Documente Academic

Documente Profesional

Documente Cultură

Design Review Report For Bridges in Northern Uganda

Încărcat de

solebTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design Review Report For Bridges in Northern Uganda

Încărcat de

solebDrepturi de autor:

Formate disponibile

May 2011

C CO ON NS SU UL LT TA AN NC CY Y S SE ER RV VI IC CE ES S

f fo or r

C

C

O

O

N

N

S

S

T

T

R

R

U

U

C

C

T

T

I

I

O

O

N

N

O

O

F

F

B

B

R

R

I

I

D

D

G

G

E

E

S

S

I

I

N

N

N

N

O

O

R

R

T

T

H

H

W

W

E

E

S

S

T

T

U

U

G

G

A

A

N

N

D

D

A

A

D

DDE

EES

SSI

IIG

GGN

NN R

RRE

EEV

VVI

IIE

EEW

WW R

RRE

EEP

PPO

OOR

RRT

TT

(

((F

FFI

IIN

NNA

AAL

LL)

))

Ethiopia

Office

(Head Office)

P.O.Box 62668; Tel. 0114391065 /0114391499 /0114 391733 /0114393004; Fax 0114391230 /0114391617

E-mail: saba.eng@ethionet.et Web-site: www.saba-engineering.com

Addis Ababa, Ethiopia

Uganda

Office

P. O. Box 21321, Plot No. 1376, Block No. 244, Muyenga Diplomat Zone

Tel. +25641267547; Fax. +25641268352; Mobile +256772712178, Email: saba-

uganda@infocom.co.ug

Kampala, Uganda

T

TTH

HHE

EE R

RRE

EEP

PPU

UUB

BBL

LLI

IIC

CC O

OOF

FF U

UUG

GGA

AAN

NND

DDA

AA

U

UUg

gga

aan

nnd

dda

aa N

NNa

aat

tti

iio

oon

nna

aal

ll R

RRo

ooa

aad

dds

ss A

AAu

uut

tth

hho

oor

rri

iit

tty

yy

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Uganda National Roads Authority i

SABA Engineering P.L.C

TABLE OF CONTENTS

Page

LIST OF FIGURES ................................................................................................................ iv

LIST OF TABLES ................................................................................................................... v

1 INTRODUCTION ................................................................................................... 1-1

1.1 General ......................................................................................................... 1-1

1.2 Scope of the Design Review ........................................................................ 1-2

1.3 Purpose and Content of the Report ............................................................... 1-3

1.4 Approach of Design Review ........................................................................ 1-3

2 FIELD INVESTIGATION BY THE DESIGN REVIEW CONSULTANT ....... 2-1

2.1 Project Background ...................................................................................... 2-1

2.2 Field Visit ..................................................................................................... 2-1

2.3 Factual Findings ........................................................................................... 2-1

2.4 Recommendation .......................................................................................... 2-2

2.4.1 Supervision Team ............................................................................ 2-2

2.4.2 Surveying Work ............................................................................... 2-2

3 GEOTECHNICAL INVESTIGATION OF BRIDGE SITES AND

CONSTRUCTION MATERIAL SOURCES ........................................................ 3-1

3.1 General ......................................................................................................... 3-1

3.2 Determination of Allowable Bearing Pressure for Bridge Foundations ....... 3-1

3.3 Foundation Recommendation ....................................................................... 3-2

3.4 Investigation of Construction Material Sources ........................................... 3-7

3.4.1 General ............................................................................................ 3-7

3.4.2 Potential Quarry Stone Sources ...................................................... 3-7

3.4.3 Potential Gravel (Muram) Sources ............................................... 3-17

3.4.4 Potential Sand Sources .................................................................. 3-22

4 HYDROLOGICAL and HYDRAULIC STUDY REVIEW ................................ 4-1

4.1 Background .................................................................................................. 4-1

4.2 Objective ...................................................................................................... 4-1

4.3 Hydrology ..................................................................................................... 4-2

4.4 Data Collection ............................................................................................. 4-2

4.4.1 DEM and Aerial Photographs ......................................................... 4-2

4.5 Drainage Characteristics, Geology and Topography .................................... 4-2

4.6 Climate ......................................................................................................... 4-5

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Uganda National Roads Authority ii

SABA Engineering P.L.C

4.7 Peak Discharge Estimation ........................................................................... 4-5

4.7.1 Rational Method .............................................................................. 4-5

4.7.2 SCS Method ..................................................................................... 4-6

4.7.3 Regression Equation ........................................................................ 4-7

4.7.4 Historic data Analysis ..................................................................... 4-7

4.7.5 TRRL Flood Model ......................................................................... 4-7

4.8 Hydrology Review Summery ..................................................................... 4-49

4.9 Hydraulics .................................................................................................. 4-49

4.10 HEC Ras 4.0 Bridge Hydraulic Analysis ................................................... 4-50

4.11 HY-8.7 Culvert Hydraulic Analysis ........................................................... 4-62

4.12 Culvert Hydraulic Design Review Output ................................................. 4-70

4.13 Hydraulic Design Review .......................................................................... 4-70

4.14 Existing Structures Physical Assessment ................................................... 4-71

4.15 Conclusion and Recommendations ............................................................ 4-76

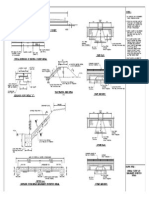

5 STRUCTURAL DESIGN REVIEW ...................................................................... 5-1

5.1 General ......................................................................................................... 5-1

5.2 Scope ............................................................................................................ 5-1

5.3 Structural System ......................................................................................... 5-1

5.4 Design Codes ................................................................................................ 5-2

5.5 Materials Properties ...................................................................................... 5-3

5.5.1 Concrete Grade: .............................................................................. 5-3

5.5.2 Reinforcement Steel ......................................................................... 5-3

5.5.3 Structural steel grade: ..................................................................... 5-3

5.6 Design Limit States ...................................................................................... 5-3

5.6.1 Strength Limit State ......................................................................... 5-3

5.6.2 Serviceability Limit State ................................................................ 5-4

5.7 Minimum Clear Cover to Reinforcement ..................................................... 5-4

5.8 Detailed Design Review of Bridges ............................................................. 5-4

5.8.1 Superstructure ................................................................................. 5-4

5.8.2 Substructure .................................................................................... 5-4

5.8.3 Review Procedure ........................................................................... 5-5

5.9 Geometric Design Review of Approach Road ............................................. 5-6

5.10 Conclusion and Recommendation ................................................................ 5-7

5.10.1 Structural Analysis .......................................................................... 5-7

5.10.2 Foundation ...................................................................................... 5-7

6 KIA-KIA BRIDGE REVIEW ................................................................................ 6-1

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Uganda National Roads Authority iii

SABA Engineering P.L.C

6.1 Background .................................................................................................. 6-1

6.2 Field Investigation ........................................................................................ 6-2

6.2.1 General ............................................................................................ 6-2

6.2.2 Field Visit ........................................................................................ 6-2

6.2.3 Surveying Work .............................................................................. 6-3

6.2.4 Geotechnical Investigations ............................................................ 6-5

6.2.5 Investigation of Construction Material Sources .............................. 6-5

6.2.6 Physical Hydrological Investigation ............................................... 6-7

6.3 Preliminary Design ....................................................................................... 6-8

6.3.1 General ............................................................................................ 6-8

6.3.2 Hydrological and Hydraulic Analysis ............................................. 6-8

6.3.3 Geometric Design .......................................................................... 6-13

6.3.4 Structures ....................................................................................... 6-13

6.4 Conclusions and Recommendations ........................................................... 6-14

7 NYAGAK-3 Culvert Hydraulic Design Adjustment ............................................ 7-1

8 TENDER DOCUMENT REVIEW ........................................................................ 8-1

8.1 Introduction .................................................................................................. 8-1

8.2 Section I: Invitation to Bid ........................................................................... 8-2

8.3 Section II: Instructions to Bidders ................................................................ 8-2

8.3.1 Contents of Bid Documents ............................................................. 8-2

8.3.2 Documents Comprising the Bid ....................................................... 8-2

8.4 Section III: Bidding Data ............................................................................. 8-3

8.5 Section IV: Part 1: General Conditions of Contract ..................................... 8-3

8.6 Section V: Part 2: Conditions of Particular Application .............................. 8-3

8.6.1 Contract Documents ........................................................................ 8-3

8.6.2 Settlement of Disputes ..................................................................... 8-4

8.6.3 Changes in Cost and Legislation..................................................... 8-4

8.7 Section VI: Technical Specifications ........................................................... 8-7

8.7.1 General Specifications .................................................................... 8-7

8.7.2 Special Provisions for the Standard Technical Specifications ........ 8-7

8.7.3 New Work Items .............................................................................. 8-7

8.8 Section VII: Forms of Bid, Appendix to Bid and Bid Security .................. 8-11

8.8.1 Appendix to Form of Tender ......................................................... 8-11

8.8.2 Tender Security ............................................................................. 8-25

8.9 Section VIII: Bill of Quantities .................................................................. 8-26

8.9.1 BOQ Specific Remark .................................................................... 8-26

8.9.2 New Updated BOQ ........................................................................ 8-26

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Uganda National Roads Authority iv

SABA Engineering P.L.C

8.10 Section IX: Form of Agreement, Forms of Performance Security, Bank

Guarantee for Advance Payment & Letter of Acceptance ......................... 8-26

8.10.1 Form of Agreement ........................................................................ 8-26

8.10.2 Letter of Acceptance ...................................................................... 8-27

8.11 Section X: Drawings .................................................................................. 8-28

8.12 Section XI: Dispute Resolutions Procedure ............................................... 8-28

9 CHANGES MADE ON THE TENDER DOCUMENT UNDER THE NEW

SCOPE OF WORK ................................................................................................. 9-1

LIST OF FIGURES

Page

Figure 2-1: Location of 21 Bridges ............................................................................ 2-3

Figure 4-1: Areas for Calculation of 2 and 7 Day Antecedent Rainfall ................. 4-11

Figure 4-2: Soil zones .............................................................................................. 4-12

Figure 4-3: Rainfall Time (T

P

) Zones ...................................................................... 4-16

Figure 4-4: 2yr 24hrs point storm rainfall ................................................................ 4-18

Figure 4-5: 10 year to 2 year ratio ........................................................................... 4-19

Figure 4-6: Flood Factor .......................................................................................... 4-20

Figure 4-7: Oluffe Bridge catchment area drainage description .............................. 4-22

Figure4-8: Oluffebridge catchment area floworinetation ........................................ 4-23

Figure 4-9: Ore culvert watershed area drainage pattern ......................................... 4-26

Figure 4-10: Ore culvert drainage orientation with elevation labeling .................... 4-27

Figure 4-11 Enve Bridge drainage pattern ............................................................... 4-31

Figure 4-12: Enve bridge drainage orientation with elevation labeling .................. 4-32

Figure 4-13: Goli bridge drainage pattern ............................................................... 4-35

Figure 4-14: Goli bridge drainage orientation with elevation labeling .................... 4-36

Figure4-15: Lebijo Culvert e drainage ..................................................................... 4-40

Figure 4-16: Lebijo Culvert drainage orientation with elevation labeling .............. 4-41

Figure 4-17: Enyau-3Bridge drainage pattern ......................................................... 4-46

Figure 4-18: Enyau-3 bridge drainage orientation with elevation labeling ............. 4-47

Figure 4-19: Oluffe proposed bridge U/S & D/S cross sectional view.................... 4-51

Figure 4-20: Oluffe proposed bridge with 25 years design flood ............................ 4-52

Figure 4-21: Enve proposed bridge U/S & D/S cross sectional view ...................... 4-54

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Uganda National Roads Authority v

SABA Engineering P.L.C

Figure 4-22: Enve proposed bridge with 25 years design flood .............................. 4-55

Figure 4-23: Goli proposed bridge U/S & D/S cross sectional view ....................... 4-57

Figure 4-24: Goli proposed bridge with 25 years design flood ............................... 4-58

Figure 4-25: Enyau-3 proposed bridge U/S & D/S cross sectional view ................ 4-60

Figure 4-26: Enyau-3 proposed bridge with 25 years design flood ......................... 4-61

Figure 4-27: Ore existing culvert cross sectional view ............................................ 4-64

Figure 4-28: Ore new culvert cross sectional view .................................................. 4-66

Figure 4-29: Lebijo existing culvert cross sectional view ....................................... 4-68

Figure 4-30: Lebijo culvert (with additional culvert) cross sectional view. ............ 4-70

Figure 6-1: Kia-Kia Stream catchment and cross section over view ......................... 6-8

Figure 6-2: kia kia flood plain cross section along with water surface and proposed

structures position ................................................................................. 6-13

LIST OF TABLES

Page

Table 2-1: List of GPS Data for Bridges ................................................................... 2-4

Table 3-1: Presumptive Allowable Pressures for Different Foundation Conditions . 3-2

Table 3-2: Review of Bridge Site Foundation Investigation and Presumptive

Allowable Pressures ............................................................................... 3-4

Table 3-3: Review of Bridge Site Foundation Investigation and Presumptive

Allowable Pressures as per the new scope of work

(Lot 1,Lot 2 &Lot 3) ............................................................................... 3-6

Table 3-4: Summary of Test Results on Rock Sources ............................................. 3-7

Table 3-5: Summary of Laboratory test results of the potential gravel sources ...... 3-22

Table 3-6: Summary of Laboratory test results of the potential Sand sources ........ 3-28

Table 4-1: Bridge catchment area physiographic description

(As per the new scope) ........................................................................... 4-4

Table 4-2: Antecedent Moisture Conditions for Storms of Greater than 50mm ..... 4-10

Table 4-3: Standard contributing area coefficients (Cs) .......................................... 4-13

Table 4-4: Catchment Wetness Factor (C

W

) ........................................................... 4-14

Table 4-5: Land Use Factor (C

L

) ............................................................................ 4-14

Table 4-6: Catchment lag Times ............................................................................. 4-15

Table 4-7: Rainfall time (T

p

) for East African 10 year storms ............................... 4-17

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Uganda National Roads Authority vi

SABA Engineering P.L.C

Table 4-8: Oluffe Bridge Catchment TRLL Model 25 Years Peak Discharge

Determination ....................................................................................... 4-24

Table 4-9: Ore Culvert Catchment TRLL Model 25 Years Peak Discharge

Determination ....................................................................................... 4-28

Table 4-10:Enve Bridge Catchment TRLL Model 25 Years Peak Discharge

Determination ....................................................................................... 4-33

Table 4-11:Goli Bridge Catchment TRLL Model 25 Years Peak Discharge

Determination ....................................................................................... 4-37

Table 4-12: Lebijo Culvert Catchment TRLL Model 25 Years Peak Discharge

Determination ....................................................................................... 4-42

Table 4-13:Enyau-3 bridge Catchment TRLL Model 25 Years Peak Discharge

Determination ....................................................................................... 4-48

Table 4-14: Ore existing culvert input data for HY-8.7 hydraulic analysis ............ 4-63

Table 4-15: Ore existing culvert hydraulic analysis summery (scenario one) ........ 4-63

Table 4-16: Ore existing culvert input data for HY-8.7 hydraulic analysis ............ 4-65

Table 4-17: Ore new culvert hydraulic analysis summery (scenario two) ............. 4-65

Table 4-18: Lebijo existing culvert input data for HY-8.7 hydraulic analysis ....... 4-67

Table 4-19: Lebijo Existing culvert hydraulic analysis summery (scenario one) ... 4-67

Table 4-20: Lebijo culvert (additional culvert) HY-8.7 input data .......................... 4-69

Table 4-21: Lebijo culvert (with additional culvert) hydraulic analysis summery

(scenario two) ....................................................................................... 4-69

Table 4-22: bridge physical survey summery for the 6 bridges under the new

scope of services. .................................................................................. 4-72

Table 4-23: Lot 1 bridge physical survey summery ............................................... 4-73

Table 4-24: Lot 2 bridge physical survey summery ............................................... 4-74

Table 4-25: Lot 3 bridge physical survey summery ............................................... 4-75

Table 5-1: List of Sample Bridges ............................................................................. 5-1

Table 5-2: Slope ratio table (Vertical to Horizontal ratio) ......................................... 5-6

Table 6-1:Kia-Kia Bridge Catchment TRLL Model 25 Years Peak Discharge

Determination ......................................................................................... 6-9

Table 8-1: Bill 1000 General .................................................................................. 8-8

Table 8-2: Bill 3000 Earth Works and Pavement Layers of Gravel or

Crushed Stone ......................................................................................... 8-9

Table 8-3: Bill 5000 Ancillary Road Works ........................................................... 8-9

Table 8-4: Bill 6000 Structures ............................................................................... 8-9

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Uganda National Roads Authority vii

SABA Engineering P.L.C

Table 8-5: Bill No 8: Schedule of Day Works ......................................................... 8-10

Table 8-6: Summary of currencies of the Bid .......................................................... 8-12

Table 8-7: Interest Rates .......................................................................................... 8-12

Table 8-8: Weightings for use with Local Currency (UGSH) ................................. 8-13

Table 8-9: Weightings for use with Foreign Currency 1: ........................................ 8-13

Table 8-10: Weightings for use with Foreign Currency 2: ...................................... 8-14

Table 8-11: Weightings for use with Foreign Currency 3: ...................................... 8-15

Table 8-12: Summary of Payment Currencies ......................................................... 8-16

Table 8-13: Weightings Applicable for Bill No. 3: Earth Works &

Pavement layers .................................................................................... 8-17

Table 8-14: Weightings Applicable for Bill No. 2 & 6 Drainage & Structures ...... 8-17

Table 8-15: Weightings Applicable for Bill No. 5 Ancillary Works ....................... 8-18

Table 8-16: Local Currency ..................................................................................... 8-19

Table 8-17: Foreign Currency 1 (FC1)(a) ................................................................ 8-19

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Ministry of Works and Transport 1-1

SABA Engineering P.L.C

1 INTRODUCTION

1.1 General

Recognizing the vital role the road network plays in enabling national objectives to be

achieved, the Government of Uganda, represented by the Ministry of Works and

Transport (MoWT) recently Uganda National Roads Authority took the

responsibility, is undertaking improvements to the countrys road network to a

standard that can cope with the present and anticipated traffic growth.

With financial support of the Arab Bank and Economic Development in Africa

(BADEA), economic and technical studies for rehabilitation of 66 bridges in the

eastern and northern regions of the country were carried out in 2002. Following

outcomes of the study, the bridges were rank ordered and placed in priorities 1 and 2

according to traffic levels, existing structural condition and risk of flooding. Based on

these criteria, 21 bridges were placed in priority I and the rest in priority II.

Twenty one (21) priority I structures have been selected for inclusion in phase 1 of

the implementation scheme. The Detailed Engineering Design and Tender

Documents for the Project have been prepared by an International Consultant, ACE

Consulting Engineers in the year 2002/ 2003.

The consultancy contract agreement between the Ministry of Works and Transport

and SABA Engineering Plc was signed on May 30

th

, 2007.

Though the project has progressed through design review stage, recently Ugandan

National Road Authority has agreed with BADEA to scale down the project scope to

exclude all the bridges located along the Vurra-Arua-Koboko-Oraba road where the

road is scheduled for upgrading under World Bank Financed Transport Sector

development Program (TSDP).The very recent revised scope now comprises only 6

bridges packaged to Enayao-3, Alla-1, Goli, Nyagak-3, Nyacara, Pakwala, bridges.

The bridges are subdivided into three lots as shown on the table below

LOT I LOT II LOT III

Arua Nebbi Nebbi

1 Alla Goli Nyacara

2 Enyau 3 Nyagak 3 Packwala

This Design Review report mainly emphasis 21 bridges in North West Uganda

including the recently agreed 10 bridges packaged but engineering estimates and

tender documents are revised based on the new scope for subsequent retendering

purpose. Kia-Kia bridge which took a special concern due to design insufficiency

problem as discussed with UNRA on 19 July 2010 also included and elaborated as

separate chapter though review report on Kia Kia bridge submitted to the client

before this report.

No

Lot and District

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Ministry of Works and Transport 1-2

SABA Engineering P.L.C

The high cost of the civil work as compared to the available budget has forced the

client to seek alternative solution by abandoning Kia-Kia bridge which is considered

to be very expensive, Cido Bridge which is replaced in 2003 and still in a good

condition except its single lane configuration and Ora2 & Ora2.

Objectives of the Project

The project is divided into two distinct phases:

Stage I: Pre Construction Services

Stage II: Construction Supervision

The objectives of the services as described in the Terms of Reference are:

In Pre Construction phase, the Consultant familiarize himself with the

designs, reports and tender documents relating to the project; inspect the

respective bridge sites and propose any minor modifications deemed

necessary on the designs and packaging of the works. Subsequently the

consultant will assist the Client with procurement of Contractors.

During the Construction Supervision phase, supervise construction of the

Works (on behalf of the Employer) throughout the entire construction phase,

including the defects liability (maintenance) period.

1.2 Scope of the Design Review

In accordance with the Contract Agreement, the main objectives of the Design

Review are to carry out the following;

To Review all documents of previous studies, designs, reports etc after

acquainting himself with the location and structural condition of each bridge

structure included in the project, and compare these with the intervention measure

proposed for the structure.

To carry out field and laboratory tests where necessary to enable verification of

essential aspects in the detailed engineering design. This will also include

information on construction material sources.

Based on the above, recommend minor modifications deemed necessary to the

designs, bills of quantities, cost estimates and any other relevant aspects.

Accordingly prepare any necessary drawings at appropriate scales, incorporating

any modifications approved by the Client.

To prepare a detailed time schedule for the project and for each structure

assuming a practical sequence of activities under given climatic conditions and

taking into account the time for procuring a contractor. The expected cash flow

shall also be indicated.

The consultant shall satisfy himself with suitability of the existing bidding

documents (or propose any amendments thereof) prepared for national

competitive bidding,

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Ministry of Works and Transport 1-3

SABA Engineering P.L.C

1.3 Purpose and Content of the Report

Tue purpose of this report is to provide a full and detailed description of the work

undertaken by the consultant in carrying out the design review services of each

respective review task. The report is dealing with all technical aspects of the projects

review works, detailed information, investigations, results and recommendations.

The following aspects of the Engineering Design Review have been addressed within

the report:

Section 1: General Introduction

Section 2: Field Investigation by the Design Review Consultant

Section 3: Geotechnical Investigation of Bridge sites and Construction

Material Sources Geotechnical Investigation

Section 4: Hydrological and Hydraulic Study Review

Section 5: Structural Design Review

Section 6: Tender Document Review

1.4 Approach of Design Review

Basically, the design review was carried out as per our technical proposal. Both field

investigations and desktop studies were carried out in the respective disciplines.

Details are presented in subsequent sections of this report.

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Ministry of Works and Transport 2-1

SABA Engineering P.L.C

2 FIELD INVESTIGATION BY THE DESIGN REVIEW

CONSULTANT

2.1 Project Background

The selected bridges are located along national and district roads in the north

western region of Uganda in the districts of Arua and Nebbi and are categorized in

three Lots.

The Detailed Engineering Design and Tender Documents for the Project have been

prepared by an International Consultant, ACE Consulting Engineers in the year 2002/

2003.

The consultancy contract agreement between the Ministry of Works and Transport

and SABA Engineering Plc was signed on May 30

th

, 2007.

2.2 Field Visit

The review consultant conducted the field investigation for the Project from

September 27/2007 to October 1/2007. Kia-Kia and Pakwala bridge sites were not

visited due to their inaccessibility. The team composition is shown below;

S.No Name Profession/ Assignment

1

2

3

4

5

Dereje Tilahun

Kassa Dessie

Michael Abebe

Yared Amdie

Samuel Girma

Resident Engineer/ Team leader

Material Engineer

Structural Engineer

Hydrologist

Surveyor

Two personnel that were assigned from the Ministry of Works have been with the

team all the time.

2.3 Factual Findings

Of the 21 bridges considered under the review found in this project, all are proposed

to be replaced by the design consultant. The following main reasons are given for

replacement,

The non-compliance of the design load of the existing structure with the

required specifications.

The existing bridge width is too narrow.

The level of the existing bridge is lower than the flood water level.

The present span length of the bridge increases the water velocity, which

leads to the erosion of the substructure.

Construction of Bridges in North West Uganda Design Review Report

____________________________________________________________________________________________

Ministry of Works and Transport 2-2

SABA Engineering P.L.C

The review consultant has visited all the sites except Kia Kia and Pakwala Bridge

sites, which were inaccessible at the time of the visit. The location of the bridges/

bridge sites under the new work scope is shown in Figure 2-1.

2.4 Recommendation

Following the completion of the field visit, the review consultant would like to bring

the following general recommendations.

2.4.1 Supervision Team

The field investigation during the review period took five days to cover the nineteen

sites. The proposed one team is in no way sufficient to efficiently conduct the

supervision work, so the following personnel list is advisable;

Full Time Staff

Resident Engineer (1)

Assistant Resident Engineer (3)

Senior Surveyors (3)

Inspector of Works (3)

Intermittent Staff

Material Engineer (1)

Contract/ Claims Engineer (1)

Environment Specialist (1)

The Design Consultant has also included office, vehicle and housing for Assistant

Resident Engineer for each lot. In addition, the Engineers house drawing prepared by

the Design Consultant also shows a housing accommodation for the Assistant

Resident Engineer. This shows that the Design Consultant has considered the

necessity of Assistant Resident Engineer for each lot. But it will be advisable to

assign resident engineer to address the revised neighboring lots and assistant resident

engineer for the other lot according to the new consensus.

2.4.2 Surveying Work

The design consultant established bench marks using relative coordinates and did not

connect it to the national grid. This has created problem in locating the bench marks.

Even on the BMs found, the markings are no more there. If it was tied to the national

grid, it would have been easier to identify each BM.

During the construction stage, the consultant will tie the bench marks to the national

grid.

Construction of Bridges in North West Uganda Design Review Report

Ministry of Works and Transport 2-3

SABA Engineering P.L.C

Figure 2-1: Location of 21 Bridges

Figure 2-1: Location of 21 Bridges Legend: Location: selected 6 bridges

7

14

Bridge Legends

Lot II

Lot I

Lot III

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 2-4

SABA Engineering P.L.C

Table 2-1: List of GPS Data for Bridges

No Description East North Elevation

1 Alla 285641 321381 873

2 Enyo-3 267062 333770 1192

3 Enayu-1 267125 342069 1140

4 Enve 267147 348930 1152

5 Oluffe 270332 352993 1119

6 Ayi 271353 360296 1106

7 Yoyo 271976 368197 1128

8 Oru 272522 369028 1106

9 Apa-1 272909 375995 1184

10 Ore 272892 373464 1165

11 Kochi 273325 381108 1194

12 Debara 265890 390867 1137

13 Lebijo 279881 380785 1064

14 ORA 1 321246 300833 636

15 ORA 2 321235 300861 628

16 Nyagak 3 266974 270220 1514

17 Goli 280863 263203 1375

18 Cido 262039 284418 1297

19 Nyacara 274042 287827 1003

Note: The highlighted including Pakwala bridges in table 2.1 above are the one

considered under the newly revised scope of work.

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-1

SABA Engineering P.L.C

3 GEOTECHNICAL INVESTIGATION OF BRIDGE SITES

AND CONSTRUCTION MATERIAL SOURCES

3.1 General

Preliminary foundation investigations were conducted by the Design Consultant,

Arab Consulting engineers (ACE), on the major river crossing sites to identify

possible bearing layers and make recommendations on bearing capacity and

determine the required depth of foundation for safely conveying the superstructure

loads to the supporting strata. The field investigation and laboratory testing were

conducted by the Central Materials Laboratory in 2003.

The drilling investigations involved Standard Penetration Tests (SPT) and recovery of

undisturbed and disturbed soil/silty sand samples for laboratory tests. However, depth

of drilling was limited to top of hard stratum; no drilling was made in hard

formations/rock strata. Thus, the strength and extent of hard formations were not

adequately investigated. It seems that due to these uncertainties, a very low bearing

capacity of 300KPa has been assumed for all hard formations including those where

rock outcrops are evident.

The design consultant recommended placing the foundation on replaced soil/selected

granular fill material over river beds were exposed rock are encountered on the

surface, for example Ayi, Yoyo, Apa and Lebijo crossing sites. This has a potential

risk of scouring of the foundation soil; hence the review consultant recommends

placing the footings on the rock strata where sound rock is encountered at shallow

depths.

3.2 Determination of Allowable Bearing Pressure for Bridge Foundations

Most of the river crossings are constituted of alluvium deposit which is mainly clayey

silty/sandy loam on top of weathered gneiss. Rocky outcrops are visible at some

rivers.

Allowable (presumptive) bearing pressure values are commonly assigned for the

foundation bearing layers for foundation design purposes, taking their geology,

compactness of alluvial deposits, and degree of weathering and consistency of rock

outcrops, if any, into consideration as classified during the site investigation.

The presumptive bearing pressure values recommended by different codes of

practice, design manuals and reference texts for different type of foundation materials

and consistency are presented in Table 3.1 below.

The presumptive bearing pressure values for various foundation materials have been

adopted from the following code of standards, design manuals and reference texts:

Foundation Analysis and Design, 5th Edition, McGraw-Hill Companies,

Inc., 1996, by J. E. Bowles;

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-2

SABA Engineering P.L.C

Naval Facilities Engineering Command Design Manual (NAVFAC DM -

7.02, sec.4, table1: on Foundations & Earth Structures, 1986);

Overseas Road Note No. 9, Transport Research Laboratory (TRL), Design

of Small Bridges; 2nd Edition, 2000.

Table 3-1: Presumptive Allowable Pressures for Different Foundation Conditions

*Depth of ground water is assumed to be not less than B below the

base of foundation.

The presumptive bearing pressures should be used with caution to allow for the

uncertainties as determination of the actual extent and jointing requires drilling and

coring.

3.3 Foundation Recommendation

The minimum depth below riverbed at which the bottom of abutment / pier will be

placed is governed by the maximum scour depth and the presence of a good bearing

layer. An average depth of 2 meters below the lowest level of the river bed, is

recommended for those crossing foundations composed of alluvial deposits, is

recommended. For riverbanks and riverbeds composed of rock outcrops, a minimum

depth of 0.5m in sound rock for keying (anchorage) purpose is recommended. The

presumptive bearing pressures are used with caution assuming soft rock to allow for

the uncertainties.

Type of Bearing Material

Consistency in

place

Recommended Allowable

Bearing Pressure (KPa)

ORN 9 NAVFAC Bowles

Massive igneous and

metamorphic rock (basalt,

granite, gneiss)

Hard and sound 10,000 7,600 9,600

Foliated metamorphic rock

and sedimentary rocks (un-

weathered)

Medium hard and

sound

4,000 3,300 -

Weathered or broken bed rock

of any kind

Soft rock 1,500 1,000 1,400

Gravel, gravel-sand mixtures,

boulder gravel mixtures , and

Sand with little gravel

[Non-cohesive Soils]

-Dense/very

compact

-Medium dense

- Loose

600

500

150

600

480

280

400*

380*

200

Clay [Cohesive Soils]

Silt

-Hard

-Stiff

-Hard

-Stiff

200

150

200

150

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-3

SABA Engineering P.L.C

The bearing pressure values recommended by the Design Consultant are generally

conservative and need to be amended during construction. Investigation by core

drilling (ASTM D2113) is neither feasible nor scope of this assignment; it is foreseen

that verification/confirmatory investigations would be scheduled during construction,

by means of rotary core drilling to a depth of at least 10m in soft /loose formation and

at least 3 meters into solid rock. If the foundation conditions encountered during

excavation are different from what has been revealed or assumed at design stage, the

necessary modifications on the foundation design shall be made by the engineer.

Pile load test shall also be conducted for bridges to be founded on pile foundations.

Static Load Tests are performed to determine the ultimate failure load of a foundation

pile and to determine the piles capability of supporting a load without excessive or

continuous displacement. The purpose of such tests is to verify that the allowable

loads used for the design of a pile are appropriate and that the installation procedure

is satisfactory. The Pile Load Test shall be conducted in accordance with the

procedures given in ASTM D1143.

Hence pay items for the structures shall include the estimated costs for confirmatory

investigations by core drilling and for pile load testing in the BOQ.

Tables 3.2 and 3.4 present the summary of Geotechnical Investigations conducted by

the Design Consultant.

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-4

SABA Engineering P.L.C

Table 3-2: Review of Bridge Site Foundation Investigation and Presumptive Allowable Pressures

Sr.

No.

River

Name

Route & District

GPS

Coordinates

Foundation Material Description

Bearing Capacity (K Pa)

and footing depth (m)

recommended by the Design

Consultant (ACE)

1 Enayu-1

Arua-Koboko-Orba

(Arua)

267125 E,

342069 N

Arua side: Sandy clay with

few gravels 0.7m 5.0m,

SPT values: 7,8,9 at 3.0m

-Hard pan/rock below 5.0m

(refusal to penetration)

Koboko side: Stiff Sandy clay

0.7m 5.0m,

-Hard pan/rock below 5.0m

300KPa ,

Average footing depth 2.7m

2 Enve

Arua-Koboko-

Oraba(Arua)

267147 E,

348930 N

Dark brown silty clay on both abutments and the river bed

300KPa ,

Average footing depth 2.0m

3 Oluffe

Arua-Koboko-

Oraba(Arua)

270332 E,

352993 N

Arua side: Firm Sandy clay ,

SPT values: 3,2,4 at 1.5m and

7,9,9 at 3.0m and Hard

pan/weathered rock below

5.0m

Koboko side:

Sandy clay 2.0 6.0m,

Hard pan/rock below 6.0m

300KPa ,

Average footing depth 2.0m

4 Ayi

Arua-Koboko-

Orba(Arua)

271353 E,

360296 N

Rocky outcrops at both abutments and the river bed

300KPa ,

Average footing depth 2.0m

5 Kia-Kia

Arua-Wandi-Invep-

Rhino-Camp

Odupi Side: Grayish brown

firm clay up to 3.0m below

which is a hard pan/rock

Rhino Camp side: Loose

Brown sand up to 9.0m and

medium dense below 9.0m:

N-values at 6.0m and 9.0m are 10

and 24, respectively.

Pile foundation on Rhino

Camp sided

6

Yoyo

Arua-Koboko-Oraba

(Arua)

271976 E,

368197 N

Rock outcrops at both abutments, silty clay/sand 300KPa ,

Average footing depth 1.6m

7

Oru

Arua-Koboko-Oraba

(Arua)

272522 E,

369028 N

0.0 -4.0m: Loose Clayey sand and hard formation below 4.0m

300KPa ,

Average footing depth 1.6m

8 Apa-1

Arua-Koboko-Oraba

(Arua)

272909 E,

375995 N

0 4.0m Silty Sand on downstream

and exposed rock on up stream,

hard formation below 4.0m

300KPa ,

Average footing depth 2.5m

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-5

SABA Engineering P.L.C

Sr.

No.

River

Name

Route & District

GPS

Coordinates

Foundation Material Description

Bearing Capacity (K Pa)

and footing depth (m)

recommended by the Design

Consultant (ACE)

9

Ore

Arua-Koboko-Oraba

(Arua)

272892 E,

373464 N

Silty Sand at both abutments

300KPa ,

Average footing depth -------

m

10 Kochi

Arua-Koboko-Oraba

(Arua)

273325 E,

301108 N

Silty sand and sandy Clay, up to

300KPa ,

Average footing depth 2.0m

11

Debara

Arua-Koboko-Oraba

(Arua)

265890 E,

390867 N

Clayey silt alluvium, with some boulders exposed on down stream

300KPa ,

Average footing depth 0.3m

12

Lebijo

Arua Koboko-

Yumbe (Arua)

279881E,

380785N

Exposed rock at abutments and pier position

300KPa ,

Average footing depth -----m

13

Ora-1

(Lot 3)

Nebbi-Akaba-

Kucwiny-Wadela

(Nebbi)

321246E,

300833N

Arua side:

Sandy clay : 0 3.0m,

Below 3.0m hard pan

Pakwach side:

Stiff, black clay 0-2.0m

Granular fill material,

2.0 6.0m black sandy clay (N-value=8),

6.0m -14m (N-value=15) Black to gray Clay

Pile foundation on Pakwach

side

14

Cido

(Lot 2)

Nebbi-Goli-

Japanziri-Erussi

(Nebbi)

262039E,

284418N

Goli side: Dense Sandy

clay with gravel

(0.0 3.0m),

Hard pan below 3.0m

Errusi side: Sandy clay with quartz gravel

(0.0 4.0m),

Hard pan below 4.0m; i.e. refusal to

penetration,

N-value=45

300KPa ,

Average footing depth 2.3m

15

Ora-2

(Lot 3)

Nebbi-Akaba-

Kucwiny-

Wadela(Nebbi)

321235E,

300861N

Dense Silty Sand at both abutments 300 KPa

Note: All the bridges on table 3-2 are excluded under the revised work scope.

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-6

SABA Engineering P.L.C

Table 3-3: Review of Bridge Site Foundation Investigation and Presumptive Allowable Pressures as per the new scope of work (Lot

1,Lot 2 &Lot 3)

Sr.

No.

River

Name

Route & District

GPS

Coordinates

Foundation Material Description

Bearing Capacity (K Pa)

and footing depth (m)

recommended by the Design

Consultatnt (ACE)

1

Alla-1

Arua-Inde-packwach

(Arua)

285641 E,

321381 N

Arua side:

Brown to red silty

clay/alluvium, with gravel.

Hard pan at 2.0m

Inde side:

Light brown silty clay/alluvium 300KPa ,

Average footing depth 2.5m

2 Enayu-3 Arua-Ediofe (Arua)

267062 E,

333770 N

Reddish brown clayey Sand at both abutments

300KPa ,

Average footing depth 1.6m

3

Nyagak-3

Jqang-Okoro-

Alyenda(Nebbi)

266974E,

270220N

Silty Clay with few gravel at both abutments

300KPa ,

Average footing depth 2.5m

4

Goli

Nebbi-Goli

Custom-Mahagi

(Nebbi)

280863E,

263203N

Goli customs side:

Stiff to very stiff sandy clay with

gravel,

SPT-values: 5,6,7 at 3.0m and 12,

11,9 at 6.0m,

Hard pan (refusal to pen.) at 8.0m

Mahagi side:

Sandy clay with gravel,

SPT-values: 3,4,5 at 3.0m

Hard pan below 5.0m

300KPa ,

Average footing depth -----m

5

Nyacara

Nebbi-Erussi

(Nebbi)

274042E,

287827N

Sandy gravel with boulders

300KPa ,

Average footing depth 1.8 m

6

Pakwala

Nebbi-Erussi

(Nebbi)

300KPa ,

Average footing depth 2.7m

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-7

SABA Engineering P.L.C

3.4 Investigation of Construction Material Sources

3.4.1 General

As part of the assignments in the Design Review Contract, the Consultant (SABA

Eng.) has conducted field investigations and laboratory tests on Potential

Construction Material sources; i.e. to enable verification of the findings during

detailed engineering design. These included assessment of the Geotechnical

Investigations report, and identification of construction material sources which were

conducted by the Design Consultant (ACE).

Based on the physical inspection of the potential construction material sources and

results of laboratory tests conducted on some representative samples, the Design

Review Consultant has evaluated the available design documents with regards to

adequacy of the investigations and compliance of the values obtained with relevant

standard specification requirements.

A total of twelve (12) locations; i.e. 7 were potential stone sources, 4 sand sources,

and 1 gravel source have been investigated by the Design Consultant. However, 5

(five) of these sources are located near Lira and Soroti district HQs, which are very

far from the project sites. The gravel source is located on the Lira Aloi road, 6.4Km

from Lira town.

3.4.2 Potential Quarry Stone Sources

Coarse aggregate for concrete has to be strong, durable and must have a particle size

distribution and particle shape which provide high mechanical stability.

Potential sources of hard rock for production of crushed aggregate for concrete works

were identified by the Design Consultant. Based on the test results report, conducted

by the Central Materials Laboratory in June 2003, four (4) of the stone quarry

samples tested meet all the specification requirements for concrete aggregates. The

following table has been taken directly from the Materials Investigation Report

prepared by the Design Consultant:

Table 3-4: Summary of Test Results on Rock Sources

Sr.

No.

Rock Source

Specific

gravity

(g/cc)

Water

Abs.

(%)

Acv

(%)

Aiv

(%)

Tfv

(KN)

Laa

(%)

SSS

(%)

Bitumen Affinity

1 Oparra (Arua) 2.5 0.1 29 30 150 28 0.3 Good

2

Over Senia

River

2.6 0.8 19 23 180 16 0.5 Good

3 Ngweny 2.6 0.2 16 11 200 18 0.3 Good

4 Akia 2.7 0.1 19 19 170 22 0.4 Fair

5 Ngetta 2.6 0.3 27 23 160 23 0.2 Good

Spec. Limits >2.5 -

25

Max.

26

Max

160

Min.

28

Max

12

Max

Good

ACV Aggregate Crushing Value, AIV-Aggregate Impact Value, TFV-10% Fines

Value LAA Los Angeles Abrasion, SSS Sodium Sulfate Soundness

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-8

SABA Engineering P.L.C

From the test results, it can be concluded that with the exception of the rock source at

Oparra (Arua) which has marginally weaker values, all the investigated rock sources

fulfill the specification requirements.

The Design Review Consultant has inspected these sources and identified additional

potential sources. Photographs of the sites showing selected features of the source and

location of each quarry stone from the bridge sites is also given. Under the newly

revised scope of work all construction material indicated under lot 2 below can be

considered for Lot 1 bridges. Similarly the material sites under lot 3 could be

shared by lot 2 and lot 3 bridges.

3.4.2.1 Stone Quarry Sites Proposed For Lot 1

Priority 1 Lot 1

Description

Quarry Name Orawa

Location 3.5 km from Arua Town

Road Name Arua Air field Road

GPS Coordinates Elevation 1198

Easting 36N 269053

Northing 337155

Estimated Quantity (Cum) >11,000 m3

Overburden Varies from 0 -1.5m

Access Existing and in good Condition

Rock type Gneiss

Degree of weathering Un weathered

Distance from: Enyau 3 bridge 5 km

Enyau 1 bridge 7 km

Enve bridge 14 km

Oluffe bridge 21 k m

Ayi bridge 31 km

Alai-1 bridge 30.5 km

Kia Kia bridge 70 km

photos

Orawa-Photo 1 through 6

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-9

SABA Engineering P.L.C

Orawa Site- Photo 3Orawa

Orawa Site Photo 1 Orawa Site- Photo 2

Orawa Site Photo 3 Orawa Site Photo 4

Orawa Site Photo 5 Orawa Site Photo 6

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-10

SABA Engineering P.L.C

Description

Quarry Name Arivu

Location 14 km from Arua Town

Road Name Arua Nebbi Road

GPS Coordinates Elevation 1027

Easting 36N 274510

Northing 319462

Estimated Quantity

( Cum)

>100,000 m3

Overburden None

Access Existing and in good Condition

Rock type Gneiss

Degree of weathering Minor surface disintegrations

Distance from: Enyau 3 bridge 18.1km

Enyau 1 bridge 23.5 km

Enve bridge 31 km

Oluffe bridge 37.2 k m

Ayi bridge 47.7 km

Alai-1 bridge 23 km

Kia Kia bridge 88 km

photos Arivu Site Photo 1 through 4

Priority 2 Lot 1

Arivu Site Photo 1 Arivu Site Photo 2

Arivu Site Photo 3 Arivu Site Photo 4

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-11

SABA Engineering P.L.C

Priority 3 Lot 1

Description

Quarry Name Ovisoni , adjacent to Ovisoni trading centre, LHS

Location 14 km from Arua Town

Road Name Arua Odiya -Vurra customs Road

GPS Coordinates Elevation 1337

Easting 36N 264731

Northing 321521

Estimated Quantity

(Cum)

>1,000 m3

Overburden 0.1-0.5m

Access Existing and in good Condition

Rock type Gneiss

Degree of weathering Un weathered

Distance from; Enyau-3 bridge 18.1km

Enyau-1 bridge 23.5 km

Enve bridge 31 km

Oluffe bridge 37.2 k m

Ayi bridge 47.7 km

Alai-1 bridge 27km

Kia Kia bridge 88 km

photos Ovisoni Site- Photo 1 through 4

Ovisoni Site- Photo 1 Ovisoni Site- Photo 2

Ovisoni Site- Photo 3 Ovisoni Site- Photo 4

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-12

SABA Engineering P.L.C

3.4.2.2 Stone Quarry Sites Proposed For Lot 2

Priority 1- Lot 2

Description

Quarry Name Liru New proposal

Location 14 km from koboko Town

Road Name Koboko- liru Road

GPS Coordinates Elevation 1198

Easting 36N 269053

Northing 337155

Estimated Quantity ( Cum) > 11,000 m3

Overburden Varies from 0 -1.5m

Access Existing and in good Condition

Rock type Gneiss

Degree of weathering Un weathered

Distance from: Yoyo bridge 26 km

Oru bridge 25 km

Ore bridge 20.3 km

Apa bridge 18 k m

Kochi bridge 16 km

Lebijo bridge 20.3 km

Debara bridge 30 km

photos Liru Site Photo 1 through 4

Liru Site Photo 1 Liru Site Photo 2

Liru Site Photo 3 Liru Site Photo 4

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-13

SABA Engineering P.L.C

3.4.2.3 Stone Quarry Sites Proposed For Lot 3

Priority 1 Lot 3

Description

Quarry Name Acwera Chinese Quarry

Location 12.3 km from NebbiTown

Road Name Nebbi- Pakwach Road

GPS Coordinates Elevation 985

Easting 36N 295868

Northing 273361

Estimated Quantity ( Cum) >10,000 m3

Overburden Varies from 0 -1.5 m

Access Existing and in good Condition

Rock type Granite

Degree of weathering Un weathered

Distance from: Nyacara bridge 13.3 km

Pakwala bridge 15.3 km

Goli bridge 26.3 km

Cido bridge 29.3 k m

Nyagak 3 bridge 51.3 km

Ora-1 bridge 37 km

Ora-2 bridge 37 km

photos Acwera Chinese Qs Photo 1 through 4

Acwera Chinese Qs Photo 1 Acwera Chinese Qs Photo 2

Acwera Chinese Qs Photo 3 Acwera Chinese Qs Photo 4

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-14

SABA Engineering P.L.C

Priority 2 Lot 3

Description

Quarry Name Ngweny kumi

Location 3.6 km from NebbiTown

Road Name Nebbi- Goli Road ( New road in angir village)

GPS Coordinates Elevation 1097

Easting 36N 285917

Northing 271332

Estimated Quantity ( Cum) >15,000 m3

Overburden Varies -1m approx

Access Existing and in good Condition

Rock type Gneiss

Degree of weathering Un weathered boulders

Distance from; Nyacara bridge 2.6 km

Pakwala bridge 0.7 km

Goli bridge 12 km

Cido bridge 15 k m

Nyagak 3 bridge 42.6 km

Ora-1 bridge 49.6 km

Ora-2 bridge 49.6 km

photos Ngweny k- Photo 1 through 4

Ngweny kumi - Photo 1 Ngweny k - Photo 2

Ngweny k - Photo 3 Ngweny k - Photo 4

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-15

SABA Engineering P.L.C

Priority 3 Lot 3

Description

Quarry Name Cananyira rock New proposal

Location 1.2 km from NebbiTown

Road Name Nebbi- cananyira Road

GPS Coordinates Elevation 986

Easting 36N 288156

Northing 273405

Estimated Quantity ( Cum) >10,000 m3

Overburden None

Access Existing and in good Condition

Rock type Gneiss

Degree of weathering Un weathered

Distance from; Nyacara bridge 1.5 km

Pakwala bridge 4 km

Goli bridge 15 km

Cido bridge 18k m

Nyagak 3 bridge 40 km

Ora-1 bridge 47.5 km

Ora-2 bridge 47.5 km

photos Cananyira Photo 1 through 2

Cananyira Photo 1 Cananyira Photo 2

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-16

SABA Engineering P.L.C

Priority 4 Lot 3

Description

Quarry Name Angir rocks New proposal

Location 1.6 km from NebbiTown

Road Name Nebbi- Goli Road ( near Angir primary school)

GPS Coordinates Elevation 1061

Easting 36N 286537

Northing 272491

Estimated Quantity ( Cum) >5,000 m3

Overburden None

Access Available and in good Condition

Rock type Gneiss

Degree of weathering Un weathered

Distance from: Nyacara bridge 0.6 km

Pakwala bridge 2.4 km

Goli bridge 12.4 km

Cido bridge 15.4 k m

Nyagak 3 bridge 40.6 km

Ora-1 bridge 47.6 km

Ora-2 bridge 47.6 km

photos Angir Photo 1 through 2

Angir Photo 1 Angir Photo 2

3.4.2.4 Conclusions and Recommendations on Potential Stone Sources:

Following the investigations conducted on the stone quarry sites proposed by the

design consultant, the following is recommendable:

For Lot 1: Stone aggregates from Orawa, Arivu or Ovisoni quarries are

recommended.

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-17

SABA Engineering P.L.C

For Lot 2: The virgin rock at Liru (new proposal) is recommended as source

of stone aggregates ( as per the revised scope of work this material site

should be considered for lot 1 if the need arise)

For Lot 3: Stone Quarries Acwera Chinese Quarry, Ngweny Kumi,

Cananyira rock (new proposal) and Angir rock (new proposal) are

recommended. ( as per the revised scope of work these material site shall be

considered for both Lot 2 and Lot 3)

Ngetta Hill Quarry (5.3 Km from Lira town, on Lira kitgum road), Akia Hill Quarry

(5.9 km from Lira Town, on Lira Aloi road) and Ochuloi Quarry (19Km from

Soroti town, on Soroti Lira road), are all located at distances that are not

economically viable (more than 300Km far) relative to the project sites and are

therefore not recommendable for use as aggregate sources.

3.4.3 Potential Gravel (Muram) Sources

Gravel sources were not identified by the Design Consultant, for all the three lots.

Granular borrow materials are required for construction of embankments in approach

roads and for backfilling behind abutments. The Design Review Consultant has

identified a total of eleven (11) potential sources of gravel and collected

representative samples for laboratory tests.

It should, however, be noted that the construction material sources identified during

this phase are by no means exhaustive. Additional sources should be further located

and investigated by the contractors during construction.

I. Location of Gravel Sources for Lot 1:

Sample ID Location/nearest town Estimated Qty (m

3

)

G1/Lot (1)

11 Km from Arua town,

Arua District, Kijomoro Subcounty,

Near Loliragoro town

85,000

(200mx340mX1.3m)

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-18

SABA Engineering P.L.C

Gravel G1/Lot 1 (1) Gravel G1/Lot 1 (2)

Sample ID Location/nearest town Estimated Qty (m

3

)

G2/Lot (1)

19 Km from Arua town,

Arua District, Oleba Subcounty, 2Km

from Oleba Trading Center (Existing

Pit)

10,000

(165mx70mX1.0m)

G2/Lot 1 (1) Borrow area used by MoWT G2/Lot 1 (2) Borrow area used by MoWT

Sample ID Location/nearest town Estimated Qty (m

3

)

G3/Lot (1)

29 Km from Arua town,

Arua District, Oluffe Subcounty,

near Ombere town ( Existing Pit)

17,000

(150mx100mX1.2m)

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-19

SABA Engineering P.L.C

G3/Lot 1 (1) G3/Lot 1 (2)

Sample

ID

Location/nearest town Estimated Qty (m

3

)

Gravel

Arua

TC

8Km from Arua town, along Arua-Ajono

Road, Vura Subcounty, near Gil-gil

Existing Borrow pit, 200m away from

Congo/Uganda Boarder (at Ajono village)

100,000 (200mx500mx1m)

Sample ID Location/nearest town Estimated Qty (m

3

)

Gravel at Ala 1

Bridge

5Km from Arua town, along Arua

Pakwach Road, Ajiya Subcounty,

near Ajiya

8,600

(120mx60mx1.2m)

II. Location of Gravel Sources for Lot 2:

Sample ID Location/nearest town Estimated Qty (m

3

)

G1/Lot 2

5.5Km from Koboko town, along

Arua Koboko Road, Midia

Subcounty, near Danya TC

28,800

(120mx240mx1.0m)

Sample ID Location/nearest town Estimated Qty (m

3

)

G2/Lot 2

8.0Km from Koboko town, along

Arua Koboko Road, Midia

Subcounty, near Koboko

74,880

(320mx180mx1.3m)

Note: The Bridges under lot 2 are discarded under the new scope of work. Thus

these material locations can be considered for lot 1 bridges if the need arise,

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-20

SABA Engineering P.L.C

G2/Lot 2

Sample ID Location/nearest town Estimated Qty (m

3

)

G3/Lot 2

8.0Km from Koboko town, along

Arua Koboko Road, Midia

Subcounty, near Koboko

74,880

(320mx180mx1.3m)

G3/Lot 2 (a) G3/Lot 2 (b)

G3/Lot 2 (a) G3/Lot 2 (b)

G3/Lot 2 (1) G3/Lot 2 (2)

Sample ID Location/nearest town Estimated Qty (m

3

)

G4/Lot 2

8.0Km from Koboko town, along

Arua Koboko Road, Midia

Subcounty, near Koboko

74,880

(320mx180mx1.3m)

G4/Lot 2 (a) G4/Lot 2 (a)

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-21

SABA Engineering P.L.C

III. Location of Gravel Sources for Lot 3:

Sample ID Location/nearest town Estimated Qty (m

3

)

G1/Lot 3

5.0Km from Nebbi town, near Okeya Village,

Used by MoWT

> 10,000

(150mx50mx1.5m)

G1/Lot 3(a) G1/Lot 3(b)

Sample ID Location/nearest town Estimated Qty (m

3

)

G2/Lot 3

5.0Km from Nebbi town, near Okeya Village,

Used by MoWT

> 100,000

(210mx300mx1.5m)

G2/Lot 3 (a) G2/Lot 3 (b)

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-22

SABA Engineering P.L.C

Table 3-5: Summary of Laboratory test results of the potential gravel sources

Sr. ID

Location

Grading, % passing

Sieves

Laboratory Test Results

2.0

mm

0.425

mm

0.075

mm

LL

(%)

PI

(%)

OMC

(%)

MDD

(g/cc)

BS Light

CBR

@ 95%

MDD

G1-Lot1

11 Km from Arua town, Arua

District, Kijomoro Subcounty,

Near Loliragoro town

39 30

20

46

25 11 2.02 26

G2-Lot1

19 Km from Arua town, Arua

District, Oleba Subcounty,

2Km from Oleba T C

40 30 23

47

24

11

2.06 20

G3-Lot1

29 Km from Arua town, Arua

District, Oluffe Subcounty,

near Ombere town

52 39 25 46 24 14 1.82 10

ALA 1

Bridge

5Km from Arua town, along

Arua Pakwach Road

38 30 22 50 25 12 1.86 22

Arua TC

8Km from Arua town, along

Arua-Ajono Road, Vura

Subcounty, near Gil-gil

42 32 25 45 21 11 1.84 27

G1-Lot2

5.5Km from Koboko town,

along Arua Koboko Road

43 33 25 44 24 10 1.96 20

G2-Lot2

8.0Km from Koboko town,

along Arua Koboko Road

32 25 13 36 17 10 12.10 45

G3-Lot2

8.0Km from Koboko town,

along Arua Koboko Road

50 34 21 45 22 10 1.90 18

G4-Lot2

8.0Km from Koboko town,

along Arua Koboko Road

36 27 16 37 23 11 1.98 27

G1-Lot3

5.0Km from Nebbi town, near

Okeya Village

44 33 22 40 22 10 2.03 15

G2 - Lot3 5.0Km from Nebbi town 45 33 25 42 21 11 2.02 37

Spec. requirements for Subbase to be used

for approach road & backfill

<45 <15 > 25

The test results revealed that the most of the identified gravel sources have relatively

good CBR values (>20%) strength but all have higher plasticity to be directly used as

subbase. Thus, it is recommended stabilized the materials with lime (usually 3% to

5% with the red clayey sandy lateritic gravels in Uganda), in order to improve both

on their plasticity and CBR values to within the specification limits.

Those sources with CBR values more than 10% and less than 20% can be used for

improved subgrade layers and embankments for approach roads.

3.4.4 Potential Sand Sources

The Design Consultants have identified and tested three sources of sand. The sources

were from Oreku on the Arua-Koboko Road, Ayi 1 on the Arua-Koboko Road, and

Akaba which is 6.6Km from Nebbi town. The test results showed that had high clay

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-23

SABA Engineering P.L.C

contents and only the sand from Akaba fulfilled the specification limits for gradation.

As a result, only the sand from Akaba was recommended to be used as a filter media

(drainage layer) under high embankments and crushed fine was recommended

instead.

Efforts have been made by the Design Review consultant to exhaustively search for

possible sources of sand in the project area. As a result, the following sand sources

have been identified and laboratory tests conducted on them to assess their suitability

for concrete and mortar works.

I. Potential Sand Sources for Lot 1

Sample ID Location/nearest town Estimated Qty (m3)

S1/Lot 1

6.2Km from Arua town, from

Enyayu River bridge, on Arua

Koboko - Oraba Road

3,000

S1/Lot1 (1) S1/Lot1 (2)

S1/Lot1 (3) S1/Lot1 (4)

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-24

SABA Engineering P.L.C

Sample ID Location/nearest town Estimated Qty (m3)

S2/Lot 1

17Km from Arua town, near Kijomoro

town, from Enve river bridge, on Arua

Koboko - Oraba Road

2,000

S2/Lot 1(1) S2/Lot 1(2)

Sample ID Location/nearest town Estimated Qty (m3)

S3/Lot 1

33.7Km from Arua town, near

Nyoro town, from Ayi river

bridge, on Arua Koboko - Oraba

Road

2,000

S3/Lot 1 (1) S3/Lot 1 (2)

Sample ID Location/nearest town Estimated Qty (m

3

)

ALA River Sand

17Km from Arua town, Arivu

Subcounty, from ALA river

bridge

2,000

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-25

SABA Engineering P.L.C

II. Potential Sand Sources for Lot 2

Sample ID Location/nearest town Estimated Qty (m

3

)

S1/Lot2

Near Oleba town, from Oru 1

river bridge, on Arua Koboko

Oraba Road

1,000

S1/Lot2 (1) S1/Lot2 (2)

Sample ID Location/nearest town Estimated Qty (m

3

)

S2/Lot2

8.2Km from Koboko town, from

Lebijo river bridge, on Koboko

Yumbe Road, Appx. 2.1Km from

the Road

4,000

S2/Lot2 (1) S2/Lot2 (2)

Sample ID Location/nearest town Estimated Qty (m

3

)

S3/Lot 2

Otumbari Subcounty, from Oru

river bridge,

3,000

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-26

SABA Engineering P.L.C

S3/Lot 2 (1) S3/Lot 2 (2)

III. Potential Sand Sources for Lot 3

Sample ID Location/nearest town Estimated Qty (m3)

S1/Lot 3

9.0Km from Nebbi town, from

Acwera river bridge, along Nebbi

Wadi Lai district rural road,

2Km off the highway

2,500

S1/Lot 3 (1) S1/Lot 3 (2)

S1/Lot 3 (C)

S1/Lot 3 (3) S1/Lot 3 (4)

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-27

SABA Engineering P.L.C

Sample ID Location/nearest town Estimated Qty (m3)

S2/Lot 3

5.0Km from Nebbi town, from

Akaba river bridge, along Nebbi

Pakwach Road

2,500

S2/Lot 3 (1) S2/Lot 3 (2)

S2/Lot 3 (3) S2/Lot 3 (4)

Sample ID Location/nearest town Estimated Qty (m3)

S3/Lot 3

30Km from Nebbi town, from

Nam-Rwadho river bridge, along

Nebbi Pakwach Road

4,000

S3/Lot 3 (1) S3/Lot 3 (2)

Construction of Bridges in North West Uganda Design Review Report

Uganda National Roads Authority 3-28

SABA Engineering P.L.C

Table 3-6: Summary of Laboratory test results of the potential Sand sources

From the laboratory test results, it can be seen that most of the identified sources can be used with some treatment, either blending to meet the

grading requirements or by washing to remove clay lumps and minor organics contents.

Sr.

No.

Location

Of Sand

Sieve Analysis, % passing, mm

Silt and

Clay

Content

(%)

Compressive

Strength of

Cement Mortar

(7 days, MPa)

Comments

10.0 5.0 2.36 1.18 0.60 0.30 0.15

1 S1/Lot 1 100 99 94 83 51 8 2 1.8 30 Meets grading I

2 S2/Lot 1 100 99 92 38 28 3.8 32 Very fine, needs blending

3 S3/Lot 1 97 94 89 73 34 6 4 3.4 28 Meets grading II

4 Lot 1- C 99 98 97 90 69 10 4 3.2 30 Meets Grading III

5 S1/Lot 2 100 98 94 70 13 5 4.2 29 Fine, needs blending

6 S2/Lot 2 100 98 90 65 13 3 2.0 35 Fine, needs blending

7 S3/Lot 2 100 99 97 87 51 14 4 1.6 31 Meets grading II

8 S1/Lot 3 100 99 95 79 38 8 3 2.0 30 Meets grading II

9 S2/Lot 3 100 97 88 66 34 6 2 1.6 29 Meets grading I

10 S3/Lot 3 98 95 84 65 39 16 11 9.6 35

High Clay Content, needs

washing

11 ALA River Sand 96 94 91 81 56 14 3 2.4 32 Meets grading II

Ugandan Grading

Spec. I

100 90-100 60-95 30-70 15-34 5-20 0-10 6% Max. 28 Min.

II 100 90-100 75-100 55-90 35-59 8-30 0-10

III 100 90-100 85-100 75-100 60-79 12-40 0-10

IV 100 95-100 95-100 90-100 80-100 15-50 0-15

Construction of Bridges in North West Uganda

Design Review Report

Uganda National Roads Authority 4-1

SABA Engineering P.L.C

4 HYDROLOGICAL and HYDRAULIC STUDY REVIEW