Documente Academic

Documente Profesional

Documente Cultură

BLOQUE

Încărcat de

Alvaro Alexis Mendoza PradaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

BLOQUE

Încărcat de

Alvaro Alexis Mendoza PradaDrepturi de autor:

Formate disponibile

2010 SECTION V

ARTICLE 4

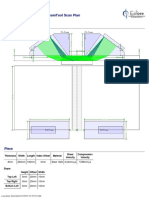

FIG. T-434.2.1 NON-PIPING CALIBRATION BLOCKS

3T

1/ T 2 1/ T 4

D

1/ T 2 3/ T 4

6 in. (150 mm)

CT

1/ T 2

T

1/ T 2 1/ T 2

1/ T 2

Cladding (if present)

Minimum dimensions D = 1/2 in. (13 mm) Width = 6 in. (150 mm) Length = 3 x Thickness

Weld Thickness, t, in. (mm) Up to 1 (25) Over 1 (25) through 2 (50) Over 2 (50) through 4 (100) Over 4 (100) Minimum dimension.

Calibration Block Thickness, T, in. (mm) 4 (19) or t 112 (38) or t 3 (75) or t t 1 (25)

3

Hole Diameter, in. (mm) 32 (2.5) 8 (3) 3 16 (5) [Note (1)]

1 3

Notch Dimensions, in. (mm) Notch depth p 2% T Notch width p 14 (6) max. Notch length p 1 (25) min.

GENERAL NOTES: (a) Holes shall be drilled and reamed 1.5 in. (38 mm) deep minimum, essentially parallel to the examination surface. (b) For components equal to or less than 20 in. (500 mm) in diameter, calibration block diameter shall meet the requirements of T-434.1.7.2. Two sets of calibration reectors (holes, notches) oriented 90 deg from each other shall be used. Alternatively, two curved calibration blocks may be used. (c) The tolerance for hole diameter shall be 132 in. (0.8 mm). The tolerance for hole location through the calibration block thickness (i.e., distance from the examination surface) shall be 18 in. (3 mm). (d) For blocks less than 34 in. (19 mm) in thickness, only the 12T side-drilled hole and surface notches are required. (e) All holes may be located on the same face (side) of the calibration block, provided care is exercised to locate all the reectors (holes, notches) to prevent one reector from affecting the indication from another reector during calibration. Notches may also be in the same plane as the in-line holes (See Appendix J, Fig. J-431). As in Fig. J-431, a sufcient number of holes shall be provided for both angle and straight beam calibrations at the 14T, 12T, and 34T depths. (f) Notch depths shall be 1.6%T minimum to 2.2%T maximum. When cladding is present, notch depth on the cladding side of the block shall be increased by the cladding thickness, CT (i.e., 1.6%T + CT minimum to 2.2%T + CT maximum). (g) Maximum notch width is not critical. Notches may be made by EDM or with end mills up to 14 in. (6.4 mm) in diameter. (h) Weld thickness, t, is the nominal material thickness for welds without reinforcement or, for welds with reinforcement, the nominal material thickness plus the estimated weld reinforcement not to exceed the maximum permitted by the referencing Code Section. When two or more base material thicknesses are involved, the calibration block thickness, T, shall be determined by the average thickness of the weld; alternatively, a calibration block based on the greater base material thickness may be used provided the reference reector size is based upon the average weld thickness. NOTE: (1) For each increase in weld thickness of 2 in. (50 mm) or fraction thereof over 4 in. (100 mm), the hole diameter shall increase 116 in. (1.5 mm).

47

S-ar putea să vă placă și

- DAC Block Details PDFDocument2 paginiDAC Block Details PDFShrikant UtekarÎncă nu există evaluări

- Welds Written ReportDocument4 paginiWelds Written ReportChris Paulo100% (1)

- Example Slide of User Functions: Time Guide The Slide Should Be Finished byDocument70 paginiExample Slide of User Functions: Time Guide The Slide Should Be Finished byHskumarReddy KarriÎncă nu există evaluări

- Process Piping ASME BN31.3Document40 paginiProcess Piping ASME BN31.3shabbir626100% (1)

- Beamtool Scan Plan: Inspection LayoutDocument4 paginiBeamtool Scan Plan: Inspection LayoutMohan RajÎncă nu există evaluări

- Bevel Information Bevel Data Table BevelDocument3 paginiBevel Information Bevel Data Table BevelJ.CarrascoÎncă nu există evaluări

- Weld Scanning ProcedureDocument5 paginiWeld Scanning ProcedureLutfi IsmailÎncă nu există evaluări

- Iso-Tc135-Sc3 - Iso - Dis - 2400 - 2011 PDFDocument12 paginiIso-Tc135-Sc3 - Iso - Dis - 2400 - 2011 PDFVuong Tran VanÎncă nu există evaluări

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 paginiUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mÎncă nu există evaluări

- Penetrants TESTINGDocument86 paginiPenetrants TESTINGsankaran_muthukumarÎncă nu există evaluări

- Ultrasonic Phased Array Technique For Austenitic Weld Inspection PDFDocument4 paginiUltrasonic Phased Array Technique For Austenitic Weld Inspection PDFRAFAEL ANDRADEÎncă nu există evaluări

- Small Diameter Tube and Pipe Inspection With Phased Array PDFDocument7 paginiSmall Diameter Tube and Pipe Inspection With Phased Array PDFAlanka PrasadÎncă nu există evaluări

- Dye Penetration TestDocument66 paginiDye Penetration Testezarul fitri100% (1)

- Paut Paper PDFDocument7 paginiPaut Paper PDFAyesha GeÎncă nu există evaluări

- Jireh Circ It ScannerDocument2 paginiJireh Circ It ScannerMarcos Kaian Moraes RodriguesÎncă nu există evaluări

- Book Review Ultrasonic Flaw Detection For TechniciansDocument1 paginăBook Review Ultrasonic Flaw Detection For TechniciansabanzabalÎncă nu există evaluări

- PRR CalculationDocument4 paginiPRR CalculationnavitaÎncă nu există evaluări

- Phased Array Practical ExamDocument2 paginiPhased Array Practical ExamMarcus AntoniusÎncă nu există evaluări

- Thickness Gauging Level 2 (Questions & Answers)Document3 paginiThickness Gauging Level 2 (Questions & Answers)kingston100% (2)

- MX2 Training Program 10G VerifyExitAngleDelay On IIWDocument21 paginiMX2 Training Program 10G VerifyExitAngleDelay On IIWANH TAI MAIÎncă nu există evaluări

- Iqi'sDocument6 paginiIqi's24inspector100% (1)

- Evaluation For Paut ASME 8 DIV 2Document3 paginiEvaluation For Paut ASME 8 DIV 2Woodrow FoxÎncă nu există evaluări

- Ect MAD 8D Calibration Procedure: Using The Vertical Volts MethodDocument7 paginiEct MAD 8D Calibration Procedure: Using The Vertical Volts MethodShanmukhaTeliÎncă nu există evaluări

- Mini-Wheel Encoder: Standard InclusionsDocument2 paginiMini-Wheel Encoder: Standard InclusionsGhaithÎncă nu există evaluări

- Beam Focusing Behavior of Linear Phased ArraysDocument10 paginiBeam Focusing Behavior of Linear Phased ArraysUriel Peña100% (1)

- VT, PT, MT, Ut, RT, Iwi-C and Iwe - TbsinspectionDocument3 paginiVT, PT, MT, Ut, RT, Iwi-C and Iwe - TbsinspectionDimasÎncă nu există evaluări

- Penetrant TestingDocument36 paginiPenetrant Testingkumarmm1234100% (1)

- Ultrasonic Report: Probe Details and Position (Fig 1)Document2 paginiUltrasonic Report: Probe Details and Position (Fig 1)BALA GANESH100% (1)

- Omniscan Mx2 Training Program: Introduction To Phased Array Using The Omniscan Mx2Document38 paginiOmniscan Mx2 Training Program: Introduction To Phased Array Using The Omniscan Mx2hcmcrlhoÎncă nu există evaluări

- Ut Job Knowledge - TwiDocument10 paginiUt Job Knowledge - TwiBhanu Pratap ChoudhuryÎncă nu există evaluări

- Ultrasonic Examination Austenitic and Dissimilar WeldsDocument6 paginiUltrasonic Examination Austenitic and Dissimilar WeldshocimtmÎncă nu există evaluări

- Beamtool Scan Plan Inspection Layout: 50Mm 289Mm 223Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/ΜsDocument3 paginiBeamtool Scan Plan Inspection Layout: 50Mm 289Mm 223Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/Μsநந்த குமார் சம்பத் நாகராஜன்Încă nu există evaluări

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFDocument11 paginiInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014Încă nu există evaluări

- UT Testing-Section 4Document146 paginiUT Testing-Section 4Charlie Chong100% (1)

- IRIS SetupDocument32 paginiIRIS SetupAqib AliÎncă nu există evaluări

- Calibration Methods: Seen in The Figure) - This Can Be Attributed To The DivergenceDocument4 paginiCalibration Methods: Seen in The Figure) - This Can Be Attributed To The DivergenceKevin HuangÎncă nu există evaluări

- ASNTDocument5 paginiASNTshifaÎncă nu există evaluări

- Weld-Solution en LTR 201712 WebDocument8 paginiWeld-Solution en LTR 201712 WebLương Hồ VũÎncă nu există evaluări

- 24 Practical Visual InspectionDocument5 pagini24 Practical Visual InspectionMai Anh TaiÎncă nu există evaluări

- Requirements For Non-Destructive Examination Methods Eddy CurrentDocument21 paginiRequirements For Non-Destructive Examination Methods Eddy Currentzemog001Încă nu există evaluări

- Acceptance Standards UtDocument3 paginiAcceptance Standards UtAhmed GomaaÎncă nu există evaluări

- Omniscan TofdDocument4 paginiOmniscan Tofdsdmkl85Încă nu există evaluări

- Ut Scanning Step For ExaminationDocument3 paginiUt Scanning Step For ExaminationMohdHuzairiRusliÎncă nu există evaluări

- PAUT of ''CRA WELDSDocument7 paginiPAUT of ''CRA WELDSDurgamadhaba Mishra100% (1)

- Basic Principles of Ultrasonic TestingDocument101 paginiBasic Principles of Ultrasonic TestingJohn Eric OliverÎncă nu există evaluări

- 7.5CCEV-35-16-A15 Esp 12,5 MM 1 Grupo Index - 20 MM Raiz 40-60° COBRADocument2 pagini7.5CCEV-35-16-A15 Esp 12,5 MM 1 Grupo Index - 20 MM Raiz 40-60° COBRAwilfran villegasÎncă nu există evaluări

- Introduction To Ultrasonic Thickness MeasurementDocument18 paginiIntroduction To Ultrasonic Thickness MeasurementNail Widya Satya100% (1)

- PA Probe Catalog en 201304Document24 paginiPA Probe Catalog en 201304Durgamadhaba Mishra100% (2)

- Advances in Tube Testing 2008Document39 paginiAdvances in Tube Testing 2008AhmedA.Hassan100% (1)

- DGS DGS MethodDocument6 paginiDGS DGS MethodAlzaki AbdullahÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- ASME Sec VIII Div 1 Ed 2010 471 PDFDocument9 paginiASME Sec VIII Div 1 Ed 2010 471 PDFStephen Maloba100% (1)

- ASME Section VIII Division 1 C - AceptacionDocument9 paginiASME Section VIII Division 1 C - AceptacionAngela Buitrago100% (1)

- NDT AcceptanceDocument62 paginiNDT Acceptancebommakanti srinivasÎncă nu există evaluări

- Lecture Notes 08Document30 paginiLecture Notes 08georgekenjiputraÎncă nu există evaluări

- UT 7 Displaying Ultrasonic Indications Angle Beam Inspection WithDocument21 paginiUT 7 Displaying Ultrasonic Indications Angle Beam Inspection WithAZAZ AHMADÎncă nu există evaluări

- Asme Viii d1 Ma Appendix 4Document8 paginiAsme Viii d1 Ma Appendix 4Chihiya Fitria Nurhayati100% (1)

- NDT ACC. CriteriaDocument6 paginiNDT ACC. CriteriaBalakumar100% (5)

- NDT ACC CriteriaDocument6 paginiNDT ACC Criteriavsnaiduqc100% (1)

- FIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )Document10 paginiFIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )mahmoud_allam3Încă nu există evaluări

- Weld Seam Inspection of Thick Wall Austenitic Steel Tubes BeyondDocument8 paginiWeld Seam Inspection of Thick Wall Austenitic Steel Tubes BeyondAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Inspeccion Por RadiografiaDocument9 paginiInspeccion Por RadiografiaAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Quantitative Analysis of Eddy Current NDE DataDocument12 paginiQuantitative Analysis of Eddy Current NDE DataAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Eectromagnetic Nondestructive Evaluation PDFDocument321 paginiEectromagnetic Nondestructive Evaluation PDFKalai VananÎncă nu există evaluări

- Advanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionDocument9 paginiAdvanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionAsiriHemanthaÎncă nu există evaluări

- Weld Evaluation Guide - RADIOGRAFIA - PDFDocument20 paginiWeld Evaluation Guide - RADIOGRAFIA - PDFCharly Teodoro BrownÎncă nu există evaluări

- Quantitative Analysis of Eddy Current NDE DataDocument12 paginiQuantitative Analysis of Eddy Current NDE DataAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- 560-000-PI-T-001 Rev.1Document1 pagină560-000-PI-T-001 Rev.1Alvaro Alexis Mendoza PradaÎncă nu există evaluări

- Advanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionDocument9 paginiAdvanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionAsiriHemanthaÎncă nu există evaluări

- Post Weld Heat TreatmentDocument2 paginiPost Weld Heat TreatmentgullenariÎncă nu există evaluări

- Ensuring Weld Quality in Structural Applications: by Duane K. Miller, SC.D., P.EDocument16 paginiEnsuring Weld Quality in Structural Applications: by Duane K. Miller, SC.D., P.Ecentaury2013Încă nu există evaluări

- PA Probe Catalog en 201308Document24 paginiPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaÎncă nu există evaluări

- FIG. 1 Rectangular Tension Test SpecimensDocument1 paginăFIG. 1 Rectangular Tension Test SpecimensAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Epp y Equipos SoldaduraDocument100 paginiEpp y Equipos SoldaduraAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Aisi and Aisc StandardDocument11 paginiAisi and Aisc StandardkonstruktorbudowlanyÎncă nu există evaluări

- Weld Seam Inspection of Thick Wall Austenitic Steel Tubes BeyondDocument8 paginiWeld Seam Inspection of Thick Wall Austenitic Steel Tubes BeyondAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Steam Generator Inspections Faster, Cheaper and BetterDocument17 paginiSteam Generator Inspections Faster, Cheaper and BetterAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- ISO AwarenessDocument9 paginiISO AwarenessAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Optimization of The Inspection Schedule For Surface-Breaking CracksDocument15 paginiOptimization of The Inspection Schedule For Surface-Breaking CracksAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Advanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionDocument9 paginiAdvanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionAsiriHemanthaÎncă nu există evaluări

- BLOQUEDocument1 paginăBLOQUEAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Pana UT EN 201301Document52 paginiPana UT EN 201301k_sakpolachet_heartÎncă nu există evaluări

- UT Technotes 2011.enDocument11 paginiUT Technotes 2011.enAlexandru StefanÎncă nu există evaluări

- Quantitative Analysis of Eddy Current NDE DataDocument12 paginiQuantitative Analysis of Eddy Current NDE DataAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Evolution of NDT Personnel Qualification and Certification atDocument4 paginiEvolution of NDT Personnel Qualification and Certification atAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Steel Tapping Screws For Cold-Formed Steel Framing ConnectionsDocument5 paginiSteel Tapping Screws For Cold-Formed Steel Framing ConnectionsAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- D 10.11Document20 paginiD 10.11Alvaro Alexis Mendoza PradaÎncă nu există evaluări

- European Welding New-StandardsDocument39 paginiEuropean Welding New-StandardsJOECOOL67100% (3)

- MPI Y-7 ACDC Yoke InstructionsDocument3 paginiMPI Y-7 ACDC Yoke InstructionsAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- K-Series Final 030911Document54 paginiK-Series Final 030911Alvaro Alexis Mendoza PradaÎncă nu există evaluări

- Mittal Corp LTD 22ND November 2022Document4 paginiMittal Corp LTD 22ND November 2022Etrans 9Încă nu există evaluări

- TC 9-237 Welding 1993Document680 paginiTC 9-237 Welding 1993enricoÎncă nu există evaluări

- International Business EnvironmentDocument5 paginiInternational Business EnvironmentrahulÎncă nu există evaluări

- LS Series Hand Crimping ToolsDocument4 paginiLS Series Hand Crimping ToolsbaolifengÎncă nu există evaluări

- Surface News - 20130704 - Low Res PDFDocument9 paginiSurface News - 20130704 - Low Res PDFYoko GoldingÎncă nu există evaluări

- Galanz - Galaxy 7-9-12K - SPLIT PDFDocument42 paginiGalanz - Galaxy 7-9-12K - SPLIT PDFUbaldo BritoÎncă nu există evaluări

- Assignment Business EnvironmentDocument9 paginiAssignment Business EnvironmentVikram MayuriÎncă nu există evaluări

- CH 2 How LAN and WAN Communications WorkDocument60 paginiCH 2 How LAN and WAN Communications WorkBeans GaldsÎncă nu există evaluări

- TM9-238 Deepwater Fording of Ordnance Materiel PDFDocument35 paginiTM9-238 Deepwater Fording of Ordnance Materiel PDFdieudecafeÎncă nu există evaluări

- AW-NB037H-SPEC - Pegatron Lucid V1.3 - BT3.0+HS Control Pin Separated - PIN5 - Pin20Document8 paginiAW-NB037H-SPEC - Pegatron Lucid V1.3 - BT3.0+HS Control Pin Separated - PIN5 - Pin20eldi_yeÎncă nu există evaluări

- Mobilcut 102 Hoja TecnicaDocument2 paginiMobilcut 102 Hoja TecnicaCAGERIGOÎncă nu există evaluări

- PT Shri Krishna Sejahtera: Jalan Pintu Air Raya No. 56H, Pasar Baru Jakarta Pusat 10710 Jakarta - IndonesiaDocument16 paginiPT Shri Krishna Sejahtera: Jalan Pintu Air Raya No. 56H, Pasar Baru Jakarta Pusat 10710 Jakarta - IndonesiaihsanlaidiÎncă nu există evaluări

- Maverick Research: World Order 2.0: The Birth of Virtual NationsDocument9 paginiMaverick Research: World Order 2.0: The Birth of Virtual NationsСергей КолосовÎncă nu există evaluări

- Case Chart Complete (Business Law)Document29 paginiCase Chart Complete (Business Law)LimShuLingÎncă nu există evaluări

- Leadership Style SurveyDocument3 paginiLeadership Style SurveyJanelle BergÎncă nu există evaluări

- Power Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range EDocument8 paginiPower Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range Ejrz000Încă nu există evaluări

- The Perceived Barriers and Entrepreneurial Intention of Young Technical ProfessionalsDocument6 paginiThe Perceived Barriers and Entrepreneurial Intention of Young Technical ProfessionalsAnatta OngÎncă nu există evaluări

- Descriptive Na Ly TicsDocument112 paginiDescriptive Na Ly TicsJay Mart AvanceñaÎncă nu există evaluări

- 1491559890CL 0417 PDFDocument48 pagini1491559890CL 0417 PDFCoolerAdsÎncă nu există evaluări

- Ins200 Assignment Hazardous PlaceDocument10 paginiIns200 Assignment Hazardous PlaceNur Syafatin Natasya86% (7)

- Mercantile Law Zaragoza Vs Tan GR. No. 225544Document3 paginiMercantile Law Zaragoza Vs Tan GR. No. 225544Ceasar Antonio100% (1)

- Casesheet 086 Siwertell Hermasa Brazil Grain Unloader TerminalDocument2 paginiCasesheet 086 Siwertell Hermasa Brazil Grain Unloader TerminalersÎncă nu există evaluări

- Farmers' Satisfaction With The Paddy Procurement Practices of The National Food Authority in The Province of Palawan, PhilippinesDocument13 paginiFarmers' Satisfaction With The Paddy Procurement Practices of The National Food Authority in The Province of Palawan, PhilippinesPsychology and Education: A Multidisciplinary JournalÎncă nu există evaluări

- Top Ten Helicopter Checkride TipsDocument35 paginiTop Ten Helicopter Checkride TipsAbhiraj Singh SandhuÎncă nu există evaluări

- Data MiningDocument721 paginiData MiningAuly Natijatul AinÎncă nu există evaluări

- All About Ignition Coils: Technical InformationDocument15 paginiAll About Ignition Coils: Technical InformationTrương Ngọc ThắngÎncă nu există evaluări

- Netaji Subhas Open UniversityDocument4 paginiNetaji Subhas Open UniversityraydipanjanÎncă nu există evaluări

- Glaciogenic: Hydrocarbon SystemsDocument2 paginiGlaciogenic: Hydrocarbon SystemsAHMEDÎncă nu există evaluări

- Inductive Grammar Chart (Unit 2, Page 16)Document2 paginiInductive Grammar Chart (Unit 2, Page 16)Michael ZavalaÎncă nu există evaluări

- Future Generation Computer SystemsDocument18 paginiFuture Generation Computer SystemsEkoÎncă nu există evaluări