Documente Academic

Documente Profesional

Documente Cultură

Guidef 97 2 PDF

Încărcat de

Noushad P HamsaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Guidef 97 2 PDF

Încărcat de

Noushad P HamsaDrepturi de autor:

Formate disponibile

1997 GUIDELINE for

SELECTION, INSTALLATION AND SERVICING OF RESIDENTIAL HUMIDIFIERS

Guideline F

4301 NORTH FAIRFAX DRIVE

ARLINGTON, VIRGINIA 22203

IMPORTANT

SAFETY RECOMMENDATIONS

It is strongly recommended that the product be designed, constructed, assembled and installed in accordance with nationally recognized safety requirements appropriate for products covered by this guideline. ARI, as a manufacturers' trade association, uses its best efforts to develop guidelines employing state-of-theart and accepted industry practices. However, ARI does not certify or guarantee safety of any products, components or systems designed, tested, rated, installed or operated in accordance with these guidelines or that any tests conducted under its standards will be non-hazardous or free from risk.

Note: This guideline supersedes ARI Guideline F-1988.

Price $10.00 (M) $20.00 (NM) Printed in U.S.A.

Copyright 1997, by Air-Conditioning and Refrigeration Institute Registered United States Patent and Trademark Office

TABLE OF CONTENTS SECTION Section 1. Section 2. Section 3. Section 4. Section 5. Section 6. Section 7. Section 8. PAGE Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Factors Affecting Design Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Humidity Load Determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Equipment Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Installation Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Servicing Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

TABLES Table 1. Table 2. Determination of Humidification Requirements . . . . . . . . . . . . . . . . . . . . . . 2 Selection Based on Type of Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 3

APPENDICES Appendix A. Appendix B. Appendix C. References - Normative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 References - Informative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Periodic Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ARI GUIDELINE F-1997

SELECTION, INSTALLATION AND SERVICING OF RESIDENTIAL HUMIDIFIERS

Section 1. Purpose 1.1 Purpose. The purpose of this guideline is to establish, for humidifiers; definitions of terms; factors and calculation procedures for determining humidification loads; equipment selection procedure; installation practices; and servicing practices. 1.1.1 Intent. This document is intended for the guidance of the industry, including manufacturers, engineers, installers contractors and users. 1.1.2 Review and Amendment. This document is subject to review and amendment as technology advances. 3.3.1 Central System Humidifier. A humidifier that discharges into the air stream of a system. It may be mounted in or on the following: a. b. c. d. e. Return air duct Return air plenum Heating or cooling unit Supply air duct Supply air plenum

3.3.2 Self-Contained Humidifier. A humidifier that discharges into the space to be humidified and which is designed to be operated only with an installed water make-up line and electrical services. This device may or may not be installed within the humidified space. 3.4 Shall, Should, Recommended, or It Is Recommended. Shall, should, recommended, or it is recommended shall be interpreted as follows: 3.4.1 Shall. Where shall or shall not is used for a provision specified, that provision is mandatory if compliance with the standard is claimed. 3.4.2 Should, Recommended, or It Is Recommended. Should, recommended, or it is recommended is used to indicate provisions which are not mandatory but which are desirable as good practice. 3.5 Types of Water. 3.5.1 Demineralized Water. Water that has been treated to remove minerals. 3.5.2 Medium Hard Water. Untreated water with a total mineral content of 5-15 grains per gallon [0.0850.257 grams per liter]. 3.5.3 Naturally Soft Water. Untreated water with low mineral contentusually below 5 grains of total hardness per gallon [0.085 grams of total hardness per liter] and relatively free of chlorides. 3.5.4 Softened Water. Water that has been treated by the ion exchange process (used widely in residential treatment) to exchange the hardness-causing minerals with water soluble sodium salts. Quantity of total dissolved solids (TDS) remains unchanged.

Section 2. Scope 2.1 Scope. This guideline applies to central system and self-contained humidifiers, as defined in ARI Standards 610 and 620, installed in residential and small commercial applications.

Section 3. Definitions 3.1 Definitions. All terms in this document will follow the standard industry definitions in the current edition of ASHRAE Terminology of Heating, Ventilation, AirConditioning and Refrigeration unless otherwise defined in this section. 3.2 Classes of Humidifiers. 3.2.1 Atomizing (Nozzle, Centrifugal, Ultrasonic). Discharges very fine droplets of water which evaporate to raise the level of relative humidity of the air. 3.2.2 Evaporative (Evaporative Wetted Media). Discharges water in the gaseous state to raise the level of relative humidity of the air. Its energy source is not an integral part of the humidifier. 3.2.3 Steam (Immersion Heaters, Electrodes). Discharges water in gaseous state to raise the level of humidity of the air. Its energy source is part of the humidifier. 3.3 Humidifier. A device to add moisture to the air.

ARI GUIDELINE F-1997 3.5.5 Very Hard Water. Untreated water with a total mineral content of more than 15 grains per gallon [0.257 grams per liter]. 4.1.2 Design Inside Conditions.** The design inside conditions to be used for the calculation of humidity requirements are 75EF [23.9EC] and 30% R.H. 4.1.3 Ventilation. Ventilation in a residence is, in most current practices, handled by infiltration. Some installations use a positive inlet duct. For load estimates, calculate the infiltration and positive air quantity (if any) and add the two. 4.1.3.1 Infiltration. Infiltration may be estimated as follows: a. For tight constructionuse air change per hour. b. For average constructionuse 1 air change per hour. c. For loose construction and/or maximum ventilation factoruse 2 air changes per hour. Chapter 20 of the ASHRAE Handbook HVAC Systems and Equipment defines a tight house as one ...assumed to be well insulated, have vapor barriers, tight storm doors and windows with weatherstripping, and its fireplace will be dampered. An average house will be insulated, have vapor barriers, loose storm doors and windows, and a dampered fireplace. A loose house will probably be one constructed before 1930, have little or no insulation, no storm doors or windows, no weatherstripping, no vapor barriers and quite often will have a fireplace without an effective damper.

Section 4. Factors Affecting Design Load 4.1 General. The following should be specified as a basis for the calculation of design humidification loads and equipment selection: a. Design outside conditions b. Design inside conditions c. Size and physical characteristics of residence (1) Heated volume of space to be conditioned. (2) Tightness of structure, insulation, storm windows and doors or equivalent, etc. (CAUTION: Some older structures may have inadequate protection against water vapor transmission through walls, which may result in damage from excessive moisture.) d. Quantity of outside air entering the heated volume of the structure (1) Exhaust fans (2) Fireplace dampers (Open fireplace dampers greatly increase the addition of outside air to the heated volume of the structure; satisfactory performance of a humidifier, as applied to a given structure, is based upon these dampers being closed.) e. Internal load generated (1) In calculating humidity load requirements in residential applications, internal load factors have not been included because of the variance which will occur in living habits, e.g., bathing and laundry habits, cooking, number of occupants, etc. 4.1.1 Design Outside Conditions.* The design outside conditions to be used for calculating humidity requirements are as follows: a. for tight construction . . . . . . . 0EF [-17.8EC] and 80% R.H. b. for average construction . . . . . 20EF [-6.7EC] and 80% R.H. c. for loose construction . . . . . . . 31EF [-0.6EC] and 80% R.H.

Section 5. Humidity Load Determination 5.1 Humidity load requirements are determined from Table 1.

Derived from Fig. 1, Chapter 20, 1996 ASHRAE Handbook HVAC Systems and Equipment,, see B 1.1.

**

Obtained from Standard Rating Conditions of ARI Standards 610 and 620, See B1.3 and 1.4 respectively.

ARI GUIDELINE F-1997 2. Air changes per hour (tight construction) = 1/2 (See 4.1.3.1) 3. G (indoor) at 75EF [23.9EC] & 30% R.H. = 39 gr/lb dry air [5.58 g/kg dry air] (See 4.1.2.) G (outdoor) at 0EF [-17.8EC] & 80% R.H. = 4 gr/lb dry air [0.57 g/kg dry air] (See 4.1.1.) )G = 35 gr/lb dry air [5.00 g/kg dry air] 4. Humidity load requirement =

Table 1. Determination of Humidification Requirements, gallons per day [liters per day]* Size of Building, sq. ft. [m2] Type of Construction Tight Average Loose

500 [46.45] 2.1 [7.96] 3.3 [12.51] 4.6 [17.43] 1000 1500 2000 2500 3000 [92.90] [139.35] [185.80] [232.25] [278.70] 4.2 [15.92] 6.5 [24.64] 9.2 [34.87] 6.4 [24.26] 9.8 [37.14] 13.8 [52.30] 8.5 [32.22] 13.1 [49.65] 18.4 [69.74] 10.6 [40.17] 16.3 [61.78] 12.7 [48.13] 19.6 [74.28]

V R)G V R)G 6.36 gal/day [24.19 L/day] 33,000 35.13

23.0 27.6 [87.17] [104.60]

* Based on 8 ft. [2.44 m] ceiling height. An amount of 2 gallons per day [7.57 liters per day] may be deducted from these figures if it is desired to take credit for internal sources of humidity (based on a family of four).

Section 6. Equipment Selection 6.1 Types. Select equipment which is suitable for use with the existing or proposed heating system: i.e., central system humidifier or self-contained humidifier. 6.2 Water Conditions. Select the class of humidifier which will operate satisfactorily with a minimum of maintenance using the types of water supply available, as shown in Table 2. (See 3.4, and 3.4.1 through 3.4.5.) 6.3 Limitations. 6.3.1 In all cases, equipment shall be used only within the recommended limitations of the manufacturer except where specific approval for deviation is obtained from the manufacturer. 6.3.2 Services available, i.e., electricity, water, drain, etc., physical layout, space available and accessibility for service may further limit the selection of equipment.

5.2 If it is desired to calculate the humidity load for any reason, such as for buildings of unusual design, the following equation may be used:

24 V R )G V R )G ' ' gal/day L 7000 8.34 33,000 24 V R )G V R )G ' ' L/day L 1000 1 35.13

Where: 24 = Hours per day V = Total volume of space being humidified, cu ft [m3] R = Calculated air changes per hour )G = Difference in moisture content of air between inside and outside conditions, grains of moisture per lb [grams of moisture per kilogram] of dry air (See 4.1.1 and 4.1.2.) L = Specific volume of moist air at inside design conditions = 13.6 cu ft per lb of dry air [0.848 m3/kg of dry air] 7000 = no. of grains per lb [1000 = no. of g/kg] 8.34 = lbs per gallon of water [1.0 = kg/L of water] 5.2.1 Example.

Table 2. Selection Based on Type of Water Supply

Classes of Humidifiers

Atomizing Evaporative Medium Naturally Hard Soft Water Water X X --X Very Hard Water** --X Softened Water* --X Demineralized Water* X X

Steam

* Humidifier construction should use non-corrodible components. ** Excessive water hardness can increase maintenance requirements of humidifiers.

1. Space being humidified: 30 ft [9.14 m] 50 ft [15.24 m] 8 ft [2.44 m] = 12,000 cu ft [339.88 m3]

ARI GUIDELINE F-1997 6.4 Capacity. 6.4.1 Central System Equipment of adequate capacity to satisfy the demand load calculated shall be selected using the rating published in accordance with ARI Standard 610 and corrected to the operating conditions of the system. 6.4.1.1 The ARI Standard 610 rated capacity shall be corrected to the actual capacity to be realized in a given system by the following method: a. Adjusted to reflect actual amount of time the system operates (usually 75% of total time, but this can vary based on heating equipment selected for a given demand load) to maintain the temperature desired in the space when minimum outside design temperatures exist. Note: Steam units may turn on fan when increase in humidity is required and capacity does not need adjustment. Adjusted to reflect actual temperature of the air passing into the evaporative equipment when such temperature is other than that used in the standard rating. (See manufacturers specifications.) Adjusted to reflect actual static pressure differential from supply to return side of the system when such differential is other than the 0.20 in. of H2O [49.8 Pa] used in the standard rating and selecting evaporative equipment utilizing this method of inducing air flow through the humidifier. (See manufacturers specifications.) Adjusted to reflect the velocity of air flow through the system when such differs from the 800 ft/min [4.06 m/s] used in the standard rating. (See manufacturers specifications.) Adjusted to reflect any other deviation from ARI Standard Rating Conditions specifically required by manufacturers published literature, i.e., water pressure, etc. (See manufacturers specifications.) Adjusted to reflect supplementary water heat to be used when such heat is other than 120EF [48.9EC] used in the standard rating. (See manufacturer's specifications) 6.4.2 Self-Contained Equipment of adequate capacity to satisfy the demand load calculated shall be selected using the rating published in accordance with ARI Standard 620 and corrected to the operating conditions of the equipment. 6.4.2.1 The ARI Standard 620 rated capacity shall be corrected to the actual capacity to be realized from the equipment by the following method: a. Adjusted to reflect actual static pressure differential between inlet and outlet of the unit when this differential is other than 0 in. of H2O [0 Pa] used in the standard rating. (See manufacturers specifications.) b. Adjusted to reflect supplementary water heat to be used when such heat is other than 120EF [48.9EC] used in the standard rating. (See manufacturers specifications.) c. Adjusted to reflect any other deviation from ARI Standard Rating Conditions specifically required by manufacturers published literature, i.e., water pressure, etc. (See manufacturers specifications.) 6.5 Accessory Selection. 6.5.1 Humidistat. Manufacturers recommendations shall be followed to obtain optimum performance and to avoid possible problems. 6.5.1.1 A humidistat control shall be used when any central system humidifier is selected for use on a system to be operated on constant air circulation (CAC). 6.5.1.2 A humidistat control shall be used when any type humidifier is selected that has a corrected capacity rating under actual operating conditions that exceeds the demand load calculated. 6.5.1.3 A humidistat control is recommended to prevent the possibility of overhumidification. 6.5.2 Other Accessories. Re-circulating pumps, valves, etc. shall be selected as recommended by the manufacturer of the humidifier selected.

b.

c.

d.

e.

f.

ARI GUIDELINE F-1997 6.6 Building Codes. Equipment shall be selected to meet all pertinent local, state, or national codes. This applies to humidifiers, humidistats, and other accessory items. 7.3.2 Prevention of Water Damage. If the humidifier is located in or above finished space such that an accidental overflow may damage floors, carpets, wall finishes, etc., a means should be provided to prevent damage in the event overflow occurs. If the humidifier has no provisions for connecting an overflow drain, a drain pan with a drain hose should be installed beneath the humidifier. 7.4 Electrical Connections. Most humidifiers are low power consuming devices and can be connected in parallel with an existing motor load (with the same voltage) on an existing fuse. On multi-speed blower motors, avoid high voltage feedback loops from other speed taps. It should be noted that many humidifiers are designed to be connected to a separately protected circuit (See manufacturers specifications). A means for disconnecting the power supply to the humidifier shall be provided. All wiring shall conform to local, state and national codes. 7.4.1 It may be necessary to wire steam generating units with time delay relays or temperature switches so when the humidifier is turned off, the furnace blower continues to carry away the residual steam until the water is cooled. 7.4.2 It may be necessary to wire steam generating units and atomizing units with a sail or pressure differential switch to turn the humidifier off if air flow in the air handling system is interrupted. 7.5 Start-Up and Check-Out. After installation is completed, operate the total system through several complete cycles of events, preferably with a system thermostat and humidistat, if installed. Observe for normal operation as recommended by manufacturer. Following the running of several complete cycles of events, set the thermostat system switch, temperature selector and humidistat at customers desired settings. It is also wise to have the user perform all steps for familiarization. Before leaving the premises, present the owners manual to the customer and review it with him. 7.6 Customer Education. THIS CAN BE THE MOST IMPORTANT STEP IN THE INSTALLATION. Explain to the customer what to expect from the humidifier and supervise him or her in a cleaning operation in order to instill self-confidence and make them aware of any precautions while doing this.

Section 7. Installation Practices 7.1 General. A satisfactory humidifier installation depends upon the use of diligence in utilizing good installation practices. It should be kept in mind that every customer has definite expectations for performance and serviceability of the unit and if these conditions are met, the result will be a satisfactory installation. A constant awareness of these points will guide the installer to making good detailed decisions as the installation progresses. 7.1.1 Cleaning. Although this section is primarily concerned with installation of the unit, the installer must keep in mind that when a humidifier atomizes water or changes it to a gaseous state, a residue will accumulate, necessitating regular maintenance for cleaning. Serviceability must be as easy as possible and is greatly affected by the installation methods. 7.1.2 Manufacturers Instructions. Humidifier manufacturers supply installation instructions with the units which should be carefully followed and supplemented by this standard as required. 7.2 Installer Familiarization. The installer should familiarize himself with the product, taking particular note of the humidifier's components. Electrical parts which may need to be replaced should be observed and easy access planned for after the unit is installed. 7.3 Location. The location of a humidifier for use in existing heating systems is usually determined at the job site. Manufacturers installation instructions usually provide sketches showing typical mounting arrangements on duct systems. Installing a humidifier on existing ductwork may dislodge dust and dirt; therefore, vacuum-clean through the mounting hole in the area of humidifier installation. In new systems, future construction and basement finishing must be considered and ample access must be reserved for the maintenance and service of the humidifier. 7.3.1 Outdoor Installation. Most humidifiers are intended for installation indoors and, unless the manufacturers instructions specifically allow unheated area installation, assume indoor heated location only.

ARI GUIDELINE F-1997 Explain anything that they may later see or hear to prevent anxiety or dissatisfaction, such as condensation on windows, normal mineral buildup, normal operating sounds, etc. Mention time lag incident to reaching equilibrium in a new installation. Also indicate the advantages of humidification which they will enjoy and be sure to explain that limitations imposed by the structure will determine the level of humidity which can be maintained. Also, teach the customer how and when to adjust the humidistat for various ranges of outdoor temperatures. 8.2 Periodic Maintenance Check List. Appendix C contains an example of a check list for use by the user or service personnel. This type of check list is a result of extensive use in the field by many service organizations and reflects their suggestions. There are two advantages to using a check list. First, it helps the service person to develop an efficient routine; and second, gives him an outline of service that can be reviewed by the owner. 8.3 Special Maintenance Considerations. Humidifier designs are of three basic categories, evaporating, steam and atomizing. Depending upon the particular design of humidifier, there are usually special maintenance routines which must be followed regularly in order to insure continued performance of the unit. Since these routines will vary, it is particularly important that the user familiarize himself with any special maintenance considerations by studying the user material supplied with the humidifier. For new installations, the humidifier should be inspected monthly to determine a proper maintenance schedule.

Section 8. Servicing Practices 8.1 Regular Care and Servicing. As with all automatic and mechanical devices, humidifiers require periodic maintenance and servicing either by the user or competent service personnel to provide continued customer satisfaction, longer equipment life and a reduction in emergency service callsresulting in lower annual cost to the customer.

ARI GUIDELINE F-1997

APPENDIX A. REFERENCES - NORMATIVE

None.

APPENDIX B. REFERENCES - INFORMATIVE

B1 Listed here are standards, handbooks and other publications which may provide useful information and background but are not considered essential. References in this appendix are not considered part of the guideline. B1.1 ASHRAE Handbook - 1996 Systems and Equipment, Chapter 20, Humidifiers, 1996, American Society of Heating, Refrigerating and Air Conditioning Engineers, Inc., 1791 Tullie Circle N.E., Atlanta, GA 30329, U.S.A. B1.2 ASHRAE Terminology of Heating, Ventilation, Air Conditioning & Refrigeration, 1991, American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc., 1791 Tullie Circle N.E., Atlanta, GA, 30329, U.S.A. B1.3 ARI Standard 610-96, Central System Humidifiers for Residential Applications, 1996, AirConditioning and Refrigeration Institute, 4301 North Fairfax Drive, Suite 425, Arlington, Virginia, 22203, U.S.A. B1.4 ARI Standard 620-96, Self-Contained Humidifiers for Residential Applications, 1996, AirConditioning and Refrigeration Institute, 4301 North Fairfax Drive, Suite 425, Arlington, Virginia, 22203, U.S.A.

ARI GUIDELINE F-1997

APPENDIX C. PERIODIC MAINTENANCE CHECKLIST

PREVENTIVE MAINTENANCE AND SERVICE CHECK LIST FOR HUMIDIFIERS Customer Equipment Location Date Last Inspected Inspected By Humidifier: Address Contract No. Date This Inspection

Company Name: Inspect, Check, Clean and Adjust, When Necessary, All Items Listed

Model Number:

EVAPORATING MEDIA OR ATOMIZER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clean or replace media, filters and flow restrictors, as required, or clean all parts, if atomizing STEAM GENERATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace cylinder or clean parts and replace immersion heater SUMP AND DRAIN LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clean sump and drain lines and make sure drains and drain lines are free of restrictions. Check for leaks and proper water level. FANS AND MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fan, check for deterioration and balance. Fan setscrew, check for tightness. lubricate motor bearings as required. CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Water flow, check for proper flow rate. Humidistat, check for proper operation. All electrical terminals for tightness. Disconnect switch, check operation

Key:

T - OK,

V - Need Additional Service,

VV - Repair or Replace

Remarks:

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Total Heat (BTU/hr) 500 X GPM X T (Water) - TONS 24 X GPM X T (Water) - GPM Cooler (24 X TONS) / T (Water)Document1 paginăTotal Heat (BTU/hr) 500 X GPM X T (Water) - TONS 24 X GPM X T (Water) - GPM Cooler (24 X TONS) / T (Water)Nedunuri.Madhav MurthyÎncă nu există evaluări

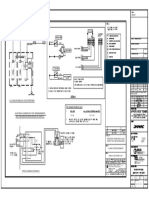

- 003-Ansul R-102 System P & I D-P&IDDocument1 pagină003-Ansul R-102 System P & I D-P&IDNoushad P HamsaÎncă nu există evaluări

- Chilled Water Pipe SizingDocument2 paginiChilled Water Pipe SizingLarry Bea77% (13)

- Commonly Used Hvac FormulaeDocument5 paginiCommonly Used Hvac FormulaezakirnagarÎncă nu există evaluări

- CVGF svn02b E4Document68 paginiCVGF svn02b E4Noushad P HamsaÎncă nu există evaluări

- KX SeriesDocument24 paginiKX SeriesNoushad P HamsaÎncă nu există evaluări

- RWV Balancing Valve TrainingDocument33 paginiRWV Balancing Valve TrainingNoushad P HamsaÎncă nu există evaluări

- Duct Leakage TestingDocument51 paginiDuct Leakage Testingducatti996chÎncă nu există evaluări

- Head PressDocument2 paginiHead PressNoushad P HamsaÎncă nu există evaluări

- Urban Planning & MEP EbookDocument153 paginiUrban Planning & MEP EbookNoushad P HamsaÎncă nu există evaluări

- Balancing BasicsDocument14 paginiBalancing BasicspbharrisÎncă nu există evaluări

- CTV Chiller WeightsDocument5 paginiCTV Chiller WeightsNoushad P HamsaÎncă nu există evaluări

- CompressorsDocument7 paginiCompressorssyedahmedsabirÎncă nu există evaluări

- CVGF svn02b E4Document68 paginiCVGF svn02b E4Noushad P HamsaÎncă nu există evaluări

- Cvhesvn03den 305Document80 paginiCvhesvn03den 305Noushad P HamsaÎncă nu există evaluări

- A Guide To Air FiltrationDocument50 paginiA Guide To Air FiltrationNoushad P HamsaÎncă nu există evaluări

- A Guide To Absorption CoolingDocument54 paginiA Guide To Absorption CoolingNoushad P HamsaÎncă nu există evaluări

- Dynamic Storage in BuildingsDocument114 paginiDynamic Storage in BuildingsNoushad P HamsaÎncă nu există evaluări

- Buffer Tank Hesabı PDFDocument4 paginiBuffer Tank Hesabı PDFDevrim GürselÎncă nu există evaluări

- Copper Tube DesignDocument34 paginiCopper Tube DesignNoushad P HamsaÎncă nu există evaluări

- Urban Planning & MEP EbookDocument153 paginiUrban Planning & MEP EbookNoushad P HamsaÎncă nu există evaluări

- Energy Planning A Guide To PractitionersDocument75 paginiEnergy Planning A Guide To PractitionersNoushad P HamsaÎncă nu există evaluări

- A Guide To Air FiltrationDocument50 paginiA Guide To Air FiltrationNoushad P HamsaÎncă nu există evaluări

- Building Regulation BookDocument135 paginiBuilding Regulation BookNenad Stjepanovic100% (1)

- Construction Materials E-BookDocument98 paginiConstruction Materials E-BookNoushad P Hamsa100% (1)

- Plumbing Installations Home Owner Guide PDFDocument19 paginiPlumbing Installations Home Owner Guide PDFskilmagÎncă nu există evaluări

- Plumbing Installations Home Owner Guide PDFDocument19 paginiPlumbing Installations Home Owner Guide PDFskilmagÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Procedure For Control of Documents and RecordsDocument3 paginiProcedure For Control of Documents and RecordsmrugeshjÎncă nu există evaluări

- UIWeb ViewDocument4 paginiUIWeb Viewjackmailsjohn9456Încă nu există evaluări

- HiPath 3000 v6.0 SMDocument1.202 paginiHiPath 3000 v6.0 SMAngel Fernando RosasÎncă nu există evaluări

- Anytone At-5189 ManualDocument38 paginiAnytone At-5189 Manual9w2nrÎncă nu există evaluări

- Laboratory Standard and Design GuidelineDocument75 paginiLaboratory Standard and Design GuidelineSin Quee CheÎncă nu există evaluări

- Accident Blackspot Investigation HandbookDocument37 paginiAccident Blackspot Investigation HandbookMichael DixonÎncă nu există evaluări

- VoIP 20100826Document566 paginiVoIP 20100826nitin10685Încă nu există evaluări

- Hydraulic Engine Control ManualtflexDocument36 paginiHydraulic Engine Control ManualtflexJulie LafranceÎncă nu există evaluări

- Canon Ir3225n Ir3235n Ir3245n PrintersDocument4 paginiCanon Ir3225n Ir3235n Ir3245n PrintersirteenÎncă nu există evaluări

- Reflection Paper 1Document2 paginiReflection Paper 1Dela Peña, Rey Igino K.Încă nu există evaluări

- Dial IndicatorsDocument42 paginiDial IndicatorsNaresh KesarkarÎncă nu există evaluări

- Mercedes V 220 2015 Owners ManualDocument360 paginiMercedes V 220 2015 Owners ManualMusaHamzic100% (1)

- Directional Control Valves Ng6 Ng32 Do3 d10 PDFDocument92 paginiDirectional Control Valves Ng6 Ng32 Do3 d10 PDFchidambaram kasiÎncă nu există evaluări

- NCOER NCODP Nov13Document21 paginiNCOER NCODP Nov13tetrakhanÎncă nu există evaluări

- Tags Description - Meaning - DefinitionDocument23 paginiTags Description - Meaning - DefinitionArun MohanarajÎncă nu există evaluări

- Configuration & Installation of A Base Transceiver Station (BTS) - Telemax's WeblogDocument4 paginiConfiguration & Installation of A Base Transceiver Station (BTS) - Telemax's WeblogRohail AfzalÎncă nu există evaluări

- Code GeassDocument71 paginiCode GeassRaymond Santos EstrellaÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument17 paginiDisclosure To Promote The Right To InformationIndira MukherjeeÎncă nu există evaluări

- GSM Modem PDFDocument2 paginiGSM Modem PDFFalling SkiesÎncă nu există evaluări

- 2003 Nissan Altima 2.5 Serivce Manual PBDocument8 pagini2003 Nissan Altima 2.5 Serivce Manual PBAndy DellingerÎncă nu există evaluări

- 2010 Transit BrochureDocument16 pagini2010 Transit BrochureHomer Skelton Ford of MillingtonÎncă nu există evaluări

- 966h 972h Sn-bj6 WXZ Bs6 NpeDocument75 pagini966h 972h Sn-bj6 WXZ Bs6 NpeevanÎncă nu există evaluări

- Guidance Brochure BRCGS Transition ENG A4 Final 1Document8 paginiGuidance Brochure BRCGS Transition ENG A4 Final 1jai soniÎncă nu există evaluări

- Pps Seat 163 Seat Ateca EngDocument71 paginiPps Seat 163 Seat Ateca EngManu Fran0% (2)

- A Guide To The Project Management Body of Knowledge - PMBOKDocument211 paginiA Guide To The Project Management Body of Knowledge - PMBOKTony Bertram100% (7)

- C# Event ProcessingDocument25 paginiC# Event ProcessingHPK12Încă nu există evaluări

- Bit TorrentDocument4 paginiBit Torrent1000taniyaÎncă nu există evaluări

- Upto 145kV 40ka 3150A Operating ManualDocument12 paginiUpto 145kV 40ka 3150A Operating ManualNiloy DebroyÎncă nu există evaluări

- Cisco 819 Integrated Services Router Configuration GuideDocument204 paginiCisco 819 Integrated Services Router Configuration GuideAndrew_R_WaltonÎncă nu există evaluări

- 4G Kpi Ibd HPDocument20 pagini4G Kpi Ibd HPYalzlelfÎncă nu există evaluări