Documente Academic

Documente Profesional

Documente Cultură

4 Unrestrained Beams - 2011

Încărcat de

Melinda GordonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

4 Unrestrained Beams - 2011

Încărcat de

Melinda GordonDrepturi de autor:

Formate disponibile

1

Unrestrained Beams

23/8/2012

2

Introduction

LateralTorsionalBuckling

Lateraldeflectionandtwisting

SpecialcaseswhereLTBcheckscanbeignored

MomentResistance

Momentcheck

ApproachesfordeterminingthereductionfactorforLTB

LTBCurves GeneralCase

LTBCurves&ImperfectionFactors

BucklingCurvesforLTB

ElasticCriticalMomentforLTB

CorrectionFactorforNonUniformMomentC

1

LTBCurves RolledSectionsorEquivalentWeldedSections

LTBCurves&ImperfectionFactors

ComparisonofBucklingCurvesGiveninClauses6.3.2.2&6.3.2.3

Simplifiedmethodfordeterminationofnondimensionalslenderness

DesignProcedureforLTB

Examples

ExampleURB1(BucklingresistanceofUB)

Outline

23/8/2012

3

= Lateral torsional buckling (LTB) is a form of buckling that involves both

lateral deflection and twisting. It is a member buckling mode associated

with slender unrestrained beams loaded about their major axis.

= Checks for lateral torsional buckling should be carried out on all

unrestrained segments of beams(between points where lateral restraint

exists).

= If continuous lateral restraint is provided to the beam, then lateral

torsional buckling will be prevented and failure will be due to in-plane

bending and/or shear (refer to restrained beams).

= The load at which LTB occurs may be substantially less than the beam

in-plane bending capacity.

Introduction

23/8/2012

4

Lateral Torsional Buckling

23/8/2012

5

Lateral Torsional Buckling (LTB)

Demonstration of LTB on a cantilever

Cross-section of the

free end of an

unloadedcantilever

Cross-section of the free end of the

cantilever that undergoes LTB when

subjected to MAJORaxis moment

minor axis

moment M

z

major axis

moment M

y

Cross-section of the deflected

free end of the cantilever IF

subjected to minor axis moment

LTB involves both a lateral deflection

and a torsional twist angle

23/8/2012

6

When member is subjected to MAJORaxis moment, the upper flange & web are in compressionand

act as a strut.

Being free to move, the compression elements would tend to move laterally

However, the tension flange and web are reluctant to move, creating resistance to lateral movement.

As such, the cross-section twistswhen it deflects, with the tension flange and web dragging behind.

Weak axis of

compressive section

Partial section under compression

Strong axis of

compressive section

Member subjected to MAJORaxis moment Elements under compression

prone to buckling

Elements under tension

resist buckling

T-section would deflect in the same direction as minor

axis buckling

LateralDeflectionandTwisting

23/8/2012

23/8/2012

7

Both flange free to rotate on plan

Lateral Torsional Buckling

Both flanges restrained from rotation on plan

End Support Conditions

Eurocode3:DesignofSteelStructures RLiew&SDPang

8

SpecialCaseswhereLTBcheckscanbeignored

The following are cases where LTB checks can be ignored:

=SHS, CHS, circular or square bar

=Fully laterally restrained beams

=Minor axis bending

= for welded sections

= for hot rolled sections

9

Z

Z

Minor axis bending

Y

Y

Major axis bending

major axis

moment M

y

No LTB for minor axis bending

SHS and CHS under bending

No LTB

23/8/2012

10

11

Buckling Resistance

EN 1993-1-1 (Cl 6.3.2.1)

Each segment between intermediate lateral restraints or between the end supports of a

member subject to major axis bending should be verified against lateral torsional

buckling using the following:

The design buckling resistance moment, M

b,Rd

of a laterally unrestrained beam should

be taken as :

MomentCheck

where W

y

is the appropriate section modulus

W

y

= W

pl,y

for Class 1 and 2 cross-sections

W

y

= W

el,y

for Class 3 cross-sections

W

y

= W

eff,y

for Class 4 cross-sections

LT

is the reduction factor for LTB

23/8/2012

EN 1993-1-1 (Cl 6.3.2.2 & 6.3.2.3)

Cl 6.3.2.2 is for general case adopting the lateral torsional buckling curves given by

equations 6.56

Cl 6.3.2.3 is for rolled section or equivalent welded section adopting the lateral torsional

buckling curves given by equations 6.57.

ApproachesforDeterminingtheReductionFactorforLTB

GeneralCase/RolledSectionsorEquivalentWeldedSections

EN 1993-1-1 (Cl 6.3.2.4)

This method utilizes a simplified assessment approach for beams with restraints in

buildings given by equations 6.59 and 6.60. for info only

SimplifiedAssessmentMethodsforBeamswithRestraintsinBuildings

EN 1993-1-1 (Cl 6.3.4)

This method may be used when the above methods do not apply. for info only

GeneralMethodforStructuralComponents

23/8/2012

Eurocode3:DesignofSteelStructures RLiew&SDPang

13

LTBCurves GeneralCase

EN 1993-1-1 (Cl 6.3.2.2)

For the general case, the value of

LT

for the appropriate non-dimensional slenderness

is given as follows:

where

LT

is an imperfection factor

M

cr

is the elastic critical moment for LTB

The general case method is meant to be used for deep slender beams that are outside the range

of shapes of rolled sections.

Thegeneralcaseisalsoapplicabletorolledandweldedsectionsbutprovidesamore

conservativeestimateofthebucklingresistance.

conservative method for general use

(6.56)

23/8/2012

14

Table 6.4: Recommended lateral torsional buckling curves for cross-sections

Table 6.3: Recommended values for imperfection factors for lateral torsional buckling curves

Buckling curve a b c d

Imperfection factor

LT

0.21 0.34 0.49 0.76

Cross-section Limits Buckling curve

Rolled I-sections

h/b 2

h/b > 2

a

b

Welded I-sections

h/b 2

h/b > 2

c

d

Other cross-sections d

LTBCurves&ImperfectionFactors GeneralCase

23/8/2012

15

LT

BucklingCurvesforLTB

LT

=0.21

=0.34

=0.49

=0.76

16

For doubly symmetric cross-sections loaded through its shear center, the elastic critical

moment is given by:

where C

1

is the correction factor for non-uniform bending moment

L

cr

is the buckling length of the beam/segment

G is the shear modulus

I

T

is the torsion constant

I

W

is the warping constant

I

z

is the section second moment of area about minor axis

NCCI (SN003a-EN-EU)

ElasticCriticalMomentforLTB GeneralCase

23/8/2012

Eurocode3:DesignofSteelStructures RLiew&SDPang

For hot-rolled doubly symmetric I and H sections, may be conservatively simplified

to:

17

As a further simplification, C

1

may also be conservatively taken = 1.0.

SimplifiedAssessmentof

where

Eurocode3:DesignofSteelStructures RLiew&SDPang

18

The value of can be conservatively estimated by the following table for hot-rolled doubly

symmetric I and H sections with lateral restraints at both ends of the segment only.

Grade

S235

S275

S355

S420

S460

L

cr

= kL = effective length

i

z

= radius of gyration about the minor axis

E = 210kN/mm

2

C

1

effect can be included by dividing the value by

SimplifiedforIandHSections

where

23/8/2012

19

C

1

valuesforendmomentloading

C

1

valuesfortransverseloading

CorrectionFactorforNonUniformMomentC

1

GeneralCase

C

1

1.0

(C

1

= 1.0 corresponds to the most

severe case loading condition of

constant bending moment)

Eurocode3:DesignofSteelStructures RLiew&SDPang

EffectiveLengthforBeamswithoutIntermediateRestraint

20

For destabilizingload, L

cr

= DL = 1.2 L

1

3

2

L

cr

= kL or DL

Eurocode3:DesignofSteelStructures RLiew&SDPang

21

TypicalBeamSupportConditionsinBuildingFrame

1.Flanges are fully

restrainedagainst rotation

on plan

2.Flanges are partially

restrainedagainst rotation

on plan

3.Flanges are freeto rotate

on plan

1

3

2

Eurocode3:DesignofSteelStructures RLiew&SDPang

22

DestabilizingLoad NeutralLoad StabilizingLoad

Eurocode3:DesignofSteelStructures RLiew&SDPang

23

Cantilever

Source: The Institution of Structural Engineers Manual for the

design of steelwork building structures to Eurocode 3

C

1

should be 1.0 for cantilever

Effective length

L

cr

= kL = DL

where

D = parameter for destabilizing load

Eurocode3:DesignofSteelStructures RLiew&SDPang

24

LTBCurves Rolled SectionsorEquivalentWeldedSections

EN 1993-1-1 (Cl 6.3.2.3) less conservative method

For rolled or equivalent welded sections in bending, the value of

LT

for the appropriate

non-dimensional slenderness is given as follows:

where

= 0.4 (rolled sections, hot finished and cold formed hollow sections)

= 0.2 (welded sections)

= 0.75 (rolled sections, hot finished and cold formed hollow sections)

= 1.00 (welded sections)

(6.57)

23/8/2012

25

Table 6.5: Recommended lateral torsional buckling curves for cross-sections

Cross-section Limits Buckling curve

Rolled I- and H- sections, and hot-finished hollow sections

h/b 2

2.0 < h/b < 3.1

b

c

Angles (for moments in the major principal plane) and

other hot-rolled sections

d

Welded sections and cold-formed hollow sections

h/b 2

2.0 < h/b < 3.1

c

d

Table 6.3: Recommended values for imperfection factors for lateral torsional buckling curves

Buckling curve a b c d

Imperfection factor

LT

0.21 0.34 0.49 0.76

LTBCurves&ImperfectionFactors Rolled

SectionsorEquivalentWeldedSections

h

b

Eurocode3:DesignofSteelStructures RLiew&SDPang

Modifying

LT

forMomentGradientEffect

EN1993-1-1 Clause 6.3.2.3(2) and the SS NA.2.18.

The reduction factor is modified to take account of the moment distribution between the

lateral restraints of members using the reduction factor f :

26

27

LT

ComparisonofBucklingCurvesGiveninClauses6.3.2.2&6.3.2.3

LT

Buckling curve for general case

(Cl 6.3.2.2)

RolledI Sectionwithh/b<2

Buckling curve for rolled section

(Cl 6.3.2.3)

23/8/2012

Eurocode3:DesignofSteelStructures RLiew&SDPang

BeamswithIntermediateRestraint

Where a beam has effective intermediate restraints the moment resistance can be

based on the length between restraints. For destabilizing load, L

cr

= 1.2 L.

28

Secondary beams providing

lateral and torsional restraint.

Effective length of

compression flange

L

cr

Effective length of

compression flange

L

cr

Eurocode3:DesignofSteelStructures RLiew&SDPang

BeamswithIntermediateRestraints

Lateral torsional buckling resistance checks should be carried out on all unrestrained segments of

beams (between the points where lateral restraint exists).

The effect of moment distribution between the lateral restraints may be taken into account by

modifying

LT

using Equation 6.58 from EN1993-1-1 Cl 6.3.2.3(2).

29

Illustration of flanges being free to

rotate on plan along span

Plan

Bottom flange

Top flange

y

z

x

u

23/8/2012

30

Design Procedure for LTB

ODetermine buckling curve (a, b, c, or d) from Table 6.4or Table 6.5.

ODetermine imperfection factor

LT

from Table 6.3after identifying the buckling curve.

ODetermine the elastic critical lateral torsional buckling moment M

cr

.

ODetermine effective buckling length L

cr

.

GCheck M

Ed

/ M

b,Rd

1.0for each unrestrained segment.

OCalculate buckling reduction factor

LT

.

ODetermine buckling resistance M

b,Rd

.

OCalculate non-dimensional slenderness .

ODetermine shear and bending moment diagram from design loads.

OSelect and classify section.

31

31

Design Flow Chart for Beams Subjected to LTB

Compute and draw the SFD and BMD

under design actions

Select a trial section for the most critical

segment based on M

b,Rd

Determine f

y

and perform section

classification

Ultimate strength check moment and

shear at critical locations

Member buckling resistance check for each

segment

Serviceability check

Section

classification

23/8/2012

32

Examples

Eurocode3:DesignofSteelStructures RLiew&SDPang

33

Example URB-1: Buckling Resistance of UB

A beam of span 10 m is simply supported at its ends and unrestrained along its length. It

supports a uniformly distributed load across the entire span and a point load at its mid-span.

Check and verify if section UB 533210101 in S355 steel is suitable for this beam. Assume

that the beam carried plaster finish.

Unfactored load values:

Dead Load UDL 5 kN/m Imposed Load UDL 10 kN/m

Point load 50 kN Point load 100 kN

5m 5m

50 kN +100 kN

5 kN/m+10 kN/m

Eurocode3:DesignofSteelStructures RLiew&SDPang

34

Ultimate Limit State

The section and loading are the same as Example RB-1.

Perform the same section classification, shear check, deflection check as described in

Example RB-1.

In this example, we will perform check on the lateral torsional buckling for this unrestrained

beam.

5m 5m

67.5 kN +150 kN

6.75 kN/m+15 kN/m

217.5 kN 217.5 kN

Design Moment

Maximum bending momentat mid-span: M

Ed

= (6.75+15)*10

2

/8 + (67.5+150)*10/4 = 816kNm.

Design Shear

Maximum shear forceat the supports: V

Ed

= 217.5kN.

UB 533210101 in S355 steel

Eurocode3:DesignofSteelStructures

35

Buckling Length

L

cr

= 10m

Elastic Critical Moment

Assume C

1

= 1.0 (conservative estimate)

Imperfection Factor

h/b = 536.7/210.0 = 2.6 > 2

Use buckling curve c (refer to Table 6.5)

Imperfection factor

LT

= 0.49 (refer to Table 6.3)

Assume beam end conditions:

Compression flange laterally restrained;

Nominal torsional restraint against rotation about longitudinal axis;

Both flanges free to rotate on plan;

Normal loading condition; k= 1.0 and L

cr

= 10m

Comment: for beam subject to UDL C

1

= 1.132

for mid-span point load C

1

= 1.365

You may select C

1

= 1.132 instead of 1.0

Eurocode3:DesignofSteelStructures

36

Eurocode3:DesignofSteelStructures

Simplified Assessment

37

Non-Dimensional Slenderness

Buckling Reduction Factor

Buckling Resistance

Since M

Ed

= 816 kNm > M

b,Rd

, resistance to lateral torsional buckling is inadequate.

(more conservative!)

Less conservative method Eq. 6.57

Eurocode3:DesignofSteelStructures

Re-design the beam Options?

38

5m 5m

67.5 kN +150 kN

6.75 kN/m+15 kN/m

217.5 kN 217.5 kN

UB 533210101 in S355 steel is inadequate

Eurocode3:DesignofSteelStructures

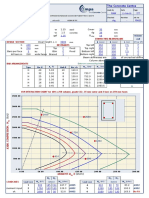

Design Table Page D-65

Select

533x312x182 UB S355 Steel,

Buckling resistance

M

by,Rd

= 965kNm > 816kNm

OK

UB 533210101 in S355 steel is

NOT adequate

M

Ed

=816kNm

L = 10 m

C

1

= 1.0

Design Table Page D-103

533x312x182 UB S355 Steel,

Design shear resistance

V

c,Rd

= 1740 kN > 217.5 kN

OK

Page D-65

39

Eurocode3:DesignofSteelStructures

B C

Example URB2

The simply supported beam shown below is restrained laterally at the ends and at the

points of load applications only. For the given loading, design the beam in S275 steel.

3m 3m 3m

Permanent:

self-weight: 3 kN/m

point load, beam 1, G

k1

= 40 kN

point load, beam 2, G

k2

= 20 kN

Beam1 Beam2

Imposed:

point load, beam 1, Q

k1

= 60 kN

point load, beam 2, Q

k2

= 30 kN

A D

40

Eurocode3:DesignofSteelStructures

Design loads:

UDL =3 1.35 =4.05 kN/m

F

D1

=40 1.35 +60 1.5 =144 kN;

F

D2

=20 1.35 +30 1.5 =72 kN

144 kN 72 kN

4.05 kN/m

3m 3m 3m

138.2

126.1

17.9

30.1

102.1

114.2

Shear (kN)

Bending (kNm)

396.5

324.5

A

B C

D

For beam segment within intermediate lateral restraints, C

1

= 1.0

41

Eurocode3:DesignofSteelStructures

42

M

Ed

= 396.5kNm ; L

cr

= 3m

Page C-67

Select 457x 191 x 82 UB S275 steel, M

b,Rd

= 421 kNm > 396 kNm

Eurocode3:DesignofSteelStructures

Tutorial questions

What are the main different behaviour between laterally

restrained and un-restrained steel beam?

Unrestrained beam deflects and buckles laterally

What are the main factors affecting the bending capacity of

laterally unrestrained steel beams?

Unbraced length, cross sectional shapes, loading, end support

conditions etc.

How do we prevent lateral torsional buckling of beams?

Use hollow sections; provide adequate lateral bracing

How do we ensure lateral restraints are effective?

Need to anchor the lateral tie

43

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Orthotropic plate bending theoryDocument3 paginiOrthotropic plate bending theoryK SrinivasÎncă nu există evaluări

- IESAV - 2b. Design of Prestressed Transfer PlateDocument39 paginiIESAV - 2b. Design of Prestressed Transfer PlateMelinda GordonÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Spreadsheets To EC2: Advisory Group Grid Line 1 RMW 202 CHG - FB625Document8 paginiSpreadsheets To EC2: Advisory Group Grid Line 1 RMW 202 CHG - FB625Khac Hoang PhamÎncă nu există evaluări

- EN STANDARDS FOR CONCRETEDocument64 paginiEN STANDARDS FOR CONCRETEMelinda Gordon75% (4)

- TCC54 Circular Column DesignDocument93 paginiTCC54 Circular Column DesignMelinda Gordon100% (1)

- ABS Fatigue Life Assessment 2014Document1 paginăABS Fatigue Life Assessment 2014Fandy SipataÎncă nu există evaluări

- Lecture 7Document193 paginiLecture 7Melinda GordonÎncă nu există evaluări

- SOM Question Bank For RevisionDocument11 paginiSOM Question Bank For RevisiongoldencometÎncă nu există evaluări

- Chapter 5 Flexural MembersDocument40 paginiChapter 5 Flexural MembersAriel Dela CruzÎncă nu există evaluări

- Polymer Compounding and FabricationDocument10 paginiPolymer Compounding and FabricationS-HafizNoman100% (1)

- TCC54 Circular Column DesignDocument96 paginiTCC54 Circular Column DesignMelinda GordonÎncă nu există evaluări

- TCC54 Circular Column DesignDocument96 paginiTCC54 Circular Column DesignMelinda GordonÎncă nu există evaluări

- Ractangular Ground Water TankDocument24 paginiRactangular Ground Water Tanksurendra_panga100% (2)

- TCC15 Resistance of Retaining MembersDocument9 paginiTCC15 Resistance of Retaining MembersMelinda GordonÎncă nu există evaluări

- Synthetic Fiber Reinforced Concrete PropertiesDocument13 paginiSynthetic Fiber Reinforced Concrete PropertiesSahir Abas0% (1)

- TCC11 Element DesignDocument8 paginiTCC11 Element DesignMelinda GordonÎncă nu există evaluări

- CFD Is 456 2000 PDFDocument85 paginiCFD Is 456 2000 PDFputra wiraÎncă nu există evaluări

- Thermal StressDocument104 paginiThermal Stressgaspardo123100% (1)

- Precast ConnectionDocument108 paginiPrecast ConnectionFreddie Koo100% (2)

- f6nm PDFDocument5 paginif6nm PDFasprclms durgapur100% (1)

- 11 Continuous BeamsDocument55 pagini11 Continuous BeamsMelinda GordonÎncă nu există evaluări

- TCC31 One-Way SlabsDocument28 paginiTCC31 One-Way Slabsmdelacua2100% (1)

- CE 5101 Lecture 10 Consolidation Monitoring MethodsDocument30 paginiCE 5101 Lecture 10 Consolidation Monitoring MethodsMelinda GordonÎncă nu există evaluări

- Design Coupling Beams Based OnACI and ECDocument11 paginiDesign Coupling Beams Based OnACI and ECNgoc Ba NguyenÎncă nu există evaluări

- 4 Chemical AdmixturesDocument59 pagini4 Chemical AdmixturesMelinda Gordon100% (1)

- 4 Chemical AdmixturesDocument59 pagini4 Chemical AdmixturesMelinda Gordon100% (1)

- TCC94 Two-Way Slabs (Tables)Document5 paginiTCC94 Two-Way Slabs (Tables)Melinda GordonÎncă nu există evaluări

- TCC52 Column Chart GenerationDocument8 paginiTCC52 Column Chart GenerationkunalÎncă nu există evaluări

- TCC33 Flat Slabs (A & D)Document37 paginiTCC33 Flat Slabs (A & D)Melinda GordonÎncă nu există evaluări

- TCC21 Subframe AnalysisDocument41 paginiTCC21 Subframe AnalysisMelinda GordonÎncă nu există evaluări

- IESAV - 2a. Analysis & Detailing of Prestressed Flat SlabDocument28 paginiIESAV - 2a. Analysis & Detailing of Prestressed Flat SlabMelinda GordonÎncă nu există evaluări

- Circular Fire CodeDocument2 paginiCircular Fire CodeMelinda GordonÎncă nu există evaluări

- Fresh ConcreteDocument60 paginiFresh ConcreteMelinda GordonÎncă nu există evaluări

- CE5101 Lecture 2 - Darcy Law and Soil Permeability (14 AUG 2013)Document54 paginiCE5101 Lecture 2 - Darcy Law and Soil Permeability (14 AUG 2013)Melinda GordonÎncă nu există evaluări

- CE5107 HC 2011 L3 Slides (Rev - Feb 2012)Document88 paginiCE5107 HC 2011 L3 Slides (Rev - Feb 2012)Melinda GordonÎncă nu există evaluări

- Lecture 4aDocument156 paginiLecture 4aMelinda GordonÎncă nu există evaluări

- Aggregates for Concrete - Properties and TestingDocument55 paginiAggregates for Concrete - Properties and TestingMelinda GordonÎncă nu există evaluări

- Selection of Concrete CompositionDocument62 paginiSelection of Concrete CompositionMelinda GordonÎncă nu există evaluări

- CE5604 Fibre Reinforced Concrete - Part 1 (Compatibility Mode)Document21 paginiCE5604 Fibre Reinforced Concrete - Part 1 (Compatibility Mode)Melinda GordonÎncă nu există evaluări

- Aggregates for Concrete - Properties and TestingDocument55 paginiAggregates for Concrete - Properties and TestingMelinda GordonÎncă nu există evaluări

- Magnetism of Nanoparticles: Effects of Size, Shape, and InteractionsDocument2 paginiMagnetism of Nanoparticles: Effects of Size, Shape, and Interactionsyanilagi5048Încă nu există evaluări

- Moment RedistributionDocument31 paginiMoment Redistributionpiyush singhÎncă nu există evaluări

- A Comparative Study of Tribological Behaviour of PVD Coatings On The Ti-6Al-4V AlloyDocument12 paginiA Comparative Study of Tribological Behaviour of PVD Coatings On The Ti-6Al-4V AlloyAna EscudeiroÎncă nu există evaluări

- HOOKES LAW - Docx MCQDocument4 paginiHOOKES LAW - Docx MCQfarogh hamid100% (2)

- Asda RetDocument4 paginiAsda RetbillymosisÎncă nu există evaluări

- On The Possibility of Laser Cladding For 304 SS Using Commercially Pure TitaniumDocument7 paginiOn The Possibility of Laser Cladding For 304 SS Using Commercially Pure Titaniumsajjad moattarÎncă nu există evaluări

- Esfuerzos Promedios y Barra Con Carga AxialDocument25 paginiEsfuerzos Promedios y Barra Con Carga AxialCarlos Ubaldo Labra FierroÎncă nu există evaluări

- Fracture Mechanics 1 EBB 334Document37 paginiFracture Mechanics 1 EBB 334Luiz CordeiroÎncă nu există evaluări

- Band GapDocument13 paginiBand Gapit rewaÎncă nu există evaluări

- Lecture Slides: The Mcgraw-Hill Companies © 2012Document73 paginiLecture Slides: The Mcgraw-Hill Companies © 2012mazlumÎncă nu există evaluări

- Introduction To Fluid Mechanics: © Fox, Mcdonald & PritchardDocument16 paginiIntroduction To Fluid Mechanics: © Fox, Mcdonald & PritchardpramudasirodzÎncă nu există evaluări

- Tin Oxide (SnO2) MaterialsDocument16 paginiTin Oxide (SnO2) Materialsozoemena29Încă nu există evaluări

- EM321 TOPIC 1 - Failure Theories and Fatigue Strength PDFDocument180 paginiEM321 TOPIC 1 - Failure Theories and Fatigue Strength PDFJoshua RajÎncă nu există evaluări

- NOED - Flexible PipesDocument34 paginiNOED - Flexible PipesZhizhou Wang100% (2)

- 3.5A. Steady Flow Energy Equation (SFEE)Document5 pagini3.5A. Steady Flow Energy Equation (SFEE)MǾhămed TăwfiķÎncă nu există evaluări

- Thermodynamics and Statistical Mechanics - NET-JRF PDFDocument47 paginiThermodynamics and Statistical Mechanics - NET-JRF PDFMayank TiwariÎncă nu există evaluări

- Shear EnhancedDocument8 paginiShear Enhancedunitedfc9612Încă nu există evaluări

- Materials: 3D Analysis of Deformation and Porosity of Dry Natural Snow During CompactionDocument15 paginiMaterials: 3D Analysis of Deformation and Porosity of Dry Natural Snow During CompactionchamanchandelÎncă nu există evaluări

- Wear of Flame-Sprayed Ni-Cr-B-Si Powder Coating On Journal For Seal ContactDocument6 paginiWear of Flame-Sprayed Ni-Cr-B-Si Powder Coating On Journal For Seal Contactmuhammad abduhÎncă nu există evaluări