Documente Academic

Documente Profesional

Documente Cultură

Copia de Vda 6 3 Questionaire

Încărcat de

Noriekxitokc's VksDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Copia de Vda 6 3 Questionaire

Încărcat de

Noriekxitokc's VksDrepturi de autor:

Formate disponibile

170411677.xlsx.

ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

Question

Pionts

Comments / Assesment Remarks

A Development

P 2 Project Management

2.1 Is the project organisation (project management) established and are tasks & authorities specified for the team leader and team members? Are the resources required for the project development planned and available and are all changes displayed? Is there a project plan and has this been agreed with the customer? Is change management in the project ensured by the project organisation? Are the responsible personnel within the organisation and in the customer's company involved in the change control system? Is there a QM plan for the project? Is this implemented and monitored regularly for compliance? Is there an established escalation process and is this implemented effectively?

nb nb nb nb nb nb nb

2.2*

2.3 2.4 2.5*

2.6

2.7*

P 3 Planning Product/Process Development Product

3.1 3.2* Are the product-specific requirements laid down? Has manufacturing feasibility been assessed in a crossfunctional manner, based on the requirements which have been determined for product & process? Are there plans for the product and process development? Have the necessary resources been taken into account for the product and process development? Is QM planning arranged for sourcing bought-in products and services? Are the process-specific requirements laid down? Has manufacturing feasibility been assessed in a crossfunctional manner, based on the requirements which have been determined for product & process? Are there plans for the product and process development? Have the necessary resources been taken into account for the product and process development? Is QM planning arranged for sourcing bought-in products and services?

nb nb nb nb nb

3.3 3.4

3.5

Process

3.1 3.2*

nb nb nb nb nb

3.3 3.4

3.5

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 1 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Quest Question Nr. P 4 Carrying out Product/Process Development Product

4.1 Have the Product FMEA / Process FMEA been drawn up? Are they up-dated as the project progresses and are corrective actions laid down? Are the stipulations arising from the plans for product and process development put into effect? Are the personnel resources in place and qualified? Is the infrastructure in place and appropriate? Based on the requirements, are the necessary evidence and releases available for the various phases? Are the planning activities associated with sourcing outside products and services implemented effectively? Is the transfer of the project to production controlled in order to secure the product launch? Have the Product FMEA / Process FMEA been drawn up? Are they up-dated as the project progresses and are corrective actions laid down? Are the stipulations arising from the plans for product and process development put into effect? Are the personnel resources in place and qualified? Is the infrastructure in place and appropriate? Based on the requirements, are the necessary evidence and releases available for the various phases? Are the productions control plans used for the various phases and are production, test and inspection documents derived from them? Has a pre-production run been carried out under serial production conditions to obtain production approval / release? Are the planning activities associated with sourcing outside products and services implemented effectively? Is the transfer of the project to production controlled in order to secure the product launch?

Pos.

Pionts

Comments / Assesment Remarks

nb

4.2 4.3 4.4 4.5*

nb nb nb nb nb nb

4.8

4.9

Process

4.1

nb

4.2

nb nb nb nb nb nb nb nb

4.3 4.4 4.5*

4.6

4.7

4.8

4.9

B Full Production

P 5 Supplier Management Are only approved/released and quality-capable 5.1*

suppliers selected?

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 2 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr. 5.2 5.3 5.4* 5.5* 5.6 5.7

Question

Are the customer's requirements taken into account in the supply chain? Have target agreements for delivery performance been agreed with suppliers and put into operation? Are the necessary approvals/releases available for the out-sourced products and services? Is the quality of the out-sourced products and services ensured? Are incoming goods stored appropriately? Are personnel qualified for the various tasks and are responsibilities defined?

Pionts

nb nb nb nb nb nb

Comments / Assesment Remarks

P 6 Process Analysis Serial Production Process step 1: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 1 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 3 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.3.2*

Question

Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

Pionts

nb nb

Comments / Assesment Remarks

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb

6.6.4

nb

Process step 2: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials?

Process Name 2 nb nb

6.1.3

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 4 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.1.4

Question

Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Pionts

nb nb

Comments / Assesment Remarks

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of product and process?

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 5 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.6.2

Question

Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

Pionts

nb

Comments / Assesment Remarks

6.6.3

nb nb

6.6.4

Process step 3: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 3 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production facilities / tools controlled?

nb Seite 6 von 17

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.4.2*

Question

Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

Pionts

nb nb nb

Comments / Assesment Remarks

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb nb

6.6.4

Process step 4: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 4

nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan?

nb Seite 7 von 17

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

Question

Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

Pionts

nb nb nb nb nb

Comments / Assesment Remarks

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb nb

6.6.4

Process step 5: Erstellt: Rita Demmeler-Wirth

Process Name 5 Version/Stand: 2.6/27.09.2011 Seite 8 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Question Nr. 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Pionts

nb nb

Comments / Assesment Remarks

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2

nb nb Seite 9 von 17

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.5.3*

Question

In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

Pionts

nb nb

Comments / Assesment Remarks

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb nb

6.6.4

Process step 6: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 6 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 10 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.3.1 6.3.2*

Question

Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

Pionts

nb nb nb

Comments / Assesment Remarks

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb nb

6.6.4

Process step 7: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials?

Process Name 7 nb nb

6.1.3

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 11 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.1.4

Question

Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Pionts

nb nb

Comments / Assesment Remarks

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of product and process?

nb

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 12 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.6.2

Question

Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

Pionts

nb

Comments / Assesment Remarks

6.6.3

nb nb

6.6.4

Process step 8: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 8 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production facilities / tools controlled?

nb Seite 13 von 17

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.4.2*

Question

Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

Pionts

nb nb nb

Comments / Assesment Remarks

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb nb

6.6.4

Process step 9: 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Process Name 9 nb nb

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan?

nb Seite 14 von 17

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

Question

Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

Pionts

nb nb nb nb nb

Comments / Assesment Remarks

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed? In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2 6.5.3*

nb nb nb nb

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb nb

6.6.4

Process step 10: Erstellt: Rita Demmeler-Wirth

Process Name 10 Version/Stand: 2.6/27.09.2011 Seite 15 von 17

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Question Nr. 1 Process Input

6.1.1* 6.1.2 Has the project been transferred from development to serial production? Are the necessary quantities / production batch sizes of incoming materials available at the right time and at the right place (stores; work-station)? Are incoming materials stored appropriately and are transport facilities / packing arrangements suitable for the special characteristics of the incoming materials? Are the necessary identifications / records / approvals available and allocated appropriately to the incoming materials? Are changes to the product or process in the course of serial production tracked and documented?

Pionts

nb nb

Comments / Assesment Remarks

6.1.3

nb

6.1.4

nb nb

6.1.5

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and test/inspection documents, based on the production control plan? Are production operations checked / approved and are setting data logged? Can the customer's specific product requirements be satisfied with the production facilities used? Are significant characteristics controlled in production? Are scrap, rework and setting parts kept separate and identified? Is the flow of materials and parts secured against mixing / wrong items? Are operators given responsibility and authority to monitor the quality of product and process? Are the operators able to carry out their allotted tasks and are their qualifications kept up-to-date? Is there a personnel employment plan?

nb nb nb nb nb nb

6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6

3 Personnel Support

6.3.1 6.3.2*

nb nb nb

6.3.3

4 Material Ressources

6.4.1 6.4.2* How are the maintenance and overhaul of production facilities / tools controlled? Can the quality requirements be monitored effectively with the test, inspection and measurement facilities employed? Are the work-stations and test/inspection areas suitable for requirements? Are tools, equipment and test/inspection facilities stored correctly? Are target requirements set for product and process? Are quality and process data logged in such a way that they can be assessed?

nb nb nb nb

6.4.3 6.4.4

5 Process Effectiveness Level

6.5.1 6.5.2

nb nb Seite 16 von 17

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

170411677.xlsx.ms_office

Questionaire VDA 6.3-2010

Supplier:

Date: Client:

Pos.

Quest Nr.

6.5.3*

Question

In the case of deviations from product and process requirements, are the causes analysed and the corrective actions checked for effectiveness? Are processes and products audited regularly?

Pionts

nb nb

Comments / Assesment Remarks

6.5.4*

6 Process Result / Output

6.6.1* 6.6.2 Are the customer's requirements met in terms of product and process? Are quantities / production batch sizes aligned with requirements and are they forwarded to the next process stage in a targeted manner? Are products / components stored in an appropriate manner and are transport facilities / packing arrangements suitable for the special characteristics of the products / components? Are the necessary records / releases carried out and stored appropriately?

nb nb

6.6.3

nb nb

6.6.4

P 7 Customer Support / Customer Satisfaction / Services 7.1* 7.2 7.3* 7.4

Are the customer's requirements satisfied regarding QM system, product (on delivery) and process? Is customer support ensured? Is the supply of parts ensured? If there are deviations from quality requirements, are failure analyses carried out and corrective actions implemented effectively? Is there a process which ensures that analysis of defective parts is carried out? Are personnel qualified for the various tasks and are responsibilities defined?

nb nb nb nb nb nb

7.5 7.6

Erstellt: Rita Demmeler-Wirth

Version/Stand: 2.6/27.09.2011

Seite 17 von 17

S-ar putea să vă placă și

- 8D Process: D0: Prepare For Problem SolvingDocument4 pagini8D Process: D0: Prepare For Problem SolvingBoby SaputraÎncă nu există evaluări

- Plato Scio Fmea Presentation 01Document22 paginiPlato Scio Fmea Presentation 01Shree BiradarÎncă nu există evaluări

- Project Manufacturing A Complete Guide - 2020 EditionDe la EverandProject Manufacturing A Complete Guide - 2020 EditionÎncă nu există evaluări

- Introduction To MTripleP IMetalDocument21 paginiIntroduction To MTripleP IMetalKrishna Mohan T.RÎncă nu există evaluări

- FMEADocument64 paginiFMEAbipin.chouguleÎncă nu există evaluări

- GMs Drill Deep and Wide Example MatrixDocument3 paginiGMs Drill Deep and Wide Example MatrixDavid MorenoÎncă nu există evaluări

- Control Plan-StampingDocument2 paginiControl Plan-StampingVipin Jangra100% (1)

- 004drill Deep & Wide Workshop Training 6.0-2Document36 pagini004drill Deep & Wide Workshop Training 6.0-2patima_sv4875100% (1)

- Amef Aiag Vda PDFDocument240 paginiAmef Aiag Vda PDFEfrain MartinezÎncă nu există evaluări

- Formel Q-Capability Version 6.0 Supplier Training - Product AuditDocument11 paginiFormel Q-Capability Version 6.0 Supplier Training - Product AuditVijay LadÎncă nu există evaluări

- Dead Endclamp Failure AnalysisDocument26 paginiDead Endclamp Failure AnalysisRK KumarÎncă nu există evaluări

- INGFRT-11 Run at RateDocument3 paginiINGFRT-11 Run at RateMarisol RubioÎncă nu există evaluări

- QSBDocument62 paginiQSBLorenzo HolguinÎncă nu există evaluări

- Escalation Procedure Updated 020915Document30 paginiEscalation Procedure Updated 020915Joezel Juaman Maglajos100% (1)

- Apqp 2Document2 paginiApqp 2Isabel SierraÎncă nu există evaluări

- Homologation and Self-CertificationDocument10 paginiHomologation and Self-CertificationAli Raza Virk100% (1)

- 402050A - Quality & Reliability Engg-sYLLABUSDocument2 pagini402050A - Quality & Reliability Engg-sYLLABUSashish RautÎncă nu există evaluări

- Send/Propose & General Releasing Tips: Version: IMDS Release 10.0Document39 paginiSend/Propose & General Releasing Tips: Version: IMDS Release 10.0Vanessa Alves Moreira100% (1)

- Controlling The Assembly Process With The Use of SPCDocument6 paginiControlling The Assembly Process With The Use of SPCSRIDHAREEE61Încă nu există evaluări

- UntitledDocument19 paginiUntitledSuresh KumarÎncă nu există evaluări

- Web Basedq1 Manufacturing Site Assessment Application: June 2020Document19 paginiWeb Basedq1 Manufacturing Site Assessment Application: June 2020Ernesto PadillaÎncă nu există evaluări

- Tuv Rheinland Training Schedule 2017Document19 paginiTuv Rheinland Training Schedule 2017ramnathÎncă nu există evaluări

- Sensor KistlerDocument2 paginiSensor KistlerFco JavierÎncă nu există evaluări

- Prozessreadinessaudit FS - 01057-En Revision - 5Document18 paginiProzessreadinessaudit FS - 01057-En Revision - 5truongngvÎncă nu există evaluări

- Apqp Cp-FaqsDocument3 paginiApqp Cp-FaqsAhmet Yavuz100% (1)

- First Off & Last OffDocument2 paginiFirst Off & Last OffKaran MalhiÎncă nu există evaluări

- CG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0Document30 paginiCG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0masprast.devegaÎncă nu există evaluări

- APQP Checklist Design PDFDocument3 paginiAPQP Checklist Design PDFShiva SÎncă nu există evaluări

- Drill DeepDocument9 paginiDrill DeepDiogo Andrade FonteneleÎncă nu există evaluări

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocument3 paginiRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanÎncă nu există evaluări

- MV Transformer Failures & MitigationDocument9 paginiMV Transformer Failures & Mitigationsomjit_mohanty3326Încă nu există evaluări

- Process Implementation V 1.1Document12 paginiProcess Implementation V 1.1Droisys IncÎncă nu există evaluări

- Redesigning Enterprise Process For E-BusinessDocument211 paginiRedesigning Enterprise Process For E-BusinessMuarif AsdaÎncă nu există evaluări

- 1.4.quality GateDocument15 pagini1.4.quality GateMOHAN SÎncă nu există evaluări

- Apqp - Layered Process Audit-1594636097 SAMPLE 4Document9 paginiApqp - Layered Process Audit-1594636097 SAMPLE 4ubraghuÎncă nu există evaluări

- VDAqmc2014 Engl DownloadDocument172 paginiVDAqmc2014 Engl DownloadLuis SosaÎncă nu există evaluări

- APQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareDocument2 paginiAPQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareselvamÎncă nu există evaluări

- Agilent Calibration FrequencyDocument6 paginiAgilent Calibration Frequencyzilangamba_s4535Încă nu există evaluări

- Qrs2012 Rev.6 en (Mmvo) .Document160 paginiQrs2012 Rev.6 en (Mmvo) .Jairo E. V RÎncă nu există evaluări

- Our Approach To QualityDocument3 paginiOur Approach To QualityabhirejanilÎncă nu există evaluări

- Shainin Vs Six SigmaDocument4 paginiShainin Vs Six Sigmabaro4518Încă nu există evaluări

- QA Processes, Tools and Metrics: Group 1Document18 paginiQA Processes, Tools and Metrics: Group 1Rhea AgulayÎncă nu există evaluări

- Minimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFDocument9 paginiMinimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFFer Jesus Nieves UribeÎncă nu există evaluări

- QC 080000-2005 (2nd Ed) IECQ-HSPMDocument16 paginiQC 080000-2005 (2nd Ed) IECQ-HSPMISO VintecomÎncă nu există evaluări

- Measurement System Analysis (Msa) : Company LOGODocument8 paginiMeasurement System Analysis (Msa) : Company LOGOபுதுகை பாலாÎncă nu există evaluări

- Vda 6.3 Yellow Print 3. 3rd Completely Revised Edition July 2016Document10 paginiVda 6.3 Yellow Print 3. 3rd Completely Revised Edition July 2016Nada RiahiÎncă nu există evaluări

- Control Plan & FMEADocument13 paginiControl Plan & FMEAAmit LuniaÎncă nu există evaluări

- 06131-En-23 Inspection ReportDocument4 pagini06131-En-23 Inspection ReportSerchecko JaureguiÎncă nu există evaluări

- Quality Management SystemDocument29 paginiQuality Management SystemArunÎncă nu există evaluări

- Capacity Verification Run at Rate IpaDocument4 paginiCapacity Verification Run at Rate IpaBES100% (1)

- Volkswagen Group Customer Specific Requirements March 2022 1Document6 paginiVolkswagen Group Customer Specific Requirements March 2022 1Tania HernandezÎncă nu există evaluări

- Apqp Ppap TrainingDocument2 paginiApqp Ppap TrainingAnkur DhirÎncă nu există evaluări

- Requirements Comparison TS16949 VDA61Document22 paginiRequirements Comparison TS16949 VDA61TarunaiÎncă nu există evaluări

- TL FMP 11 AA Self Assessment ChecklistDocument27 paginiTL FMP 11 AA Self Assessment ChecklistKhansa NadhifaÎncă nu există evaluări

- Conducting Temperature Uniformity Surveys of Furnaces Used To Heat Treat Steel ProductsDocument4 paginiConducting Temperature Uniformity Surveys of Furnaces Used To Heat Treat Steel Productssaran saranÎncă nu există evaluări

- Apqp (1) (VBS)Document111 paginiApqp (1) (VBS)MR KonarengineeringÎncă nu există evaluări

- MSA Example WorkbookDocument41 paginiMSA Example Workbookll vvÎncă nu există evaluări

- 8D Form InstructionDocument9 pagini8D Form InstructionLokesh NarasimhaiahÎncă nu există evaluări

- Matrix ManagementDocument8 paginiMatrix ManagementGrace Saragih100% (1)

- ReferencesDocument5 paginiReferencesGR MaggiÎncă nu există evaluări

- 3rd QE Business Ethics (2019)Document4 pagini3rd QE Business Ethics (2019)ma.paz100% (1)

- Email ListDocument6 paginiEmail ListSkanda KarthikÎncă nu există evaluări

- Porters Five Force Analysis - FYBMSDocument5 paginiPorters Five Force Analysis - FYBMSDeepak OswalÎncă nu există evaluări

- UNDP On Good GovernanceDocument14 paginiUNDP On Good Governancerasedul islamÎncă nu există evaluări

- IMchap 02Document26 paginiIMchap 02Tulika BajajÎncă nu există evaluări

- New Paths For Administrative LawDocument11 paginiNew Paths For Administrative LawJuan Camilo PuentesÎncă nu există evaluări

- (Lecture Notes in Computer Science 6000 - Security and Cryptology) Ed Gerck (Auth.), David Chaum, Markus Jakobsson, Ronald L. Rivest, Peter Y. A. Ryan, Josh Benaloh, Miroslaw Kutylowski, Ben Adida (EdDocument410 pagini(Lecture Notes in Computer Science 6000 - Security and Cryptology) Ed Gerck (Auth.), David Chaum, Markus Jakobsson, Ronald L. Rivest, Peter Y. A. Ryan, Josh Benaloh, Miroslaw Kutylowski, Ben Adida (EdGraham BorderwolfÎncă nu există evaluări

- Leansixsigma - Vincen DRDocument32 paginiLeansixsigma - Vincen DRdeneherwantoÎncă nu există evaluări

- Strategic Planning Checklist Template in ExcelDocument2 paginiStrategic Planning Checklist Template in ExcelFrancisco SalazarÎncă nu există evaluări

- Community Participation in EducationDocument35 paginiCommunity Participation in EducationJayCesarÎncă nu există evaluări

- ERP (Enterpreneur Resource Planing) Prince Dudhatra-9724949948Document19 paginiERP (Enterpreneur Resource Planing) Prince Dudhatra-9724949948pRiNcE DuDhAtRaÎncă nu există evaluări

- Applicant Tracking System (ATS)Document2 paginiApplicant Tracking System (ATS)SplatttttttÎncă nu există evaluări

- ABESA Election Report 2023Document9 paginiABESA Election Report 2023MichaelÎncă nu există evaluări

- Sexual Assault at The University of British Columbia: Prevention, Response, and AccountabilityDocument52 paginiSexual Assault at The University of British Columbia: Prevention, Response, and AccountabilityCKNW980Încă nu există evaluări

- Systematic Approach To Successful Implementation of ITILDocument8 paginiSystematic Approach To Successful Implementation of ITILJuliano S.M. BatistelaÎncă nu există evaluări

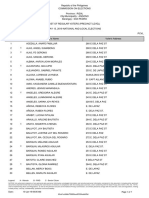

- PCVL - NLE - 5801010 (San Pedro) PDFDocument88 paginiPCVL - NLE - 5801010 (San Pedro) PDFEmel Teodocio Capistrano0% (1)

- Business Strategy & HRMDocument18 paginiBusiness Strategy & HRMDhananjay ShrivastavÎncă nu există evaluări

- Achieving Competitive Advantage With Information SystemsDocument45 paginiAchieving Competitive Advantage With Information Systemslvincent7Încă nu există evaluări

- Sample Management Review Form2Document17 paginiSample Management Review Form2Ishu MehraÎncă nu există evaluări

- NIST CSF Risk CMM-2017 EmptyDocument19 paginiNIST CSF Risk CMM-2017 EmptyLuisÎncă nu există evaluări

- Summary On Republic Act 6713 Code of Conduct and Ethical Standards For Public Officials and EmployeesDocument3 paginiSummary On Republic Act 6713 Code of Conduct and Ethical Standards For Public Officials and EmployeesAndrei AndoyÎncă nu există evaluări

- Field Project PresentationDocument12 paginiField Project PresentationManjiree Ingole JoshiÎncă nu există evaluări

- Data Management Standards - enDocument136 paginiData Management Standards - enPhuc Pham100% (3)

- Management Science - April-2016 PDFDocument4 paginiManagement Science - April-2016 PDFpranithÎncă nu există evaluări

- 35 Best PracticesDocument185 pagini35 Best Practicesmjc45100% (1)

- Controlling TechniquesDocument35 paginiControlling TechniquesKrishna Yadav100% (2)

- CRM Model QPDocument2 paginiCRM Model QPMohan VamsiÎncă nu există evaluări

- Certified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsDocument2 paginiCertified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsSunStar Philippine NewsÎncă nu există evaluări