

Manual Proctor Test (What youll be doing)

(Figure courtesy of westest.net)

Slide 8 of 37

14.330 Soil Mechanics Soil Compaction SP-SM

% Fines = 6%

Maximum Dry Density MDD or d,max = 112.2 pcf

Zero Air Voids (ZAV) Line Gs = 2.6

d = 1+ w

Revised 2/2012

From soil composition notes:

Optimum Moisture Content OMC = 11.5%

Slide 9 of 37

14.330 Soil Mechanics Soil Compaction

ZERO AIR VOIDS LINE

Dry Unit Weight (d) (i.e. no water):

Weight of Solids (Ws ) d = = Volume (V) 1+ w

zav = Zero Air Void Unit Weight:

zav

Gs w Gs w w = = = 1 + e 1 + wGs w + 1 Gs

Slide 10 of 37

Revised 2/2012

14.330 Soil Mechanics Soil Compaction

FACTORS AFFECTING SOIL COMPACTION 1. Soil Type Grain size distribution Shape of soil grains Specific gravity of soil solids 2. Effect of Compaction Effort More energy Greater compaction

Revised 2/2012

Slide 11 of 37

14.330 Soil Mechanics Soil Compaction

TYPES OF COMPACTION CURVES

Lee and Suedkamp (1972)

A. Single Peak

Dry Unit Weight d

(Most Soils)

C B D

B. 1 Peak

A

Cohesive Soils LL<30

C. Double Peak

Cohesive Soils LL<30 or Cohesive Soils LL>70

Moisture Content w

after Figure 4.5. Das FGE (2005)

D. No Definitive Peak

Uncommon Cohesive Soils LL>70

Slide 12 of 37

Revised 2/2012

14.330 Soil Mechanics Soil Compaction

EFFECT OF COMPACTION ENERGY

In general:

Compaction Energy = Compaction Energy =

Revised 2/2012

d,max OMC

Figure 4.6. Das FGE (2005).

Slide 13 of 37

14.330 Soil Mechanics Soil Compaction

EFFECT OF COMPACTION ON COHESIVE SOILS

Dry Side Wet Side

Dry Side Particle Structure Flocculent

Dry Side Particle Structure Dispersed

OMC

Figure 4.22. Das FGE (2005).

Revised 2/2012 Slide 14 of 37

14.330 Soil Mechanics Soil Compaction

EFFECT OF COMPACTION ON COHESIVE SOILS

Hydraulic Conductivity (k): Measure of how water flows through soils In general: Increasing w = Decreasing k Until ~ OMC, then increasing w has no significant affect on k

Figure 4.23. Das FGE (2005).

Revised 2/2012 Slide 15 of 37

14.330 Soil Mechanics Soil Compaction

EFFECT OF COMPACTION ON COHESIVE SOILS

Unconfined Compression Strength (qu) : Measure of soil strength In general: Increasing w = Decreasing qu Related to soil structure: Dry side Flocculent Wet Side Dispersed

Figure 4.24. Das FGE (2005).

Revised 2/2012 Slide 16 of 37

14.330 Soil Mechanics Soil Compaction

FIELD COMPACTION EQUIPMENT

4 Common Types:

1. Smooth Drum Roller 2. Pneumatic Rubber Tired Roller 3. Sheepsfoot Roller (Tamping Foot) 4. Vibratory Roller (can be 1-3)

Smooth Drum

Pneumatic Rubber Tired

Sheepsfoot

Vibratory Drum

Revised 2/2012

Slide 17 of 37

14.330 Soil Mechanics Soil Compaction

FIELD COMPACTION EQUIPMENT

Photographs courtesy of:

myconstructionphotos.smugmug.com http://cee.engr.ucdavis.edu/faculty/ boulanger/ Holtz and Kovacs (1981)

Revised 2/2012

Slide 18 of 37

14.330 Soil Mechanics Soil Compaction

Equi pme nt typ es

Rammers

Rammers deliver a high impact force (high amplitude) making them an excellent choice for cohesive and semicohesive soils. Frequency range is 500 to 750 blows per minute. Rammers get compaction force from a small gasoline or diesel engine powering a large piston set with two sets of springs. The rammer is inclined at a forward angle to allow forward travel as the machine jumps. Rammers cover three types of compaction: impact, vibration and kneading. [See Figure 17]

MT-76D Diesel-Powered Rammer

FIELD COMPACTION EQUIPMENT

EQUIPMENT TYPES

Fine Grained Soils

Vi bra tory p l a t es

Vibratory plates are low amplitude and high frequency, designed to compact granular soils and asphalt. Gasoline or diesel engines drive one or two eccentric weights at a high speed to develop compaction force. The resulting vibrations cause forward motion. The engine and handle are vibration-isolated from the vibrating plate. The heavier the plate, the more compaction force it generates. Frequency range is usually 2500 vpm to 6000 vpm. Plates used for asphalt have a water tank and sprinkler system to prevent asphalt from sticking to the bottom of the baseplate. Vibration is the one principal compaction effect. [See Figure 17]

MVC-77H Vibratory Plate

Course Grained Soils

Course Re v ersi b l e vi bra tory p l a t es Grained In addition to some of the standard vibratory plate features, reversible plates have two eccentric weights Soils that allow smooth transition for forward or reverse

travel, plus increased compaction force as the result of dual weights. Due to their weight and force, reversible plates are ideal for semi-cohesive soils.

Revised 2/2012

MVH-402DS Reversible Plate

A reversible is possibly the best compaction buy dollar for dollar. Unlike standard plates, the reversibles forward travel may be stopped and the machine will maintain its force for spot compaction.

Figure courtesy of Soil Compaction: A Basic Handbook by MultiQuip.

Figure 17

Slide 19 of 37

14.330 Soil Mechanics Soil Compaction

FIELD COMPACTION EQUIPMENT

from Holtz and Kovacs (1981)

Revised 2/2012 Slide 20 of 37

14.330 Soil Mechanics Soil Compaction

FIELD COMPACTION TESTING

Relative Compaction (R or C.R.):

d ( field ) R(%) = 100 d ,max

5 Common Field Test Methods: 1. Sand Cone (ASTM D1556) 2. Rubber Balloon Method (D2167) 3. Nuclear Density (ASTM D2922) 4. Time Domain Reflectometry (D6780) 5. Shelby Tube (not commonly used)

Revised 2/2012 Slide 21 of 37

14.330 Soil Mechanics Soil Compaction

FIELD COMPACTION TESTING

SAND CONE

(ASTM D1556)

BALLON

(ASTM D2167)

NUCLEAR

(ASTM D2922 & ASTM D3017)

TDR

(ASTM D6780)

METHOD

Advantages

Large Sample Accurate

Large Sample Direct Reading Obtained Open graded material Slow Balloon breakage Awkward Surface not level Soil pumping Void under plate

Fast Easy to re-perform More Tests No sample Radiation Moisture suspect Miscalibration Rocks in path Surface prep req. Backscatter

Fast Easy to re-perform More Tests

Disadvantages

Time consuming Large area required Void under plate Sand bulking Sand compacted Soil pumping

Under research

Errors

Under Research

Revised 2/2012

after Soil Compaction: A Basic Handbook by MultiQuip. Photographs courtesy of Durham Geo/Slope Indicator and myconstructionphotos.smugmug.com.

Slide 22 of 37

14.330 Soil Mechanics Soil Compaction

FIELD COMPACTION TESTING

SAND CONE TEST

Sa nd Cone Test (ASTM D1556-90)

A small hole (6 x 6 deep) is dug in the compacted material to be tested. The soil is removed and weighed, then dried and weighed again to determine its moisture content. A soils moisture is figured as a percentage. The specific volume of the hole is determined by filling it with calibrated dry sand from a jar and cone device. The dry weight of the soil removed is divided by the volume of sand needed to fill the hole. This gives us the density of the compacted soil in lbs per cubic foot. This density is compared to the maximum Proctor density obtained earlier, which gives us the relative density of the soil that was just compacted. [See Figure 12]

mine its moisture content. A soils moistur as a percentage. The specific volume of the determined by filling it with calibrated dry from a jar and cone device. The dry weigh soil removed is divided by the volume of s needed to fill the hole. This gives us the de the compacted soil in lbs per cubic foot. Th is compared to the maximum Proctor dens tained earlier, which gives us the relative d the soil that was just compacted. [See Figu

Nuclear D e nsi ty (ASTM D2922-91)

Nuclear D e nsi ty (ASTM D2922-91)

Figure 12

Soil Modulus (soil sti ffness) NUCLEAR TEST This field-test method is a ver y recent development tions. This is a very fast, safe method of tes that replaces soil density testing. Soil stiffness is the stiffness. Soil stiffness is the desired engine ratio of force-to -displacement. Testing is done by a property, not just dr y density and water co machine that sends vibrations into the soil and then This method is currently being researched me a su r es t he de fl e c t i on o f t he so il f r om t he v i b r a b1990. y the Federal H ighwa yA dm inistration. Figures courtesy of Soil Compaction: A Basic Handbook by MultiQuip and TRB State of the Art Report 8, Slide 23 of 37 Revised 2/2012 8

Sand Cone Method (D1556-07)

Figure 12

Nuclear Density meters are a quick and fairly accurate way of determining density and moisture content. The meter uses a radioactive isotope source NUCLEAR TEST (Cesium 137) at the soil surface (backscatter) or from a probe placed into the soil (direct transmission). The isotope source gives off photons (usually Gamma rays) which radiate back to the meter s detectors on the bottom of the unit. Dense soil absorbs more radiation than loose soil and the readings reflect overall density. Water content (ASTM D3017) can also be read, all within a few minutes. A relative Proctor Density is obtained after comparing maximum density with the compaction results from the test. [See Figure 13] Figure 13

Balloon Method (D2167-08)

Nuclear Density meters are a quick and fa rate way of determining density and mois content. The meter uses a radioactive isoto (Cesium 137) at the soil surface (backscatte a probe placed into the soil (direct transmi isotope source gives off photons (usually G rays) which radiate back to the meter s de the bottom of the unit. Dense soil absorbs radiation than loose soil and the readings overall density. Water content (ASTM D301 be read, all within a few minutes. A relativ Density is obtained after comparing maxim density with the compaction results from t [See Figure 13]

Nuclear Method (D2922-05 & D3017-05)

SOIL COMPACTION HANDBOOK

14.330 Soil Mechanics Soil Compaction

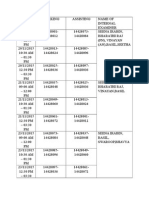

FIELD COMPACTION TESTING FREQUENCIES

Reference Year Roads Buildings or Structures Airfields Embankment Mass Earthwork Canal/Reservoir Linings Trenches & Around Structures Parking Areas Misc.

1 per lift per 300 LF 1 per lift per 10000 SF 1 per areas of doubtful compaction 1 per areas of doubtful compaction 1 per lift per 500 LF 1 per lift per 2500 LF 2000 CY 500 CY

City of Lynchburg

2004 1 per lift per 300 LF 1 per lift per 5000 SF

SCDOT QC

1996 1 per lift per 500 LF

SCDOT QA

1996 1 per lift per 2500 LF

USBR Earth Manual

1998

NAVFAC DM7.02

1986

FM 5-410

1997 1 per lift per 250 LF

1 per lift per 250 LF

1000 CY

500-1,000 CY 1 per lift per 50 LF 1 per lift per 250 SY

200 CY

200-300 CY

Revised 2/2012

Slide 24 of 37

14.330 Soil Mechanics Soil Compaction

FIELD COMPACTION TESTING LIFT HEIGHTS

State DOTs

Maryland, Massachusetts, Montana, North Dakota, Ohio, Oklahoma Connecticut, Kentucky Alabama, Arizona, California, Delaware, Florida, Idaho, Illinois, Indiana, Iowa, Kansas, Maine, Minnesota, Mississippi, Missouri, Oregon, South Carolina, South Dakota, Vermont, Virginia, Washington, Wisconsin Louisiana, New Hampshire, New Jersey, Texas, Wyoming New York

Maximum Lift Height

Max. 0.15 m (6 in) lift before compaction Max. 0.15 m (6 in) lift after compaction Max. 0.2 m (8 in) lift before compaction Max. 0.3 m (12 in) lift before compaction Depends on Soil & Compaction Equipment

Revised 2/2012

After Hoppe (1999), Lenke (2006), and Kim et al. (2009).

Slide 25 of 37

14.330 Soil Mechanics Soil Compaction

COMPACTION CHARACTERISTICS & RATINGS FOR USCS SOILS

USCS Compaction Sym. Equipment GW

Rubber Tired Smooth Drum Vibratory Roller Rubber Tired Smooth Drum Vibratory Roller Rubber Tired Sheepsfoot Rubber Tired Sheepsfoot

d,max

D698 (lb/ft3)

Evaluation for Use as Fill

Compression & Expansion Embankment Subgrade Base Course

125 135

Almost None Almost None

Very Stable

Excellent

Good

GP GM GC

115 125

Reasonably Stable Reasonably Stable Reasonably Stable

Excellent to Good Excellent to Good

Poor to Fair

120 135

Slight

Fair to Poor

115 - 130

Slight

Good

Good to Fair

after U.S. Army Engineer Waterways Experiment Station (now ERDC). (1960). The Unified Soil Classification System, Technical Memorandum No. 3-357, Vicksburg, MS. Revised 2/2012 Slide 26 of 37

14.330 Soil Mechanics Soil Compaction

COMPACTION CHARACTERISTICS & RATINGS FOR USCS SOILS

USCS Compaction Sym. Equipment SW SP SM SC

Rubber Tired Vibratory Roller Rubber Tired Vibratory Roller Rubber Tired Sheepsfoot Rubber Tired Sheepsfoot

d,max

D698 (lb/ft3)

Evaluation for Use as Fill

Compression & Expansion Embankment Subgrade Base Course

110-130

Almost None Almost None

Very Stable Reasonable stable when dense Reasonable stable when dense Reasonable stable

Good

Fair to Poor

100-120

Good to Fair Good to Fair Good to Fair

Poor

110-125

Slight

Poor

105-125

Slight to Medium

Fair to Poor

after U.S. Army Engineer Waterways Experiment Station (now ERDC). (1960). The Unified Soil Classification System, Technical Memorandum No. 3-357, Vicksburg, MS. Revised 2/2012 Slide 27 of 37

14.330 Soil Mechanics Soil Compaction

COMPACTION CHARACTERISTICS & RATINGS FOR USCS SOILS

USCS Compaction Sym. Equipment ML CL MH CH

Rubber Tired Sheepsfoot Sheepsfoot Rubber Tired Sheepsfoot Rubber Tired

d,max

D698 (lb/ft3)

Evaluation for Use as Fill

Compression & Expansion Embankment Subgrade Base Course

95-120

Slight to Medium

Poor Stability

Fair to Poor

Not Suitable Not Suitable Not Suitable Not Suitable

95-120

Medium

Good Stability Poor Stability Should not be used Fair Stability

Fair to Poor

70-95

High

Poor

Sheepsfoot

80-105

Very high

Poor to Very Poor

after U.S. Army Engineer Waterways Experiment Station (now ERDC). (1960). The Unified Soil Classification System, Technical Memorandum No. 3-357, Vicksburg, MS. Revised 2/2012 Slide 28 of 37

14.330 Soil Mechanics Soil Compaction

DYNAMIC COMPACTION

2. Deep Dynamic Compaction Insitu densification of loose soils using Deep Dynamic Compaction (DDC) is accomplished by impacting the ground with a heavy tamper. The depth of improvement and the degree of densification can be varied through the weight of the hammer, the drop height and the spacing between drops. The energy is generally applied in phases on a grid pattern over the area to be improved using either single or multiple passes. A schematic of a typical DDC setup with an accompanying photograph of the project setup is presented in Figure 3. The technique has been used successfully in a wide variety of projects (e.g. Dise et al., 1994 ; Meyer et al., 2001). The technique is described in detail by Leonards et al. (1980) and the United states Federal Highway Administration (FHWA, 1995), while ground response to DDC is discussed by Mayne et al. (1984).

Figure courtesy of www.betterground.com

Figure 1. FHWA-SA-95-037.

Figure 3. Typical DDC Setup (after FHWA, 1995).

US44 Expansion Carver, MA.

Slide 29 of 37

Revised 2/2012 For densification to be effective, the deposit to be compacted should be relatively permeable

so excess pore pressures that are generated during densification can dissipate quickly, thereby allowing the soil particles to move into a denser state of packing (FHWA, 1995). Deep dynamic compaction is typically performed on loose granular soil deposits that are relatively permeable, although DDC has been performed on other soil types such as silts (Dumas et al., 1994) and

14.330 Soil Mechanics Soil Compaction

DYNAMIC COMPACTION

Revised 2/2012

after Figure 5 (FHWA-SA-95-037).

Slide 30 of 37

14.330 Soil Mechanics Soil Compaction

DYNAMIC COMPACTION US44

Revised 2/2012

Slide 31 of 37

14.330 Soil Mechanics Soil Compaction

DYNAMIC COMPACTION US44

Revised 2/2012

(from Hajduk et al., 2004)

Slide 32 of 37

4. Examination of the difference in shear wave velocities (i.e. Vs) at constant elevation. Analysis of the corrected tip resistance results showed that with the expectation of a few isolated areas, the DDC improved the soil such that the minimum corrected tip resistance of 7.66 MPa (80 tsf) was achieved Soil within the placed fill. The qt values these isolated areas 14.330 Mechanics Soil within Compaction were within 0.1 MPa (1.0 tsf) of the minimum required value and ranged less than 0.3m (1ft) in height. Since these isolated areas were not considered to adversely affect the project, additional DDC was not recommended. Typical qt results from the Initial and Verification I testing phases are presented in Figure 6.

DYNAMIC COMPACTION US44

Figure 6. Typical Initial and Verification Phase Results. (from Hajduk Iet al., CPT 2004) of the difference in qt values ( qt) at constant elevation was achieved by calculating the change in qt at 10cm (3.94 inch) intervals between similar CPT locations for each CPT sounding at the same elevation. These changes were then averaged with depth.

Revised 2/2012 Examination Slide 33 of 37

14.330 Soil Mechanics Soil Compaction

VIBROFLOTATION

Photograph courtesy of http://www.vibroflotation.com

Figure 4.18. Das FGE (2005) (after Brown, 1977).

Revised 2/2012 Slide 34 of 37

14.330 Soil Mechanics Soil Compaction

VIBROFLOTATION

Figure 4.19. Das FGE (2005) (after Brown, 1977)

Revised 2/2012

Slide 35 of 37

14.330 Soil Mechanics Soil Compaction

Vibroflotation Probe Spacing

Figure 4.20. Das FGE (2005).

Vibroflotation Effective Grain Size Distributions

Figure 4.21. Das FGE (2005).

Revised 2/2012 Slide 36 of 37

14.330 Soil Mechanics Soil Compaction

COMPACTION ASSOCIATED COSTS

Figure courtesy of www.groundimprovement.ch.

Revised 2/2012 Slide 37 of 37

S-ar putea să vă placă și

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsDe la EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechÎncă nu există evaluări

- Shallow Foundations: Discussions and Problem SolvingDe la EverandShallow Foundations: Discussions and Problem SolvingEvaluare: 5 din 5 stele5/5 (1)

- Ce 481 Shear Strength 3Document103 paginiCe 481 Shear Strength 3phan phucÎncă nu există evaluări

- BS ConsolidationDocument25 paginiBS ConsolidationKamukwema johnÎncă nu există evaluări

- Modeling Soil and Rock with PlaxisDocument24 paginiModeling Soil and Rock with Plaxismivos4Încă nu există evaluări

- Foundation Behaviour Below An Embankment On Soft SoilsDocument9 paginiFoundation Behaviour Below An Embankment On Soft SoilsLuca BrandiÎncă nu există evaluări

- Chapter 15 Shallow Foundations - 02242010Document8 paginiChapter 15 Shallow Foundations - 02242010Tolaz KoyiÎncă nu există evaluări

- Effect of Soil on Drainage GeocompositesDocument14 paginiEffect of Soil on Drainage GeocompositesHarsha TejaÎncă nu există evaluări

- Vane Shear Test: Quickly Measure Clay Soil Shear Strength in 38 CharactersDocument7 paginiVane Shear Test: Quickly Measure Clay Soil Shear Strength in 38 CharactersAriffudinAliÎncă nu există evaluări

- Ground ImprovementDocument17 paginiGround Improvementpatelahmad77Încă nu există evaluări

- Foundations On Soft Soils For Khulna MedicalDocument6 paginiFoundations On Soft Soils For Khulna MedicalJahid Jahidul Islam KhanÎncă nu există evaluări

- Assessing Empirical Equations for Compression Index of Fine-Grained SoilsDocument12 paginiAssessing Empirical Equations for Compression Index of Fine-Grained Soilstayour007Încă nu există evaluări

- CEN-622 Advanced Foundation Engineering: By: Anumita MishraDocument31 paginiCEN-622 Advanced Foundation Engineering: By: Anumita Mishraabcd efghÎncă nu există evaluări

- Learning Outcomes: Fakulti Kejuruteraan Awam Universiti Teknologi MaraDocument3 paginiLearning Outcomes: Fakulti Kejuruteraan Awam Universiti Teknologi MaranurulselangorÎncă nu există evaluări

- Lab 8 - Ciu, Cid Triaxial TestDocument7 paginiLab 8 - Ciu, Cid Triaxial TestAmirah Shafeera0% (1)

- In Situ Testing For Highways and Runways Shukla Sivakugan 2009Document6 paginiIn Situ Testing For Highways and Runways Shukla Sivakugan 2009Marcus Vinicius100% (1)

- Geogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFDocument115 paginiGeogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFChan Hoi KitÎncă nu există evaluări

- Computers and Geotechnics: Sari W. Abusharar, Jun-Jie Zheng, Bao-Guo ChenDocument10 paginiComputers and Geotechnics: Sari W. Abusharar, Jun-Jie Zheng, Bao-Guo ChenIrvin AlbertoÎncă nu există evaluări

- ICE Paper - To Teach or Not To Teach - From Theory To PracticeDocument9 paginiICE Paper - To Teach or Not To Teach - From Theory To PracticeBobbyÎncă nu există evaluări

- Evaluation of SHANSEP Parameters For Soft Bonneville ClaysDocument67 paginiEvaluation of SHANSEP Parameters For Soft Bonneville ClaysAmanda Cervantes100% (1)

- Bearing Capacity of Rock Foundations GuideDocument19 paginiBearing Capacity of Rock Foundations GuideAhmad PooladiÎncă nu există evaluări

- Correlation Between Soaked CBR Value and CBR Obtained With DCPDocument8 paginiCorrelation Between Soaked CBR Value and CBR Obtained With DCPIvan MasubaÎncă nu există evaluări

- Cegb3014 Module 3 Slope StabilityDocument76 paginiCegb3014 Module 3 Slope StabilityMAAbuBakar100% (1)

- Triaxial Testing of Granular Soil (Colliat-Dangus, 1988)Document21 paginiTriaxial Testing of Granular Soil (Colliat-Dangus, 1988)Abraham FIgueroa ARevaloÎncă nu există evaluări

- Constitutive Relations For Soil Materials PDFDocument44 paginiConstitutive Relations For Soil Materials PDFalemorver100% (1)

- Methods for Measuring Soil Consolidation RateDocument4 paginiMethods for Measuring Soil Consolidation RateSiva JothiÎncă nu există evaluări

- Microsoft Word - 20080820 Overview of Vibro Compaction and Dynamic Compaction - 3Document9 paginiMicrosoft Word - 20080820 Overview of Vibro Compaction and Dynamic Compaction - 3nn-85614Încă nu există evaluări

- CE5101 Lecture 6 - 1D Consolidation - Terzhagi Theory (OCT 2013)Document75 paginiCE5101 Lecture 6 - 1D Consolidation - Terzhagi Theory (OCT 2013)Melinda GordonÎncă nu există evaluări

- Bearing Capacity of Shallow FoundationDocument59 paginiBearing Capacity of Shallow FoundationSyafiq Azman100% (1)

- Deep Excavation via Soil Nailing Saves CostsDocument19 paginiDeep Excavation via Soil Nailing Saves CostsgahsoonÎncă nu există evaluări

- ICE Lecture #8 Geotechnical EngineeringDocument47 paginiICE Lecture #8 Geotechnical Engineeringshahid aliÎncă nu există evaluări

- Compaction: Soil Densification TechniquesDocument43 paginiCompaction: Soil Densification TechniquesDhankotmaÎncă nu există evaluări

- Challenges Associated With Expansive Soils and Remedial MeasuresDocument13 paginiChallenges Associated With Expansive Soils and Remedial MeasuresSaurav BhattacharjeeÎncă nu există evaluări

- O-Cell® Load Testing For Drilled Shafts and Acip PilesDocument53 paginiO-Cell® Load Testing For Drilled Shafts and Acip PilesJose Eduardo GomezÎncă nu există evaluări

- Session 5 - 6 Bearing Capacity of Shallow Foundation: Course: S0484/Foundation Engineering Year: 2007: 1/0Document41 paginiSession 5 - 6 Bearing Capacity of Shallow Foundation: Course: S0484/Foundation Engineering Year: 2007: 1/0rasputin0780803494Încă nu există evaluări

- Soil Mechanics FundamentalsDocument111 paginiSoil Mechanics FundamentalsRaju VilasÎncă nu există evaluări

- Soil CompactionDocument24 paginiSoil Compactionsyah123Încă nu există evaluări

- Compression IndexDocument3 paginiCompression IndexTran Nguyen100% (3)

- CE325 - 06 Immediate SettlementDocument45 paginiCE325 - 06 Immediate SettlementRobert PrinceÎncă nu există evaluări

- Introduction to Ground Modification TechniquesDocument18 paginiIntroduction to Ground Modification TechniquesAli naveedÎncă nu există evaluări

- State of The Practice of Rigid Inclusions - 3-17-2021Document11 paginiState of The Practice of Rigid Inclusions - 3-17-2021Tanju Tahir Ökten100% (1)

- Shallow Foundation On Soil LayersDocument16 paginiShallow Foundation On Soil Layersdewishintakahlilsudoyo100% (1)

- Jamuni River Geotech ReportDocument58 paginiJamuni River Geotech ReportRoshan KejariwalÎncă nu există evaluări

- Validation and Application of the Embedded Pile Row Feature in PLAXIS 2DDocument4 paginiValidation and Application of the Embedded Pile Row Feature in PLAXIS 2DhapsinteÎncă nu există evaluări

- ECG303 - BASIC SOIL MECHANICS: CONSOLIDATION AND COMPACTIONDocument90 paginiECG303 - BASIC SOIL MECHANICS: CONSOLIDATION AND COMPACTIONMukhriz Mansor0% (1)

- Geotech Vane Shear TestDocument78 paginiGeotech Vane Shear Test'Sayed AsadullahÎncă nu există evaluări

- Soil Swelling Test MethodsDocument5 paginiSoil Swelling Test MethodswoimonyetÎncă nu există evaluări

- Chapter11 Coduto CompressibilityAndSettlementDocument160 paginiChapter11 Coduto CompressibilityAndSettlementTuğçe TürkanÎncă nu există evaluări

- Direct Shear Box and Ring Shear Test: Why Internal Friction VariesDocument17 paginiDirect Shear Box and Ring Shear Test: Why Internal Friction VariesBarry OcayÎncă nu există evaluări

- Practical Design Short Course on Geotechnical EngineeringDocument6 paginiPractical Design Short Course on Geotechnical EngineeringchinhonÎncă nu există evaluări

- On Estimating Slope Stability Reduction Due To Rain Infiltration MoundingDocument36 paginiOn Estimating Slope Stability Reduction Due To Rain Infiltration MoundingSuvadeep DalalÎncă nu există evaluări

- Introduction To Geotechnical Engineering: GroundDocument56 paginiIntroduction To Geotechnical Engineering: GroundlilachetanÎncă nu există evaluări

- GEOTECH2Document10 paginiGEOTECH2Kurt Juden Abrio PardoÎncă nu există evaluări

- Correlations With Penetration Test ResultsDocument7 paginiCorrelations With Penetration Test ResultsMohammed Faisal TÎncă nu există evaluări

- Application of Controlled Modulus Columns For Refinery and Petrochemical Tank FarmDocument14 paginiApplication of Controlled Modulus Columns For Refinery and Petrochemical Tank FarmJosep Maria100% (1)

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980De la EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Încă nu există evaluări

- Finite Element Formulation of Structural ElementsDocument1 paginăFinite Element Formulation of Structural ElementsAnu VishnuÎncă nu există evaluări

- 004 Humanities.5-20Document31 pagini004 Humanities.5-20Anu VishnuÎncă nu există evaluări

- KTU-scheme-Civil 3rd To 8th16dec - 2015Document5 paginiKTU-scheme-Civil 3rd To 8th16dec - 2015Anu VishnuÎncă nu există evaluări

- Structural Steel Design Project: Worked Example 1Document5 paginiStructural Steel Design Project: Worked Example 1Yiu Fai WongÎncă nu există evaluări

- Civil Engineering Kerala SyllabusDocument120 paginiCivil Engineering Kerala SyllabusJinu MadhavanÎncă nu există evaluări

- 10 Flooring Types & MaterialsDocument6 pagini10 Flooring Types & MaterialsAnvi GandhiÎncă nu există evaluări

- Khosla's TheoryDocument18 paginiKhosla's TheoryAnu Vishnu100% (1)

- Steel ExamplesDocument3 paginiSteel Examplesrasiq7Încă nu există evaluări

- Interlocking PDFDocument37 paginiInterlocking PDFAnu VishnuÎncă nu există evaluări

- Reduce Rail Creep with Creep IndicatorsDocument24 paginiReduce Rail Creep with Creep IndicatorsAnu VishnuÎncă nu există evaluări

- Crossing and Design of Turnout PDFDocument34 paginiCrossing and Design of Turnout PDFAnu VishnuÎncă nu există evaluări

- Part A: (Answer All Questions. Each Question Carries 4 Marks)Document2 paginiPart A: (Answer All Questions. Each Question Carries 4 Marks)Anu VishnuÎncă nu există evaluări

- s3 Btech Civl Eng PDFDocument14 paginis3 Btech Civl Eng PDFAnu VishnuÎncă nu există evaluări

- Request LetterDocument1 paginăRequest LetterAnu VishnuÎncă nu există evaluări

- S1S2 EeeDocument1 paginăS1S2 EeeAnu VishnuÎncă nu există evaluări

- Monsoon 2013Document2 paginiMonsoon 2013comeondudeffÎncă nu există evaluări

- LAB RequirementsDocument4 paginiLAB RequirementsAnu VishnuÎncă nu există evaluări

- AE Municipal Common Service PDFDocument14 paginiAE Municipal Common Service PDFAnu VishnuÎncă nu există evaluări

- Lec 12Document14 paginiLec 12Anu VishnuÎncă nu există evaluări

- AE Hydrology PDFDocument12 paginiAE Hydrology PDFAnu VishnuÎncă nu există evaluări

- MQP s5 Environmental Engineering PDFDocument2 paginiMQP s5 Environmental Engineering PDFAnu VishnuÎncă nu există evaluări

- Survey Lab ExamDocument2 paginiSurvey Lab ExamAnu VishnuÎncă nu există evaluări

- MQP s5 Water Resource Engeenring PDFDocument3 paginiMQP s5 Water Resource Engeenring PDFAnu VishnuÎncă nu există evaluări

- MS Thesis Bozkurt MerveGizemDocument136 paginiMS Thesis Bozkurt MerveGizemAnu VishnuÎncă nu există evaluări

- Commonwealth Games 2014 - Full India Schedule - IBNLiveDocument12 paginiCommonwealth Games 2014 - Full India Schedule - IBNLiveAnu VishnuÎncă nu există evaluări

- EJGE of The EdgeDocument11 paginiEJGE of The Edgechondroc11Încă nu există evaluări

- Second Phase Option Mal NotiDocument2 paginiSecond Phase Option Mal NotiAnu VishnuÎncă nu există evaluări

- CAMPUS09 Pesentation Panagiotis PapakosDocument23 paginiCAMPUS09 Pesentation Panagiotis PapakosAnu VishnuÎncă nu există evaluări

- A Novel Technique For Monitoring Contaminant Transport Through SoilsDocument14 paginiA Novel Technique For Monitoring Contaminant Transport Through SoilsAnu VishnuÎncă nu există evaluări

- StabilizationDocument57 paginiStabilizationAnu VishnuÎncă nu există evaluări

- S001Document1 paginăS001Yong Hui OngÎncă nu există evaluări

- The Effect of Aggregate Size On The Use of The Cylinder Splitting Test As A Measure of Tensile StrengthDocument7 paginiThe Effect of Aggregate Size On The Use of The Cylinder Splitting Test As A Measure of Tensile StrengthRoberto UrrutiaÎncă nu există evaluări

- Fiber Reinforced Concrete - Types, Properties and AdvantagesDocument17 paginiFiber Reinforced Concrete - Types, Properties and AdvantagesAbuBakerÎncă nu există evaluări

- Design of Beams With HolesDocument7 paginiDesign of Beams With Holes01010Încă nu există evaluări

- Constec3 Retaining WallDocument9 paginiConstec3 Retaining WallHakimi RizqyÎncă nu există evaluări

- PNS Rebar Grades and SpecificationsDocument4 paginiPNS Rebar Grades and SpecificationsAnthony AngelesÎncă nu există evaluări

- Philosophers StoneDocument5 paginiPhilosophers Stonetravellerfellow100% (1)

- Torsional Behavior of Steel Fiber Reinforced Concrete BeamsDocument7 paginiTorsional Behavior of Steel Fiber Reinforced Concrete BeamssokamantyÎncă nu există evaluări

- Behaviour of Concrete With Partial Replacement of Cement by Different Mineral Admixtures and Partial Replacement of Fine Aggregate by Optical FiberDocument10 paginiBehaviour of Concrete With Partial Replacement of Cement by Different Mineral Admixtures and Partial Replacement of Fine Aggregate by Optical FiberEditor IJTSRDÎncă nu există evaluări

- Effect of Nanoparticle Addition On Polymethylmethacrylate ResinsDocument7 paginiEffect of Nanoparticle Addition On Polymethylmethacrylate ResinsR RahmadaniÎncă nu există evaluări

- 21 27 Bulk Density Apparatus TMIDocument2 pagini21 27 Bulk Density Apparatus TMIMauricio CarestiaÎncă nu există evaluări

- Solid State ChemistryDocument105 paginiSolid State ChemistryNishit Kumar100% (1)

- Chapter 6 Mechanical Behavior of MaterialsDocument46 paginiChapter 6 Mechanical Behavior of Materialsmuhammad haris100% (1)

- Important Compatability Superlasticizes Portland CementDocument23 paginiImportant Compatability Superlasticizes Portland CementAliAliÎncă nu există evaluări

- M'hamed Bougara University 3rd International Symposium Materials Sustainable DevelopmentDocument2 paginiM'hamed Bougara University 3rd International Symposium Materials Sustainable DevelopmentIsmahene SmahenoÎncă nu există evaluări

- High Strength Epoxy Paste for RepairsDocument2 paginiHigh Strength Epoxy Paste for Repairsosama mohÎncă nu există evaluări

- Magnets Test - Key Facts About Magnets and Their PropertiesDocument5 paginiMagnets Test - Key Facts About Magnets and Their Propertiessian017Încă nu există evaluări

- Tex-601-J, Sampling and Testing Elastomeric Materials: ContentsDocument7 paginiTex-601-J, Sampling and Testing Elastomeric Materials: Contentsraviteja036Încă nu există evaluări

- Bearing Reference Guide NSK 2016Document30 paginiBearing Reference Guide NSK 2016LeroyÎncă nu există evaluări

- Final Report EditedDocument46 paginiFinal Report EditedAXCÎncă nu există evaluări

- Modern Control Tutorial 7 Presentation 390 (1) 408Document23 paginiModern Control Tutorial 7 Presentation 390 (1) 408Michael HannaÎncă nu există evaluări

- Motivation For Hydraulic Transient AnalysisDocument14 paginiMotivation For Hydraulic Transient AnalysisDeepak JoyÎncă nu există evaluări

- Design RCC StructuresDocument2 paginiDesign RCC StructuresprashmceÎncă nu există evaluări

- Working Stress DesignDocument4 paginiWorking Stress DesignUopEmptyÎncă nu există evaluări

- Cmi215.2017 - Guia TTDocument9 paginiCmi215.2017 - Guia TTalex123456789009850% (2)

- Stainless Steel Pipe and Tube SpecificationsDocument10 paginiStainless Steel Pipe and Tube SpecificationsDIBYENDU MONDALÎncă nu există evaluări

- Microstructural Examination of Ceramic MaterialDocument16 paginiMicrostructural Examination of Ceramic MaterialRudrang ChauhanÎncă nu există evaluări

- Magnetic SeparationDocument6 paginiMagnetic SeparationnomanhaimourÎncă nu există evaluări

- Essentials CatalogueDocument91 paginiEssentials CatalogueigusukÎncă nu există evaluări