Documente Academic

Documente Profesional

Documente Cultură

RC SLAB1 Software

Încărcat de

sofianina05Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RC SLAB1 Software

Încărcat de

sofianina05Drepturi de autor:

Formate disponibile

1

RC-SLAB1 Software

SUMMARY

This program performs analysis and design of RC one way slabs according to Saudi SBC and

American ACI codes. Both one-way solid slabs and joist slabs are considered. The slab or the

joist as well as the supporting beams can be analyzed and designed with automatic load transfer

from the slab to beams.

Developed by Professor Abdelhamid Charif

King Saud University, Civil Engineering Department.

Last edited in November 2009.

Both ACI / SBC coefficient method and elastic finite element method can be used for the

analysis. The code method can only be used if all its conditions are satisfied. But even if these

conditions are satisfied, the user can still choose either method for comparison purposes.

The user must first choose the type of slab and then enter all the data relevant to the slab and

beam. When entering many values in a single cell, spaces or commas should be left between

them. Material data (concrete and steel) can be entered any time. Concrete coefficient beta1 and

steel yield strain are updated and shown automatically. Ultimate steel strain is assumed unlimited

by default (ACI/SBC) but the user can change this and enter any positive value greater than or

equal to 0.010. Concrete displaced by bars in compression zone is considered.

The code condition imposing a lower limit (0.005 for SBC or 0.004 for ACI) on steel tensile

strain may be considered with either of ACI and SBC limits.

Load transfer from the solid slab or joist slab to the beams is performed by the software,

according to the beam tributary width. Beam loading may include wall line load. In a joist slab,

the inter-rib spaces may be void or contain hourdis blocks.

The beams may be designed with the original rectangular section or with the effective T-section

or L-section. The T-section (for internal beams) and L-section (for edge beams) results from the

interaction between the slab and the beam. The T-section or L-section flange width is

automatically determined by the software, according to SBC / ACI provisions.

Checking, analysis and design steps can be performed separately or in one single operation. The

output includes results of the various checks (minimum thickness, shear, flange, ...). Values of

the clear lengths, shear and moment coefficients as well as the minimum thickness are displayed

for each span. Shear force and bending moment diagrams are also displayed. When using the

code coefficient method, envelope curves of the diagrams are generated.

Design results include required steel areas as well as the number of bars and bar spacing. Code

values for minimum steel and maximum spacing are enforced. The software delivers an optimum

reinforcement pattern along the model by performing appropriate bar cutoff. Both demand and

capacity moment diagrams are produced.

Shear design is performed for beams or ribs requiring it. Single stirrup spacing is produced for

the critical section. For span design, variation of stirrup spacing is delivered.

In case of a solid one-way slab, the slab results are sent to the file "Slab-Strip.out", whereas the

beam results are in "Slab-Beam.out". For a joist slab, the rib and beam results are in files "Joist-

Rib.out" and "Joist-Beam.out".'

2

Theoretical background

Steps for the analysis and design of one-way solid slab (1-m slab strip):

(1) Thickness: Determine minimum thickness and:

If the thickness is unknown choose a value greater or equal to the minimum value

If the thickness is given, check that it is greater or equal to the minimum value

(2) Loading: Determine the dead and live uniform loading on the slab-strip (kN/m) using the

given area loads (kN/m

2

) for live load (LL) and super imposed dead load (SDL) as well as the

slab self weight: m x h SDL w

s c D

1 ) ( + = m x LL w

L

1 =

The ultimate factored load on the slab strip is:

L D u

w w w 7 . 1 4 . 1 + =

(3) Flexural analysis: Determine the values of ultimate moments at major locations (exterior

negative moment, interior negative moment and positive span moment) using the appropriate

clear lengths and moment coefficients or elastic analysis.

(4) Flexural RC design: Perform RC design using standard methods starting with the maximum

moment value. Determine the required steel area and compare with code minimum steel area.

Determine the bar spacing and compare with code maximum spacing

(5) Shrinkage reinforcement:

Determine shrinkage (temperature) reinforcement and the corresponding spacing

(6) Shear check: Perform shear check that is, check that:

u c

V V > |

If it is not checked, the thickness must be increased and repeat steps from (2)

(7) Detailing: Draw execution plans

ACI / SBC coefficient method of analysis

The ACI / SBC method (also called coefficient method) allows for various load patterns where

live load is applied on selected spans and maximum shear force and bending moment values are

obtained by the envelope curves. This simplified and approximate method allows also for the

real rotation restraint at external supports, where the real moment is not equal to zero. Elastic

analysis gives systematic zero moment values at all external pin supports. The coefficient

method is thus more realistic but is only valid for standard cases. It is advised to use this method

whenever its conditions of application are satisfied. Elastic analysis should be used only if the

conditions of the code method are not satisfied.

Conditions of application of ACI / SBC coefficient method:

1. Two spans or more

2. Spans not too different. Ratio of any two adjacent spans less or equal to 1.2. For two

successive spans (i) and (i+1), we must have : 2 . 1

) , (

) , (

1

1

s

+

+

i i

i i

L L Min

L L Max

3. Uniform loading

4. Unfactored live load less or equal to three times unfactored dead load: DL LL 3 s

5. Beams with prismatic sections

Ultimate moment and shear force are given by:

2

) (

n u m u

l W C M = |

.

|

\

|

=

2

n

u v u

l

W C V

3

For shear force, span positive moment and external negative moment, l

n

is the clear length of the

span. For internal negative moment, l

n

is the average of clear lengths of the adjacent spans.

C

m

and C

v

are the moment and shear coefficients given by SBC / ACI Tables

End

span

Interior

span

End (exterior)

support

Interior

support

Interior face

of end support

Exterior face of first

interior support

Other faces of

Interior supports

C

m

0

C

v

-1/10 -1/11 -1/11 -1/11 -1/11 -1/11

+1/11 +1/16 +1/16

1.0

1.0

1.0

1.0

1.0

1.0

1.15

a/ ACI terminology

b/ Unrestrained end More than 2 spans

C

m

-1/24(-1/16)*

C

v

-1/10 -1/11 -1/11 -1/11 -1/11 -1/11

+1/14 +1/16 +1/16

1.0

1.0

1.0

1.0

1.0

1.0

1.15

c/ Integral end More than 2 spans

C

m

-1/24 (-1/16)*

C

v

-1/9 -1/9 -1/24 (1/16)

+1/14 +1/14

1.0

1.15

1.0

1.15

d / Integral end with 2 spans

) (

1 n

L M

|

.

|

\

|

+

) (

2

1

2 1 n n

L L M

) (

1 n

L M

+

) (

2 n

L M

+

|

.

|

\

|

+

) (

2

1

2 1 n n

L L M

) (

1 n

L V

) (

2 n

L V

) (

1 n

L V

* : The exterior negative moment depends on the type of support

If the support is a beam or a girder, the coefficient is: -1/24

If the support is a column, the coefficient is: -1/16

4

Minimum thickness for beams and one way slabs

Minimum thickness is given by SBC / ACI codes as shown in this Table.

Minimum thickness for beams (ribs) and one-way slabs

unless deflections are computed and checked

Simply

supported

One end

continuous

Both ends

continuous

Cantilever

Solid one-

way slab

L / 20 L / 24 L / 28 L / 10

Beams

or ribs

L / 16 L / 18.5 L / 21 L / 8

In a continuous beam or slab strip, the minimum thickness must be determined for each span and

the final value is the greatest of them: ) ,..., , , (

min, 3 min 2 min 1 min min n

h h h h Max h =

A thickness less than the minimum value may be used but the deflections must then be computed

and checked.

Load transfer from one way solid slab to beams

Load is transferred to the beam according to its tributary width l

t

. The tributary width is

computed using mid-lines between beams, except for edge beams where it must include all the

beam width (to account for all area) and any slab offset.

The beam dead load must include the beam web weight and any possible wall load.

Dead

wall bw bw c t s c bD

w h b l x h SDL w + + + = ) ( Live

t bL

l x LL w =

Effective beam section

Because of the interaction between the slab and beam, the effective beam section is:

T-section for internal beams

L-section for edge beams

The flange width is determined according to SBC /ACI provisions.

Beam analysis and design is performed following similar steps except that shear step is a design

step where stirrups are designed.

Bar spacing and bar layer number, are updated and many re-design cycles are performed as

required.

5

Steps for the analysis and design of one-way joist slab

(1) Thickness: Determine minimum thickness and:

If the thickness is unknown choose a value greater or equal to the minimum value

If the thickness is given, check that it is greater or equal to the minimum value

(2) Geometry and loading: Check the joist dimension conditions and determine the dead and

live uniform loading on the joist (kN/m) using the given area loads (kN/m

2

) for live load (LL)

and super imposed dead load (SDL) as well as the joist self weight.

The joist tributary width is the flange width. The dead load must include the possible hourdis

block weight.

Dead

jw b jw jw c jf jf c jD

Sh h b b x h SDL w + + + = ) ( Live

jf sL

b x LL w =

The ultimate factored load on the joist is:

L D u

w w w 7 . 1 4 . 1 + =

(3) Flexural analysis: Determine the values of ultimate moments at major locations (exterior

negative moment, interior negative moment and positive span moment) using the appropriate

clear lengths and moment coefficients or elastic analysis.

(4) Flexural RC design: Perform RC design using standard methods starting with the maximum

moment value. Determine the required steel area and compare with code minimum steel area.

Determine the bar number and check layer number.

(5) Shrinkage reinforcement:

Determine shrinkage (temperature) reinforcement and the corresponding spacing

(6) Shear check: Perform shear check that is, check that:

u c

V V > |

SBC and ACI allow 10 % increase for concrete shear strength in joists.

If it is not checked, stirrups must be provided.

(7) Flange check: The flange with little or no reinforcement must be checked as a plain

concrete member, taking into account concrete tensile strength.

(8) Detailing: Draw execution plans

Load transfer from joist slab to beams

Load is transferred by joists to the beam according to its tributary width l

t

. Area load is equal to

the joist load divided by the flange width.

In order to avoid duplication of the joist-beam joint, we must use the clear tributary width l

tn

. It is

obtained by subtracting the beam width:

b t tn

b l l =

The dead load includes possible wall loading

Dead

wall b b b c tn

jf

jD

bD

w b x SDL h b l

b

w

w + + + = Live

t bL

l x LL w =

For a flange thickness less than 100 mm, the software rejects the effective T-section or L-section

for internal or edge beams. The flange must be thick enough to incorporate top steel bars with

appropriate covers. Rectangular section design is then recommended.

All the steps for one way solid slab or joist slab as well as the supporting beams are integrated in

RC-SLAB1 software.

6

Users manual

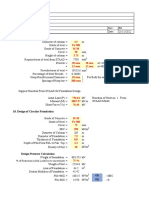

Figure 1 shows RC-SLAB1 main screen. A solid one way slab is analyzed in this case.

Figure 1: Main screen of RC-SLAB1 software

7

The following partial listing is produced by the software. It gives all checking results, analysis

results as well as RC design results for a 1 m slab strip. Shrinkage reinforcement is also delivered

Analysis and design of a 1-m wide slab strip with 4 spans

Performing various checks:

The actual thickness (mm) is: 170.00

The code minimum thickness (mm) is: 166.67

The minimum thickness is checked

The unfactored dead load (kN/m) is : 9.580

The unfactored live load (kN/m) is : 5.000

The factored ultimate uniform load (kN/m) is : 21.912

All conditions of coefficient method satisfied

Analysis using SBC/ACI coefficient method

Rectangular section dimensions (mm): Width = 1000 Thickness = 170

Moment Coefficients for first span: -1/24 1/14 -1/10

Exterior shear force: 1.0 Interior shear force: 1.15

Moments (kN.m) and shear forces (kN) for span 1:

Left -ve moment: -12.499 Right -ve moment: -29.998

Positive moment: 21.427

Left shear force: 40.537 Right shear force: 46.618

Moment Coefficients for internal span: -1/11 1/16 -1/11

Interior -ve moment: -1/11 Interior shear force: 1.0

Moments (kN.m) and shear forces (kN) for span 2:

Left -ve moment: -27.270 Right -ve moment: -27.270

Positive moment: 18.748

Left shear force: 40.537 Right shear force: 40.537

Concrete strength f'c (MPa) = 25.00

Nominal concrete shear strength Vc = sqrt(fc') x bw x d/6

Effective steel depth d (mm) = 144.00

Nominal concrete shear strength Vc (kN) = 120.000

Phi x Vc (kN) = 90.000

Maximum ultimate shear force Vu (kN) = 46.618

Shear strength is OK. No stirrups required 1

Flexural RC design of all spans using 12-mm bars

Steel grade fy (MPa) = 420.00

Code minimum steel reinforcement (mm 2) = 306.00

Corresponding maximum spacing (mm) = 369.60

Code maximum bar spacing (mm) Smax = Min(2h,300) = 300.00

Maximum bar spacing limit adopted (mm) = 300

RC design for ultimate moment (kN.m) = 21.4268

Steel area (mm 2) = 404.8943 Depth (mm) = 144.00

Bar spacing (mm) = 279.33 Adopted spacing (mm) = 250

RC design for ultimate moment (kN.m) = -29.9975

Steel area (mm 2) = 573.6875 Depth (mm) = 26.00

Bar spacing (mm) = 197.14 Adopted spacing (mm) = 175

Shrinkage steel (mm 2) = 306.00 Use of 10-mm bars

Spacing (mm) = 256.67 Maximum spacing = Min(4h,300) = 300.00

Adopted bar spacing (mm) = 250

8

Figure 2 shows analysis results for the slab-strip.

Figure 2: Analysis results for slab strip using ACI/SBC coefficient method

9

Figures 2 and 3 shows the analysis results for the slab strip, using ACI/SBC method and the

elastic method.

Figure 3: Analysis results for slab strip using elastic method

Figure 4 shows RC design results highlighting demand and capacity moment diagrams. Variable

bar spacing along the model is shown. Maximum spacing and minimum steel conditions are

enforced.

Figure 4: RC design results for slab strip showing bar spacing

10

Figure 5 shows the analysis results for an internal beam modeled as a T-section.

The detailed listing produced by the software is also shown.

Figure 4: Analysis results of an internal beam

11

Figure 5 shows design results for the beam modeled as a T-section. Optimum bar cutoff is

delivered with demand and capacity moment diagrams. It can be noted that design for

maximum\negative moment requires compression steel bars.

Figure 5: Design results for the beam

The output shows stirrup design results as well:

Shear design of the beam

Shear design using 10-mm stirrups with 3 legs

Maximum shear force at support (kN) = 407.252

Shear force at mid-span from envelope curve (kN) = 53.120

Shear force at a distance d from support (kN) = 357.398

Stirrup spacing (mm) is = 157.28 Max spacing (mm) is = 135.50

Adopted spacing (mm) = 130

Constant spacing along the span

12

Figure 6 shows the data dialog box in case of joist slabs.

Figure 6: Data dialog box for joist slabs

13

The partial listing below shows checking results and particularly detailed results of flange check

as a plain concrete member.

Analysis and design of a joist (rib) with 4 spans

Performing various checks:

The actual thickness (mm) is: 300.00

The code minimum thickness (mm) is: 216.22

The minimum thickness is checked

All conditions on joist dimensions are satisfied

Flange check as plain concrete member doubly fixed

Flange ultimate uniform load on 1-m strip (kN/m): 10.28000

Ultimate moment Mu (kN.m): 0.21417

Concrete tensile strength (MPa) : 3.50000

Nominal moment Mn (kN.m): 1.45833

Phi * Mn (kN.m): 0.94792

Flange check is OK

The unfactored dead load (kN/m) is : 4.514

The unfactored live load (kN/m) is : 1.860

The factored ultimate uniform load (kN/m) is : 9.482

All conditions of coefficient method satisfied

Concrete strength f'c (MPa) = 25.00

Nominal concrete shear strength Vc = 1.1 x sqrt(fc') x bw x d/6

Effective steel depth d (mm) = 266.00

Nominal concrete shear strength Vc (kN) = 29.260

Phi x Vc (kN) = 21.945

Maximum ultimate shear force Vu (kN) = 20.172

Shear strength is OK. No stirrups required

14

Figure 7 shows RC design results highlighting demand and capacity moment diagrams.

Shrinkage steel spacing is also delivered.

Figure 7: RC design results highlighting demand and capacity moment diagrams for the joist

S-ar putea să vă placă și

- Coefficient MethodDocument3 paginiCoefficient Methodmarx0506Încă nu există evaluări

- One Way Solid SlabDocument26 paginiOne Way Solid SlabalaajabbarÎncă nu există evaluări

- RC ContinuityDocument9 paginiRC ContinuityKutlu DarılmazÎncă nu există evaluări

- Engr. Suñega - 2wayslab-DdmDocument31 paginiEngr. Suñega - 2wayslab-DdmJustinÎncă nu există evaluări

- ONE-WAY SLABS DESIGNDocument26 paginiONE-WAY SLABS DESIGNJohn Mejia50% (4)

- Joist SlabDocument13 paginiJoist SlabAhmed Nabil80% (5)

- 2.6 Design Example Two Span Continuous Box Girder BridgeDocument17 pagini2.6 Design Example Two Span Continuous Box Girder BridgeglaydelleÎncă nu există evaluări

- Supplementary Note335Document21 paginiSupplementary Note335Syafiq ArtÎncă nu există evaluări

- Strut-And-Tie Model Design Provisions: Robin G. Tuchscherer, David B. Birrcher, and Oguzhan BayrakDocument16 paginiStrut-And-Tie Model Design Provisions: Robin G. Tuchscherer, David B. Birrcher, and Oguzhan BayrakDavid Apaza QuispeÎncă nu există evaluări

- CBDocument99 paginiCBnabnajÎncă nu există evaluări

- Beam checking strength verification resultsDocument6 paginiBeam checking strength verification resultsCSEC Uganda Ltd.Încă nu există evaluări

- Lecture10 NewDocument48 paginiLecture10 NewJule LobresÎncă nu există evaluări

- Design of One Way Slab-Basic Theory and Procedures-Dr. Latifee-16-Dec-2015v1Document18 paginiDesign of One Way Slab-Basic Theory and Procedures-Dr. Latifee-16-Dec-2015v1Ali M. MohammedÎncă nu există evaluări

- Concrete Deck DesignDocument15 paginiConcrete Deck Designmikeengineering100% (1)

- Steel Chap5 Ultimate Limit StateDocument35 paginiSteel Chap5 Ultimate Limit StateMesfin Derbew86% (7)

- RC-BIAX Analysis and Design SoftwareDocument23 paginiRC-BIAX Analysis and Design SoftwareEber Pe IsiÎncă nu există evaluări

- Two Way Column Supported SlabsDocument62 paginiTwo Way Column Supported SlabsPrince VkÎncă nu există evaluări

- Steel Design by Canadian CodeDocument94 paginiSteel Design by Canadian Codepjuvvadi100% (5)

- Reinforced Concrete Column DesignDocument19 paginiReinforced Concrete Column DesignNacho ValenteÎncă nu există evaluări

- Slab DesignDocument15 paginiSlab DesignLawrence Arellano FernandezÎncă nu există evaluări

- Slabs: Serviceability and Shear: WWW - Eurocode2.infoDocument56 paginiSlabs: Serviceability and Shear: WWW - Eurocode2.infoKai Lin TayÎncă nu există evaluări

- Csi Etabs & Safe Manual: Part III: Model Analysis & Design of SlabsDocument83 paginiCsi Etabs & Safe Manual: Part III: Model Analysis & Design of SlabsAnonymous LJ1v8KKÎncă nu există evaluări

- Direct Design MethodDocument90 paginiDirect Design Methodborja familyÎncă nu există evaluări

- Matrici de Rigiditate Din MathcadDocument13 paginiMatrici de Rigiditate Din MathcadAlice ZainelÎncă nu există evaluări

- Project SynopsisDocument24 paginiProject SynopsisselvaganeshÎncă nu există evaluări

- Design of A Pre-Stressed Bridge GirderDocument37 paginiDesign of A Pre-Stressed Bridge GirderLuis Ariel B. MorilloÎncă nu există evaluări

- EXAMPLE 9.2 - Part I PCI Bridge Design Manual EXAMPLE 9.2 - Part I PCI Bridge Design ManualDocument21 paginiEXAMPLE 9.2 - Part I PCI Bridge Design Manual EXAMPLE 9.2 - Part I PCI Bridge Design ManualDr. MOHAMED ALZAINÎncă nu există evaluări

- Manansad, Dionisa C. BSCE-3A Write Ups 2: Two Way Slabs: ConceptsDocument16 paginiManansad, Dionisa C. BSCE-3A Write Ups 2: Two Way Slabs: ConceptsRiza May SalutanÎncă nu există evaluări

- Rule of Thumb For RC DesignDocument12 paginiRule of Thumb For RC DesignJeefry Arranguez50% (2)

- Reinforced Concrete Design BS 8110Document15 paginiReinforced Concrete Design BS 8110Kutty Mansoor75% (4)

- BeamDocument42 paginiBeamlavyÎncă nu există evaluări

- RC Frame Design FeaturesDocument60 paginiRC Frame Design Featureskdb92uce100% (1)

- 5beams2 PDFDocument84 pagini5beams2 PDFAlexa BuquirÎncă nu există evaluări

- CE 412 - Lec 1 Direct Design Method-ADocument118 paginiCE 412 - Lec 1 Direct Design Method-AAlina RafeeqÎncă nu există evaluări

- Fargo Kula5Document39 paginiFargo Kula5Vulebg VukoicÎncă nu există evaluări

- CIVE-441 Steel Design (I) : Homework Assignment # 7Document26 paginiCIVE-441 Steel Design (I) : Homework Assignment # 7Mohamed GamalÎncă nu există evaluări

- ACI Moment Coefficient Design AID PDFDocument13 paginiACI Moment Coefficient Design AID PDFSufian Ahmad50% (4)

- Bridge Technology Deck DesignDocument24 paginiBridge Technology Deck DesignSteven EscheÎncă nu există evaluări

- Two Way SlabDocument17 paginiTwo Way SlabGetachew MekuriawÎncă nu există evaluări

- Multistoreyed Building 5Document11 paginiMultistoreyed Building 5V.m. RajanÎncă nu există evaluări

- CN Chap 04 - Design of Rectangular Beams and One-Way SlabsDocument38 paginiCN Chap 04 - Design of Rectangular Beams and One-Way Slabshussain ghaziÎncă nu există evaluări

- Design of Reinfonced Concrete Slab by Eng:Kusundwa 0757-537605Document53 paginiDesign of Reinfonced Concrete Slab by Eng:Kusundwa 0757-537605GoodluckÎncă nu există evaluări

- Design of Reinforced Concrete Columns PDFDocument26 paginiDesign of Reinforced Concrete Columns PDFMa Gh100% (1)

- Continuous Composite BeamsDocument27 paginiContinuous Composite BeamsbsitlerÎncă nu există evaluări

- 4 Slab DesignDocument28 pagini4 Slab DesignSarah HaiderÎncă nu există evaluări

- Unit 3 - Structural Design and Drawing (RCC-I) - WWW - Rgpvnotes.inDocument12 paginiUnit 3 - Structural Design and Drawing (RCC-I) - WWW - Rgpvnotes.insaheba khanÎncă nu există evaluări

- Design of Lateral Load Resisting Frames Using Steel Joists and Joist GirdersDocument48 paginiDesign of Lateral Load Resisting Frames Using Steel Joists and Joist GirdersJoel MooreÎncă nu există evaluări

- Hot Rolled Steel - Composite Beam Design OverviewDocument7 paginiHot Rolled Steel - Composite Beam Design Overviewsrikanth.iitkgpÎncă nu există evaluări

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDe la EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionÎncă nu există evaluări

- Cylindrical Compression Helix Springs For Suspension SystemsDe la EverandCylindrical Compression Helix Springs For Suspension SystemsÎncă nu există evaluări

- MOS Integrated Circuit DesignDe la EverandMOS Integrated Circuit DesignE. WolfendaleÎncă nu există evaluări

- O level Physics Questions And Answer Practice Papers 2De la EverandO level Physics Questions And Answer Practice Papers 2Evaluare: 5 din 5 stele5/5 (1)

- Standard-Slope Integration: A New Approach to Numerical IntegrationDe la EverandStandard-Slope Integration: A New Approach to Numerical IntegrationÎncă nu există evaluări

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- Power Systems-On-Chip: Practical Aspects of DesignDe la EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardÎncă nu există evaluări

- ConversionDocument1 paginăConversionsofianina05Încă nu există evaluări

- ScadaDocument420 paginiScadaVictor Farias GuerreroÎncă nu există evaluări

- AutoCAD Tutorial - Draw Front View of Mechanical PartDocument10 paginiAutoCAD Tutorial - Draw Front View of Mechanical PartvintiloiusÎncă nu există evaluări

- Requirements for Environmental Impact Assessment SystemDocument29 paginiRequirements for Environmental Impact Assessment SystemDaniel ReyesÎncă nu există evaluări

- Pipeline Safety Improvement of 2002 (PSIA)Document3 paginiPipeline Safety Improvement of 2002 (PSIA)sofianina05Încă nu există evaluări

- Bid Security ProvisionsDocument5 paginiBid Security Provisionssofianina05Încă nu există evaluări

- Mass HymnsDocument20 paginiMass Hymnssofianina05Încă nu există evaluări

- Design, Procurement, Construction Supervision of Hairatan-Mazar RailwayDocument101 paginiDesign, Procurement, Construction Supervision of Hairatan-Mazar RailwayDipendra ShresthaÎncă nu există evaluări

- Science Year 4 - Basic Needs of HumansDocument2 paginiScience Year 4 - Basic Needs of Humanssofianina05Încă nu există evaluări

- BGSCMExample5 1Document3 paginiBGSCMExample5 1sofianina05Încă nu există evaluări

- EnergyDocument100 paginiEnergyRizky Ardias DarmawanÎncă nu există evaluări

- Env Dao 1996-37 PDFDocument44 paginiEnv Dao 1996-37 PDFDaniel ReyesÎncă nu există evaluări

- PCAB License As Per Category - PCA Metro - PCAB Licensing ForumDocument14 paginiPCAB License As Per Category - PCA Metro - PCAB Licensing Forumsofianina05Încă nu există evaluări

- PCAB License As Per Category - PCA Metro - PCAB Licensing ForumDocument14 paginiPCAB License As Per Category - PCA Metro - PCAB Licensing Forumsofianina05Încă nu există evaluări

- Wall and Pier Coping: Building Into The Future Since 1969Document8 paginiWall and Pier Coping: Building Into The Future Since 1969sofianina05Încă nu există evaluări

- Outer Fence SpecificastionsDocument40 paginiOuter Fence Specificastionssofianina05Încă nu există evaluări

- Previews AWWA C652-11 PreDocument7 paginiPreviews AWWA C652-11 Prefructora13% (8)

- 2014 Isuzu D-Max 3Document2 pagini2014 Isuzu D-Max 3sofianina05Încă nu există evaluări

- Effluent 15aug08 PDFDocument139 paginiEffluent 15aug08 PDFRyan Michael OducadoÎncă nu există evaluări

- Catalunan Grande, Davao City in Davao Del Sur Mindanao PhilippinesDocument1 paginăCatalunan Grande, Davao City in Davao Del Sur Mindanao Philippinessofianina050% (1)

- DWS1110Document53 paginiDWS1110sofianina05Încă nu există evaluări

- Potable Glass Water Tank Specs AWWA-Queens Gap 2014-100K-10KDocument7 paginiPotable Glass Water Tank Specs AWWA-Queens Gap 2014-100K-10Ksofianina05Încă nu există evaluări

- Cement-Mortar Lined & Coated Steel PipeDocument5 paginiCement-Mortar Lined & Coated Steel Pipenay denÎncă nu există evaluări

- Allstate Specification For AstmDocument12 paginiAllstate Specification For Astmsofianina05Încă nu există evaluări

- DPWH Bantay NG LansanganDocument136 paginiDPWH Bantay NG LansanganGerardoÎncă nu există evaluări

- CarDocument96 paginiCarsofianina05Încă nu există evaluări

- GTZ Drinking PVPS PDFDocument11 paginiGTZ Drinking PVPS PDFsofianina05Încă nu există evaluări

- The Post Tender Clarification Process GuideDocument3 paginiThe Post Tender Clarification Process Guidesofianina05Încă nu există evaluări

- NWD Sandbag PamphletDocument8 paginiNWD Sandbag Pamphletsofianina05Încă nu există evaluări

- APP129Document10 paginiAPP129Gary LoÎncă nu există evaluări

- Fatigue Life Assessment of An Excavator Arm BoxDocument6 paginiFatigue Life Assessment of An Excavator Arm BoxThanh Duc NguyenÎncă nu există evaluări

- Cantilever BeamDocument5 paginiCantilever BeamAnonymous nwByj9LÎncă nu există evaluări

- Columns and StrutsDocument32 paginiColumns and StrutsRabia ZulqarnainÎncă nu există evaluări

- Analysis and Design of Commercial Complex by " Pro": StaadDocument8 paginiAnalysis and Design of Commercial Complex by " Pro": StaadSandeep HøñeyÎncă nu există evaluări

- Circular Column Design For Pole SuportDocument2 paginiCircular Column Design For Pole SuportJayÎncă nu există evaluări

- BSR IctadDocument88 paginiBSR IctadRavindu Ransara100% (1)

- Session 7-TorsionDocument31 paginiSession 7-TorsionRavi ChandraÎncă nu există evaluări

- The Determination of Standard Deviation of ConcreteDocument1 paginăThe Determination of Standard Deviation of ConcreteAkash SaikiaÎncă nu există evaluări

- Analysis and Design of Plate Girder BridgesDocument58 paginiAnalysis and Design of Plate Girder Bridgesadnan-651358Încă nu există evaluări

- C4 - Mixing, Fresh Properties, Casting, Demoulding and CuringDocument26 paginiC4 - Mixing, Fresh Properties, Casting, Demoulding and CuringTAN PANG ZORÎncă nu există evaluări

- Available Deck Sheet Profiles Section PropertiesDocument1 paginăAvailable Deck Sheet Profiles Section PropertiesKÎncă nu există evaluări

- Wind PostsDocument8 paginiWind Postsrmc_sheevakumarÎncă nu există evaluări

- SEISMIC DESIGNDocument33 paginiSEISMIC DESIGNkdb92uce100% (1)

- Pryout capacity and bearing behavior of stocky headed stud anchoragesDocument181 paginiPryout capacity and bearing behavior of stocky headed stud anchoragesemailnaravindÎncă nu există evaluări

- BTCVC701 - 1 Question PaperDocument1 paginăBTCVC701 - 1 Question Paperस्नेहल पिंपळे शेळकेÎncă nu există evaluări

- BBS of Lintel Beam - Bar Bending Schedule of Lintel Beam PDFDocument5 paginiBBS of Lintel Beam - Bar Bending Schedule of Lintel Beam PDFfelixÎncă nu există evaluări

- GIB Fire Rated Systems 2012Document84 paginiGIB Fire Rated Systems 2012Hrvoje Placko MacekÎncă nu există evaluări

- Carrillo 2017Document14 paginiCarrillo 2017Caro ContrerasÎncă nu există evaluări

- Build Up Rate Format - PlasteringDocument2 paginiBuild Up Rate Format - PlasteringFaiz Ahmad86% (29)

- Concrete Construction Article PDF - The World's Tallest Freestanding Structure Is A Functional Landmark in ConcreteDocument3 paginiConcrete Construction Article PDF - The World's Tallest Freestanding Structure Is A Functional Landmark in ConcretegiovanniÎncă nu există evaluări

- MFE Accessories Brochure (Old)Document8 paginiMFE Accessories Brochure (Old)David LawÎncă nu există evaluări

- Generator RoomDocument18 paginiGenerator RoomAnkit SuriÎncă nu există evaluări

- Proposed Marudi Bridge Over Batang Baram, Miri Division, SarawakDocument8 paginiProposed Marudi Bridge Over Batang Baram, Miri Division, SarawakKelvin LauÎncă nu există evaluări

- Column Design NSCP 2015 PDFDocument4 paginiColumn Design NSCP 2015 PDFDopias Fake100% (2)

- EC3 - Tension Member - 2021Document27 paginiEC3 - Tension Member - 2021MUHAMMAD AMIRUL ASYRAF BIN MOHD RANIÎncă nu există evaluări

- Prestressed ConcreteDocument15 paginiPrestressed ConcreteSheryll de GuzmanÎncă nu există evaluări

- MasterPolyheed 927Document2 paginiMasterPolyheed 927AMAURY DE JESUS GOMEZÎncă nu există evaluări

- Direct Design Method For QuizDocument142 paginiDirect Design Method For QuizPavan PsÎncă nu există evaluări

- FibroneDocument5 paginiFibroneBasim ThekkilÎncă nu există evaluări