Documente Academic

Documente Profesional

Documente Cultură

Api 653 Preparatory Course: Final Exam - Open Book

Încărcat de

raobabar21Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Api 653 Preparatory Course: Final Exam - Open Book

Încărcat de

raobabar21Drepturi de autor:

Formate disponibile

Professional Training and Consultation

15 20 May 2004, Dammam

API 653 PREPARATORY COURSE

Final Exam Open Book

1. Exclusive of corrosion allowance, what is the minimum nominal thickness for all new construction bottom plates? a. b. c. d. 2. inch inch 3/16 inch 5/8 inch

For new or repaired shell horizontal joints, how many radiographs shall be taken for each 50 feet of horizontal joint, not including those required at intersection of vertical and horizontal joints? a. b. c. d. 1 2 3 4

3.

The recommended minimum development time (penetrant testing ) allowed for a material made of high temperature alloy is: a. b. c. d. 5 min 10 min 7 min 60 min

4.

Select suitable Hole type (source side) penetrameter for following weld joint Weld reinf. = 1/8"

7/8 "

z a) a) No 20

Backing strip = 3/16 " thk

/var/www/apps/conversion/tmp/scratch_4/166696426.doc Created by Narciso

Page 1 of 8

Professional Training and Consultation

15 20 May 2004, Dammam

b) c) d) 5.

No 25 No 30 None of the above

If type of penetrameter is Q.1 is changed to wire type what shall be the wire designation (wire decimeter in inch) a. b. c. d. 0.025 (NO. 10) 0.016 (NO. 8) 0.032 (NO. 11) none of the above

6.

For steel plates and weld to be checked LPI, what shall be the penetration time for penetrant a. b. c. d. 10 min for weld, 5 min for plate 5 min for both 10 min for both 5 min for weld, 10 min for plate

7.

After applying the developer the examiner checked four welds for surface defects after following period, weld A- after 5 minute, weld B after 10 minute, weld C was checked after 30 minutes and weld D after 65 minutes which of the weld were checked wrongly a. b. c. d. weld weld weld weld A and B C and D D only A and D

8.

Following combination of base metal and welding electrode was qualified by a certain PQR impact testing is not required. Base Metal =SA 285 GrC Plates, thk Welding electrode = AWS E 6015 This PQR will qualify which of the following combination of base metal- welding electrodes.

/var/www/apps/conversion/tmp/scratch_4/166696426.doc Created by Narciso

Page 2 of 8

Professional Training and Consultation

15 20 May 2004, Dammam

a. b. c. d. 9.

1 thk SA 515Gr 60 plates, E 6013 electrodes 1 rhk SA 285 GrC plates, E 6013 electrodes 1 thk plates SA 516Gr70, E 7018 electrodes None of the above

For MT examination by prod techniques the spacing between prods shall be between a. b. c. d. 4 4 3 3 inch inch inch inch to to to to 12 inch 10 inch 10 inch 8 inch

10. For a tank with 130 ft diameter thickness of top course worked out was td=5mm tt=4mm. What will be minimum nominal thickness provided for this course according to API 650 for a new tank? a. b. c. d. 3/16 (5mm) 1/4 (6mm) 5/16 (8mm) None of the above

11. For a tank with diameter 100ft was found to have thickness reduction in a localized area. Minimum thickness observed (t2) was 1 inch. What will be the minimum vertical length of for the area? a. b. c. d. 40 inches 37 inches 45 inches None of the above

12. On a tank roof plate two corroded areas was observed at locations A and B for location A, average thickness = 0.085 inches, area = 105 in2 Location B, average thickness = 0.095 inches, Area = 105 in2 your decision will be:

/var/www/apps/conversion/tmp/scratch_4/166696426.doc Created by Narciso

Page 3 of 8

Professional Training and Consultation

15 20 May 2004, Dammam

a. b. c. d.

Both A and B are within limits Location A is OK, location B is art of limits Both A and B are out of limits Location B in OK, location A is out of limits

13. Hot tap connection is to be made on tank with following description shell plate thickness = inch. Design temperature =30F the plates were not tested for impact testing, (Consr. Code API 650-1974). What will be the maximum size of tapping connection? a. 8 inches NPS b. 6 inches NPS c. 10 inches NPS d. 4 inches NPS 14. A replacement plate to be used on a shell thickness of 5/8 inch, on the second course of the tank. Thickness of first course and third course is also 5/8 inch. Following 3 plates are available which one is most suitable to be used as replacement plate. a. b. c. d. Plate Plate Plate Plate thickness thickness thickness thickness = = = = 5/8 1/2 1

15. A tank is having remaining corrosion allowance of 2.5mm and corrosion rate of the shell is 0.1mm per year. What will be inspection interval for next ultrasonic thickness inspection from outside of the tank? a. b. c. d. 15 Years 12.5 Years 10 Years 5 Years

16. Typical corroded areas on a shell plate are exhibited below in figure 1 with measured thickness in inches indicated on the sketch. The un-corroded thickness of the shell palte is 0.750 inches and C.A is 0.125

/var/www/apps/conversion/tmp/scratch_4/166696426.doc Created by Narciso

Page 4 of 8

Professional Training and Consultation

15 20 May 2004, Dammam

Figure 1 AREA A 0.65 0.66 0.72 0.54 0.75 0.72 0 0.66 AREA C AREA B

0.75 The total length of a arrow line drawn is 8 inches. The length of the line in each of the corroded areas A, B and C are 1.5, 0.8 and 0.5 inches respectively. Comment on the acceptability of the corroded condition. a. The pitting can be ignored as a case of widely scattered pitting as both pitting depth and dimensions are within limits Not acceptable as size are not OK, total length of the pit dimensions is more than permitted The pitting can be ignored as a case of widely scattered pitting since depth are OK

b. c.

/var/www/apps/conversion/tmp/scratch_4/166696426.doc Created by Narciso

Page 5 of 8

Professional Training and Consultation

15 20 May 2004, Dammam

d.

The pitting cannot be ignored as a case of widely scattered pitting since depth are not OK

17. Two plates sample A and B were tested for longitudinal impact testing. Following were results observed. They belonged to Group No. I as per API 650: Results of impact test for sample A were 18ft lb, 8ft lb, 16ft lb. Results on sample B: 12ft lb, 14ft lb, 20 ft. lb Your assessment will be: a. b. c. d. sample sample sample sample A and B both OK A and B both to be re-tested B is OK, A shall be re-tested a is OK, B shall be re-tested

18. For replacement to an existing 0.25 thick shell plate of an AST, another plate of 0.25 thickness to ASTM A36 is used. What should be the minimum clear distance between the outer edges of the adjacent but welds of vertical and horizontal joints, respectively? a. b. c. d. 10 & 6 6 & 3 8 & 4 12 & 6

19. Repair of a 5/8 thick shell, using lapped (lap welded) patch plate of 1/8 thick was carried out, without informing the Owner. Such a repair is not acceptable as per API standard 653, because: a. b. c. d. Owner had not specified use of patch plate repairs Lap patch plate of less than 3/16 is not permitted Lap patch plate repair on shell thickness more than above is not permitted All of above

/var/www/apps/conversion/tmp/scratch_4/166696426.doc Created by Narciso

Page 6 of 8

Professional Training and Consultation

15 20 May 2004, Dammam

20.

As per API Standard 650, the offset between vertical seams of adjacent shells shall be a minimum distance of: a. 5 t, where t is the plate thickness of thicker shell course at the offset b. 4t, where t is the plate thickness of thicker shell course at the offset c. 3 t, where t is the plate thickness of thicker shell course at the offset d. 2 t, where t is the plate thickness of thicker shell course at the offset

21.

When butt welded annular bottom plates are used, in an AST built to API Standard 650, their width from inside of the shell shall be at least: a. b. c. d. 900 mm 300 mm 600 mm None of the above

22.

Misalignment in a completed 20 mm thick vertical seam of an AST built to API Standard 650 shall be more than: a. b. c. d. 2 mm 1.5 mm 0.8 mm 3 mm

23.

Out of roundness measured as deviation from radius measured 1 foot above the bottom corner weld of a 250 ft diameter AST built to API Standard 650, shall not exceed: a. b. c. d. 1 (25 mm) (12.7 mm) (19 mm) 1-1/4 (32 mm)

/var/www/apps/conversion/tmp/scratch_4/166696426.doc Created by Narciso

Page 7 of 8

Professional Training and Consultation

15 20 May 2004, Dammam

24. Local deviations from theoretical shape of an aboveground storage tank (AST), built to API Standard 650, specifically Peaking at vertical joints or Banding at horizontal weld joints as measured over an appropriate sweepboard of 36 shall not exceed: a. b. c. d. 19 mm (3/4) 13 mm (1/2) 16 mm (5/8) 1/8 mm (3)

25. An AST has remaining corrosion allowance of 3.2 mm. The known rate of corrosion of shell is 200 microns per year. As per API Standard 653, when should the external visual inspection by an Authorized Inspector shall be carried out at an interval not exceeding: a. b. c. d. 5 years 8 years 4 years 15 years

/var/www/apps/conversion/tmp/scratch_4/166696426.doc Created by Narciso

Page 8 of 8

S-ar putea să vă placă și

- Compressor ChecklistDocument5 paginiCompressor ChecklistJuanPabloAlvarezÎncă nu există evaluări

- API 653 PC Final OpenDocument7 paginiAPI 653 PC Final OpenMuhammad Nozar100% (1)

- Agma 9002-A86 Inch Bore and Ansi b17.1Document6 paginiAgma 9002-A86 Inch Bore and Ansi b17.1k21p81100% (2)

- P P NG Abbrev at Ons: AFC A F CDocument11 paginiP P NG Abbrev at Ons: AFC A F COlajide AkekeÎncă nu există evaluări

- Writen Practice of Qualification and Certification SHDocument15 paginiWriten Practice of Qualification and Certification SHSisira Chandrasoma100% (3)

- Ipc2012 90690Document12 paginiIpc2012 90690Marcelo Varejão CasarinÎncă nu există evaluări

- Daily Exam 7 (Closed) : Professional Training and ConsultationDocument5 paginiDaily Exam 7 (Closed) : Professional Training and ConsultationCss SfaxienÎncă nu există evaluări

- API 580 PoliciesDocument4 paginiAPI 580 PoliciesMehmet SoysalÎncă nu există evaluări

- Intro API 570Document2 paginiIntro API 570Javier Eduardo Morales MelgarÎncă nu există evaluări

- How To Study For IIT JEE in 6 MonthsDocument2 paginiHow To Study For IIT JEE in 6 MonthsShreyans JainÎncă nu există evaluări

- 0510 English As A Second Language: MARK SCHEME For The October/November 2015 SeriesDocument13 pagini0510 English As A Second Language: MARK SCHEME For The October/November 2015 SeriesChernYangEeÎncă nu există evaluări

- Allowed To Use The ASME Codes and The API Books On The First Portion of The Test Only. No ReferenceDocument209 paginiAllowed To Use The ASME Codes and The API Books On The First Portion of The Test Only. No Referencejay2kay5793Încă nu există evaluări

- API 653 QuestionsDocument4 paginiAPI 653 QuestionsRama Jeyam100% (6)

- Qame Form 2Document6 paginiQame Form 2Gen Li Togy100% (2)

- Final Exam (Open) : InstructionsDocument8 paginiFinal Exam (Open) : InstructionssujadevÎncă nu există evaluări

- Examen Parte CDocument7 paginiExamen Parte CIsmael HernándezÎncă nu există evaluări

- API 570 Mock Up Closed Book Questions 25Document18 paginiAPI 570 Mock Up Closed Book Questions 25Ravindra S. Jivani100% (1)

- Cape Economics Sba Outline 1Document3 paginiCape Economics Sba Outline 1Carlos WebsterÎncă nu există evaluări

- Forensic 3 Forensic Chemistry and ToxicologyDocument4 paginiForensic 3 Forensic Chemistry and Toxicologyrenjomar83% (6)

- API Standard 653, Tank Inspection, Repair, Alteration, and ReconstructionDocument14 paginiAPI Standard 653, Tank Inspection, Repair, Alteration, and ReconstructionSaqib KhanÎncă nu există evaluări

- Sample Questions For API 570 EDocument14 paginiSample Questions For API 570 Eمبشر أحمدÎncă nu există evaluări

- Closed Book Questions For Api 575Document25 paginiClosed Book Questions For Api 575vamsikrishna100% (1)

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 paginiSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemÎncă nu există evaluări

- API-510 Pressure Vessel Inspector Preparatory Training Program Final Exam - (Close Book)Document3 paginiAPI-510 Pressure Vessel Inspector Preparatory Training Program Final Exam - (Close Book)Ali AhmedÎncă nu există evaluări

- nb-3216.2 MIT 2007Document23 pagininb-3216.2 MIT 2007adel_izadbakhshÎncă nu există evaluări

- AE6007 Fatigue and Fracture PDFDocument53 paginiAE6007 Fatigue and Fracture PDFJustin RajaÎncă nu există evaluări

- API 510 Final Answer Closed Book1Document1 paginăAPI 510 Final Answer Closed Book1Nsidibe Michael EtimÎncă nu există evaluări

- Daily Points To Recall (Day 1) : Professional Training and ConsultationDocument3 paginiDaily Points To Recall (Day 1) : Professional Training and ConsultationshakeelahmadjsrÎncă nu există evaluări

- Api 653 Daily Points To Recall (Day 3)Document2 paginiApi 653 Daily Points To Recall (Day 3)Naveed Ahmed100% (1)

- API 510 Effectivity SheetDocument1 paginăAPI 510 Effectivity Sheetamalhaj2013Încă nu există evaluări

- API 580 Program InformationDocument1 paginăAPI 580 Program InformationAbu Huraira100% (1)

- Canada Skilled Worker Visa Application Pack 9111ehDocument27 paginiCanada Skilled Worker Visa Application Pack 9111ehJames Ojegbemi100% (2)

- Unit 3 Professional PracticeDocument8 paginiUnit 3 Professional PracticemikeÎncă nu există evaluări

- Erf and Reclassification of Positions RequirementsDocument14 paginiErf and Reclassification of Positions RequirementsDaisylyn AnicetoÎncă nu există evaluări

- API 510 Inspector Certification RequirementsDocument2 paginiAPI 510 Inspector Certification RequirementsINSTECH ConsultingÎncă nu există evaluări

- DLL EAPP Lesson No. 5Document3 paginiDLL EAPP Lesson No. 5RJ Fernandez0% (1)

- API 510 PC 20 31 Aug05 Mid Session OpenDocument7 paginiAPI 510 PC 20 31 Aug05 Mid Session OpenCss SfaxienÎncă nu există evaluări

- System Steam Turbin ETSDocument2 paginiSystem Steam Turbin ETSFebry TeguhÎncă nu există evaluări

- API 653 PC 15may04 Exam 3 OpenDocument5 paginiAPI 653 PC 15may04 Exam 3 Openraobabar21Încă nu există evaluări

- Effect of Metallurgy On Pygas Fouling PDFDocument6 paginiEffect of Metallurgy On Pygas Fouling PDFstreamtÎncă nu există evaluări

- API 653 - ASME Section V - NDE Practice Questions - 68 TermsDocument7 paginiAPI 653 - ASME Section V - NDE Practice Questions - 68 TermsSERFORTEC CIA. LTDA.Încă nu există evaluări

- Daily Points To Recall (Day 5) : Professional Training and ConsultationDocument3 paginiDaily Points To Recall (Day 5) : Professional Training and Consultationraobabar21Încă nu există evaluări

- Daily Points To Recall (DAY 1) : Professional Training and ConsultationDocument3 paginiDaily Points To Recall (DAY 1) : Professional Training and Consultationraobabar21Încă nu există evaluări

- API 510 Examination Sample ItemsDocument3 paginiAPI 510 Examination Sample ItemsMagira PasaribuÎncă nu există evaluări

- NON-DeSTRUCTIVE TESTING (Part 3-Radiographic Inspection in Industry)Document24 paginiNON-DeSTRUCTIVE TESTING (Part 3-Radiographic Inspection in Industry)Javeed A. KhanÎncă nu există evaluări

- API 510 ApplicationDocument16 paginiAPI 510 ApplicationmalawanyÎncă nu există evaluări

- Daily Points To Recall (Day 2) : Professional Training and ConsultationDocument4 paginiDaily Points To Recall (Day 2) : Professional Training and Consultationraobabar21Încă nu există evaluări

- Daily Points To Recall (Day 4) : Page 1 of 2Document2 paginiDaily Points To Recall (Day 4) : Page 1 of 2HemaÎncă nu există evaluări

- Daily Points To Recall (Day 5) : API 653 PreparatoryDocument2 paginiDaily Points To Recall (Day 5) : API 653 PreparatoryMohammed ShakilÎncă nu există evaluări

- B31 Case 181Document8 paginiB31 Case 181새한검사부경출장소Încă nu există evaluări

- 571 Document ModDocument30 pagini571 Document ModPrabhaÎncă nu există evaluări

- Future Coils For Ethylene FurnacesDocument2 paginiFuture Coils For Ethylene FurnacesAli DarvishiÎncă nu există evaluări

- SWP 1 Agustus 2019Document4 paginiSWP 1 Agustus 2019Jhon Luther PÎncă nu există evaluări

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFDocument23 paginiAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasÎncă nu există evaluări

- Assuring The Safety of Ammonia Plant Vessels and Piping Using API RP 579Document11 paginiAssuring The Safety of Ammonia Plant Vessels and Piping Using API RP 579varatharajan g rÎncă nu există evaluări

- Api 510Document1 paginăApi 510Senthil PeriyasamyÎncă nu există evaluări

- ApiDocument4 paginiApiMahmoud Alwasif100% (1)

- Api 570 Close BookDocument12 paginiApi 570 Close BookMuÎncă nu există evaluări

- Scope of MoC - Metodologia TecnicaDocument12 paginiScope of MoC - Metodologia TecnicaIsraelDavidRiquelmeArayaÎncă nu există evaluări

- The Influences of Alloy Elements On The Carburized Layer in Steels Using Vacuum Carburization in An Acetylene AtmosphereDocument7 paginiThe Influences of Alloy Elements On The Carburized Layer in Steels Using Vacuum Carburization in An Acetylene AtmosphereSumit KumarÎncă nu există evaluări

- Astm c633-79 - 1994 Leigh A Test C&RDocument8 paginiAstm c633-79 - 1994 Leigh A Test C&RastronotusÎncă nu există evaluări

- GP170101 Firefighting Equipment PDFDocument26 paginiGP170101 Firefighting Equipment PDFegfernandez21Încă nu există evaluări

- Steam Turbine Mechanical Overspeed Trip Devices: InsightDocument2 paginiSteam Turbine Mechanical Overspeed Trip Devices: InsightManoj SinghÎncă nu există evaluări

- At345 Quality Control and Reliability EngineeringDocument3 paginiAt345 Quality Control and Reliability EngineeringRacherla Mega RaniÎncă nu există evaluări

- API 653 PC 07jan08 PTR 4Document3 paginiAPI 653 PC 07jan08 PTR 4Mohammed ShakilÎncă nu există evaluări

- Packed Bed Performance AnalyticsDocument6 paginiPacked Bed Performance AnalyticsNITINÎncă nu există evaluări

- Prep Material QB-576Document5 paginiPrep Material QB-576Raheem Khan100% (1)

- Api 653 Preparatory Important Closed Book Questions: Professional Training and ConsultationDocument2 paginiApi 653 Preparatory Important Closed Book Questions: Professional Training and ConsultationNuwan RanaweeraÎncă nu există evaluări

- FFS On Nozzles Weld Defect INDOCOR MigasDocument22 paginiFFS On Nozzles Weld Defect INDOCOR MigasRDS FDSÎncă nu există evaluări

- Api 570 2015 PDFDocument4 paginiApi 570 2015 PDFSUNIL BABURAO GAVADEÎncă nu există evaluări

- Tribhuwan University: Thapathali CampusDocument53 paginiTribhuwan University: Thapathali CampusBhim Narayan Kanwar100% (1)

- Final Exam (Open) : Weld Reinf. 1/8" THKDocument7 paginiFinal Exam (Open) : Weld Reinf. 1/8" THKNuwan RanaweeraÎncă nu există evaluări

- China Coreless IntermediateDocument21 paginiChina Coreless Intermediateraobabar21Încă nu există evaluări

- Financial AnalysisDocument16 paginiFinancial Analysisraobabar21Încă nu există evaluări

- Refractory Solution FDocument5 paginiRefractory Solution Fraobabar21Încă nu există evaluări

- Bangla Steel Mill RollDocument29 paginiBangla Steel Mill Rollraobabar21Încă nu există evaluări

- Geart Failure LubricationDocument17 paginiGeart Failure Lubricationraobabar21Încă nu există evaluări

- Pavingexpert - Formwork and ShutteringDocument6 paginiPavingexpert - Formwork and Shutteringraobabar21Încă nu există evaluări

- Usrcontrol3 Plant Svcs Tcm9 12753Document8 paginiUsrcontrol3 Plant Svcs Tcm9 12753raobabar21Încă nu există evaluări

- MSS SP-115 (1999)Document11 paginiMSS SP-115 (1999)raobabar21Încă nu există evaluări

- Texas Commission On Environmental Quality Table 11 InstructionsDocument2 paginiTexas Commission On Environmental Quality Table 11 Instructionsraobabar21Încă nu există evaluări

- Capital Asset and Supply Inventory Control: Management Manual Revised August 7, 2009 Title 24 Chapter HDocument14 paginiCapital Asset and Supply Inventory Control: Management Manual Revised August 7, 2009 Title 24 Chapter Hraobabar21Încă nu există evaluări

- Trainer API NDT Welding Qaqc Aws Asme Sixsigma Iso Softskill Profile Vedagiri Umashankar Chennai India 9600162099Document2 paginiTrainer API NDT Welding Qaqc Aws Asme Sixsigma Iso Softskill Profile Vedagiri Umashankar Chennai India 9600162099raobabar21Încă nu există evaluări

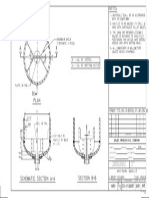

- Notes:: D I.D. of Vessel D I.D. of Bottom OutletDocument1 paginăNotes:: D I.D. of Vessel D I.D. of Bottom Outletraobabar21Încă nu există evaluări

- Rad 1/2 D: 001 C/D M88 DB-950006 00Document1 paginăRad 1/2 D: 001 C/D M88 DB-950006 00raobabar21Încă nu există evaluări

- 95000401Document1 pagină95000401raobabar21Încă nu există evaluări

- Newbold Stat8 Ism 09 GeDocument27 paginiNewbold Stat8 Ism 09 GeNahid Ibrahimzade100% (1)

- (ACV-S05) Week 05 - Pre-Task - Quiz - Weekly Quiz (PA) - INGLES IV (47891)Document5 pagini(ACV-S05) Week 05 - Pre-Task - Quiz - Weekly Quiz (PA) - INGLES IV (47891)Karla ArimoreÎncă nu există evaluări

- The Relationship of Subordinate Upward Influencing Behaviour, Satisfaction and Perceived Superior Effectiveness With Leader-Member ExchangesDocument15 paginiThe Relationship of Subordinate Upward Influencing Behaviour, Satisfaction and Perceived Superior Effectiveness With Leader-Member ExchangesGinny WengÎncă nu există evaluări

- General Psych Outline and ScheduleDocument8 paginiGeneral Psych Outline and ScheduleOlgaÎncă nu există evaluări

- Ch02 D (Vergin)Document2 paginiCh02 D (Vergin)Danudear DanielÎncă nu există evaluări

- TOEFL Test Dates in 2017Document8 paginiTOEFL Test Dates in 2017abdul mananÎncă nu există evaluări

- ACJC JC 2 H2 Maths 2011 Year End Exam Question Paper 2Document6 paginiACJC JC 2 H2 Maths 2011 Year End Exam Question Paper 2DKFBÎncă nu există evaluări

- Ankit Admit CardDocument1 paginăAnkit Admit CardMacÎncă nu există evaluări

- COmputer Programmer 20220916 174203Document1 paginăCOmputer Programmer 20220916 174203Narundra modiÎncă nu există evaluări

- Joining Your Ap Class Section For StudentsDocument2 paginiJoining Your Ap Class Section For Studentsapi-261448171Încă nu există evaluări

- 2016 Specimen Paper 1 Mark Scheme PDFDocument2 pagini2016 Specimen Paper 1 Mark Scheme PDFPanuphong KnottÎncă nu există evaluări

- Forensic 4Document3 paginiForensic 4mikoÎncă nu există evaluări

- Back To School Presentation - APDocument14 paginiBack To School Presentation - APapplemonsterÎncă nu există evaluări

- Periodic TableDocument8 paginiPeriodic TableNibha PandeyÎncă nu există evaluări

- How Graphology Fools People (Sebuah Kritik Terhadap Grafologi)Document19 paginiHow Graphology Fools People (Sebuah Kritik Terhadap Grafologi)Walben SijabatÎncă nu există evaluări

- Mor 472Document12 paginiMor 472socalsurfyÎncă nu există evaluări

- Nursing AuditDocument26 paginiNursing AuditJoe ShewaleÎncă nu există evaluări

- Effective Learning Class Room - EvaluationDocument16 paginiEffective Learning Class Room - EvaluationSheraz Ilyas100% (1)

- Neet 2018 Overview and Eligibility: National Eligibility Cum Entrance Test (Ug)Document2 paginiNeet 2018 Overview and Eligibility: National Eligibility Cum Entrance Test (Ug)Megha TyagiÎncă nu există evaluări

- Academic Audit Questions For Faculty DiscussionDocument2 paginiAcademic Audit Questions For Faculty DiscussionZaki UllahÎncă nu există evaluări