Documente Academic

Documente Profesional

Documente Cultură

Dry Type Oil Transformer

Încărcat de

Kopo EdwardDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dry Type Oil Transformer

Încărcat de

Kopo EdwardDrepturi de autor:

Formate disponibile

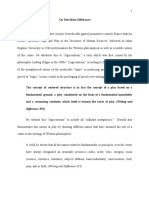

Comparison of Transformer Technologies

Sl. No. 1 2 3 4 5 6 7 8 9 10 11 12 13

PARAMETERS

Oil Cooled

Epoxy Resin Cast 7 to 11% F / 1400 C 990 C 30% 130% / 180 Min Negligible Good Yes Yes Fair Good >3% Present

Mouldless Resin Encapsulated (MLRE) 1.3 to 1.6% H / 1650 C 1150 C 5% 135% / 180 Min Negligible Good Yes Yes Good Good <1% Negligible

INTRA

Burnable Materials % Temperature Class Permitted Safe Temp. Rise Smoke Emmission % (Oil Cooled As base) Over Load Capacity/minutes from 70% base Load Maintenance cost / Year Resistance to Dusty & Corrosive atmosphere Vacuum Pressure Impregnation Suitability for Out door Use Thermal shock absortion capability Short Circuit Withstand capability Failure Rate Partial Discharge

32 to 36% A / 1050 C 550 C 100% (Base) 120% / 180 Min 100% (Base) Fair Not Always Yes Good Fair >15% Negligible

DRY & OIL TYPE TRANSFORMERS

Some of our Esteemed Clients

INTRA

(A Subsidiary of Sudhir Gensets Ltd.)

Corporate Office: Plot no.-1, Sector-34, EHTP, Gurgaon-122001, Haryana Tel.: +91-124-4168000(30 lines) Fax : +91-124-4168010 E-mail : info@sudhirgensets.com Website : www.sudhirgensets.com Factory : 31, Bommasandra Ind. Area, Bangalore - 560099 Tel. : 080-27834978, 27833024 Fax : 080-27832268 E-mail : admin@intravidyut.com Website : www.intravidyut.com

Regional Offices:

CHANDIGARH AHMEDABAD SCO - 281- First Floor, 405, Samodh Complex, Near Associated Petrol Pump, Sec.-32 D, Chandigarh - 160045 C.G. Road, Ahmedabad - 380009 Ph : 0172 - 4640417 Ph : 079-26440791/ 26460301 Fax : 0172-4640416 Fax : 079-26400190 sudhirgensets_chd@hotmail.com sudhirahd@sudhirgensets.com DELHI JAIPUR MUMBAI 507, International Trade Tower, 403,Shalimar Complex, 511, 'C' Wing, Floral Deck Plaza, Nehru Place, Church Road,Opp. M.I Road, Street No. 23, Central MIDC Road, New Delhi - 110 019 Jaipur - 302001 Andheri (E), Mumbai - 400093, Ph : 91-11-41608000 (10 Lines) Ph : 0141- 5104045 Ph : 022-28217311-12-13 Fax : 91-11-41608027 Fax : 0141-2371045 28395580, Fax : 022-28217314 info@sudhirgensets.com sglraj@sify.com sglmumbai@sudhirgensets.com

Branch Offices : Amritsar Jodhpur

Karnal

Kota Ludhiana

Surat Udaipur Vadodara

DRY TYPE TRANSFORMERS

INTRA

OIL TYPE TRANSFORMERS

Optimum Design

Each unit is tuned for optimum efficiency while operating between 45% and 65% of full load (which is the average loading) by delicate proportioning of core and winding losses. By using CRGO silicon steel mitred cores and paper enamel covered conductors the units are made compact, resulting in lower losses, better regulation and longer life. Careful design of the core and tank reduces noise level to the minimum. The clamping method adopted helps to keep the optimum properties of the grain-oriented silicon steet, without reducing their mechanical stability.

POWERGENERATION DISTRIBUTION ELECTRIFICATION

Transformers and Oil have always been synonymous with electric power. Conventional Oil type transformers use mineral base insulating oil as the medium for cooling and insulation. However modern engineering & Safety trends demand more precaution in handling Electric Power, making conventional oil cooled transformers a potential fire risk, in locations where safety is of great importance. For these applications Dry type Transformer are the only solution !

Sudhir - Powering the Nation

Sudhir is a name synonymous with Power. It stands tall in the Indian Power Generation Sector, providing complete turnkey Electrical solutions from GENERATION, DISTRIBUTION to ELECTRIFICATION. An Industry leader in the field of setting up Diesel base Captive Power Plants upto 20MW having its corporate office in Gurgaon & revenue of over INR 1000 Crs,, it has leveraged its 23-year relationship with Cummins Ltd. to capture a majority market share. The Company has a wide blue-chip customer base and operates through multiple manufacturing facilities across India and focuses on Diesel & Gas Generators, HT & LT Switchboards, Transformers and Turnkey EPC contracts. The product line includes the widest range of Diesel Gensets 15-3000 KVA with a fuel option of Gas, complete range of HT 11KV & 33KV Panels, LT Switchboards, Turnkey EPC contracts covering electrical and mechanical services of Generation, Distribution & Internal Electrification. Six ultra modern state of the art manufacturing plants strategically located in Silvassa, Athal, Jammu, Gurgaon & Bangalore help serve over 40,000 customers. Now with the Acquisition of Intra Vidyut Ltd. our product range includes Dry & Oil type Distribution Transformers, which greatly complements our Business. With this strategic acquisition along with its expansion and diversification plan SGL is poised to become leader in complete power solutions in India.

Mould-Less Resin Encapsulated - MLRE Dry Type Transformer

HV & LV wound coils are separated by means of fiber glass cylinders & supported on the frame by special porcelain supports. HV coils are made in disc form, using enameled & fiberglass covered copper strips. All conductors are treated with Polyesteramide resin during covering stage to achieve inter-turn di-electric strength of 6-8KV & eliminating trapped mechanical forces during the thermal operating cycle. LV coils are made from fiberglass covered copper strips & wound in helical form. Both coils are assembled in jigs, pre compressed, dried & encapsulated under vacuum pressure, use of mould is totally avoided. MLRE technique of resin all around the exposed surfaces of coils acts as protective covering to the insulated conductors & does not prevent heat dissipation.

Sudhir at a Glance

Sudhir - A legacy of over 3 decades A Complete Power Solution Company Equity partners - Goldman Sachs & General Electric (GE) India's largest Generator set manufacturer over 10,000 MW installation base Pan India network of offices covering all major metros and cities Six state of the art manufacturing plants, one at Silvssa, one at Gurgaon & three at Jammu and one at Bangalore 24 hours customer assistance helpline to provide prompt service support Maintenance free No trapped mechanical forces, improving the thermal operation Maximum heat dissipation Higher resistance to Short circuit forces using Disc wound coils having self - locking property

Constructional Features

Winding on HT side are provided with sufficient end-turn reinforcement for extra strength. Windings are pre shrunk and impregnated under, vacuum with hot dry Transformer oil before assembly to ensure their proper functioning. Radial as well as axial clearances and cooling ducts provided for the coils add to the safety and uniform cooling of the windings and limbs.

Salient Features of MLRE Dry Type Transformers

HT Terminal Self locking Disc Coils Ample Cooling Ducts Dual Insulated HV Conductors

Windings are designed to withstand sufficient thermal, dynamic and electrical stresses induced during operation as well as under short circuit conditions. Each tank is pressure tested and the exterior surface coated with primer and 2 coats of weather-proof paint, the shade being dark grey 1110. 6 of IS5/1980. The interior is given anti-corrosive protection with oil Hesistant varnish. Transformers are supplied with first filling of insulating oil conforming to IS-335/1980.

Intra Vidyut Ltd. at a Glance

Transformers in operation in India and Abroad since 1969 First company to manufacture Dry Type in India up to 5MVA, 22KV class A 13 year Technical Collaboration with M/S Mora Transformers AB of Sweden Pioneers in Mould-Less Resin Encapsulated type transformers Proven expertise in design for Special duty & Multi winding transformers for applications like variable speed drives, furnace duty & converter duty Type tested at CPRI ISO 9001:2000 accredited by UKAS Proven high product reliability Approved with all leading consultants & major supplies to steel plants & thermal power plants

Customized Solutions

Voltage regulation is provided with winding tappings as per customer's specifications generally at +/- 2.5% and +/- 5% of input voltage. As a standard, Tap changing is effected by means of externally hand-operated 'OFF CIRCUIT' tap-changing switch. On-Load tap changers (OLTC) with variety of steps to offer optimum control can be offered. All tap-changing switches have indicators and locking device. Special Multi tapping transformers are also in the product range, besides the special duty transformers.

No Partial Discharge, as max voltage appearing at any part of the winding is limited to the turn to turn

FR. Cylinder

Product Range

Dry Type Transformers upto 4MVA, 11KV class Oil Type Transformers upto 20MVA, 33KV class Multi Tap Transformers upto 24taps Reactors & Chokes Converter Duty Transformers

Maximum creepage available in coils Better monitoring of hot spot temperature

Radial & Axial Ducts

Quality Assurance

Least amount of combustible materials Does not emit toxic and blinding smoke in the event of a fire

Glazed Porcelain Insulators

Every transformer undergoes a series of tests throughout the manufacturing process, right from raw material stage to final stage. All routine tests are carried out at our works as per IS 11171, IEC 726 and other International Specifications. Type tests for impulse withstand short Circuit strength , etc have been conducted on representative ratings and voltage classes, at approved national test houses. The ISO certificate has also been revalidated recently.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Turnstar Special Needs Gate Semi AutomaticDocument2 paginiTurnstar Special Needs Gate Semi AutomaticKopo EdwardÎncă nu există evaluări

- Y 0720Document260 paginiY 0720Oscar Gálvez IglesiasÎncă nu există evaluări

- DC Circuitbreaker SpecsDocument62 paginiDC Circuitbreaker SpecsKopo EdwardÎncă nu există evaluări

- Dac60000 6u InvertersDocument4 paginiDac60000 6u InvertersKopo EdwardÎncă nu există evaluări

- TemBreak2 CBR LeafletDocument2 paginiTemBreak2 CBR LeafletKopo EdwardÎncă nu există evaluări

- Fi FCP3-DWR IIDocument2 paginiFi FCP3-DWR IIKopo EdwardÎncă nu există evaluări

- 5.4.3 Selection of A Grounding Scheme: 98 G C EMIDocument13 pagini5.4.3 Selection of A Grounding Scheme: 98 G C EMIKopo EdwardÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hole CapacityDocument2 paginiHole CapacityAbdul Hameed OmarÎncă nu există evaluări

- WebLMT HelpDocument12 paginiWebLMT HelpJoão LopesÎncă nu există evaluări

- Lesson 6 ComprogDocument25 paginiLesson 6 ComprogmarkvillaplazaÎncă nu există evaluări

- Biological Beneficiation of Kaolin: A Review On Iron RemovalDocument8 paginiBiological Beneficiation of Kaolin: A Review On Iron RemovalValentin GnoumouÎncă nu există evaluări

- Hdfs Default XML ParametersDocument14 paginiHdfs Default XML ParametersVinod BihalÎncă nu există evaluări

- Parliament of India: Rajya SabhaDocument64 paginiParliament of India: Rajya SabhaSivapothuraju KonathalaÎncă nu există evaluări

- 2SB817 - 2SD1047 PDFDocument4 pagini2SB817 - 2SD1047 PDFisaiasvaÎncă nu există evaluări

- A Case Study Puga Geothermal System,: OF IndiaDocument7 paginiA Case Study Puga Geothermal System,: OF IndiaPERIKALA TARUNÎncă nu există evaluări

- Technology Management 1Document38 paginiTechnology Management 1Anu NileshÎncă nu există evaluări

- Nutrition and CKDDocument20 paginiNutrition and CKDElisa SalakayÎncă nu există evaluări

- Business Analytics Emphasis Course GuideDocument3 paginiBusiness Analytics Emphasis Course Guidea30000496Încă nu există evaluări

- g6 - AFA - Q1 - Module 6 - Week 6 FOR TEACHERDocument23 paginig6 - AFA - Q1 - Module 6 - Week 6 FOR TEACHERPrincess Nicole LugtuÎncă nu există evaluări

- Quick Help For EDI SEZ IntegrationDocument2 paginiQuick Help For EDI SEZ IntegrationsrinivasÎncă nu există evaluări

- Turn Around Coordinator Job DescriptionDocument2 paginiTurn Around Coordinator Job DescriptionMikeÎncă nu există evaluări

- Snapdragon 435 Processor Product Brief PDFDocument2 paginiSnapdragon 435 Processor Product Brief PDFrichardtao89Încă nu există evaluări

- Azimuth Steueung - EngDocument13 paginiAzimuth Steueung - EnglacothÎncă nu există evaluări

- .Urp 203 Note 2022 - 1642405559000Document6 pagini.Urp 203 Note 2022 - 1642405559000Farouk SalehÎncă nu există evaluări

- 3 Carbohydrates' StructureDocument33 pagini3 Carbohydrates' StructureDilan TeodoroÎncă nu există evaluări

- Pavement Design1Document57 paginiPavement Design1Mobin AhmadÎncă nu există evaluări

- FMC Derive Price Action GuideDocument50 paginiFMC Derive Price Action GuideTafara MichaelÎncă nu există evaluări

- Chemistry: Crash Course For JEE Main 2020Document18 paginiChemistry: Crash Course For JEE Main 2020Sanjeeb KumarÎncă nu există evaluări

- Android Developer PDFDocument2 paginiAndroid Developer PDFDarshan ChakrasaliÎncă nu există evaluări

- Gemini Dollar WhitepaperDocument7 paginiGemini Dollar WhitepaperdazeeeÎncă nu există evaluări

- Electives - ArchitDocument36 paginiElectives - Architkshitiz singhÎncă nu există evaluări

- Networker Performance Tuning PDFDocument49 paginiNetworker Performance Tuning PDFHarry SharmaÎncă nu există evaluări

- Lecture 4 ENGR 243 DynamicsDocument45 paginiLecture 4 ENGR 243 DynamicsRobby RebolledoÎncă nu există evaluări

- Electro Fashion Sewable LED Kits WebDocument10 paginiElectro Fashion Sewable LED Kits WebAndrei VasileÎncă nu există evaluări

- Test Your Knowledge - Study Session 1Document4 paginiTest Your Knowledge - Study Session 1My KhanhÎncă nu există evaluări

- On Derridean Différance - UsiefDocument16 paginiOn Derridean Différance - UsiefS JEROME 2070505Încă nu există evaluări

- IKEA SHANGHAI Case StudyDocument5 paginiIKEA SHANGHAI Case StudyXimo NetteÎncă nu există evaluări