Documente Academic

Documente Profesional

Documente Cultură

Getting HSE Right and Traction 2005

Încărcat de

SHANZAY21111111Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Getting HSE Right and Traction 2005

Încărcat de

SHANZAY21111111Drepturi de autor:

Formate disponibile

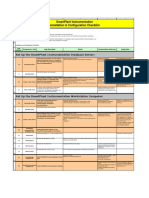

Getting HSE right and Tr@ction

Getting HSE right

A policy is only effective if people understand it and work to it. Our business-wide HSE management system, Getting HSE Right, helps line managers focus on critical needs, forecast and allocate resources, set direction for HSE activities to improve performance. During the coming year, we will be augmenting Getting HSE Right, to produce a more comprehensive operating management system (OMS) that will help improve our safety management processes and better integrate them with our operational procedures.

We set performance standards at business unit level. All BP businesses commit to deliver specific health and safety objectives as part of their annual performance contracts.

Tr@ction

Our aim is to achieve continuous performance improvements. We can do so if we know how well we are doing at any point in time. Our global reporting and management tool, Tr@ction makes it possible to record and analyse safety performance more effectively than ever before. Introduced in 2001, Tr@ction has more than 39,000 registered users. Over 81,000 incidents or near misses were reported through Tr@ction in 2005. Using Tr@ction to track our safety actions helps to ensure valuable lessons are learned and transformed into improved performance.

Other safety measures

We used a number of approaches to encourage better health and safety standards in 2005: Root cause analysis: a systematic method for investigating all accidents that helps us look beyond the immediate reasons to diagnose and address the underlying cause. Understanding these causes is often the key to avoiding similar incidents in future. Golden Rules of Safety: initially introduced in exploration and production in 2001 before group-wide adoption, the rules set out best practice health and safety guidelines for employees in a clear and accessible way. These rules help avoid repeats of serious accidents and are currently being revised to take into account lessons learnt from the root causes of recent incidents. A new version of the Golden Rules of Safety will be communicated in 2006.

Advanced Safety Auditing (ASA): introduced into BP in 1997, ASAs involves observing people at work, talking to them about the safety risks they face, then reaching agreement on how these risks can be managed. In 2005 over 267,000 ASAs were reported in Tr@ction .

Other processes, focused primarily on ensuring plant and process safety, help minimize the risks to our employees, contractors and the public. These include Hazard and Operability studies (HAZOP), Project health, safety and environment reviews (PSHER) and the BP process safety standard.

The information on this page forms part of the information reviewed and reported on by Ernst & Young as part of BP's 2005 sustainability reporting.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Dse7110 Mkii Dse7120 Mkii Operator ManualDocument100 paginiDse7110 Mkii Dse7120 Mkii Operator Manualseanfsmyth100% (1)

- Grand Rapids Controls LPA Checksheet AuditDocument7 paginiGrand Rapids Controls LPA Checksheet Auditalliceyew100% (3)

- Aggregate Crushing Value Test Lab ReportDocument2 paginiAggregate Crushing Value Test Lab ReportComr A Y ZarginaÎncă nu există evaluări

- Common Causes of Failure in Functional Safety SystemsDocument29 paginiCommon Causes of Failure in Functional Safety SystemsSHANZAY21111111Încă nu există evaluări

- 1day IntroDocument31 pagini1day IntroSHANZAY21111111Încă nu există evaluări

- 2 Process Hazard AnalysisDocument41 pagini2 Process Hazard AnalysisSHANZAY21111111Încă nu există evaluări

- Basics CompliancesitesafetystandardsDocument43 paginiBasics CompliancesitesafetystandardsSHANZAY21111111Încă nu există evaluări

- P 143017Document16 paginiP 143017SHANZAY21111111Încă nu există evaluări

- DS 00-102 31-03-08Document1 paginăDS 00-102 31-03-08SHANZAY21111111Încă nu există evaluări

- ComahDocument48 paginiComahSHANZAY21111111Încă nu există evaluări

- Plains Gas SolutionsDocument16 paginiPlains Gas SolutionsSHANZAY21111111Încă nu există evaluări

- ISA-TR84.00.02-2002 - Part 2Document44 paginiISA-TR84.00.02-2002 - Part 2yuskeilaÎncă nu există evaluări

- 201305BeaconEnglish 0Document1 pagină201305BeaconEnglish 0SHANZAY21111111Încă nu există evaluări

- Bow-Tie Lessons Learned - AicheDocument20 paginiBow-Tie Lessons Learned - Aichendve@free.fr100% (2)

- Lessons From The Gulf of Mexico Oil Well BlowoutDocument13 paginiLessons From The Gulf of Mexico Oil Well Blowoutswapneel_kulkarniÎncă nu există evaluări

- PB EmdDocument1 paginăPB EmdHarshit PatelÎncă nu există evaluări

- GP 00 02 Engineering Technical Practice (ETP) Governance and Management PrinciplesDocument10 paginiGP 00 02 Engineering Technical Practice (ETP) Governance and Management PrinciplesSHANZAY21111111Încă nu există evaluări

- 456 SuppDocument12 pagini456 SuppSHANZAY21111111Încă nu există evaluări

- Basics CompliancesitesafetystandardsDocument43 paginiBasics CompliancesitesafetystandardsSHANZAY21111111Încă nu există evaluări

- CPA Process Root Cause AnalysisDocument32 paginiCPA Process Root Cause AnalysisSHANZAY21111111Încă nu există evaluări

- Accounting For Human Systematic Error During SIL Verification WebsiteDocument21 paginiAccounting For Human Systematic Error During SIL Verification WebsiteSHANZAY21111111Încă nu există evaluări

- Aramco Safety ManaementDocument50 paginiAramco Safety Manaementmuthuswamy77Încă nu există evaluări

- Process EngineerDocument3 paginiProcess EngineerSHANZAY21111111Încă nu există evaluări

- Gu-140 (C9)Document19 paginiGu-140 (C9)SHANZAY21111111100% (1)

- F 85154 PDFDocument4 paginiF 85154 PDFMilena Lemus FonsecaÎncă nu există evaluări

- Supervisor Training Root Cause InvestigationsDocument44 paginiSupervisor Training Root Cause InvestigationsSHANZAY21111111Încă nu există evaluări

- CPA Process Root Cause AnalysisDocument32 paginiCPA Process Root Cause AnalysisSHANZAY21111111Încă nu există evaluări

- Attachment A Work Restrictions or LimitationsDocument1 paginăAttachment A Work Restrictions or LimitationsSHANZAY21111111Încă nu există evaluări

- UN Nummers GevaarlijkeStoffenDocument278 paginiUN Nummers GevaarlijkeStoffenmrbrownnlÎncă nu există evaluări

- OSHA Recordkeeping: Track Workplace Injuries Under 40 CharactersDocument35 paginiOSHA Recordkeeping: Track Workplace Injuries Under 40 CharactersSHANZAY21111111Încă nu există evaluări

- P 171811Document15 paginiP 171811SHANZAY21111111Încă nu există evaluări

- TDG 300E XgasDP4 Gas Calculation SpreadsheetDocument1 paginăTDG 300E XgasDP4 Gas Calculation SpreadsheetSHANZAY21111111Încă nu există evaluări

- Process EngineerDocument3 paginiProcess EngineerSHANZAY21111111Încă nu există evaluări

- 7 Strategies For Developing Your Own Curriculum As A New TeacherDocument5 pagini7 Strategies For Developing Your Own Curriculum As A New TeacherKhusnul KhotimahÎncă nu există evaluări

- United States Patent (19) : HoferDocument7 paginiUnited States Patent (19) : Hoferjoel marshallÎncă nu există evaluări

- VTT R 01177 17Document27 paginiVTT R 01177 17Joseph BookerÎncă nu există evaluări

- HRIS1Document24 paginiHRIS1UMESH VINAYAK ARVINDEKARÎncă nu există evaluări

- Feature Setup Description: Software Basic Data Mcs - TCBCDocument77 paginiFeature Setup Description: Software Basic Data Mcs - TCBCAlexis MauricioÎncă nu există evaluări

- Ccim Fee Refund FormDocument1 paginăCcim Fee Refund FormMohammad ShafiqueÎncă nu există evaluări

- Drilling: Drilling Is A Cutting Process That Uses A Drill Bit To Cut or Enlarge A Hole of Circular Cross-Section inDocument9 paginiDrilling: Drilling Is A Cutting Process That Uses A Drill Bit To Cut or Enlarge A Hole of Circular Cross-Section inAekanshÎncă nu există evaluări

- Civilstrips Installation NotesDocument3 paginiCivilstrips Installation NotesKoeswara SofyanÎncă nu există evaluări

- Operations and Service 69UG15: Diesel Generator SetDocument64 paginiOperations and Service 69UG15: Diesel Generator SetAnonymous NYymdHgyÎncă nu există evaluări

- Manufacturing Sodium Hyposulfite SolutionDocument2 paginiManufacturing Sodium Hyposulfite SolutionAravind KumarÎncă nu există evaluări

- Camera Raw UpdateDocument3 paginiCamera Raw UpdateHamsharfiÎncă nu există evaluări

- Sparc t8 2 Ds 3864232 PDFDocument6 paginiSparc t8 2 Ds 3864232 PDFanhtuan29Încă nu există evaluări

- Datasheet - SP 275K INH String InvDocument1 paginăDatasheet - SP 275K INH String Invsharib26Încă nu există evaluări

- On Tap Water Filter System InstructionsDocument48 paginiOn Tap Water Filter System InstructionsFilipa FigueiredoÎncă nu există evaluări

- Gas LiftDocument35 paginiGas LiftHìnhxămNơigóckhuấtTimAnh100% (1)

- Videojet 3140: Laser Marking SystemDocument2 paginiVideojet 3140: Laser Marking SystemSudiptoÎncă nu există evaluări

- 29 KprogDocument582 pagini29 KprogMike MorrowÎncă nu există evaluări

- Co-Ordinated By: DR Parul Presented By: DR GurneetDocument45 paginiCo-Ordinated By: DR Parul Presented By: DR Gurneetreenujohney100% (2)

- Floor ManualDocument35 paginiFloor ManualGihan ChathurangaÎncă nu există evaluări

- OBJECTIVES QUESTIONS RESISTIVITYDocument3 paginiOBJECTIVES QUESTIONS RESISTIVITYPankaj Kumar SinghÎncă nu există evaluări

- SDLC Phases Feasibility Analysis RequirementsDocument4 paginiSDLC Phases Feasibility Analysis RequirementsBrandon Mitchell0% (1)

- Secure Email Transaction SystemDocument32 paginiSecure Email Transaction SystemGautam Sharma100% (1)

- The Contemporary WorldDocument9 paginiThe Contemporary WorldDennis RaymundoÎncă nu există evaluări

- SmartPlant Instrumentation installation checklistDocument2 paginiSmartPlant Instrumentation installation checklistmnoormohamed82Încă nu există evaluări

- Complete Checklist for Manual Upgrades to Oracle Database 12c R1Document27 paginiComplete Checklist for Manual Upgrades to Oracle Database 12c R1Augustine OderoÎncă nu există evaluări

- 24C02BN Su18Document26 pagini24C02BN Su18Dwp BhaskaranÎncă nu există evaluări

- LCD panel and module replacement parts for saleDocument1 paginăLCD panel and module replacement parts for saleValeria bolañosÎncă nu există evaluări