Documente Academic

Documente Profesional

Documente Cultură

Manual Posicionador Power Genex

Încărcat de

rexxxx987Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Manual Posicionador Power Genex

Încărcat de

rexxxx987Drepturi de autor:

Formate disponibile

Instruction Manual

EPL Series Electro-Pneumatic Positioner

1. Read all safety instructions in this manual carefully before using this EPL positioner. All work should be done by staff with the necessary training and experience. 2. The air filter regulator should be installed before this EPL positioner. 3. The EPL positioned approved for ATEX Eex md IIB T5 must be connected to a fuse with the following ratings: - Max 125mA, breaking capacity 35A - Suitable 1/2 PF threaded, certified EEx d cable glands and plugs must be used.

Pressure Gauge Stainless Steel Output Characteristics Linear Linearity Within 1.0 % F.S Within 1.5 % F.S Sensitivity Within 0.2 % F.S Within 0.5 % F.S Hysteresis Within 1.0 % F.S Repeatability Within 0.5 % F.S Air Consumption 5 LPM (Sup. 1.4kgf/) Flow Capacity 80 LPM (Sup. 1.4kgf/) Material Aluminum Die-cast Weight 2.9 kg (with terminal box) Note: 1) 1/2 spilt range is available for 4-12mA input signal or 12-20mA input signal. 2) Operating stroke can be extended up to 80~150mm.

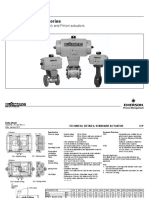

4. Air Connections

3. Mounting and Selecting RA (reverse acting) or DA (direct acting)

CAUTION: To reduce the risk of ignition of hazardous atmospheres, disconnect the device from the supply circuit before opening. Keep assembly tightly closed during operation.

A. Mounting and Attaching Feedback Lever

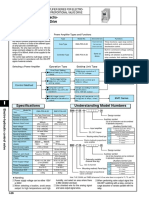

1. Part Number System

EPL

Protection Feedback Class Lever Pressure Gauge (SUP. OUT) Pilot Valve Orifice Position Connection Feedback Threads High Temp Mounting Bracket

Description Protection Class:

Code

Description Position Feedback: (only for weatherproof type) Connection Threads: (pneumatic electrical) High Temperature: (only for weatherproof type) Mounting Bracket:

Code

Mount the EPL positioner to the control valve as shown to the right. Fix the EPL positioner and the feedback lever to the control valve stem at position where the angle between the valve stem is settled to 90 degrees as shown below when the input signal is set to 12mA (50%). Be sure that the elimination spring should be installed. The feedback lever A is for stroke 1040mm and the feedback lever B is for stroke 10~80mm. For up to stroke 150mm, please connect a feedback lever A and a feedback ever B with each other. The operation angle of the EPL positioner is minimum 10 and maximum 30 .

5. Internal View

Auto/Manual screw

Stopper screw Seat adjuster

F: Flameproof Ex md IIB T6 D: Flameproof Ex md IIC T6 A: Flameproof Eex md IIB T5 ATEX I: Intrinsic safety (Ex ia IIB T6) W: Weatherproof to IP66

N: None (standard) O: Position transmitter (4~20mA output signal)

Pilot valve

Output pressure gauge Zero adjusting screw

Connect the feedback lever and the enclosed additional feedback lever with each other for a stroke extension of over 80mm.

Nozzle

Supply pressure gauge

Feedback Lever:

A: stroke (10~40mm) B: stroke (10~80mm) C: stroke (80~150mm)

3: PT 1/4 PT 1/2 (standard) 4: NPT 1/4 NPT 1/2 5: PT 1/4 M20 x 1.5

Span adjusting screw

Terminal box

Pressure Gauge:

1: 6 bar (90 psi) 2: 10 bar (150 psi)

Pilot Valve Orifice:

T: 70 (standard) H: 120 (without position feedback option) 85 (with position feedback option)

Feedback lever

[Elimination Spring Installation]

Torque motor

Case

S: Standard (actuator volume over 180 ) M: Small orifice (1.0 or 0.7) (actuator volume 90~180 )

N: None L: For DIN / IEC 534

B. Position of Span Adjuster According to Actuator Type (RA or DA)

Span adjuster is set to RA (reverse acting) as a standard factory setting. But it is necessary to re-set its position for DA (direct acting) as shown below.

Never move the seat adjuster. It was already set at the factory precisely.

2. Specifications

EPL Linear Type (Lever Feedback) Single Double 4~20mA DC (Note. 1) 235 15 Max. 7.0bar (100psi) free of oil, water, and moisture 10~80mm (Note. 2) Rc 1/4 (NPT 1/4) Rc 1/2 (NPT 1/2) Ex md IIB T6, Ex md IIC(H2) T6, IP66, Ex ia IIB T6 Eex md IIB T5 ATEX -20~70

WARNING: When adjusting or replacing a span adjuster, be sure to shut off air supply to the EPL positioner. Otherwise, the EPL positioner might react suddenly and cause damage or injury.

Input Signal Input Resistance Air Supply Standard Stroke Pneumatic Connections Electrical Connections Protection Class Ambient Temperature

Direct Acting (DA)

Reverse Acting (RA)

There happens a hunting with a small pneumatic actuator

Install two orifices at the bottom of the pilot valve as instructed in 12. Optional Restricted Pilot Valve Orifice The orifice of the Auto/Manual screw on the pilot valve is clogged. Disconnect supply air and clean the orifice with a wire attached inside of the EPL positioner cover as shown below.

The valve always opens regardless of input signal.

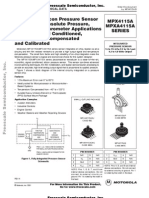

B. Specifications

Power Supply Rating Recommended Power Supply Output Signal Operating Temperature Load Impedance Max. Output Linearity Hysteresis Repeatability Adjustment 5.5~30V DC loop-powered 24V DC 4~20mA -20 to 70 0~600 ohms 30mA DC 1.0 % 1.0 % of full scale 0.5 % of full scale Zero and Span in terminal box Never move the seat adjuster. It was already set at the factory precisely. The air connections are not made properly. Check again if the pneumatic actuator type is RA (reverse acting) or DA (direct acting) and make the proper air connections. See 7. Air Connections. Re-set Zero and Span. Tighten a mounting bracket.

The valve always opens or closes with input signal Linearity is very poor Hysteresis is very poor

6. Span and Zero Adjustment

Check the proper installation of the EPL positioner and the feedback lever. Check the proper position of a span adjuster according to the actuator type (direct acting or reverse acting). Connect all air connections. Supply air and set the input signal to 4mA. Turn the zero adjusting screw clockwise or counter clockwise to set the zero position. Check the stroke of the control valve by setting the input signal to 20mA. If the stroke does not meet 100%, turn the span adjusting screw clockwise or counter clockwise until 100% is reached. Set the input signal back to 4mA and adjust the zero adjusting screw until the zero point is reached. Repeat the process of to until the desired set points are reached. If the strokes of the control valve perfectly meet 0% and 100%, each setting point of 8, 12, and 16mA is automatically reached.

C. With mA loop calibrator

D. With multimeter tester

11. Dimensions

NOTE: Due to variations in circuitry and environmental effects, often 0% is set at 4.5mA and 100% at 19.5mA to make sure that at the end points the valve will be fully open or fully closed.

E. Span and Zero Adjustment

Select RA or DA on a board in the terminal box. For reference, RA (reverse acting) is a standard factory setting. Supply 4mA input signal and turn the zero adjusting screw on a board clockwise or counter clockwise until output signal becomes 4mA. Supply 20mA input signal and turn the span adjusting screw on a board clockwise or counter clockwise until output signal becomes 20mA. Repeat the process of to until output signal approaches input signal.

7. Wire Diagrams

1. Be sure that Span and Zero of the EPL positioner should be exactly set before setting Span and Zero of the position transmitter. 2. Be sure that 5.5 - 30VDC should be supplied in case of using the mA tester (multimeter tester). 3. Check a loop power if the output power indicating lamp is not on.

CAUTION: Always check that the electrical load is within the range stated on the nameplate. Failure to remain within electrical ratings may result in damage to or premature failure of the electrical switches, sensors or transmitter electronics. NOTE: For the ATEX-approved product, please connect a fuse with the ratings of Max. 125mA, breaking capacity 35A and suitable 1/2 PF threaded certified EEx d cable glands and plugs must be used.

9. Optional Restricted Pilot Valve Orifice

WARNING: Before removing the pilot valve, be sure to disconnect the EPL positioner from the signal and compressed air source

For improved control using smaller actuators, a restricted pilot valve orifice kit is included with the EPL positioner. To install, the pilot valve must be removed from the EPL positioner. Remove four screws holding the pilot valve to the EPl positioner body. As you remove the pilot valve, be sure to hold the compensation spring in place. Flip the valve so the bottom faces you. Remove the o-rings from the out 1 and out 2 ports (as shown in the diagram at right). Place the orifice plates in their place with new O-rings above them, and re-install the pilot valve, making sure the compensation spring is back in place. The EPL positioner is now set up for smaller actuators.

Power-Genex Ltd.

44B9L, 434-9, Nonhyun-dong, Namdong-gu, Incheon 405-849 Korea Tel: +82-32-812-6644 Fax: +82-32-812-6645 www.powergenex.com sales@powergenex.com

8. Position Transmitter (420mA output signal)

A. Board View

10. Troubleshooting Tips

Troubles Solutions

S-ar putea să vă placă și

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe la EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Electro-Pneumatic Positioner EPL Series: Instruction ManualDocument8 paginiElectro-Pneumatic Positioner EPL Series: Instruction ManualSimbu ArasanÎncă nu există evaluări

- PositionerDocument13 paginiPositionerLeonidas PetrouÎncă nu există evaluări

- Calibracion E69PDocument16 paginiCalibracion E69PmktcableÎncă nu există evaluări

- Electro Pneumatic EN40Document5 paginiElectro Pneumatic EN40Harold David VillacísÎncă nu există evaluări

- Electro/Pneumatic Valve Positioners (P3300)Document6 paginiElectro/Pneumatic Valve Positioners (P3300)workt1meÎncă nu există evaluări

- Type 1000 Transducer Product Instructions: Principle of OperationDocument6 paginiType 1000 Transducer Product Instructions: Principle of OperationEdge-TecÎncă nu există evaluări

- DTB ManualDocument13 paginiDTB ManualJorge BurbanoÎncă nu există evaluări

- DWYER - RHP-3D-11.instruções PDFDocument4 paginiDWYER - RHP-3D-11.instruções PDFMarcio Issao WatanabeÎncă nu există evaluări

- T 1000 ManualDocument6 paginiT 1000 ManualCeleste PrantlÎncă nu există evaluări

- 2007 Triac ERP PositionerDocument6 pagini2007 Triac ERP PositionerAnderson SiqueiraÎncă nu există evaluări

- Series 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)Document4 paginiSeries 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)chekit9Încă nu există evaluări

- Altec Lansing 1594-B Owners ManualDocument14 paginiAltec Lansing 1594-B Owners Manualspiders34Încă nu există evaluări

- User Guide Hipot 860 PLDocument21 paginiUser Guide Hipot 860 PLarnosyÎncă nu există evaluări

- Rca ctc179cm Chassis (ET)Document32 paginiRca ctc179cm Chassis (ET)titoritomex100% (1)

- Belgas T2000EP IOMDocument4 paginiBelgas T2000EP IOMSMcÎncă nu există evaluări

- H1000e I Ema-Emc PDFDocument4 paginiH1000e I Ema-Emc PDFNguyen Van ChungÎncă nu există evaluări

- Transductor FLOWSERVE NT3000Document20 paginiTransductor FLOWSERVE NT3000Xavier EspinozaÎncă nu există evaluări

- Proportional Control Valves with Integrated 24 Volt ElectronicsDocument24 paginiProportional Control Valves with Integrated 24 Volt ElectronicsLuis Alberto RamosÎncă nu există evaluări

- Arca Valve Manual - 830 POSITIONERDocument13 paginiArca Valve Manual - 830 POSITIONERAtul bhabad0% (1)

- DeltaDocument13 paginiDeltaNguyễn Minh CườngÎncă nu există evaluări

- 3730-1 Positioner for Pneumatic Control ValvesDocument6 pagini3730-1 Positioner for Pneumatic Control ValvesJuan MuñozÎncă nu există evaluări

- D02601880 - Instruction ManualDocument2 paginiD02601880 - Instruction ManualAsyraf BadaruddinÎncă nu există evaluări

- Dixell Fan Speed Controller Setup and Wiring GuideDocument2 paginiDixell Fan Speed Controller Setup and Wiring GuidedbricchiÎncă nu există evaluări

- EMO-T EN LowDocument8 paginiEMO-T EN Low윤병택Încă nu există evaluări

- KXNSERIESDocument6 paginiKXNSERIESJorge Martin Bejarano GonzalezÎncă nu există evaluări

- Magnetrol 48-635Document36 paginiMagnetrol 48-635João LuizÎncă nu există evaluări

- Pneumatic and Apm Liquid Level ControlDocument12 paginiPneumatic and Apm Liquid Level Controlyuri0527Încă nu există evaluări

- E1 - E1A - E1Box - E1FDocument14 paginiE1 - E1A - E1Box - E1FDarek SlonskiÎncă nu există evaluări

- Welding Consumables-Stainless SteelDocument27 paginiWelding Consumables-Stainless SteelibicengÎncă nu există evaluări

- EC3-X33 Superheat Controller and ECD-002 Keypad / Display UnitDocument25 paginiEC3-X33 Superheat Controller and ECD-002 Keypad / Display UnitMojtaba GholamiÎncă nu există evaluări

- DVP Slim Digital I/O Extension Instruction SheetDocument2 paginiDVP Slim Digital I/O Extension Instruction SheetBustamante PerroneÎncă nu există evaluări

- 62 Series Servovalves Technical OverviewDocument8 pagini62 Series Servovalves Technical OverviewDevendra BangarÎncă nu există evaluări

- Masoneilan 8012 8013 FactSheet 0612Document8 paginiMasoneilan 8012 8013 FactSheet 0612Omar ChaoukiÎncă nu există evaluări

- RGS c1518Document2 paginiRGS c1518Amila AbeywickramaÎncă nu există evaluări

- Manual Servomex Xendos 1800Document20 paginiManual Servomex Xendos 1800Josh MoralesÎncă nu există evaluări

- Contador Hanyoung GE4Document4 paginiContador Hanyoung GE4Juan Felipe Vieira Gaviria0% (1)

- KX Eng PDFDocument4 paginiKX Eng PDFlinhpic99Încă nu există evaluări

- GX30R 100RDocument53 paginiGX30R 100RSergio Garcia100% (1)

- Universal 16 Amp Self Excited Automatic Voltage Regulator ManualDocument9 paginiUniversal 16 Amp Self Excited Automatic Voltage Regulator ManualJuan José Tovar Pérez100% (1)

- T83840en PDFDocument6 paginiT83840en PDFshareyhou100% (1)

- 1-1-5 en Frese OPTIMA Compact Actuators DN40-200 JUN 16Document4 pagini1-1-5 en Frese OPTIMA Compact Actuators DN40-200 JUN 16engesam2007Încă nu există evaluări

- Valtek XL Series High Performance Positioner: For Control ValvesDocument8 paginiValtek XL Series High Performance Positioner: For Control ValvesRifadli GatesÎncă nu există evaluări

- La 42102Document8 paginiLa 42102buyadiÎncă nu există evaluări

- 15 - Pressure Relay For OLTC - (AKM - 35600 - Qualitrol)Document5 pagini15 - Pressure Relay For OLTC - (AKM - 35600 - Qualitrol)Trần Minh TríÎncă nu există evaluări

- Chassis CTC186 187ABDocument20 paginiChassis CTC186 187ABjujorokoÎncă nu există evaluări

- TT100 User Manual 2012 ENGL PDFDocument90 paginiTT100 User Manual 2012 ENGL PDFErika Sears100% (1)

- Proportional Pressure Control Valves Series P2 & 4VP01Document12 paginiProportional Pressure Control Valves Series P2 & 4VP01abuzer1981Încă nu există evaluări

- AD INTERNATIONAL Model 950Document21 paginiAD INTERNATIONAL Model 950Zoeloe_2Încă nu există evaluări

- Displacer Type Level SwitchDocument10 paginiDisplacer Type Level SwitchKarthik Chockkalingam100% (1)

- Flowserve Apex 4000 PositionerDocument8 paginiFlowserve Apex 4000 PositionerCrown_12Încă nu există evaluări

- DTA Manual UsuarioDocument12 paginiDTA Manual Usuario99lea99Încă nu există evaluări

- MPXA4511A Pressure SensorDocument9 paginiMPXA4511A Pressure SensorGiuseppe ZangariÎncă nu există evaluări

- SD 16 eDocument20 paginiSD 16 eseaqu3stÎncă nu există evaluări

- AVR EA 16-Manual-EnDocument6 paginiAVR EA 16-Manual-EnSyed Mohammad NaveedÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDe la EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationÎncă nu există evaluări

- 110 Integrated Circuit Projects for the Home ConstructorDe la Everand110 Integrated Circuit Projects for the Home ConstructorEvaluare: 4.5 din 5 stele4.5/5 (2)

- Serial de Hart - ServerDocument17 paginiSerial de Hart - Serverrexxxx987Încă nu există evaluări

- PID User ManualDocument126 paginiPID User ManualPaulo ConcepcionÎncă nu există evaluări

- DPI 620 Genii ManualDocument179 paginiDPI 620 Genii Manualrexxxx987Încă nu există evaluări

- LZB Festo AG Co KG en 3 2010 PDFDocument6 paginiLZB Festo AG Co KG en 3 2010 PDFrexxxx987Încă nu există evaluări

- ATEX, IECEx & KC Certified Analog Position TransmitterDocument4 paginiATEX, IECEx & KC Certified Analog Position Transmitterrexxxx987Încă nu există evaluări

- Common Mode Inductors/EMI Filters: Special FeaturesDocument1 paginăCommon Mode Inductors/EMI Filters: Special Featuresrexxxx987Încă nu există evaluări

- 555 Timer CircuitsDocument112 pagini555 Timer Circuitsolivirus1007100% (1)

- How To Communicate Between A PanelView Plus and A MicroLogixDocument4 paginiHow To Communicate Between A PanelView Plus and A MicroLogixLauro JoseÎncă nu există evaluări

- Serial de Hart - ServerDocument17 paginiSerial de Hart - Serverrexxxx987Încă nu există evaluări

- Timer 555 DatasheetDocument11 paginiTimer 555 DatasheetMissael Lavado MarquezÎncă nu există evaluări

- Autocad LibreriasDocument1 paginăAutocad Libreriasrexxxx987Încă nu există evaluări

- Siemens Sirius 3RW30 3RW40 Manual PDFDocument212 paginiSiemens Sirius 3RW30 3RW40 Manual PDFElias Nassif GomezÎncă nu există evaluări

- HTML Code Generator V 1.0 For Simatic IT Modules CP 443-1 IT, 343-1 IT, 243-1 ITDocument18 paginiHTML Code Generator V 1.0 For Simatic IT Modules CP 443-1 IT, 343-1 IT, 243-1 ITCek Han IsengÎncă nu există evaluări

- Timer 555 DatasheetDocument11 paginiTimer 555 DatasheetMissael Lavado MarquezÎncă nu există evaluări

- 3BUS208222 4.0 en Industrial IT Quality Control Theory of Operation GuideDocument254 pagini3BUS208222 4.0 en Industrial IT Quality Control Theory of Operation Guiderexxxx987Încă nu există evaluări

- 20comm Um002 - en PDocument246 pagini20comm Um002 - en Prexxxx987Încă nu există evaluări

- Micromaster Drive On Rockwell ControlLogix v10 enDocument52 paginiMicromaster Drive On Rockwell ControlLogix v10 enLuis Chuquimia GuillenÎncă nu există evaluări

- PowerFlex 750-Series AC Drive Installation GuideDocument214 paginiPowerFlex 750-Series AC Drive Installation Guiderexxxx987Încă nu există evaluări

- 01D100 - MANUAL - ENG Sensor de FlotacionDocument14 pagini01D100 - MANUAL - ENG Sensor de Flotacionrexxxx987Încă nu există evaluări

- Micromaster Drive On Rockwell ControlLogix v10 enDocument52 paginiMicromaster Drive On Rockwell ControlLogix v10 enLuis Chuquimia GuillenÎncă nu există evaluări

- Norma ISO6722 - Cableado en VehiculosDocument13 paginiNorma ISO6722 - Cableado en VehiculosMaxwell MazariegosÎncă nu există evaluări

- Manual - Aztec THDDocument112 paginiManual - Aztec THDCesar Augusto100% (1)

- S1501 Piping SpecDocument33 paginiS1501 Piping SpecLiou Will SonÎncă nu există evaluări

- tl082 Op Amp DatasheetDocument23 paginitl082 Op Amp DatasheetnurburgÎncă nu există evaluări

- 110707Document39 pagini110707pac100% (8)

- Commentary and Worked Examples To en 1993-1-5-Plated StructuresDocument230 paginiCommentary and Worked Examples To en 1993-1-5-Plated Structuresda_116107118Încă nu există evaluări

- Igmp SnoopDocument20 paginiIgmp SnoopcetinalicanÎncă nu există evaluări

- Maintenance Coordinator Utilities: Job DescriptionDocument2 paginiMaintenance Coordinator Utilities: Job DescriptionyagolainÎncă nu există evaluări

- MRN 1391 - Ranps-Sibayak - 2021 - TDDDocument7 paginiMRN 1391 - Ranps-Sibayak - 2021 - TDDRixson SitorusÎncă nu există evaluări

- Madvac LR50e - ExprolinkDocument4 paginiMadvac LR50e - ExprolinkpppopÎncă nu există evaluări

- Bdix Server ListDocument3 paginiBdix Server ListIftekhar Rahman RihamÎncă nu există evaluări

- Currie Palletizer Product Line PDFDocument4 paginiCurrie Palletizer Product Line PDFtintucinbÎncă nu există evaluări

- NEOM-NEN-GGD-002 - 02.00 - Guideline - Third Party Testing LaboratoryDocument20 paginiNEOM-NEN-GGD-002 - 02.00 - Guideline - Third Party Testing LaboratoryAymanEssamÎncă nu există evaluări

- Cable Fault DetectorDocument25 paginiCable Fault DetectorHarshalÎncă nu există evaluări

- MVC AuthorisationDocument14 paginiMVC AuthorisationAmareswara RaoÎncă nu există evaluări

- Cisco - VPC ConceptsDocument90 paginiCisco - VPC ConceptsausmitchÎncă nu există evaluări

- C AUDSEC 731 PDF Questions and AnswersDocument5 paginiC AUDSEC 731 PDF Questions and Answersflaviolink2466Încă nu există evaluări

- SAP HANA Modeller - Tata Consultancy Services, Bglor, F2F Interview On Sun, 23rd Aug'15 (Source: Monster)Document2 paginiSAP HANA Modeller - Tata Consultancy Services, Bglor, F2F Interview On Sun, 23rd Aug'15 (Source: Monster)Mani ShankarÎncă nu există evaluări

- Quality Leader ResumeDocument11 paginiQuality Leader Resumeganeshram2305Încă nu există evaluări

- Tetra TB3Document2 paginiTetra TB3Federico MaggiÎncă nu există evaluări

- Reduced Vertical Separation Minimum: MEL RequirementDocument2 paginiReduced Vertical Separation Minimum: MEL RequirementairbusA330Încă nu există evaluări

- Instruction Manual: Color TelevisionDocument31 paginiInstruction Manual: Color TelevisionAlphaÎncă nu există evaluări

- 2006 CSTE CBOK Skill Category 2Document54 pagini2006 CSTE CBOK Skill Category 2api-3733726Încă nu există evaluări

- Mechanical Water Closets and Valve DesignsDocument4 paginiMechanical Water Closets and Valve DesignsSyafiq HakimiÎncă nu există evaluări

- Simosec enDocument44 paginiSimosec enKumar SwamiÎncă nu există evaluări

- Compa Q ArmadaDocument13 paginiCompa Q ArmadaChico SouzaÎncă nu există evaluări

- Em - 1110 2 2610Document652 paginiEm - 1110 2 2610David LeviÎncă nu există evaluări

- 2011 Cctpa RulesDocument10 pagini2011 Cctpa RulescctractorpullingÎncă nu există evaluări

- Philips NTRX300Document41 paginiPhilips NTRX300supermax900Încă nu există evaluări

- CSS NC II TESDA Offers Computer System ServicingDocument4 paginiCSS NC II TESDA Offers Computer System Servicingchandy Rendaje100% (2)