Documente Academic

Documente Profesional

Documente Cultură

Chain Scission FR Mechanism of Aliphatic Bromine Compounds in PS An PP - J. Kaspersma

Încărcat de

Victor CastrejonDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chain Scission FR Mechanism of Aliphatic Bromine Compounds in PS An PP - J. Kaspersma

Încărcat de

Victor CastrejonDrepturi de autor:

Formate disponibile

Great Lakes Chemical Corporation Technical Service EMEA

Chain Scission FR Mechanism of aliphatic bromine compounds in PS and PP

Jelle H.Kaspersma FR Technical Service Herentals, Belgium

Great Lakes Chemical Corporation Technical Service EMEA

FR Technical Service

Help FR customers with solutions Correlation between UL V2 and Glow Wire? FR compounds in HIPS and PP for E&E applications Project . FR Mechanisms for explanation

Great Lakes Chemical Corporation Technical Service EMEA

Flame Poisoning Mechanism

aromatic bromine, Sb2O3 synergist gas phase mechanism, polymer unspecific

Br FR + Sb2O3 SbBr3 + H HBr

High energy H and OH are generated in the partial oxidation cycle of hydrocarbons: start: growth: branching:

RH R + H

R + O2 ROO + RH ROOH ROOH RO + OH

+ R

High energy radicals are removed by HBr and SbBr3 , the flame is extinguished:

HBr +

H H2 +

Br

HBr + OH H2O +

Br

Great Lakes Chemical Corporation Technical Service EMEA

Chain Scission Mechanism

aliphatic bromine, in polymer melt polymers with tertiary carbon FR + Br

H H H C H C C H C H HCH HCH H H

Br FR

H abstraction

Br

HBr

H H C H C C H C H HCH HCH H H

H H C H C C H C H HCH HCH H H

scission

H CH + C H CH H

H H C C H H CH H

H C H H C

. .

+

HC H H

H H C C H HC H H

termination

H C H H CH H CH H

H C HC H CH H

Great Lakes Chemical Corporation Technical Service EMEA

Br FR additives

Br Br Br Br

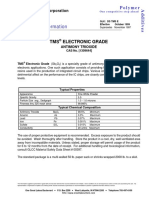

Fully aliphatic bromine FR compound Hexabromo cyclo dodecane Commercial name CD-75P used in PS CD-75Pstab contains 5% acid scavenger

Br

Br

Br Br Br CH3 C CH3 Br CH2 CH CH2 O

Br Br Br O CH2 CH CH2 Br

Mixed aliphatic/aromatic bromine FR compound Tetrabromo bisphenol A bis (2,3-dibromopropyl ether) Commercial name PE-68 used in PP

Br Br Br

Br O Br

Br

Br Br

Br

Br

Aromatic bromine FR compound Decabromo diphenyl oxide Commercial name DE-83R used in HIPS and PP

Great Lakes Chemical Corporation Technical Service EMEA

FR test methods

UL94 V2:

2 times flame application for 10 seconds Average burn time less than 25 seconds Burning drips are allowed

Glow Wire:

Application of hot wire at 960, 850 or 750oC On most critical area of molded part Contact for 30 seconds Additional burn time less than 30 seconds (60 in total) Burning drips are not allowed

Great Lakes Chemical Corporation Technical Service EMEA

Results of CD-75Pstab in HIPS

HIPS with 6.5% rubber FR loading for Glow Wire 960oC vs. UL94 V2

Glow Wire 960oC thickness CD-75Pstab content Av.burn time 1 mm 2.1 % 10 20 sec

UL 94 V2 thickness CD-75stab content Av.burn time 0.8 mm 1.6 % 2 sec

1.5 mm

4.2 % 10 20 sec

1.6 mm

1.6 %

5 sec

3 mm

2.1 % 10 20 sec

3.2 mm

1.6 %

2 sec

Great Lakes Chemical Corporation Technical Service EMEA

Result of CD-75Pstab in HIPS

Effect of rubber and mineral oil

CD-75Pstab in 1.5 mm Glow Wire plaque at 960oC HIPS with 6.5 % rubber HIPS MFI 7 with 1.8 % mineral oil Mineral oil Result Rubber Result CD-75Pstab Av.burn time CD-75Pstab Av.burn time 1.8 % 4.2 % Pass 39 sec 6.5 % 4.2 % Pass 10 20 sec

0.9 %

4.2 %

Pass

5 sec

9.5 %

6.0 %

Pass

10 20 sec

Great Lakes Chemical Corporation Technical Service EMEA

Results of CD-75Pstab + Dicumene in HIPS

H HC H C HC H H H HC H C HC H H 2 H HC H C HC H H

HIPS with 6.5% rubber

Glow Wire 960oC on 1.5 mm CD-75Pstab Result Dicumene Av. burn time 4.2 % Pass 16 sec UL94 V2 on 1.6 mm CD-75Pstab Dicumene 1.6 % Result Av. burn time Pass 3 sec

3.0 %

0.3 %

Pass

12 sec

1.6 %

1.6 %

Pass

1 sec

4.0 %

Fail

> 60 sec

1.6 %

Fail

> 30 sec

Great Lakes Chemical Corporation Technical Service EMEA

Results of CD-75Pstab + Sb2O3 in HIPS

HIPS with 6.5% rubber

Glow Wire 960oC on 1.5 mm CD-75Pstab Sb2O3 Result Av.burn time 4.2 % Pass 16 sec

UL94 V2 on 1.6 mm CD-75Pstab Sb2O3

Result Av.burn time Pass 5 sec

1.6 %

4.2 %

1.4 %

Pass

14 sec

1.0 %

0.33 %

Fail

> 30 sec

3.5 %

1.2 %

Pass

12 sec

2.0 %

0.67 %

Fail

> 30 sec

Great Lakes Chemical Corporation Technical Service EMEA

Conclusions for CD-75Pstab in HIPS

Additive effects indicate: Chain Scission is the main mechanism for V2: - Sb2O3 removes Br radicals from the melt, fails V2 - Dicumene enhances Chain Scission, a real synergist A mixed Chain Scission/Flame Poisoning Mechanism for Glow Wire: - Both Sb2O3 and Dicumene are synergists - Strong effect of rubber on FR loading by counteracting flow UL V2 easier to pass than Glow Wire in HIPS - No Sb2O3 for Flame Poisoning, needed more for Glow Wire

Great Lakes Chemical Corporation Technical Service EMEA

Results of PE-68 + Sb2O3 in PP

PP homopolymer MFI 11

FR/Sb2O3 PE-68 % Sb2O3 % UL94 V2 0.8 mm

1.0 2.0 3.0 1.5 % 1.5 % 1.5 % 1.5 % 0.75 % 0.5 % Result / Av. burn time Pass Pass Pass 4 sec Pass Pass 5 sec 3 sec Fail (1/10 fail) Pass 2 sec 4 sec Pass 3 sec 2 sec

6.0 1.5 % 0.25 % No result

1.6 mm Fail (4/10 fail)

Fail (1/10 fail) Fail (3/10 fail)

3.2 mm

Great Lakes Chemical Corporation Technical Service EMEA

Results of PE-68 in PP

PP homopolymer MFI 11 Glow Wire 960oC vs UL94 V2 loading

Glow Wire 960oC gage PE-68 Sb2O3 1.0 % 1.0 mm 0.33 % 1.0 % 1.5 mm 0.33 % 1.0 % 3.0 mm 0.33 %

Result Av.burn time Pass 21 sec Pass 25 sec Pass 31 sec

UL 94 V2 gage PE-68 Sb2O3 1.5 % 0.8 mm 0.5 % 1.5 % 1.6 mm 0.5 % 1.5 % 3.2 mm 0.5 %

Result Av.burn time Pass 2 sec Pass 3 sec Pass 6 sec

Great Lakes Chemical Corporation Technical Service EMEA

Conclusions for PE-68 in PP

Additive effects indicate: A mixed Chain Scission/FlamePoisoning Mechanism for V2 and Glow Wire - Aliphatic Br sustains the Chain Scission mechanism - Aromatic Br sustains Flame Poisoning with Sb2O3 synergist - Lower FR loading for Glow Wire vs V2: Flame Poisoning more important for Glow Wire than for V2

Great Lakes Chemical Corporation Technical Service EMEA

Comparison of Br FR load levels for V2 and V0

Aliphatic or mixed Aliphatic/Aromatic vs fully Aromatic Br

HIPS 6.5% rubber CD-75Pstab Sb2O3 DE-83R Sb2O3 Aliphatic Br Aromatic Br

UL94 V2 1.6 mm UL94 V0 1.6 mm PP homopol MFI 11 UL94 V2 1.6 mm UL94 V0 1.6 mm

1.6 %

6.0 % 2.0 %

1.1 %

5.0 %

8.0 %

3.0 %

11.5 % 3.5 %

5.7 %

9.5 %

PE-68

Sb2O3

DE-83R Sb2O3

Mixed Br

Aromatic Br

1.5 %

0.5 %

unknown

1.0 %

10.0 %

3.0 %

23.0 % 10.0 %

6.8 %

19.1 %

Great Lakes Chemical Corporation Technical Service EMEA

Conclusions on Chain Scission in V2/V0 in PS and PP

Comparison of Aliphatic and Aromatic Br in V2 and V0 in HIPS: - For V2 Aliphatic Br is 450% more effective than Aromatic Br - For V0 Aliphatic Br is 60% more effective than Aromatic Br Comparison of mixed Aliphatic/Aromatic and Aromatic Br in V0 in PP: - For V0 mixed Aliphatic/Aromatic Br is 280% more effective than Aromatic Br

The Chain Scission Mechanism is more effective

Great Lakes Chemical Corporation Technical Service EMEA

Results of Mixed Br FR vs Non Hal FR in PP

V2 and V0 in 1.6 mm

HO CH2

CH2 O P C CH2 O CH2 O

NH-1197

NH-1197, Pentaerithritol phosphate NH-1511, blend of NH-1197 with phosphate synergist

PE-68 vs Non Hal NH-1511 in PP homopolymer MFI =11 FR additive FR loading for FR loading for UL94 V0 in 1.6 mm UL94 V2 in 1.6 mm PE-68 + Sb2O3 NH-1511 10% PE-68 + 3.3% Sb2O3 28 % 1.5% PE-68 + 0.5% Sb2O3 23 %

Great Lakes Chemical Corporation Technical Service EMEA

Final Conclusions

Relative importance of Chain Scission vs. Flame Poisoning: - for V2 Chain Scission is most important - for Glow WireChain Scission and Flame Poisoning are equally important - for V0 Flame Poisoning is most important, but Chain Scission contributes a lot Aliphatic Br FR`s are very effective for European FR ratings in PS and PP Non-Halogen FR`s can be effective for V0 by a Charring Mechanism Non-Halogen FR`s are not effective for V2/Glow Wire: no Chain Scission

S-ar putea să vă placă și

- Technical Information: TMS - VHPDocument1 paginăTechnical Information: TMS - VHPVictor CastrejonÎncă nu există evaluări

- Technical Information: Pyrobloc® Sap2 and Sap5Document2 paginiTechnical Information: Pyrobloc® Sap2 and Sap5Victor CastrejonÎncă nu există evaluări

- Technical Information: Sodium Antimonate-EDocument1 paginăTechnical Information: Sodium Antimonate-EVictor CastrejonÎncă nu există evaluări

- Ongard 2 PDFDocument1 paginăOngard 2 PDFVictor CastrejonÎncă nu există evaluări

- Technical Information: Antimony Trioxide Wetted GradesDocument1 paginăTechnical Information: Antimony Trioxide Wetted GradesVictor CastrejonÎncă nu există evaluări

- Polymer additive for polyester productionDocument1 paginăPolymer additive for polyester productionVictor CastrejonÎncă nu există evaluări

- Suptms PDFDocument1 paginăSuptms PDFVictor CastrejonÎncă nu există evaluări

- Tmse PDFDocument1 paginăTmse PDFVictor CastrejonÎncă nu există evaluări

- Pyrobloc SAP-2 PDFDocument1 paginăPyrobloc SAP-2 PDFVictor CastrejonÎncă nu există evaluări

- Technical Information: TMS Catalyst Grade PHPDocument1 paginăTechnical Information: TMS Catalyst Grade PHPVictor CastrejonÎncă nu există evaluări

- Tmse PDFDocument1 paginăTmse PDFVictor CastrejonÎncă nu există evaluări

- Pyrobloc SAP-5 PDFDocument1 paginăPyrobloc SAP-5 PDFVictor CastrejonÎncă nu există evaluări

- Technical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideDocument2 paginiTechnical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideVictor CastrejonÎncă nu există evaluări

- Atstemp PDFDocument1 paginăAtstemp PDFVictor CastrejonÎncă nu există evaluări

- Tms PDFDocument2 paginiTms PDFVictor CastrejonÎncă nu există evaluări

- Atomeg PDFDocument2 paginiAtomeg PDFVictor CastrejonÎncă nu există evaluări

- Technical Information: Microfine VHPDocument1 paginăTechnical Information: Microfine VHPVictor CastrejonÎncă nu există evaluări

- Technical Information: Atc-HclDocument1 paginăTechnical Information: Atc-HclVictor CastrejonÎncă nu există evaluări

- Technical Information: Microfine Catalyst Grade PVHP Antimony TrioxideDocument1 paginăTechnical Information: Microfine Catalyst Grade PVHP Antimony TrioxideVictor CastrejonÎncă nu există evaluări

- Technical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideDocument2 paginiTechnical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideVictor CastrejonÎncă nu există evaluări

- Technical Information: Antimony TrichlorideDocument1 paginăTechnical Information: Antimony TrichlorideVictor CastrejonÎncă nu există evaluări

- Technical Information: Antimony MetalDocument1 paginăTechnical Information: Antimony MetalVictor CastrejonÎncă nu există evaluări

- Atocg PDFDocument1 paginăAtocg PDFVictor CastrejonÎncă nu există evaluări

- Technical Information: Microfine Catalyst Grade PHP Antimony TrioxideDocument1 paginăTechnical Information: Microfine Catalyst Grade PHP Antimony TrioxideVictor CastrejonÎncă nu există evaluări

- Polymer One competitive step aheadDocument1 paginăPolymer One competitive step aheadVictor CastrejonÎncă nu există evaluări

- PolymerAdditives - Thanox 1076 - TDS - 2012-JuneDocument1 paginăPolymerAdditives - Thanox 1076 - TDS - 2012-JuneVictor CastrejonÎncă nu există evaluări

- Atomao9 PDFDocument2 paginiAtomao9 PDFVictor CastrejonÎncă nu există evaluări

- THANOX 1035 Technical Data SheetDocument1 paginăTHANOX 1035 Technical Data SheetVictor CastrejonÎncă nu există evaluări

- PolymerAdditives - Thanox 1098 - TDS - April-2013Document1 paginăPolymerAdditives - Thanox 1098 - TDS - April-2013Victor CastrejonÎncă nu există evaluări

- PolymerAdditives - Thanox 1010 - TDS - 2011-AugustDocument1 paginăPolymerAdditives - Thanox 1010 - TDS - 2011-AugustVictor CastrejonÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- CalorDocument4 paginiCalorAlex AngelÎncă nu există evaluări

- Rotational Moulding Design GuideDocument14 paginiRotational Moulding Design Guidesushant3240Încă nu există evaluări

- Constec3 Retaining WallDocument9 paginiConstec3 Retaining WallHakimi RizqyÎncă nu există evaluări

- Mechanics of Material Lab6Document36 paginiMechanics of Material Lab6NiroexÎncă nu există evaluări

- The Predictive Capability of Failure Mode Concept-Based Strength Criteria For Multi-Directional Laminates-Part BDocument30 paginiThe Predictive Capability of Failure Mode Concept-Based Strength Criteria For Multi-Directional Laminates-Part BChris KořánÎncă nu există evaluări

- S001Document1 paginăS001Yong Hui OngÎncă nu există evaluări

- New Porous Coating for Improved Metal Forming LubricationDocument4 paginiNew Porous Coating for Improved Metal Forming LubricationfbraysÎncă nu există evaluări

- STI03 Yield and FailureDocument30 paginiSTI03 Yield and FailureDeepak ChachraÎncă nu există evaluări

- AISC/ASCE Student Steel Bridge Competition Analysis in STAAD.ProDocument59 paginiAISC/ASCE Student Steel Bridge Competition Analysis in STAAD.ProglbforuÎncă nu există evaluări

- Fibre Reinforced Polymer Composites As Internal and External Reinforcements For Building ElementsDocument15 paginiFibre Reinforced Polymer Composites As Internal and External Reinforcements For Building ElementsFauzi AlifkaÎncă nu există evaluări

- HW2 Fall 2022Document3 paginiHW2 Fall 2022hamza balÎncă nu există evaluări

- Bearings-131 Part 1Document74 paginiBearings-131 Part 1Khaled HassanÎncă nu există evaluări

- Catalogo InaDocument63 paginiCatalogo InaIrwin ParedesÎncă nu există evaluări

- Magnets Test - Key Facts About Magnets and Their PropertiesDocument5 paginiMagnets Test - Key Facts About Magnets and Their Propertiessian017Încă nu există evaluări

- Hamerlug Unions (Anson)Document15 paginiHamerlug Unions (Anson)Leonardo ViannaÎncă nu există evaluări

- Orthodontic Material Properties NewDocument71 paginiOrthodontic Material Properties NewHiba AbdullahÎncă nu există evaluări

- Air MusclesDocument32 paginiAir MusclesMohammed ShahinÎncă nu există evaluări

- Meta SubjectDocument33 paginiMeta SubjectSwanandÎncă nu există evaluări

- Yarn List: UNI EN ISO 9001:2000 Cert. N° 93-1Document12 paginiYarn List: UNI EN ISO 9001:2000 Cert. N° 93-1Mile SareskiÎncă nu există evaluări

- Bearing Reference Guide NSK 2016Document30 paginiBearing Reference Guide NSK 2016LeroyÎncă nu există evaluări

- Final Report EditedDocument46 paginiFinal Report EditedAXCÎncă nu există evaluări

- Metallography of AISI 1010 Steel and A 40 W/o Ag - 60 W/o Cu Alloy Laboratory Experiment #6aDocument2 paginiMetallography of AISI 1010 Steel and A 40 W/o Ag - 60 W/o Cu Alloy Laboratory Experiment #6aNaCho BeltránÎncă nu există evaluări

- Engineering Page - Heat Exchangers - TEMA DesignationDocument4 paginiEngineering Page - Heat Exchangers - TEMA DesignationBipin GiriÎncă nu există evaluări

- 21 27 Bulk Density Apparatus TMIDocument2 pagini21 27 Bulk Density Apparatus TMIMauricio CarestiaÎncă nu există evaluări

- 1 en SKF Heavy Duty Spherical Plain BearingsDocument12 pagini1 en SKF Heavy Duty Spherical Plain BearingsFernando RockerÎncă nu există evaluări

- The Effect of Aggregate Size On The Use of The Cylinder Splitting Test As A Measure of Tensile StrengthDocument7 paginiThe Effect of Aggregate Size On The Use of The Cylinder Splitting Test As A Measure of Tensile StrengthRoberto UrrutiaÎncă nu există evaluări

- Torsional Behavior of Steel Fiber Reinforced Concrete BeamsDocument7 paginiTorsional Behavior of Steel Fiber Reinforced Concrete BeamssokamantyÎncă nu există evaluări

- Materials 16 00121 v2Document15 paginiMaterials 16 00121 v2clarence8bacligÎncă nu există evaluări

- Asme B16.5Document11 paginiAsme B16.5jacquesmayol100% (1)

- Cmi215.2017 - Guia TTDocument9 paginiCmi215.2017 - Guia TTalex123456789009850% (2)